Ultra-low temperature convective radiation heating system based on porous adobe heat storage

A technology of radiant heating and ultra-low temperature, applied in heating systems, household heating, heating methods, etc. Short distance between hot surfaces and good heat storage and release performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

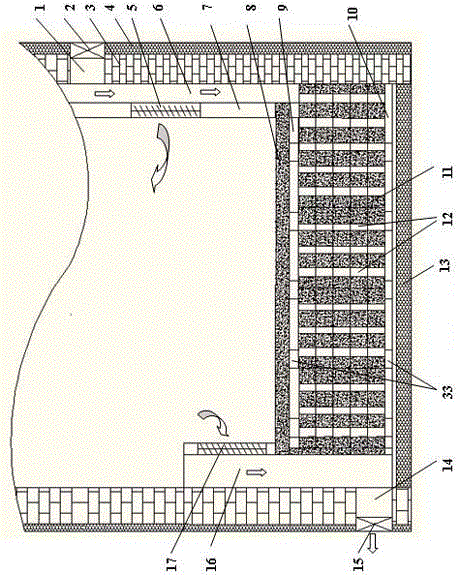

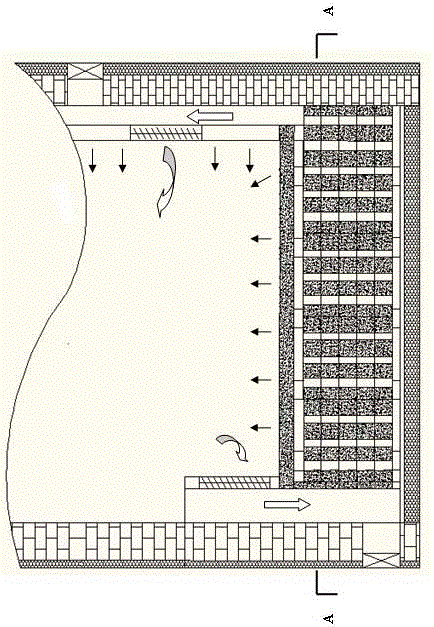

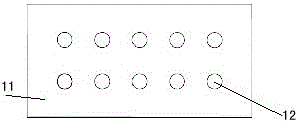

[0033] Embodiment 1 of the present invention such as Figure 1~6 As shown, the heat storage working method is as follows figure 1 As shown, the heating works as figure 2 As shown, the adobe is as shown in the figure, and the arrangement of a single layer of adobe is as follows Figure 6 shown. The working mode of heat storage in Embodiment 1 of the present invention is to open the valve or baffle 2, open the valve or baffle 15, close the hot air louvers 5 and cold air louvers 17, and the hot air provided by the heating device runs downward from the hot air duct 6, Enter the upper confluence channel 9 connected with the hot air duct 6, and then enter the adobe inner hole 12 after the flow is evenly dispersed by the upper confluence channel 9, and the cold air after heat exchange and cooling through the adobe inner hole 12 enters the lower confluence channel 10, and passes through the lower confluence channel 10. After confluence, the confluence channels 10 enter the cold ai...

Embodiment 2

[0037] On the basis of Example 1, the figure 1 , Figure 6 The adobe 11 in the vertical placement, such as Figure 7 As shown, make the adobe inner holes 12 in a horizontal state and parallel to the air flow direction, and keep the adobe inner holes 12 in relative positions on a line, so that the adobe inner holes 12 in relative positions are connected into a tube shape, A certain space is left on both sides of the heating body as an upper confluence channel 9 and a lower confluence channel 10, wherein the upper confluence channel 9 communicates with the hot air channel 6, and the lower confluence channel 10 communicates with the cold air channel 16 and the air outlet 14. It should be noted that this method of laying the inner hole of the adobe horizontally and placing the confluence channel vertically has a simple structure, convenient installation, and small air flow resistance, but it is not conducive to the heat transfer from the adobe in the lower layer to the ground flo...

Embodiment 3

[0039] On the basis of Example 1, the figure 1 , Figure 6 The adobe 11 in the middle is vertically placed, such as Figure 8 As shown, make the adobe inner holes 12 in a horizontal state and be perpendicular to the air flow direction, and keep the adobe inner holes 12 in relative positions on a line, so that the adobe inner holes 12 in relative positions are connected into a tube shape, and Keep a certain distance between the two adobes 11 to make it a hot air flow plate channel, and leave a certain space on both sides of the adobe heat storage body to make it an upper confluence channel 9 and a lower confluence channel 10, wherein the upper confluence channel 9 and the hot air The air duct 6 communicates with each other, and the lower confluence channel 10 communicates with the cold air duct 16 and the air outlet 14 . It should be noted that the flow resistance of the plate channel is small, the inner hole of the adobe and the surface of the adobe are in contact with the h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com