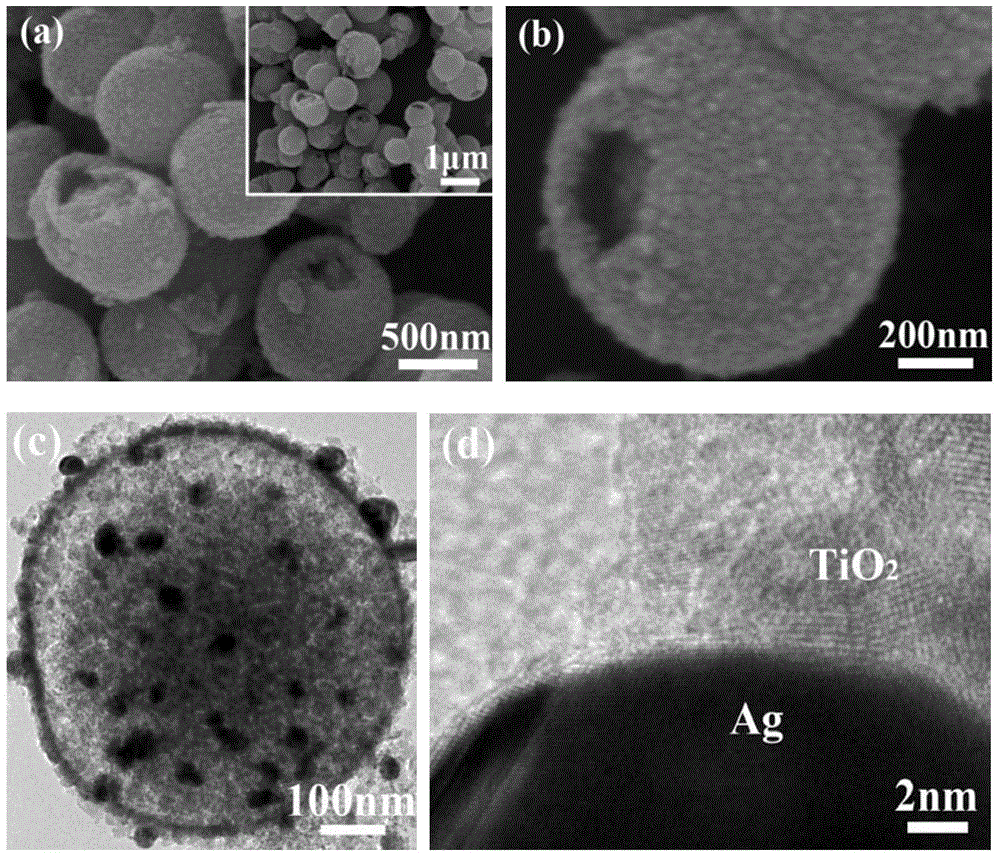

Titanium dioxide-silver composite core-shell structure sphere and its preparation method and application

A technology of titanium dioxide and composite core, which is applied in the field of titanium dioxide-silver composite core-shell structure spheres and its preparation, can solve the problems of low Ag composite efficiency, long preparation cycle, and low composite ratio, so as to reduce the waste of silver sources and prepare The method is simple and the effect of high silver composite ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

