A kind of preparation method of lignin-based environmental protection phenolic resin adhesive

An environmentally friendly phenolic resin and lignin-based technology, applied in adhesives, aldehyde/ketone condensation polymer adhesives, adhesive types, etc., can solve problems such as complex production processes, release of harmful substances, and reduced production efficiency. Wide range of raw material sources, simple production process, and good economic value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

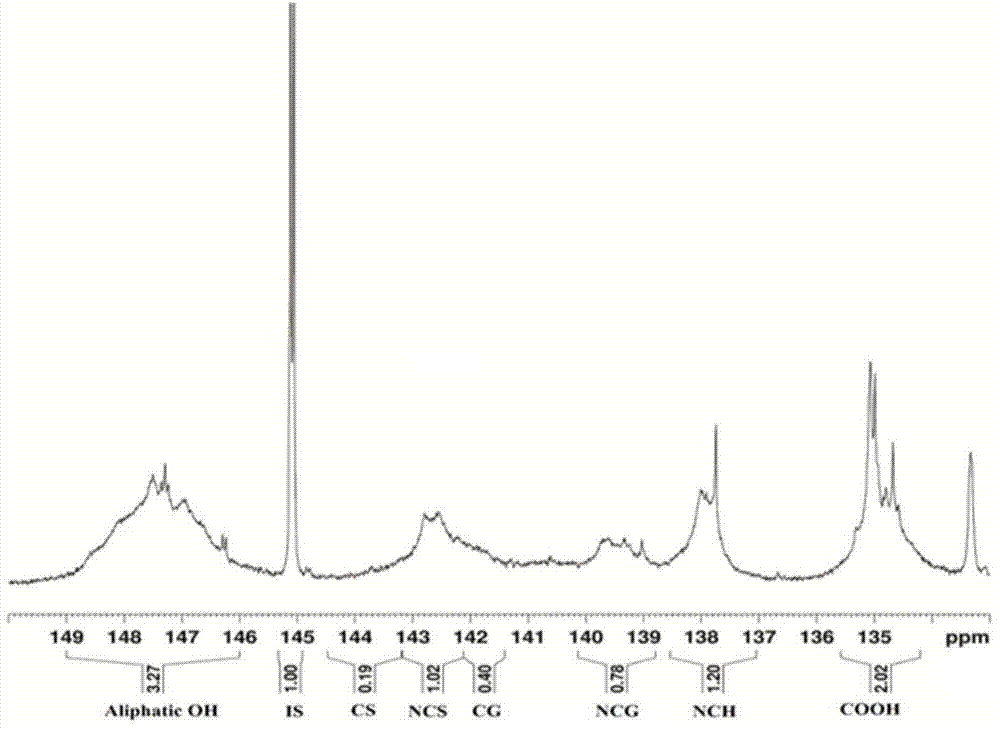

Embodiment 1

[0040]1) The ratio of phenol, corncob alkali lignin raw material and formaldehyde in this example is: phenol 84.6g, corncob alkali lignin 9.4g, formaldehyde solution 111.90g.

[0041] 2) First add 9.4g of corncob alkali lignin, 84.6g of phenol and 55.95g of the first batch of formaldehyde solution into the three-necked flask, stir evenly, then add the first batch of sodium hydroxide solution (30wt%) 31.33g into the reaction system at an appropriate speed , then raise the temperature of the system to 80°C, and keep it warm for 60 minutes;

[0042] 3) Add the second batch of sodium hydroxide solution 2.61g and the second batch of formaldehyde solution 18.65g at an appropriate speed, and keep warm for 20min at 80°C;

[0043] 4) Add the third batch of formaldehyde solution 18.65g and the third batch of sodium hydroxide solution 5.22g, and the reaction system continues to react at 80°C for 20 minutes;

[0044] 5) Add 18.65g of the fourth batch of formaldehyde solution and 7.83g of...

