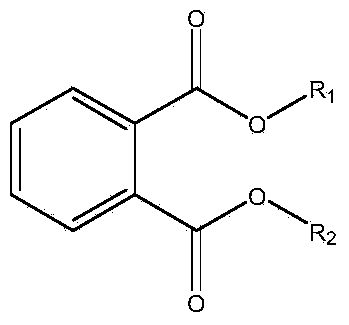

Method for enriching and detecting phthalate ester compound in wine sample by ionic liquid-dispersive liquid-liquid microextraction

A technology of ester compounds and phthalic acid, which is applied in the field of enrichment and detection of phthalate compounds in wine samples by ionic liquid-dispersion liquid-liquid microextraction, can solve the problems of complex organic matrix and high ethanol content , to achieve the effect of simple operation, less usage, accurate and effective measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

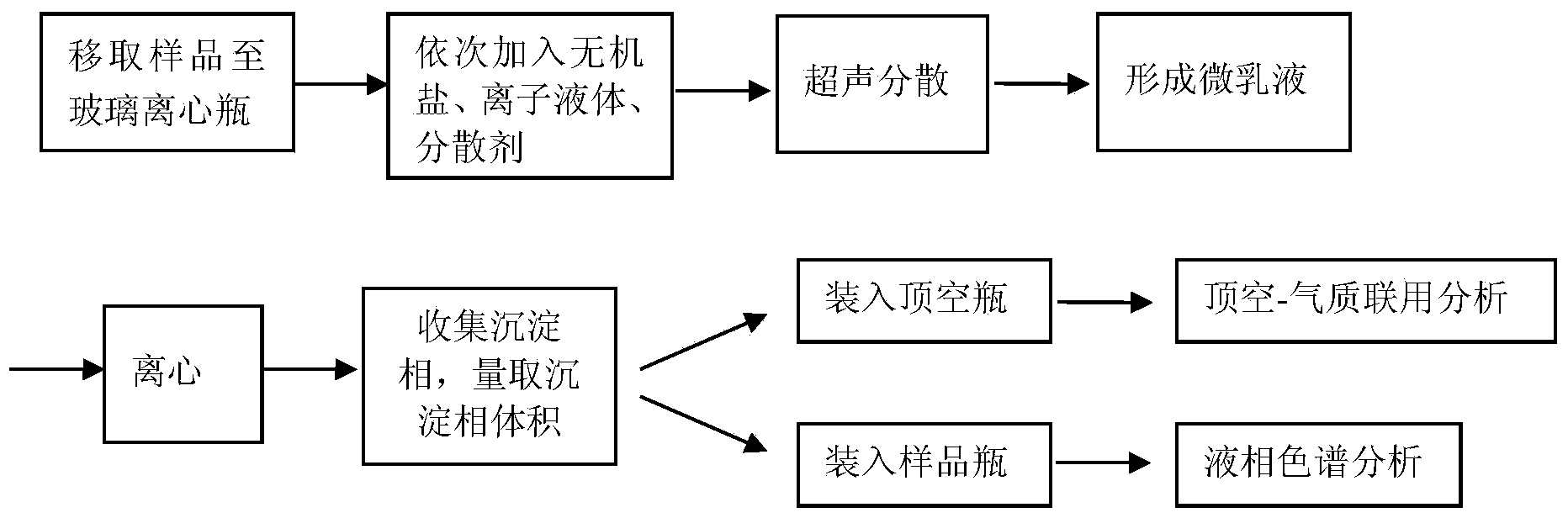

Method used

Image

Examples

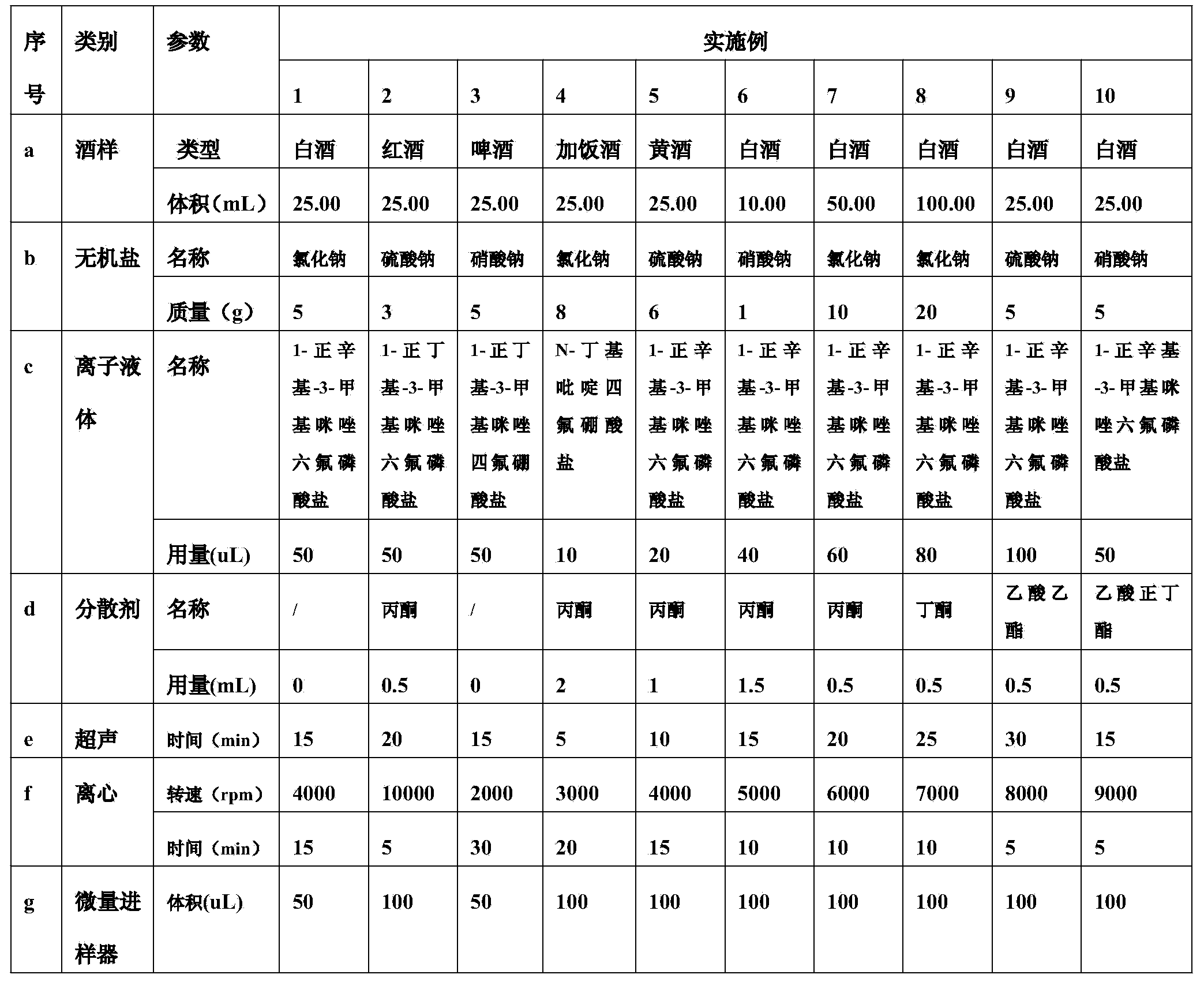

Embodiment 1

[0026] Accurately pipette 25.00mL (three spiked samples of each of the following three concentrations) liquor samples were added with concentrations of 0.01, 0.05 and 0.10mg / L six common phthalates (phthalates) Diethyl dicarboxylate (DEP), diisobutyl phthalate (DIBP), dibutyl phthalate (DBP), dicyclohexyl phthalate (DCHP), diethyl phthalate diethylhexyl ester (DEHP) and dioctyl phthalate (DOP)) in a glass centrifuge tube, add After dissolving 5g of sodium chloride, add 50 μL of 1-n-octyl-3-methylimidazolium