A method for porous carbon loaded nano metal oxide or nano metal material

A nano-metal and oxide technology, applied in the field of porous carbon-loaded nano-metal oxides or nano-metal materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Example 1: Porous carbon loaded nano-Fe

[0024] Synthetic raw materials: glucose, urea, Fe(NO 3 ) 3· 9H 2 O (iron nitrate)

[0025] (1) Weigh 10 g glucose, 1 g urea and 0.1 g Fe(NO 3 ) 3· 9H 2 O in a 100 mL beaker, then place the beaker in a heatable magnetic stirrer. The temperature of the magnetic stirrer was raised to 100° C., and the stirring was continued for 60 min until the medicine in the beaker was in a molten state.

[0026] (2) From the molten liquid mentioned in (1), take out a part of the solution and put it in a 120°C oven as sample A, and put the other part of the solution into a high-temperature reaction kettle and put it in a 120°C oven as sample B, and react for 48 hours. A dark brown bulky solid was obtained, and sample B was dark brown dense solid.

[0027] (3) Grind the sample A and sample B obtained in (2) with a mortar, and divide them into two crucibles, and then put them under N 2 Heat treatment at 550°C for 7 hours under protection to...

experiment example 2

[0029] Experimental example 2: Porous carbon supported nano-SnSb alloy

[0030] Synthetic raw materials: glucose, urea, SnCl 2· 2H 2 O (Stannous Chloride), SbCl 3 (antimony chloride)

[0031] (1) Weigh 1 g glucose, 10 g urea, 0.3 g SnCl 2· 2H 2 O and 0.3 g SbCl 3 In a 100 mL beaker, then place the beaker in a heatable magnetic stirrer. The temperature of the magnetic stirrer was raised to 220°C, and the stirring was continued for 60 min until the drug in the beaker formed a molten state.

[0032] (2) Afterwards, put the beaker into an oven at 250°C and react for 1 hour to obtain a dark brown puffy solid.

[0033] (3) Grind the product obtained in (2) with a mortar and put it in a crucible. The product obtained by the reaction was heated at 250°C in 5% H 2 / N 2 Under the condition of heat treatment for 24 hours, the porous carbon-loaded nano-SnSb alloy is obtained.

