Tail gas purification catalyst with soft metal wire carrier substrate

A tail gas purification and metal wire technology, applied in the direction of metal/metal oxide/metal hydroxide catalyst, physical/chemical process catalyst, catalyst activation/preparation, etc., can solve the problem of invariable structure, difficult application of catalyst, complicated installation, etc. problems, to achieve the effect of improving adhesion, low cost, and convenient installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

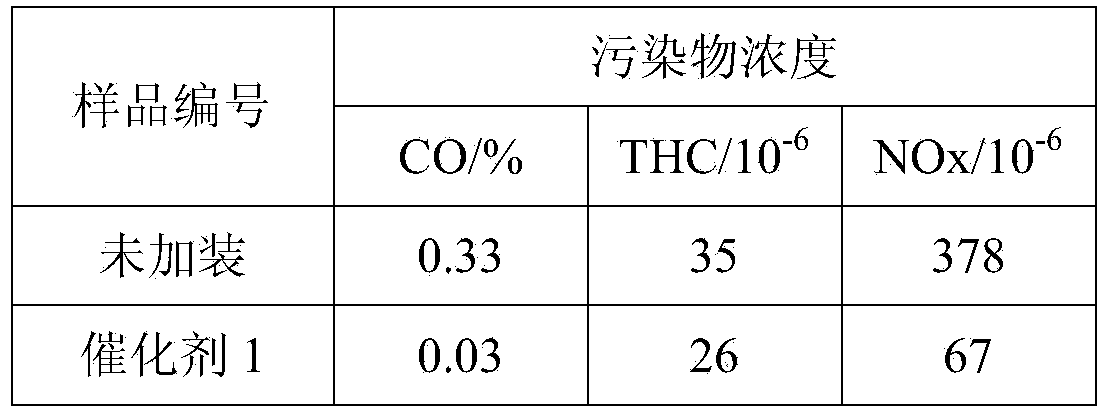

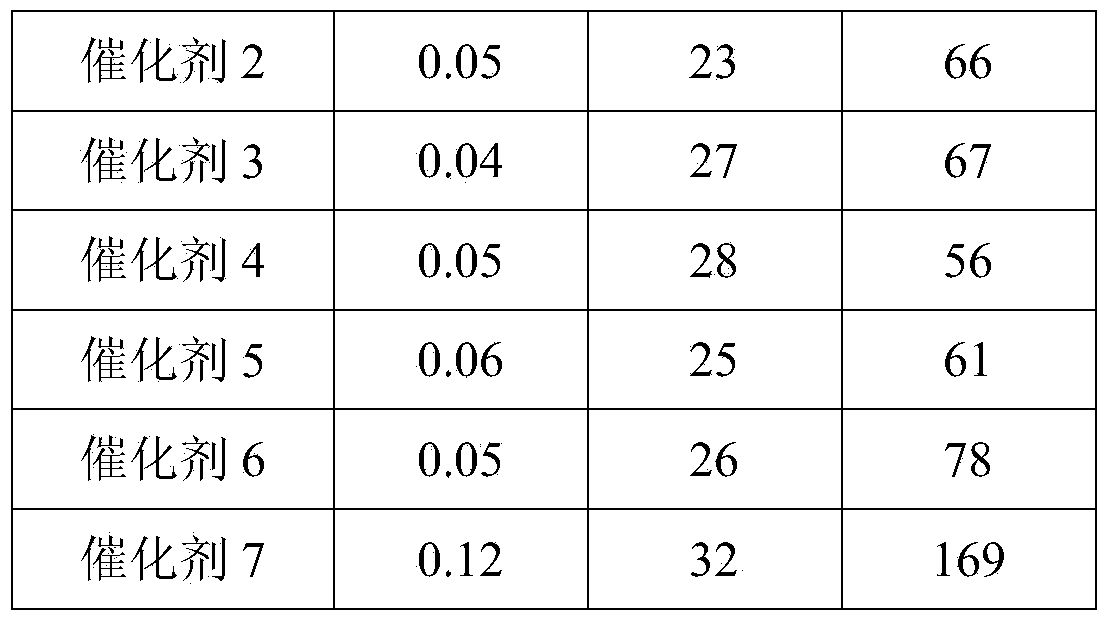

Examples

Embodiment 1

[0032] Prepare the pretreated FeCrAl metal wire soft carrier: soak 15g of FeCrAl metal wire soft carrier in acetone solution for 10 minutes, remove it and blow it dry with a hair dryer; then soak it in 2% hydrochloric acid for 5 minutes, take it out and dry it; Rinse with caustic soda solution for 3 minutes, then rinse with pure water. Place in an air-ventilated muffle furnace for calcination at 950°C for 5 hours, and then cool down to room temperature for coating.

[0033] Preparation of aluminum-alkaline earth composite oxide, every 100 parts of aluminum-alkaline earth composite oxide is made of the following components by weight: 85 parts of aluminum oxide, 5 parts of alkaline earth metal oxide, 10 parts of rare earth element: according to the element ratio in the product Take the raw materials of aluminum nitrate, magnesium carbonate and lanthanum carbonate and disperse them in water, in the presence of organic template agent hexadecyltrimethylammonium bromide, hydrotherma...

Embodiment 2

[0040] Prepare the pretreated FeCrAl metal wire soft carrier: soak 15g of FeCrAl metal wire soft carrier in acetone solution for 10 minutes, remove it and blow it dry with a hair dryer; then soak it in 1% hydrochloric acid for 5 minutes, take it out and dry it; Rinse with caustic soda solution for 3 minutes, then rinse with pure water. Place in an air-ventilated muffle furnace for calcination at 900°C for 6 hours, and then cool down to room temperature for coating.

[0041] Prepare aluminum-alkaline earth composite oxide, every 100 parts of aluminum-alkaline earth composite oxide is made of the following components by weight: 90 parts of aluminum oxide, 5 parts of alkaline earth metal oxide, 5 parts of rare earth element: weigh according to the element ratio in the product Take the raw materials of aluminum carbonate, barium nitrate and cerium nitrate and disperse them in water, in the presence of the organic template cetyltrimethylammonium oxide, hydrothermally treat at 100°C...

Embodiment 3

[0048] Prepare the pretreated FeCrAl metal wire soft carrier: soak 15g of FeCrAl metal wire soft carrier in ethanol solution for 10 minutes, remove it and blow it dry with a hair dryer; then soak it in 3% hydrochloric acid for 5 minutes, take it out and dry it; Rinse with caustic soda solution for 3 minutes, then rinse with pure water. Place it in an air-ventilated muffle furnace for calcination at 1000°C for 4 hours, and then cool down to room temperature for coating.

[0049] Preparation of aluminum-alkaline earth composite oxide, every 100 parts of aluminum-alkaline earth composite oxide is made of the following components by weight: 85 parts of aluminum oxide, 5 parts of alkaline earth metal oxide, 10 parts of rare earth element: according to the element ratio in the product Take aluminum nitrate, strontium nitrate and yttrium carbonate as raw materials and disperse them in water, in the presence of organic template triblock copolymer, hydrothermally treat at 180°C for 12h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com