Preparation method and application of cage-shaped titanium dioxide sensitized by copper carboxyl phenyl porphyrin

A technology of carboxyphenyl porphyrin and phenyl porphyrin, which is applied in the field of preparation of caged titanium dioxide, can solve the problems of harsh conditions, endanger human health and environmental safety, drug resistance of harmful bacteria and the like, and achieve mild synthesis conditions. Simple and effective for improving application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Step 1: TiO 2-x(1) Preparation

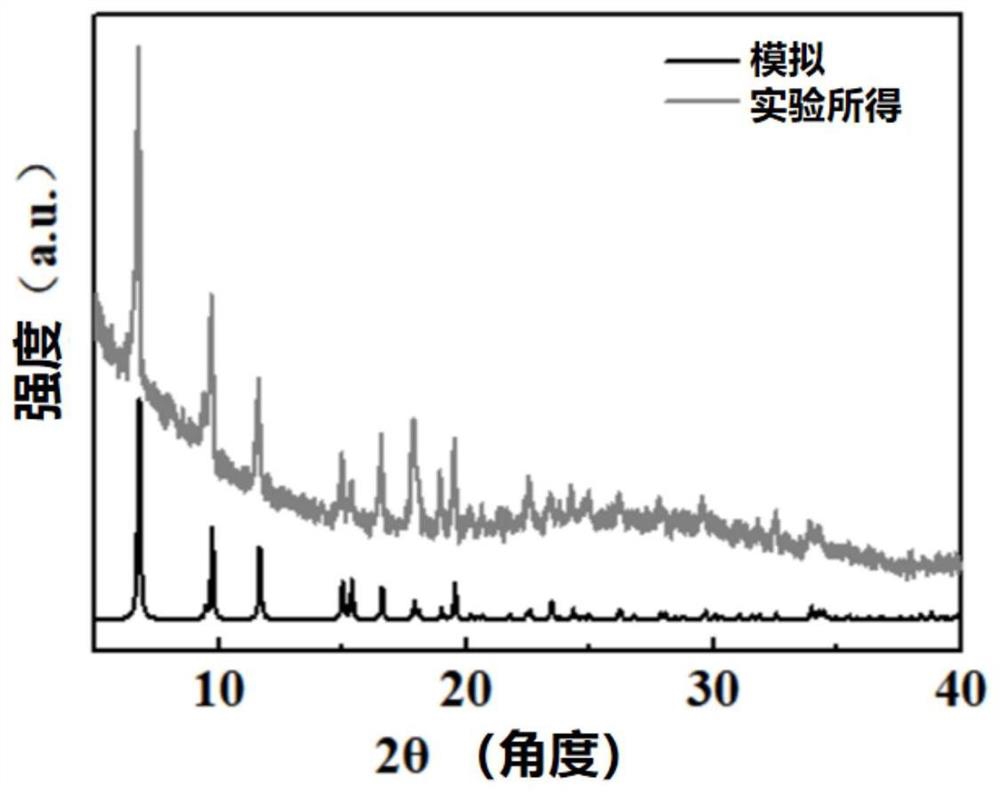

[0031] Tetraisopropyl titanate (0.6 mmol) and 2-aminoterephthalic acid (1.2 mmol) were dispersed in a mixed solvent of anhydrous DMF (5 mL) and anhydrous methanol (5 mL). After stirring at room temperature for 10 min, the solution was transferred to a Teflon-lined autoclave and heated at 150 °C for 15 h in a constant temperature blast drying oven. The yellow powder was collected by centrifugation, and the collected powder was washed twice with DMF to remove residual organic ligands, washed twice with anhydrous methanol to remove DMF, and dried under vacuum at 100 °C for 12 h to obtain NH 2 -MIL-125(1), by figure 1 The known diffraction peaks are consistent with the simulated diffraction peaks, and the crystal form is good.

