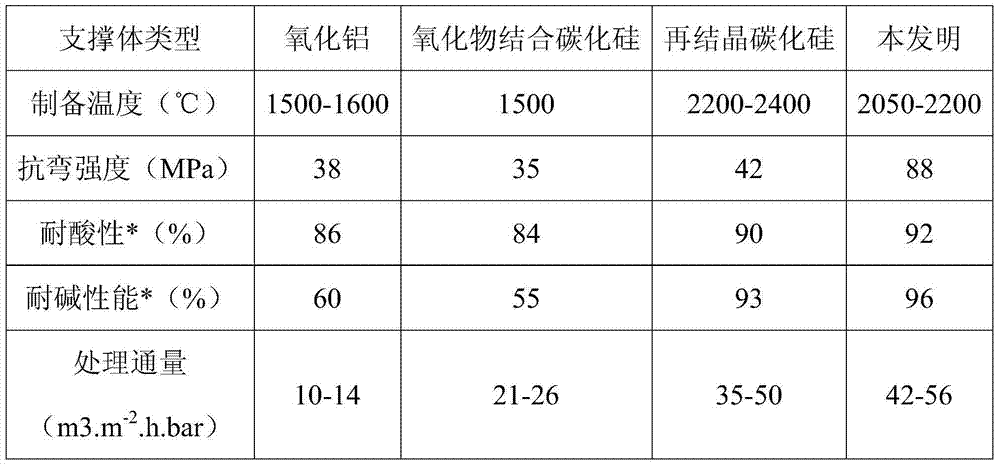

Acid and alkali corrosion-resistant silicon carbide porous support

A technology of porous support and silicon carbide, applied in the direction of chemical instruments and methods, applications, household appliances, etc., to achieve the effect of improving corrosion resistance, increasing porosity, and reducing low-temperature damage rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

