Thermoplastic polyester elastomer composition and application thereof

A thermoplastic polyester and elastomer technology, applied in the field of thermoplastic polyester elastomer composition, can solve the problems of low production efficiency, increased processing cost, damage and permanent deformation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026]100 parts by weight of polyethylene terephthalate having a number average molecular weight of 30,000 and 33.3 parts of polycaprolactone diol having a number average molecular weight of 10,000 were stirred for 1 hour at 230 to 245° C. and 130 Pa, and the resin was confirmed to be transparent. , taken out, cooled to obtain polyester-polyester block copolymer (thermoplastic polyester elastomer).

[0027] Melting and blending the above-mentioned copolymer, antioxidant and talcum powder on a twin-screw extruder at 225-235° C., quenching in water and granulating. The polymer pellets were injection molded into strips, and their melt index (230°C, 2.16kg), compression set and mechanical strength were measured.

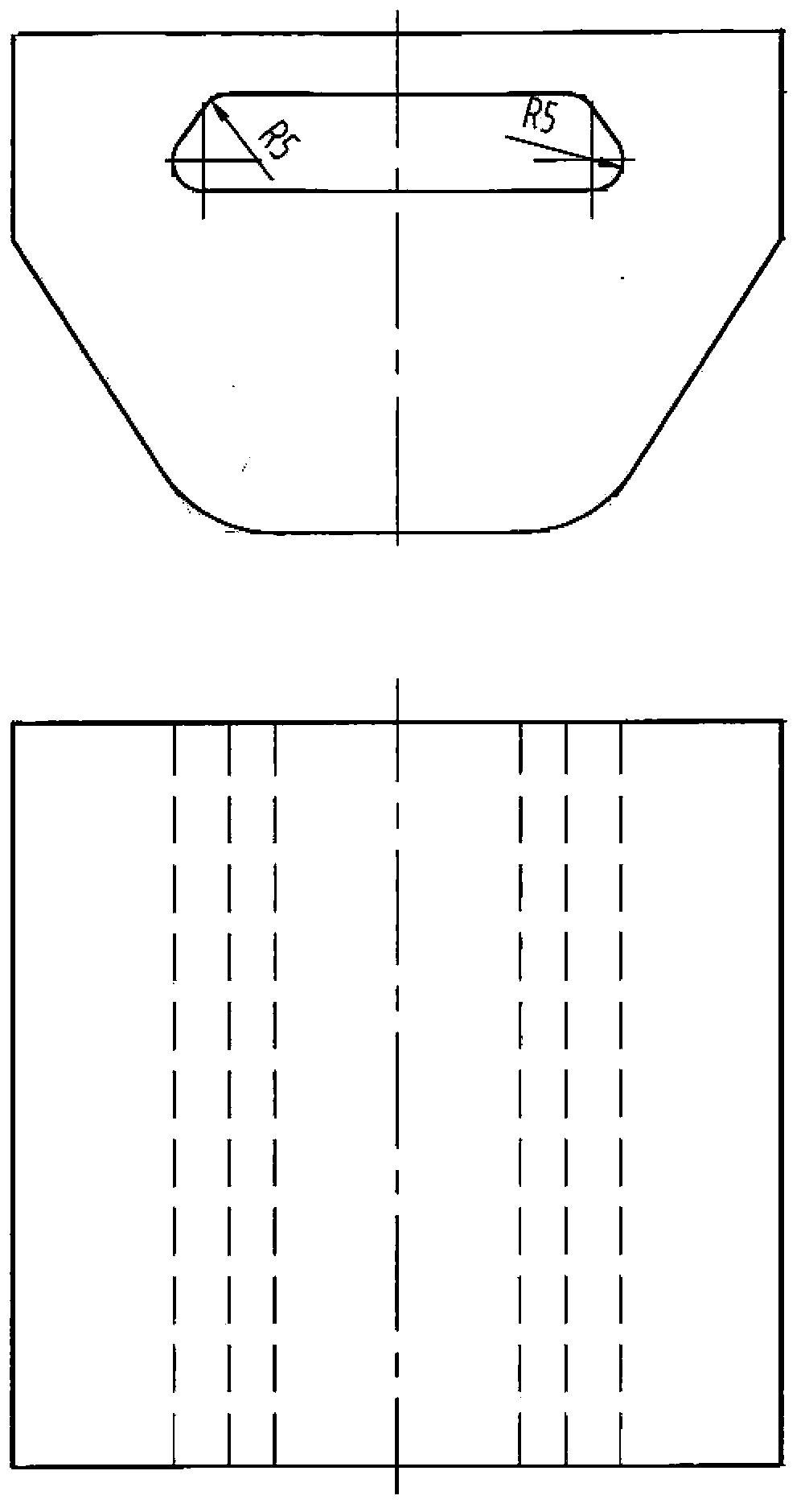

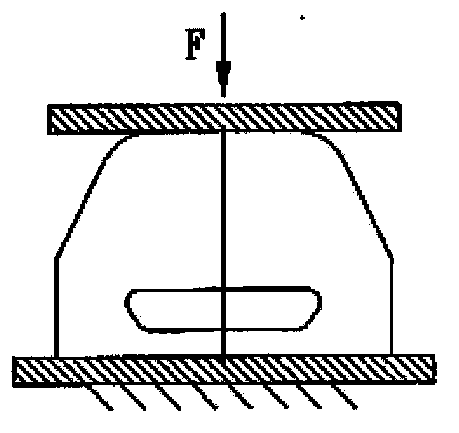

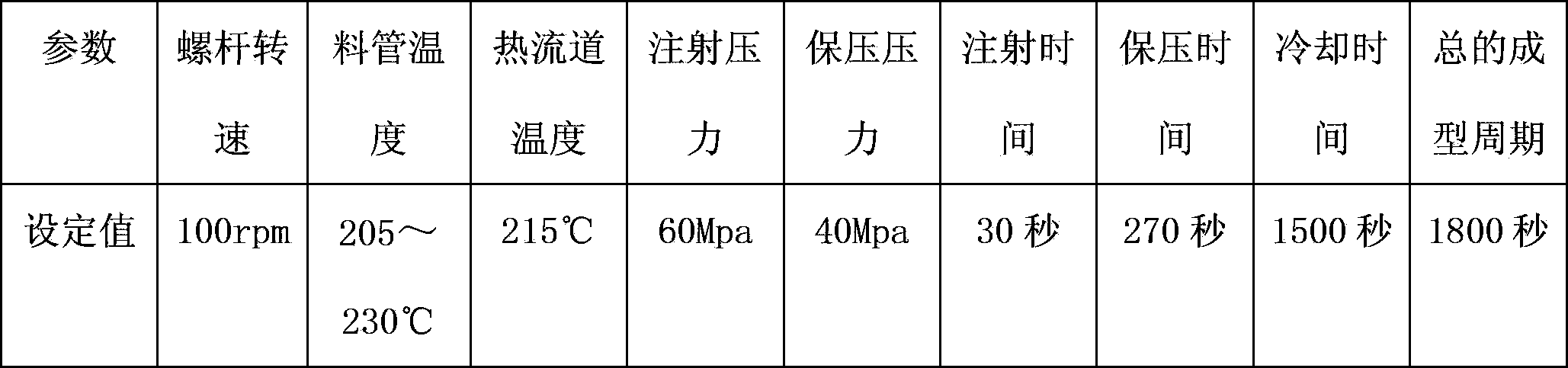

[0028] Through a multi-station injection molding machine, and through the processing conditions of the following table 1, as attached figure 1 auxiliary spring shown. Immediately put the molded product into a constant temperature oven for annealing treatment. The heati...

Embodiment 2

[0032] For Example 1, polycaprolactone diol with a number average molecular weight of 5,000 was used instead of polycaprolactone diol with a number average molecular weight of 10,000.

Embodiment 3

[0034] For Example 1, polycaprolactone diol with a number average molecular weight of 20,000 was used instead of polycaprolactone diol with a number average molecular weight of 10,000.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com