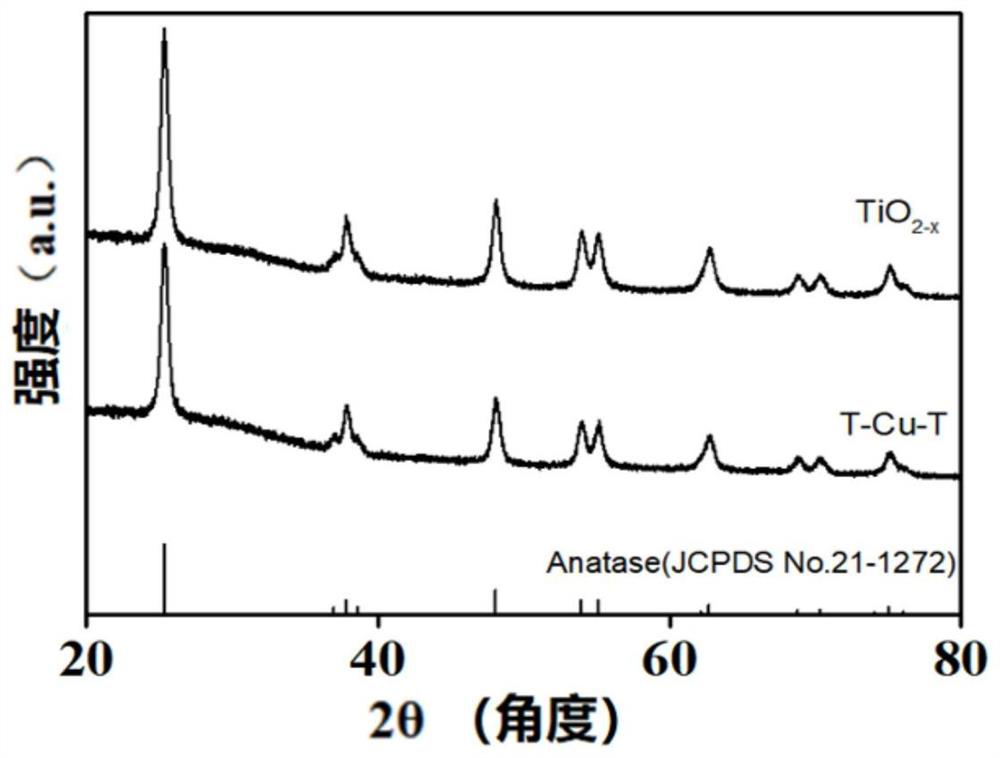

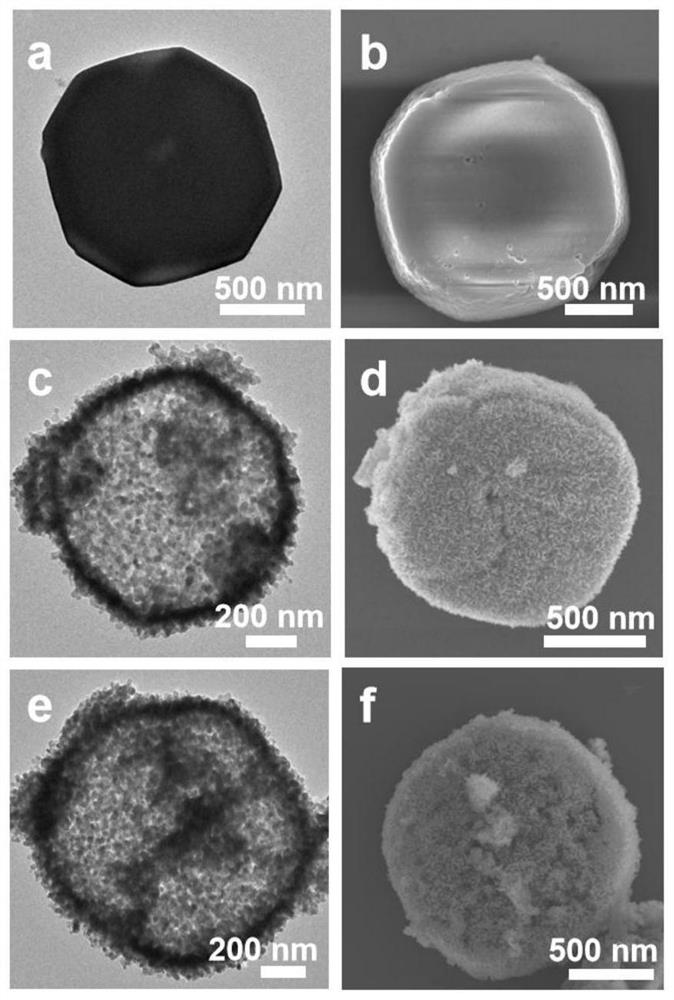

[0032] will NH 2 - MIL-125(1) (10 mg) was sonicated into a vial containing absolute ethanol (5 mL). L-Alanine (47.5 mg) was introduced into the above mixture, then the vial was placed in an autoclave with a Tefl...

Embodiment 2

[0049] Step 1: Cage TiO 2-x (2) Preparation

[0050] Tetraisopropyl titanate (0.6 mmol) and 2-aminoterephthalic acid (1.08 mmol) were dispersed in a mixed solvent of anhydrous DMF (5 mL) and anhydrous methanol (4 mL). After stirring at room temperature for 5 min, the solution was transferred to a Teflon-lined autoclave and heated at 140 °C for 13 h in a constant temperature blast drying oven. The yellow powder was collected by centrifugation, and the collected powder was washed once with DMF to remove residual organic ligands, washed once with anhydrous methanol to remove DMF, and dried under vacuum at 90 °C for 10 h to obtain NH 2 -MIL-125(2).

[0051] will NH 2 - MIL-125(2) (10 mg) was sonicated into a vial containing absolute ethanol (5.6 mL). L-Alanine (45 mgl) was introduced into the above mixture, then the vial was placed in an autoclave with a Teflon liner and heated at 170°C for 22h. The gray-colored precipitate was collected by centrifugation, washed twice with a...

Embodiment 3

[0061] Step 1: Cage TiO 2-x (3) Preparation

[0062] Tetraisopropyl titanate (0.6 mmol) and 2-aminoterephthalic acid (1.32 mmol) were dispersed in a mixed solvent of anhydrous DMF (5 mL) and anhydrous methanol (6 mL). After stirring at room temperature for 15 min, the solution was transferred to a Teflon-lined autoclave and heated at 160 °C for 17 h in a constant temperature blast drying oven. The yellow powder was collected by centrifugation, and the collected powder was washed three times with DMF to remove residual organic ligands, washed three times with anhydrous methanol to remove DMF, and dried under vacuum at 110 °C for 14 h to obtain NH 2 -MIL-125(3).

[0063] will NH 2 - MIL-125(3) (10 mg) was sonicated into a vial containing absolute ethanol (4.5 mL). L-Alanine (50 mg) was introduced into the above mixture, then the vial was placed in a Teflon-lined autoclave and heated at 182 °C for 26 h. The gray-colored precipitate was collected by centrifugation, washed 4 t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com