Method for preparing solid polymeric aluminum ferric sulfate by use of bauxite oxide

A technology of solid polymerization and ferric aluminum sulfate, which is applied in the direction of ferric sulfate, etc., can solve the problems of increasing the complexity of the preparation process of solid polymer ferric aluminum sulfate, the inability to be widely used in industry, and the failure to meet the processing requirements, so as to facilitate industrial production and facilitate Transportation and storage, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] The method of utilizing alumina ore of the present invention to prepare solid polyaluminum ferric sulfate comprises the following steps:

[0029] Step 1, after crushing the alumina ore through a 200-mesh sieve;

[0030] Step 2, roasting in a muffle furnace at a temperature of 500°C for about 60 minutes, and then roasting at 800°C for 1 hour;

[0031] Step 3: Put 20 g of the calcined alumina into a reaction kettle with a temperature of 80°C and a pressure of 5 atm, and add 11 mol / L of sulfuric acid in a jet flow according to the solid-to-liquid ratio of 1.6:1. The atomized particle size is 5000μm; after stirring evenly, add 9mol / L sulfuric acid, the atomized particle size is 3000μm; after stirring evenly, add 8mol / L sulfuric acid, the atomized particle size is 2000μm; 60min;

[0032] Step 4: Add in sequence a stabilizer with a P / [Fe+Al] of 0.08 such as phosphoric acid, a small amount of an oxidant such as hydrogen peroxide, and an alkalizing agent with a [OH] / [Fe+Al] o...

Embodiment 2

[0035] Step 1, crushing alumina ore through a 120-mesh sieve;

[0036] Step 2: Baking in a muffle furnace at 400°C for about 30 minutes, and then firing at 800°C for about 1 hour,

[0037] Step 3: Put 20g of the calcined alumina into a reaction kettle with a temperature of 80°C and a pressure of 3atm, and add 10mol / L sulfuric acid in a jet flow according to the liquid-solid ratio of 1.4:1. The atomized particle size is 3000μm; after stirring evenly, add 8mol / L sulfuric acid, the atomized particle size is 2000μm; after stirring evenly, add 7mol / L sulfuric acid, the atomized particle size is 1500μm; fully stir and heat the acid solution 60min,

[0038] Step 4: Add in sequence a stabilizer with a P / [Fe+Al] of 0.1 such as phosphoric acid, a small amount of an oxidant such as hydrogen peroxide and an alkalizing agent with a [OH] / [Fe+Al] of 1.0 such as sodium hydroxide and stir for 40 minutes to hydrolyze and polymerize, then stop Heating out;

[0039] Step 5, aging for 36 hours ...

Embodiment 3

[0041] The method of utilizing alumina ore of the present invention to prepare solid polyaluminum ferric sulfate comprises the following steps:

[0042] Step 1, after crushing the alumina ore through a 100-mesh sieve;

[0043] Step 2, roasting in a muffle furnace at a temperature of 800°C for about 60 minutes;

[0044]Step 3. Put 20g of roasted alumina into a reaction kettle with a temperature of 120°C and a pressure of 2atm, and add 10mol / L sulfuric acid in a jet flow according to a solid-to-liquid ratio of 1.4:1; fully stir Then heat and dissolve in acid for 40 minutes;

[0045] Step 4: Add in sequence a stabilizer with a P / [Fe+Al] of 0.09, a small amount of oxidant and an alkalizing agent with a [OH] / [Fe+Al] of 1.6, stir for 30 minutes, stop heating and take out;

[0046] Step 5, aging for about 40 hours to obtain a light yellow viscous solid product.

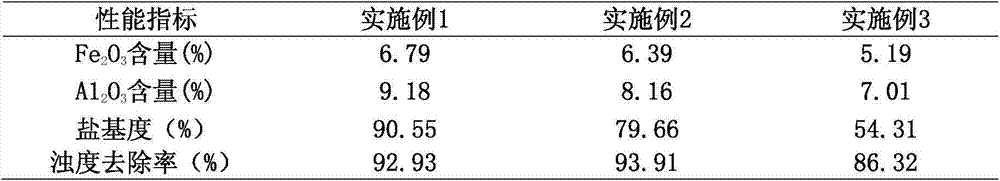

[0047] The product performance table of the described solid polyaluminum ferric sulfate prepared by the method for prep...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com