A Pretreatment Process for Improving the Quality of Polysilicon Thin Film

A technology of polycrystalline silicon thin film and amorphous silicon thin film, which is applied in the direction of polycrystalline material growth, metal material coating process, crystal growth, etc., can solve the problems of high cost, complicated equipment, unfavorable induced crystallization, etc. Smooth full, large grain size effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

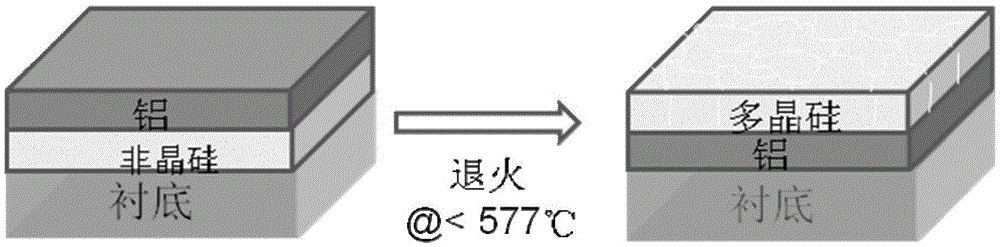

[0024] Embodiment 1 The schematic diagram of the AIC method described in the present invention is as figure 1 shown

[0025] A layer of amorphous silicon (a-Si) is first deposited on the substrate by PECVD. The substrate may be one of a glass substrate, a ceramic substrate, a stainless steel substrate, and the like. The thickness of α-Si:H is between 1nm-1μm. Then vapor-deposit a layer of aluminum (Al) on the amorphous silicon by vacuum coating method, the thickness of aluminum is also between 1nm-1μm, the thickness ratio of α-Si:H and Al is about 1:1, if it cannot be guaranteed, Then the thickness of α-Si:H should be greater than that of Al. After forming the substrate / amorphous silicon / aluminum structure, annealing is performed at a temperature lower than the eutectic temperature of Si and Al at 577°C (it can be as low as about 350°C) to form a substrate / aluminum / polysilicon structure, thereby preparing polysilicon seed layer.

[0026] Utilize the method provided by the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com