Water-based adhesion agent and preparation thereof

An adhesive and water-based technology, which is applied in the field of water-based adhesives and its preparation, can solve the problems of liver and kidney damage, carcinogenicity, and human body damage, and achieve the effects of reducing toxicity, increasing bonding strength, and increasing curing speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

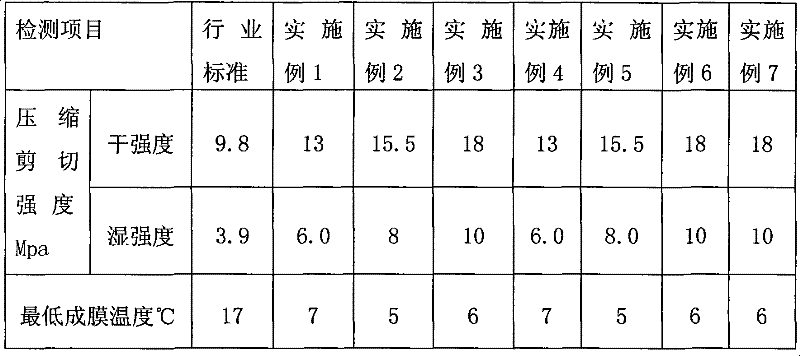

Examples

Embodiment 1

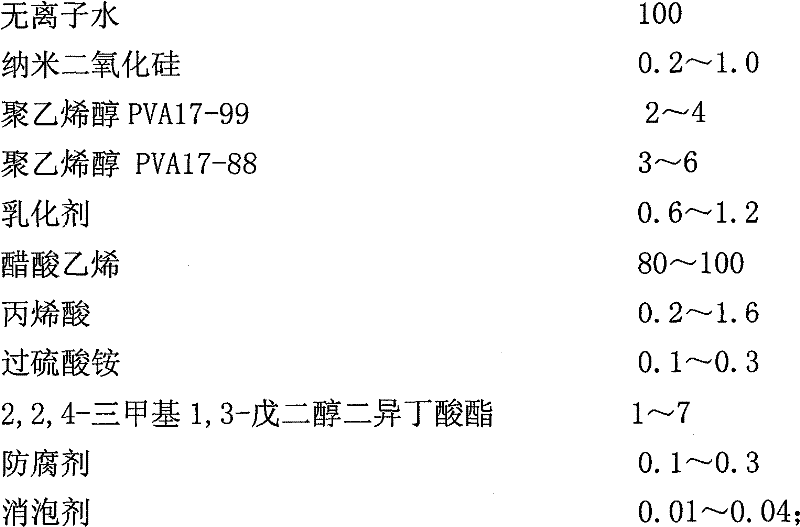

[0036] (1) Weigh the raw materials according to the ratio in Table 1.

[0037] (2) Mix vinyl acetate and acrylic acid evenly to make a mixed monomer.

[0038] (3) Disperse nano-silica in deionized water at a speed of 1500 rpm to form a nano-silica solution.

[0039] (4) Add nano-silica solution, polyvinyl alcohol, and defoamer into the reaction kettle, heat up to 85°C and keep the gas off for 3 hours, and cool down to 40°C after completely dissolving.

[0040] (5) Add 5% of the total amount of emulsifier and TXIB into the reaction kettle, and stir well.

[0041] (6) Continue to add 10% of the mixed monomer in the reactor, raise the temperature to 65°C, add 30% of the total amount of ammonium persulfate, initiate polymerization, generate seed emulsion, heat up to 75°C, and then add the mixed monomer dropwise and the balance of ammonium persulfate.

[0042] (7) After the dropwise addition, heat up to 90°C, heat-preserve and mature for 1 hour, add the remainder of TXIB dropwis...

Embodiment 2

[0044] (1) Weigh the raw materials according to the ratio in Table 1.

[0045] (2) Mix vinyl acetate and acrylic acid evenly to make a mixed monomer.

[0046] (3) Disperse nano-silica in deionized water at a speed of 1500 rpm to form a nano-silica solution.

[0047] (4) Add nano-silica solution, polyvinyl alcohol, and antifoaming agent into the reaction kettle, heat up to 95°C and keep the air off for 1 hour, and cool down to 50°C after completely dissolving.

[0048] (5) Add 20% of the total amount of emulsifier and TXIB into the reaction kettle, and fully stir evenly.

[0049] (6) Continue to add 20% of the mixed monomer in the reactor, raise the temperature to 75°C, add 35% of the total amount of ammonium persulfate, initiate polymerization, generate seed emulsion, heat up to 85°C, and then add the mixed monomer dropwise and the balance of ammonium persulfate.

[0050] (7) After the dropwise addition, heat up to 90°C, heat-preserve and mature for 1 hour, add the remainder ...

Embodiment 3

[0052] (1) Weigh the raw materials according to the ratio in Table 1.

[0053] (2) Mix vinyl acetate and acrylic acid evenly to make a mixed monomer.

[0054] (3) Disperse nano-silica in deionized water at a speed of 1500 rpm to form a nano-silica solution.

[0055] (4) Add nano-silica solution, polyvinyl alcohol, and antifoaming agent into the reaction kettle, heat up to 90°C and keep the gas off for 2 hours, and cool down to 45°C after completely dissolving.

[0056] (5) Add 10% of the total amount of emulsifier and TXIB into the reaction kettle, and fully stir evenly.

[0057] (6) Continue to add 15% of the mixed monomer in the reactor, heat up to 70°C, add 33% of the total amount of ammonium persulfate, initiate polymerization, generate seed emulsion, heat up to 80°C, and then add the mixed monomer dropwise and the balance of ammonium persulfate.

[0058] (7) After the dropwise addition, heat up to 90°C, heat-preserve and mature for 1 hour, add the remainder of TXIB dro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com