Controlled-release fertilizer and production method thereof

A technology of slow-release fertilizers and compound fertilizers, applied in fertilizer mixtures, fertilization devices, applications, etc., can solve problems such as high manufacturing costs and complex production processes, and achieve the effects of improving fertilizer efficiency, increasing crop yield, and inhibiting urease activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

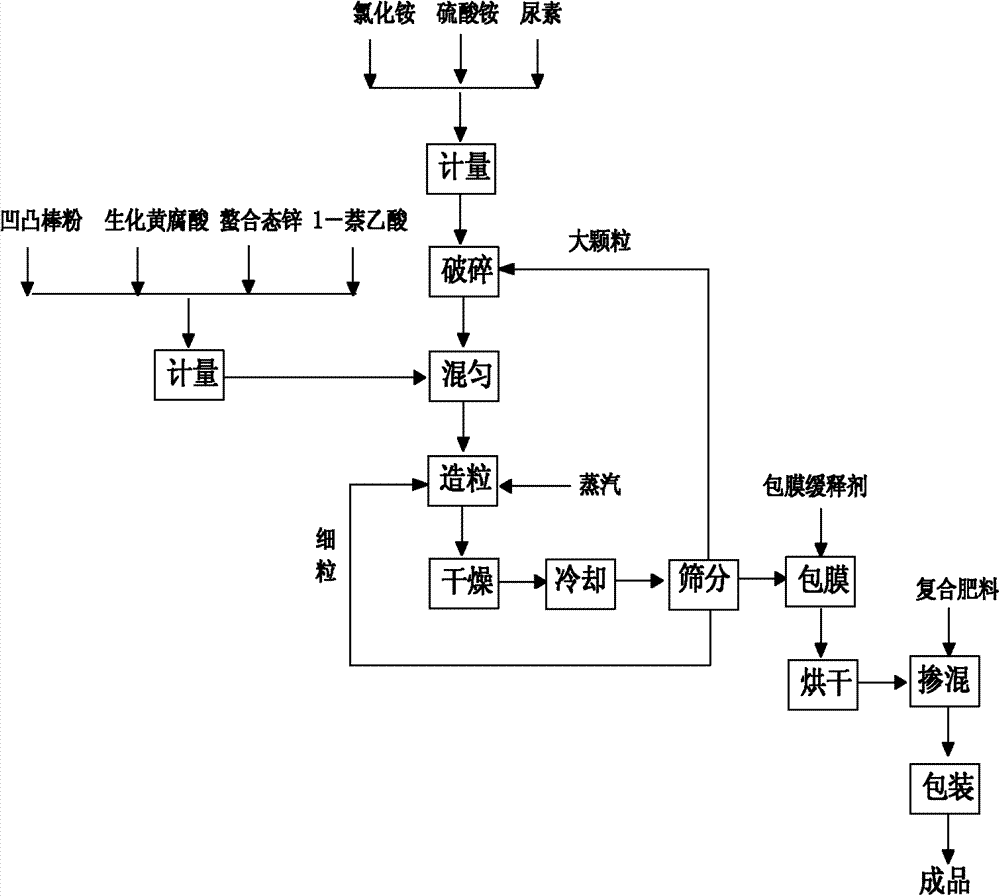

Method used

Image

Examples

Embodiment 1

[0039] Total nutrients (N+P 2 o 5 +K 2 O) ≥ 44%, the specification is 20-11-13 (chlorine-containing) slow-release fertilizer, the specific process steps are as follows:

[0040] (1) Measure 135.1kg of ammonium chloride (containing N-24.0%), 72.0kg of ammonium sulfate (containing N-20.5%), and 540.3kg of urea (containing N-46.2%) respectively, and put the ammonium chloride and ammonium sulfate through chain The urea is crushed by a special crusher for urea, and then the crushed material is sent to a twin-shaft mixer, mixed with 54.0kg attapulgite powder, 36.0kg biochemical fulvic acid, 18.0kg chelated zinc, 0.5kg1-naphthaleneacetic acid Mix evenly, and then send to the disc granulator;

[0041] (2) Spray an appropriate amount of steam on the above-mentioned mixture in the disc granulator;

[0042] (3) One stage of drying, one stage of cooling and coarse and fine screening are adopted. After screening, particles with a particle size of 2.00-4.75mm enter the coating machine, ...

Embodiment 2

[0047] Total nutrients (N+P 2 o 5 +K 2 O) ≥ 41%, the specification is 18-12-11 (potassium sulfate type) slow-release fertilizer, the specific process steps are as follows:

[0048] (1) Measure 41.5kg of ammonium sulfate (containing N-20.5%) and 622.8kg of urea (containing N-46.2%) respectively, crush the ammonium sulfate through a chain crusher, and pass the urea through a special urea crusher, and then send the crushed materials to Enter in the twin-shaft mixer, mix evenly with 81.0kg attapulgite powder, 51.9kg biochemical fulvic acid, 25.9kg chelated zinc, 0.4kg1-naphthalene acetic acid, and then send it into the drum granulator;

[0049] (2) Spray an appropriate amount of steam on the above-mentioned mixture in the drum granulator;

[0050] (3) One stage of drying, one stage of cooling and coarse and fine screening are adopted. After screening, particles with a particle size of 2.00-4.75mm enter the coating machine, large particles larger than 4.75mm are returned to crus...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com