Method for preparing graphene structure-like copper-indium-sulfur nanosheet array membrane

A nanosheet array, graphene technology, applied in metal material coating process, coating and other directions, can solve the problems of harsh production conditions, difficult to control, excessive impurities, etc., and achieve the effect of low price and high repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] This embodiment includes the following steps:

[0033] 1) Prepare 6mmol of cuprous chloride and 6mmol of indium chloride, add 10mL of triethanolamine, 8mL of acetone, and 8mL of sodium citrate solution (0.1mol / L) into the reaction kettle, and stir for 10min;

[0034] 2) Add 8mL of ammonia water (28-30%) to the above mixture, and stir for 10min;

[0035] 3) Finally, add 7.2mmol of sulfur source (the molar ratio of sulfur powder / thiourea is 2 / 1), add 10mL of hydrazine hydrate, and add water / ethylene glycol mixed solvent to make the reaction liquid reach 80% of the volume of the reactor;

[0036] 4) Insert the substrate (FTO conductive glass) into the reactor, and quickly pour in the prepared chemical reaction solution, and seal the reactor tightly. The temperature of the solvothermal reaction in a muffle furnace is 180° C., and the reaction time is 12 hours.

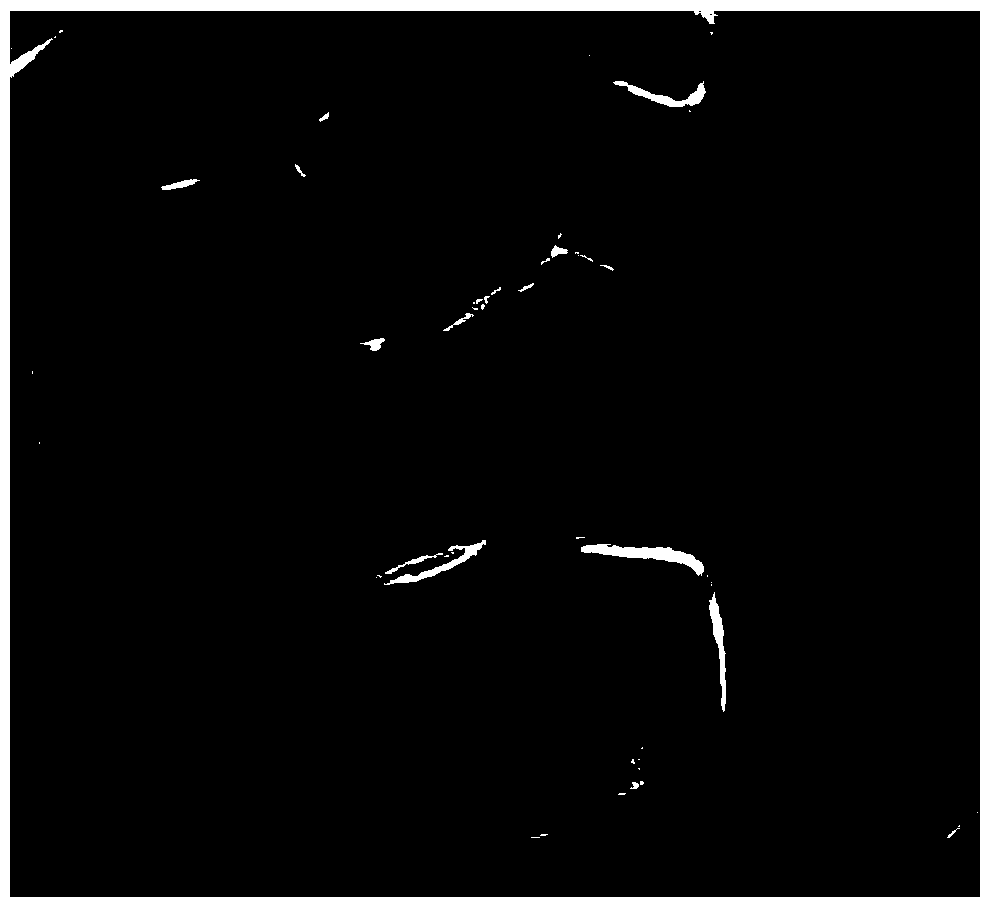

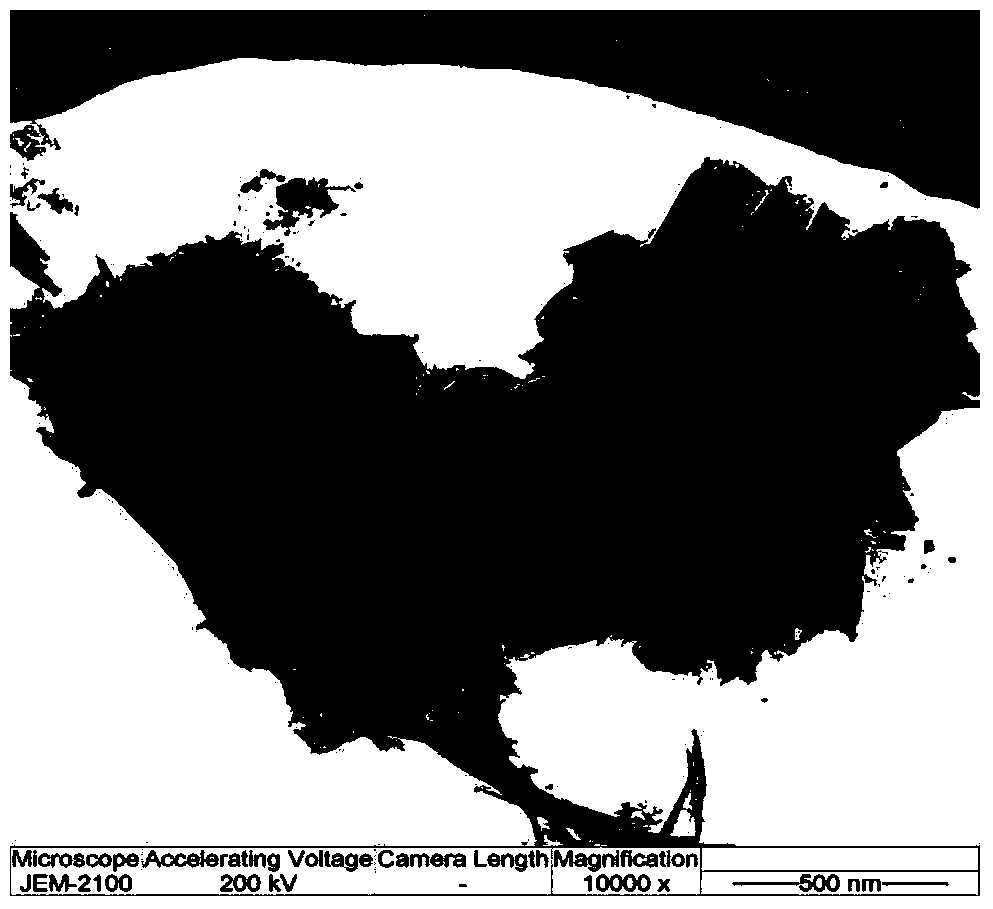

[0037] Such as Figure 1 ~ Figure 3 As shown, the CuInS prepared in this example 2 The nanosheet thin film ar...

Embodiment 2

[0039] This embodiment includes the following steps:

[0040] 1) Prepare 6mmol of cuprous chloride and 6mmol of indium chloride, add 10mL of triethanolamine, 8mL of acetone, and 8mL of sodium citrate solution (0.1mol / L) into the reaction kettle, and stir for 10min;

