Preparation method for cement auxiliary-grinding strengthener of polyethylene glycol amine ester carboxylic acid system

A technology of polyol urethane carboxylic acid and grinding aid enhancer, which is applied in the field of preparation of polyol urethane carboxylic acid cement grinding aid enhancer to achieve stable performance, simple operation process, good grinding aid and strengthening effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

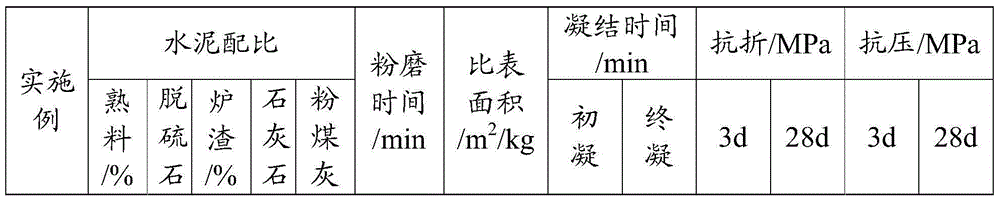

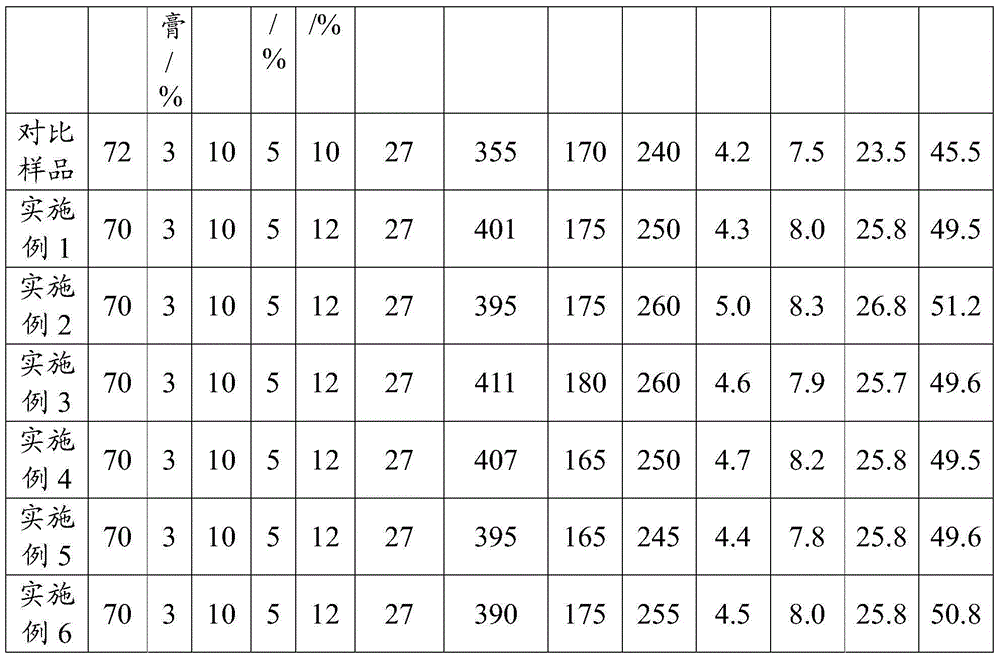

Examples

Embodiment 1

[0023] (1) Esterification reaction:

[0024] Add 1.0 mol of triethanolamine and 2.0 mol of lauryl acrylate into a reactor equipped with a stirrer, a thermometer, and a condensing device to react at an esterification temperature of 80°C and a reaction time of 5 hours to obtain esterified monomers.

[0025] (2) Preparation of polyol urethane carboxylic acid cement grinding aid:

[0026] In terms of parts by mass, 80 parts of allyl polyoxyethylene ether and 80 parts of water are placed in a reactor to stir, heat up, and dissolve; 15 parts of the esterified monomer prepared above and 25 parts of water are configured into a solution ①; 2 parts of ammonium persulfate and 25 parts of water are prepared into solution ②; 1 part of 2-mercaptoacetic acid and 25 parts of water are prepared into solution ③; when the temperature rises to 60°C, add solutions ①, ② and ③ dropwise at the same time, and add The time is 3h, and after the dropwise addition, keep the temperature constant for 1h. ...

Embodiment 2

[0028] (1) Esterification reaction:

[0029] Add 1.0 mol of triisopropanolamine and 3.0 mol of hydroxypropyl acrylate into a reactor equipped with a stirrer, a thermometer, and a condensing device to react at an esterification temperature of 85°C and a reaction time of 4.5 hours to obtain esterified monomers.

[0030] (2) Preparation of polyol urethane carboxylic acid cement grinding aid:

[0031] In terms of parts by mass, 90 parts of methyl alkenyl polyoxyethylene ether and 80 parts of water are placed in a reactor to stir, heat up, and dissolve; 20 parts of the esterification monomer prepared above and 25 parts of water are configured into a solution ①; Mix 3 parts of ammonium persulfate and 25 parts of water into a solution ②; mix 0.5 parts of 2-mercaptoacetic acid and 25 parts of water into a solution ③; when the temperature rises to 70°C, add solutions ①, ② and ③ dropwise at the same time, drop Adding time is 3h, after the dropwise addition is completed, keep the temper...

Embodiment 3

[0033] (1) Esterification reaction:

[0034] Add 1.5 mol of triethanolamine and 2.0 mol of ethyl acrylate into a reactor equipped with a stirrer, a thermometer, and a condensing device to react at an esterification temperature of 80° C. and a reaction time of 5 hours to obtain esterified monomers.

[0035] (2) Preparation of polyol urethane carboxylic acid cement grinding aid:

[0036] In terms of parts by mass, 90 parts of polyethylene glycol monomethyl ether methacrylate (molecular weight is 1200) and 80 parts of water are placed in the reactor to stir, heat up, and dissolve; 15 parts of the esterified monomer prepared above and 25 parts of water are prepared into a solution ①; 3 parts of ammonium persulfate and 25 parts of water are prepared into a solution ②; 0.5 parts of 3-mercaptopropionic acid and 25 parts of water are prepared into a solution ③; when the temperature rises to 80°C, drop Add solutions ①, ② and ③, the dropwise addition time is 3h, after the dropwise addi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com