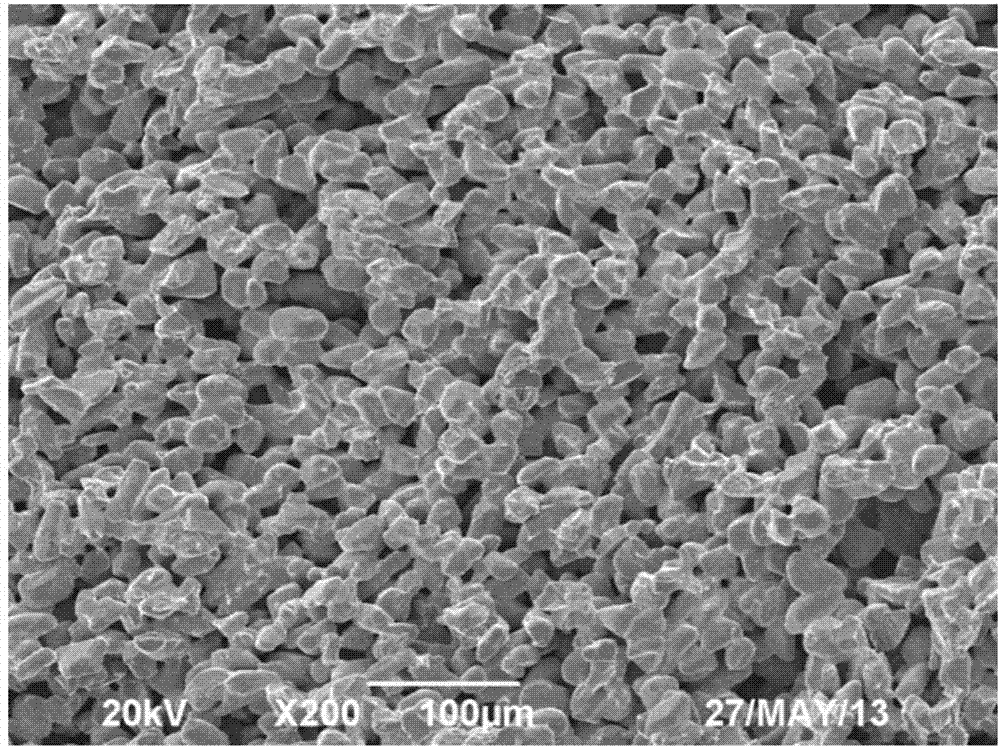

Image

Examples

Embodiment 1

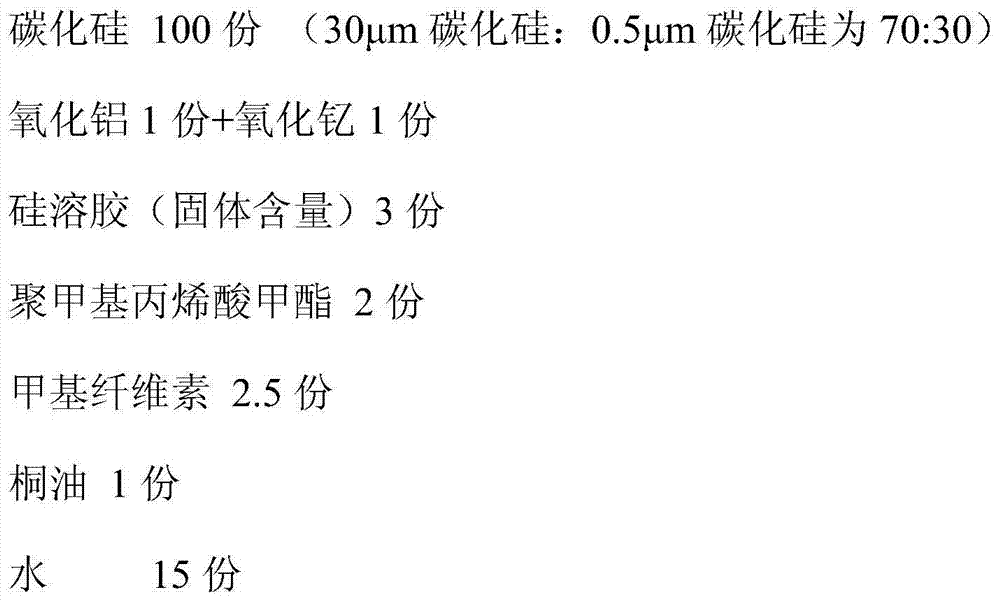

[0049] Embodiment 1: the raw material composition of described silicon carbide porous support body is:

[0050]

[0051] The preparation steps of silicon carbide porous support are as follows: (1) first mix 0.5 μm silicon carbide powder with alumina and yttrium oxide evenly, then mix the aforementioned premix with 30 μm silicon carbide powder, methyl cellulose, polymethyl methacrylate Mix the ester evenly in proportion; (2) Mix water, silica sol, and tung oil in proportion; (3) Mix, knead and knead the premixed (1) and (2) in proportion to form plastic mud; ( 4) Extrude the mud material through a mold to form a green body; (5) Dry the green body and calcinate it in the air at 700 ° C to remove organic substances such as methyl cellulose and polymethyl methacrylate; (6) After the aforementioned calcined The support body is fired in an argon protection furnace, the temperature is raised to 1650°C at 30°C / min, and kept for 1h, then raised to 1900°C at 30°C / min, kept for 1h, an...

Embodiment 2

[0053] Embodiment 2: The silicon carbide porous support body raw material is composed of:

[0054]

[0055] The preparation steps of silicon carbide porous support are as follows: (1) first mix 1 μm silicon carbide powder with alumina and yttrium oxide evenly, then mix the aforementioned premix with 30 μm silicon carbide powder, methyl cellulose, polymethyl methacrylate Mix evenly in proportion, (2) mix water, silica sol, and tung oil in proportion; (3) mix the premixed (1) and (2) in proportion, knead, and knead into mud; (4) Extrude the slime through a mold to form a green body; (5) Dry the green body and calcinate it in the air at 700°C to remove organic substances such as methyl cellulose and polymethyl methacrylate; (6) The support body after the calcined Fire in an argon protection furnace, heat up to 1650°C at 30°C / min, hold for 1h, then raise the temperature to 1900°C at 30°C / min, hold for 1h, then raise the temperature to 2200°C at 30°C, hold for 1h, with the furna...

Embodiment 3

[0057] Embodiment 3: the silicon carbide porous support body raw material is composed of:

[0058]

[0059]

[0060] The preparation steps of silicon carbide porous support are as follows: (1) first mix 0.5 μm silicon carbide powder with alumina and cerium oxide evenly, then mix the aforementioned premix with 25 μm silicon carbide powder, hydroxypropyl methylcellulose, polymethyl cellulose (2) Mix water, silica sol, and tung oil in proportion; (3) Mix the premixed (1) and (2) in proportion, knead and knead into mud ; (4) Extrude the mud through a mold to form a green body; (5) Dry the green body and calcinate it in the air at 750°C to remove organic matter such as hydroxypropyl methylcellulose and polymethyl methacrylate; (6 ) Burn the above-mentioned calcined support in an argon protection furnace, raise the temperature at 30°C / min to 1600°C, keep it for 1h, then raise the temperature at 30°C / min to 1800°C, keep it for 1h, and then raise the temperature at 30°C to 2100°...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com