[0041] 2) Add 10mL of ammonia water (28-30%) to the above mixture, and stir for 10min;

[0042] 3) Finally, add 7.2mmol of sulfur source (the molar ratio of sulfur powder / thiourea is 2 / 1), add 10mL of hydrazine hydrate, and add water / ethylene glycol mixed solvent to make the reaction liquid reach 80% of the volume of the reactor;

[0043]4) Insert the substrate (FTO conductive glass) into the reactor, and quickly pour in the prepared chemical reaction solution, and seal the reactor tightly. The temperature of the solvothermal reaction in a muffle furnace is 100° C., and the reaction time is 2 h.

Embodiment 3

[0045] This embodiment includes the following steps:

[0046] 1) Prepare 6mmol of cuprous chloride and 6mmol of indium chloride, add 10mL of triethanolamine, 8mL of acetone, and 8mL of sodium citrate solution (0.1mol / L) into the reaction kettle, and stir for 10min;

[0047] 2) Add 8mL of ammonia water (28-30%) to the above mixture, and stir for 10min;

[0048] 3) Finally, add 7.2mmol of sulfur source (the molar ratio of sulfur powder / thiourea is 2 / 1), add 10mL of hydrazine hydrate, and add water / ethylene glycol mixed solvent to make the reaction liquid reach 80% of the volume of the reactor;

[0049] 4) Insert the substrate (FTO conductive glass) into the reactor, and quickly pour in the prepared chemical reaction solution, and seal the reactor tightly. The temperature of the solvothermal reaction in a muffle furnace is 240° C., and the reaction time is 24 hours.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com