Recoatable UV radiation cured coating for plastic as well as production method and application method of coating

A technology of radiation curing and production method, applied in polyurea/polyurethane coatings, coatings, devices for coating liquids on surfaces, etc. effect of voc

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

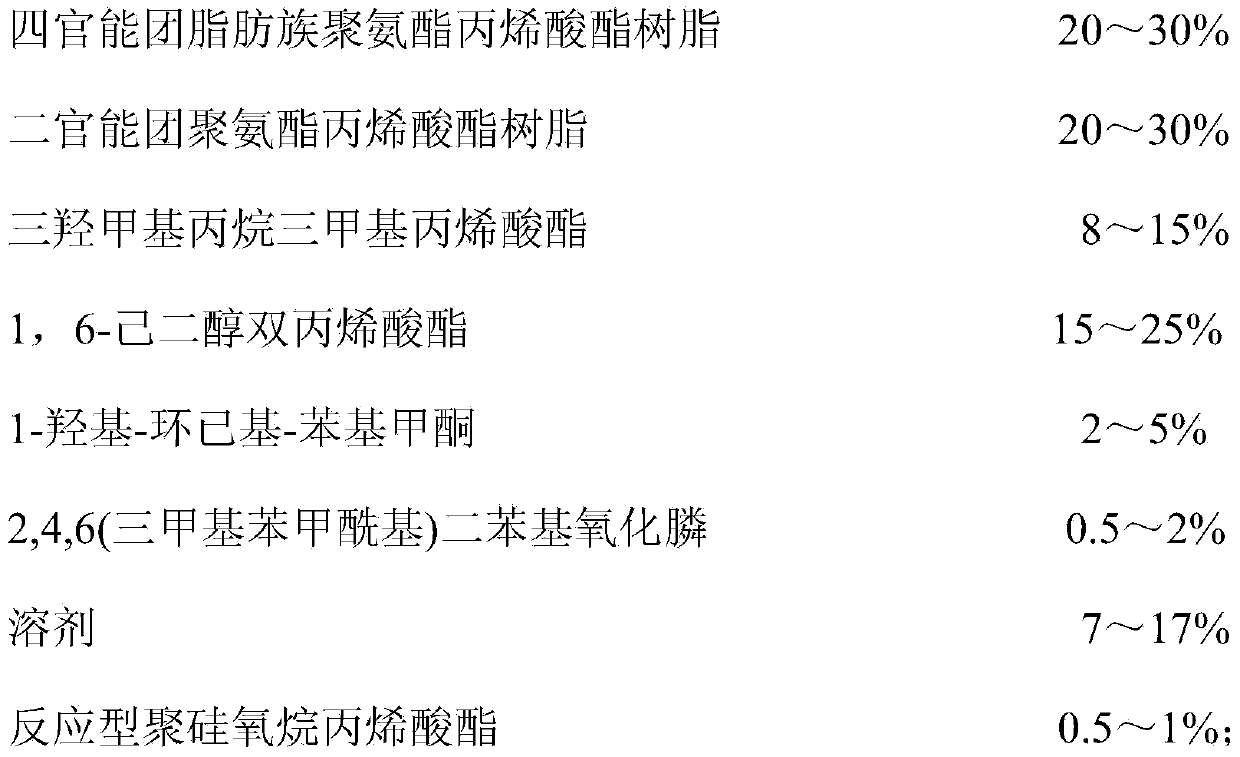

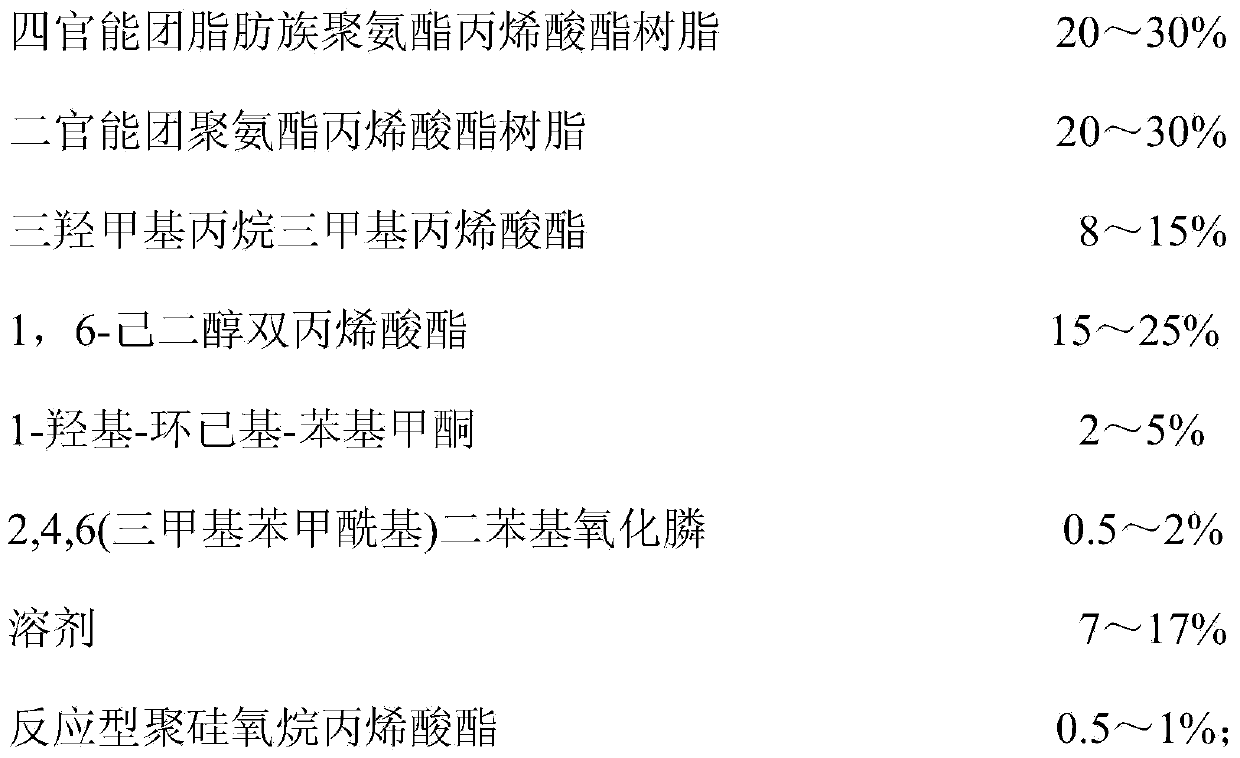

[0032] The production method of UV radiation curing coating for recoatable plastics comprises the following steps:

[0033] (1) Weigh the raw materials according to the content of each component in Table 1; wherein the mixed solvent is composed of butanone: n-butanol: ethyl acetate=60:15:25 by weight.

[0034] (2) Mixing and dispersing resin monomers: Take a clean paint-making tank, mix tetrafunctional aliphatic urethane acrylate resin, difunctional urethane acrylate resin, trimethylolpropane trimethacrylate, 1,6-hexanediol Add the diacrylate to the paint-making tank, and stir with a high-speed disperser at a speed of 1200-1500 rpm for 8-15 minutes;

[0035] (3) Dissolution of photoinitiator: Mix 1-hydroxy-cyclohexyl-phenyl ketone, 2,4,6(trimethylbenzoyl)diphenylphosphine oxide with mixed solvent, use a high-speed disperser to dissolve The rotating speed of 500-600rpm is stirred until it is completely dissolved, and after filtering with a 500-mesh filter screen, it is standby...

Embodiment 2

[0045] The content of each component is shown in Table 1, and the production method and usage method are shown in Example 1.

Embodiment 3

[0047] The content of each component is shown in Table 1, and the production method and usage method are shown in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com