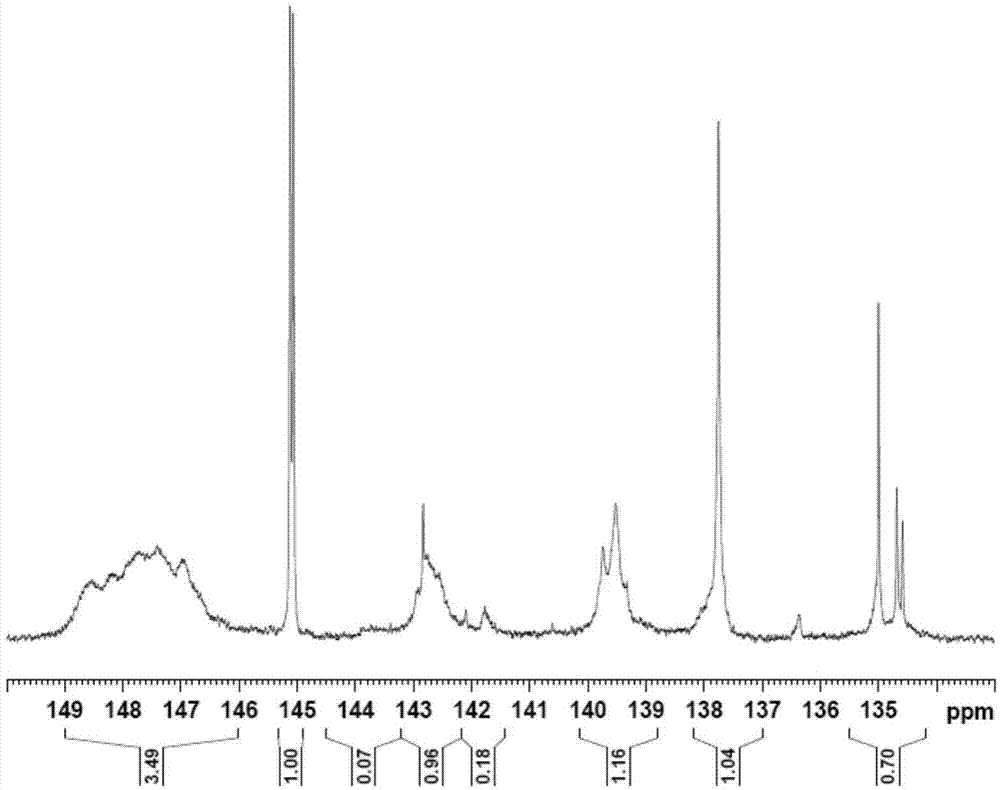

Embodiment 2

[0048] 1) The ratio of phenol, corn cob lignin and formaldehyde in this example is: 75.2g of phenol, 18.8g of lignin, and 102.16g of formaldehyde solution.

[0049] 2) First add 18.8 corncob alkali lignin, 75.2g phenol and 51.08g of the first batch of formaldehyde solution into the three-necked bottle, stir evenly, then add the first batch of sodium hydroxide solution (30wt%) 31.33g into the reaction system at an appropriate speed, Then raise the temperature of the system to 80°C, and keep it warm for 60 minutes;

[0050] 3) Add the second batch of sodium hydroxide solution 2.61g and the second batch of formaldehyde solution 17.03g at an appropriate speed, and keep warm for 20min at 80°C;

[0051] 4) Add the third batch of formaldehyde solution 17.03g and the third batch of sodium hydroxide solution 5.22g, and the reaction system continues to react at 80°C for 20 minutes;

[0052] 5) Add 17.03g of the fourth batch of formaldehyde solution and 7.83g of the fourth batch of sodi...

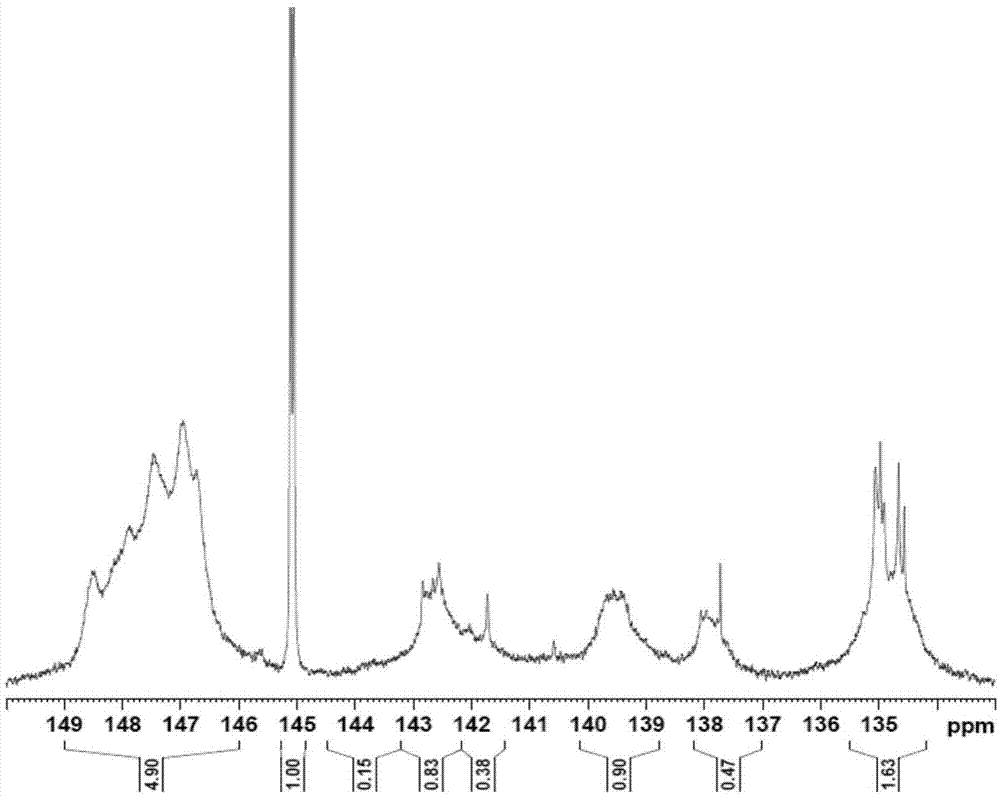

Embodiment 3

[0056] 1) The ratio of phenol, corncob lignin and formaldehyde in this example is: 65.8g of phenol, 28.2g of lignin, and 92.42g of formaldehyde solution.

[0057] 2) First add 28.2g of corncob alkali lignin, 65.8g of phenol and 46.21g of the first batch of formaldehyde solution into the three-necked flask, stir evenly, and add the first batch of sodium hydroxide solution (30wt%) 31.33g into the reaction system at an appropriate speed , then raise the temperature of the system to 80°C, and keep it warm for 60 minutes;

[0058] 3) Add the second batch of sodium hydroxide solution 15.67g and the second batch of formaldehyde solution 5.40g at an appropriate speed, and keep warm for 20min at 80°C;

[0059] 4) Add the third batch of formaldehyde solution 15.40g and the third batch of sodium hydroxide solution 2.61g, and the reaction system continues to react at 80°C for 20 minutes;

[0060] 5) Add 15.40g of the fourth batch of formaldehyde solution and 5.22g of the fourth batch of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com