A nitrogen-doped porous carbon fiber material and its preparation method and application

A technology of nitrogen-doped porous carbon and fiber materials, applied in the fields of fiber chemical characteristics, textiles and papermaking, electrical components, etc., can solve the problems of not being widely used in the fields of energy and environment, complex synthesis methods, and incapable of large-scale preparation. The effect of low price, high specific surface area and good electrochemical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Example 1. Preparation of nitrogen-doped porous carbon fiber material and its electrochemical performance test

[0033] Heat 1000mL of an aqueous solution containing 0.64g citric acid and 1.26g melamine (the molar ratio of melamine to citric acid is 3:1) and stir (80°C) until the melamine is completely dissolved; then cool to 4°C for standing precipitation, and white crystals are precipitated. After filtering and drying, it is the precursor of the combination of melamine and citric acid. Put 5g of the above precursor into a quartz tank, spread it evenly, put it into a tube furnace, first pass Ar gas for 10 minutes, the Ar gas flow rate is 50ml / min, and then increase the temperature to 900 °C at a rate of 2 °C / min. Keep calcining for 4 hours; then cool to room temperature under the condition of Ar gas to obtain nitrogen-doped porous carbon fiber material.

[0034] 1) Characterization of nitrogen-doped porous carbon fiber materials:

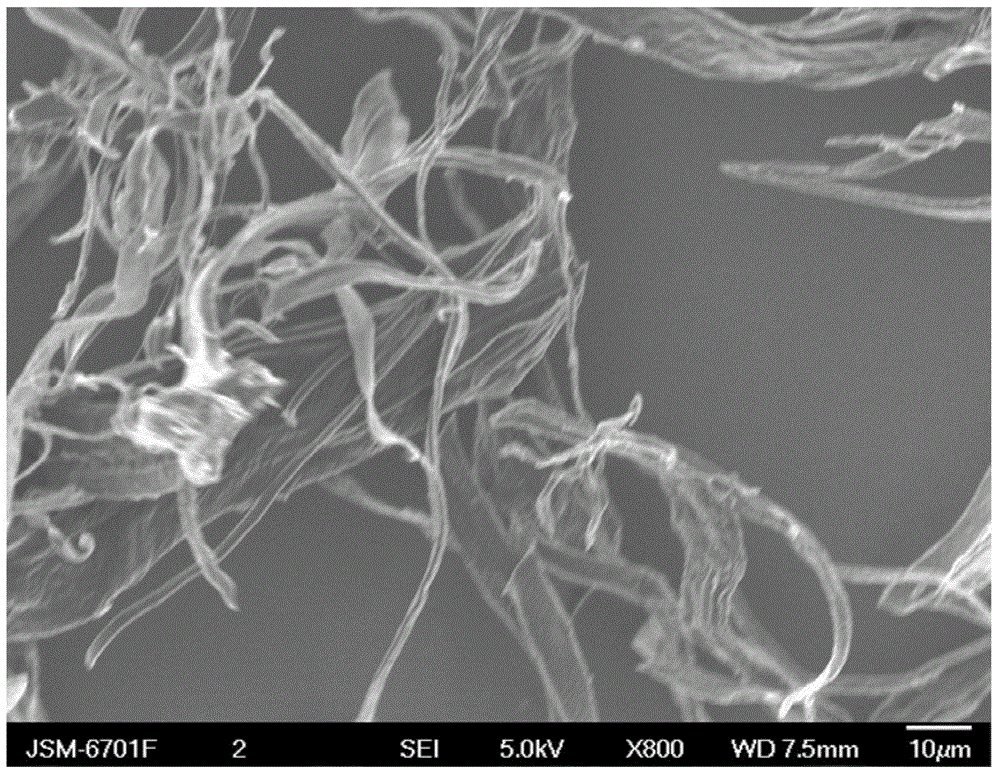

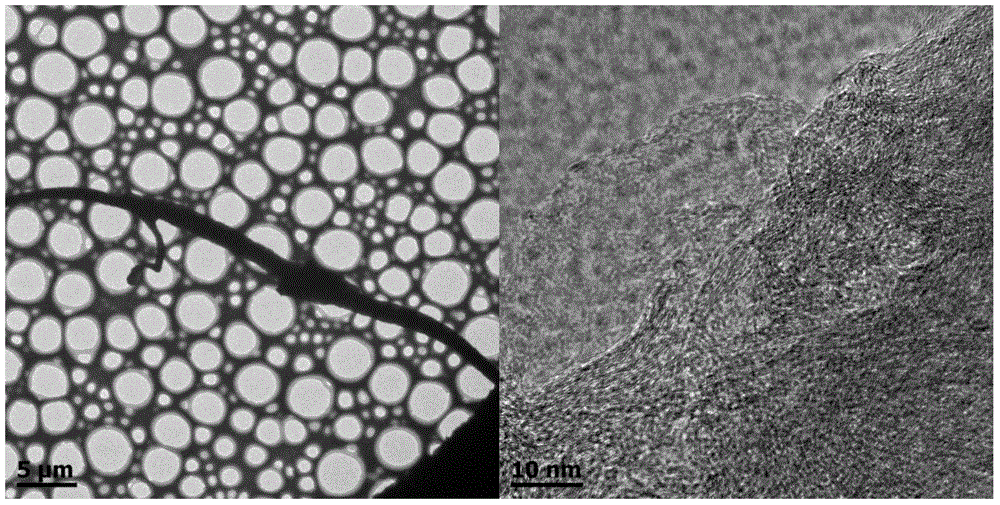

[0035] The morphology of the nitrog...

Embodiment 2

[0041] Example 2, Preparation of nitrogen-doped porous carbon fiber material and its electrochemical performance test