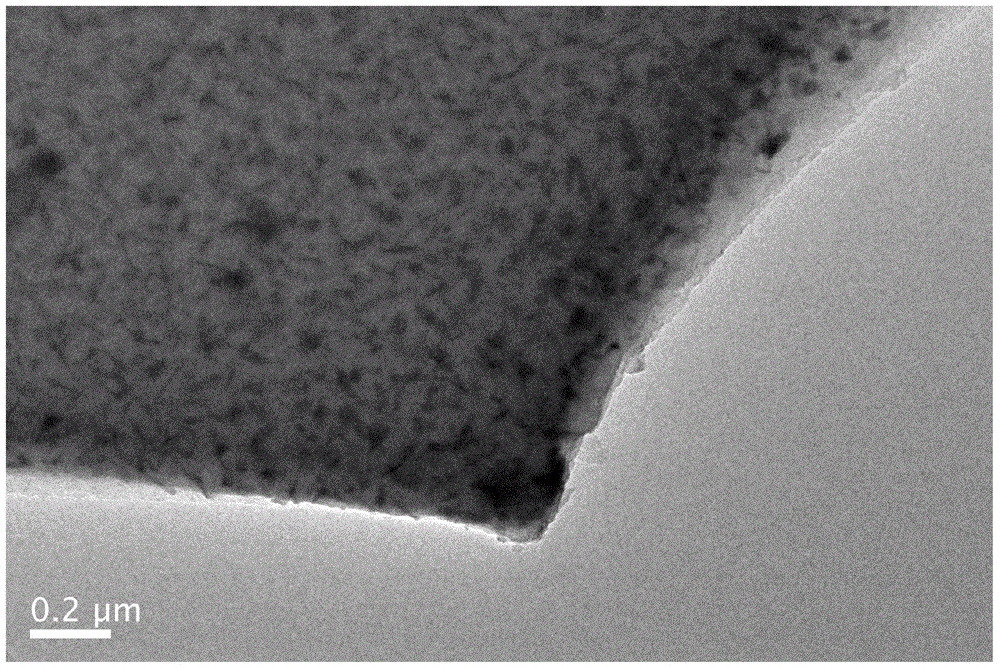

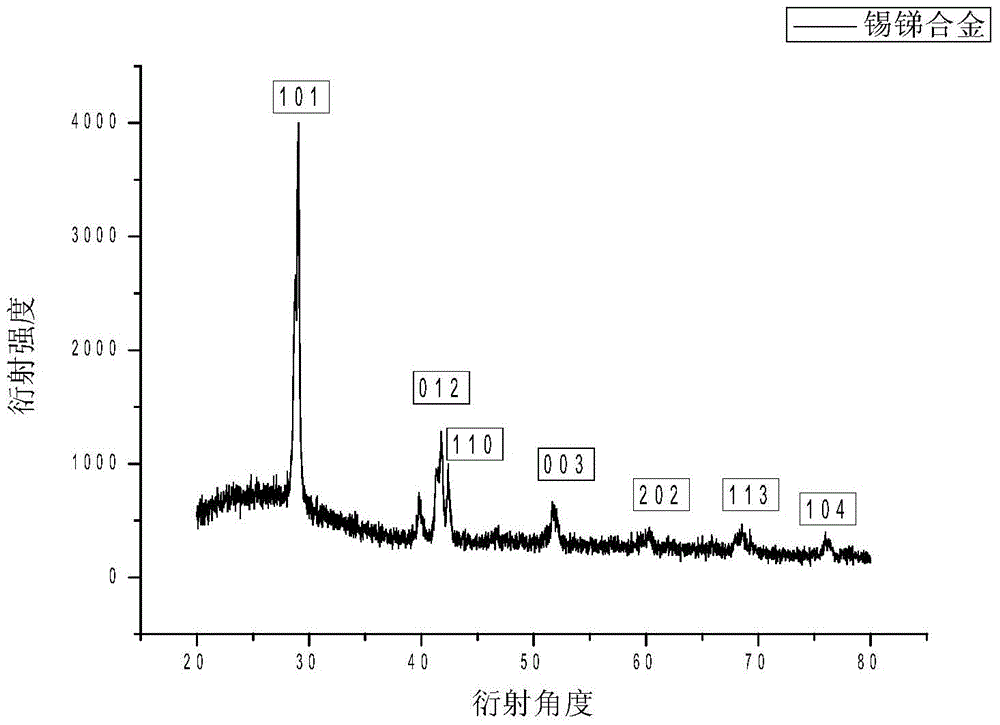

[0034] figure 1 It is a TEM image of nano-SnSb alloy supported on porous carbon. In the figure, it c...

experiment example 3

[0035] Experimental example 3: Porous carbon supports nano-Pd

[0036] Synthetic raw materials: fructose, urea, Pd(NO 3 ) 2· 2H 2 O (palladium nitrate)

[0037] (1) Weigh 100 g fructose and 1 g urea into a 100 mL beaker, then place the beaker in a heatable magnetic stirrer. The temperature of the magnetic stirrer was raised to 180°C, and the stirring was continued for 10 min until the drug in the beaker formed a molten state.

[0038] (2) Weigh 0.1 g Pd(NO 3 ) 2· 2H 2 Add O into the molten liquid described in (1), and keep stirring for 8 min until the solution is clear. Afterwards, the molten liquid was added into a hydrothermal reaction kettle and placed in an oven at 180° C., and reacted for 24 hours to obtain a dark brown solid.

[0039] (3) Grind the product obtained in (2) with a mortar and put it in a crucible. The product obtained by the reaction was heated at 1100°C in 5%H 2 / N 2 After heat treatment for 3 hours under the same conditions, the porous carbon-s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com