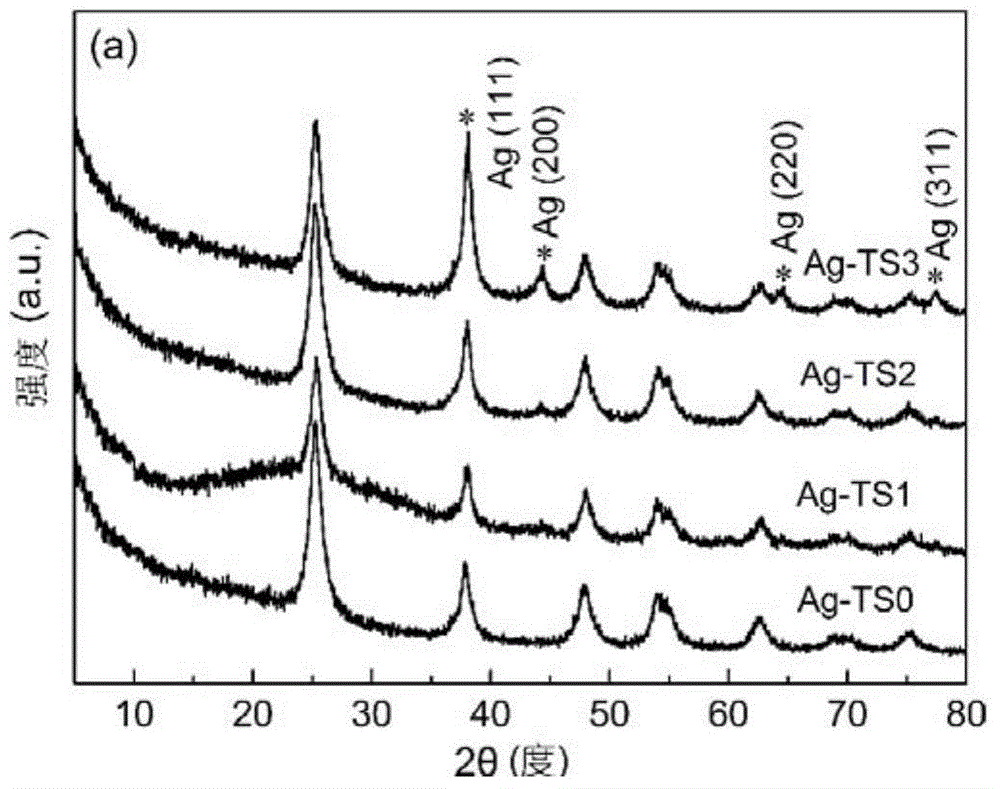

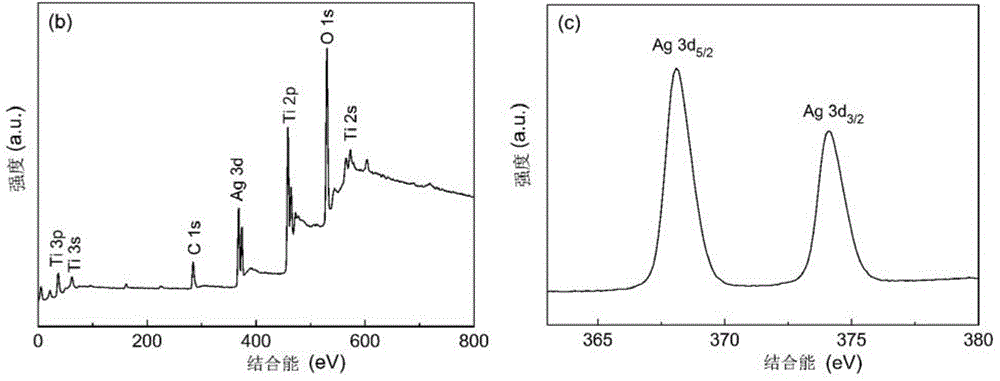

Embodiment 1

[0035] The concrete steps of preparation are:

[0036] First, according to the molar ratio of 1.5:4.5:0.044, titanyl sulfate, urea and silver nitrate were added to the aqueous ethanol solution with a concentration of 55% to obtain a mixed solution; wherein, the titanyl sulfate in the mixed solution and the The molar ratio of ethanol is 1:50. Then the mixed solution is placed in a microwave heating airtight state, and reacted at a temperature of 160 ° C for 30 minutes; wherein, the frequency of microwave heating is 2450 MHz, the power is 1000 W, and the carrier forming the airtight state is a polytetrafluoroethylene autoclave. The target product in the reaction solution. After that, it is subjected to solid-liquid separation, washing and drying; wherein, the solid-liquid separation treatment is centrifugation, the speed of centrifugation is 3000-8000r / min, and the time is 3-8min, and the washing treatment is to use deionized water and Wash the separated target product with et...

Embodiment 2

[0038] The concrete steps of preparation are:

[0039] First, according to the molar ratio of 1.8:4.3:0.01, titanyl sulfate, urea and silver nitrate were added to the aqueous ethanol solution with a concentration of 53% to obtain a mixed solution; wherein, the titanyl sulfate in the mixed solution and the The molar ratio of ethanol is 1:100. Then the mixed solution is placed in a sealed state of microwave heating, and reacted at a temperature of 170 ° C for 23 minutes; wherein, the frequency of microwave heating is 2450 MHz, the power is 1050 W, and the carrier forming a sealed state is a polytetrafluoroethylene autoclave. The target product in the reaction solution. After that, it is subjected to solid-liquid separation, washing and drying; wherein, the solid-liquid separation treatment is centrifugation, the speed of centrifugation is 3000-8000r / min, and the time is 3-8min, and the washing treatment is to use deionized water and Wash the separated target product with ethan...

Embodiment 3

[0041] The concrete steps of preparation are:

[0042] First, according to the molar ratio of 2:4:0.05, titanyl sulfate, urea and silver nitrate were added to a 50% ethanol aqueous solution to obtain a mixed solution; wherein, the titanyl sulfate in the mixed solution and the ethanol aqueous solution The molar ratio of ethanol is 1:150. Then the mixed solution is placed in a sealed state of microwave heating, and reacted at a temperature of 180 ° C for 18 minutes; wherein, the frequency of microwave heating is 2450 MHz, the power is 1100 W, and the carrier forming a sealed state is a polytetrafluoroethylene autoclave. The target product in the reaction solution. After that, it is subjected to solid-liquid separation, washing and drying; wherein, the solid-liquid separation treatment is centrifugation, the speed of centrifugation is 3000-8000r / min, and the time is 3-8min, and the washing treatment is to use deionized water and Wash the separated target product with ethanol un...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com