[0042] Heat 1000mL of an aqueous solution containing 0.64g citric acid and 1.29g cyanuric acid (the molar ratio of cyanuric acid to citric acid is 3:1) and stir (60°C) until the cyanuric acid is completely dissolved; then cool to 4°C After static precipitation, white crystals are precipitated, filtered and dried, which is the precursor of the combination of cyanuric acid and citric acid. Put 5g of the above precursor into a quartz tank, spread it evenly, put it into a tube furnace, first pass Ar gas for 10 minutes, the Ar gas flow rate is 50ml / min, and then increase the temperature to 800°C at a rate of 4°C / min. Calcined for 2 hours; then cooled to room temperature under Ar gas conditions to obtain a nitrogen-doped porous carbon fiber material.

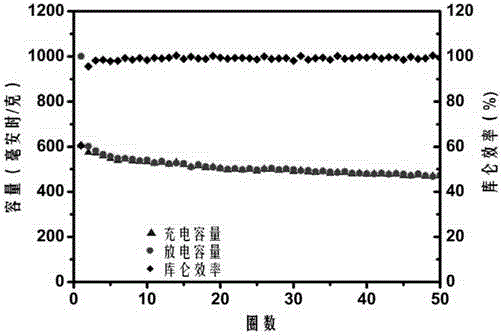

[0043] Electrochemical performance characterization of nitrogen-doped porous carbon fiber material: The positive ...

Embodiment 3

[0044] Example 3, Preparation of nitrogen-doped porous carbon fiber material and its electrochemical performance test

[0045] Heat 1000mL of an aqueous solution containing 0.90g oxalic acid and 1.26g melamine (the molar ratio of melamine to oxalic acid is 1:1) and stir (100°C) until the melamine is completely dissolved; then cool to 4°C for standing precipitation, and white crystals are precipitated, filtered and dried , which is the precursor of the combination of cyanuric acid and oxalic acid. Put 5g of the above-mentioned precursor into a quartz tank, spread it evenly, put it into a tube furnace, first pass Ar gas for 10 minutes, the Ar gas flow rate is 50ml / min, and then increase the temperature to 900 °C at a rate of 4 °C / min. Calcined for 2 hours; then cooled to room temperature under Ar gas conditions to obtain a nitrogen-doped porous carbon fiber material.

[0046] Electrochemical performance characterization of nitrogen-doped porous carbon fiber material: The positi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com