Preparation method of cobalt molybdate and graphene nanocomposite

A nano-composite material and graphene technology, which is applied in the field of preparation of cobalt molybdate and graphene nano-composite materials, achieves the effect of simple and easy operation, low cost, and solving difficulties in large-scale application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

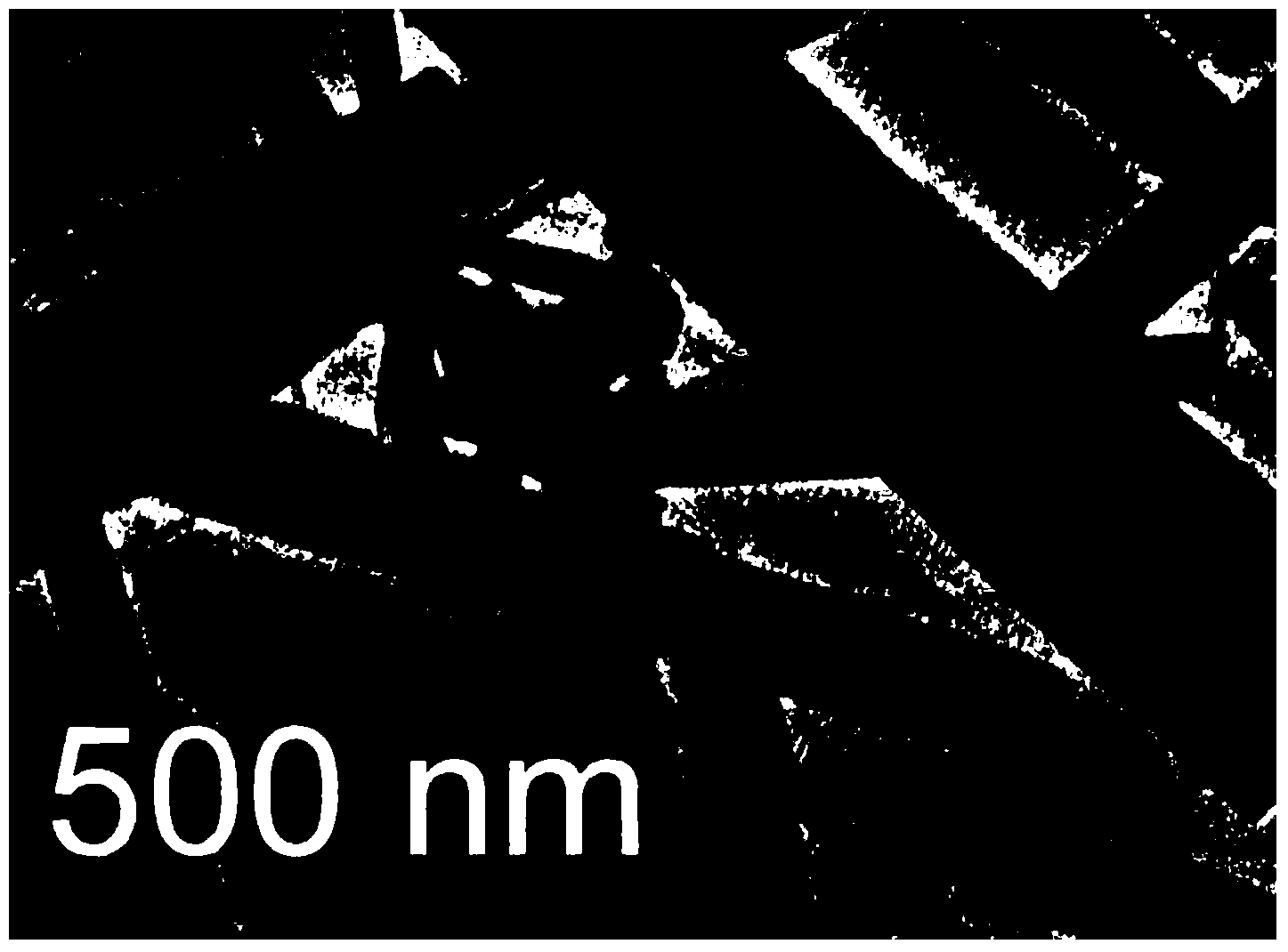

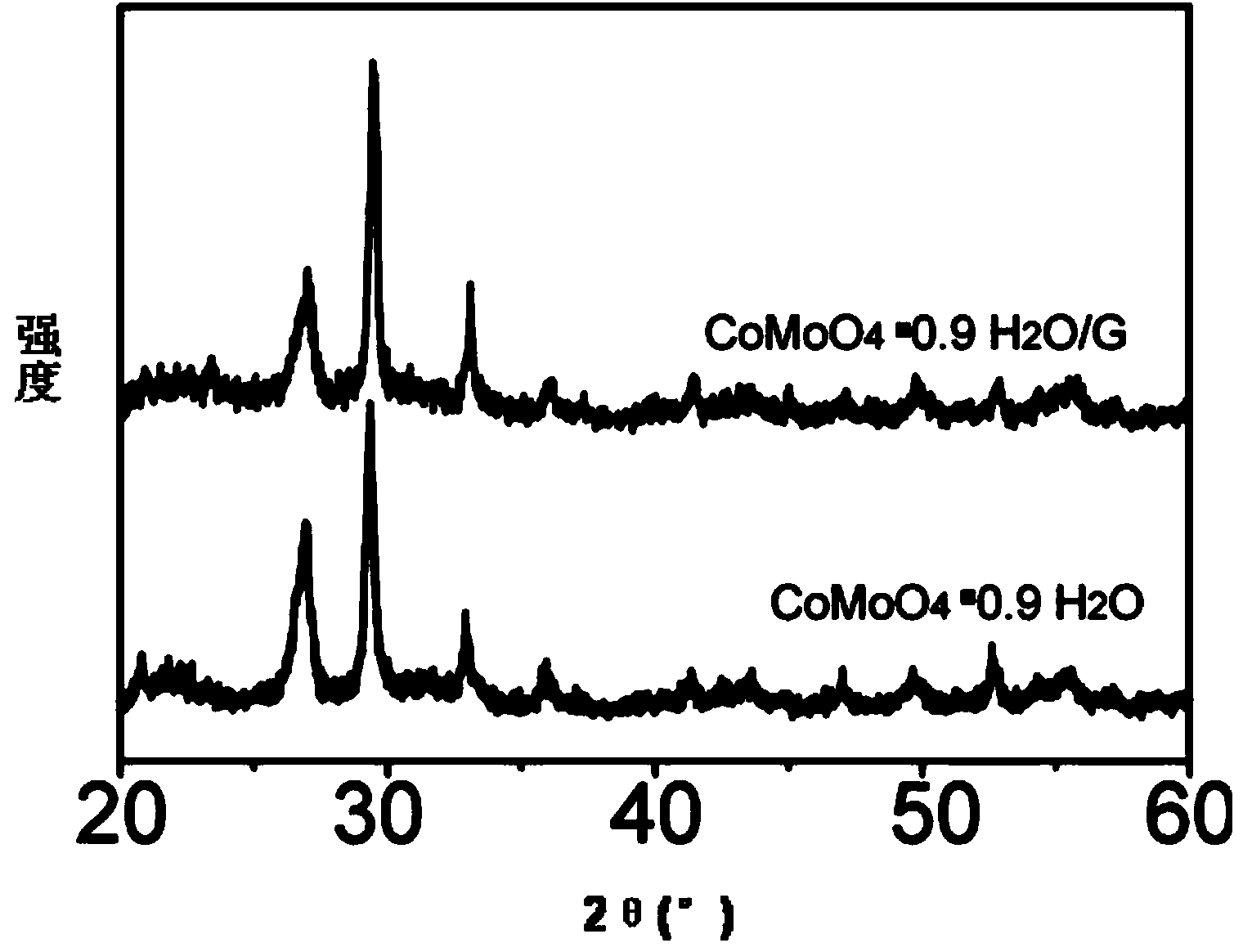

Image

Examples

Embodiment 1

[0025] (1) Disperse 10mg graphene oxide in 5ml deionized water, ultrasonic for 4h;

[0026] (2) Add CoCl to the graphene oxide solution after ultrasonication 2 ·6H 2 O2mmol and deionized water 40ml, stirred for 30min;

[0027] (3) Add Na to the above solution 2 MoO 4 2H 2 02mmol, continue to stir for 5h; then move into a 50ml polytetrafluoroethylene reactor, and react at 120°C for 15h;

[0028] (4) After the reaction, cool to room temperature, centrifuge the obtained product, wash with deionized water and ethanol solvent respectively, and dry.

Embodiment 2

[0030] (1) Disperse 10mg graphene oxide in 5ml deionized water, ultrasonic for 4h;

[0031] (2) Add CoCl to the graphene oxide solution after ultrasonication 2 ·6H 2 O2mmol and deionized water 40ml, stirred for 30min;

[0032] (3) Add Na to the above solution 2 MoO 4 2H 2 02mmol, continue to stir for 5h; then move into a 50ml polytetrafluoroethylene reactor, and react at 180°C for 15h;

[0033] (4) After the reaction, cool to room temperature, centrifuge the obtained product, wash with deionized water and ethanol solvent respectively, and dry.

Embodiment 3

[0035] (1) Disperse 30mg graphene oxide in 5ml deionized water, ultrasonic for 4h;

[0036] (2) Add CoCl to the graphene oxide solution after ultrasonication 2 ·6H 2 O2mmol and deionized water 40ml, stirred for 30min;

[0037] (3) Add Na to the above solution 2 MoO 4 2H 2 O2mmol, continued to stir for 5h; then moved into a 50ml polytetrafluoroethylene reactor and reacted at 180°C for 15h.

[0038] (4) After the reaction, cool to room temperature, centrifuge the obtained product, wash with deionized water and ethanol solvent respectively, and dry.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com