hexafluorophosphate ionic liquid as the extraction agent, without adding a dispersant, and perform ultrasonic extraction (ultrasonic dispersion, such as commercially available conventional 50-500W power Ultrasonic emulsification apparatus, etc.; or use ultrasonic power: 150-1500W, ultrasonic frequency: 20--40KHz, power supply: 220 / 380V50HZ ultrasonic conditions can achieve ultrasonic dispersion) 15min, dispersed to form a microemulsion; centrifuge at 4000rpm After 15 minut...

Embodiment 2

[0029] Accurately pipette 25.00mL red wine samples to add six common phthalate compounds (diethyl phthalate (DEP), diisobutyl phthalate) at concentrations of 0.1, 0.5 and 1.0 mg / L (DIBP), dibutyl phthalate (DBP), dicyclohexyl phthalate (DCHP), diethylhexyl phthalate (DEHP) and dioctyl phthalate (DOP) ) of the spiked wine sample (red wine sample 2 with no phthalates detected) in a glass centrifuge tube, add 3g of sodium sulfate to the centrifuge tube respectively, after dissolving, add 50μL of 1-n-butyl-3-methyl The imidazole hexafluorophosphate ionic liquid was used as the extraction agent, 0.5 mL of acetone was added as the dispersant, ultrasonically extracted for 20 min, and dispersed to form a microemulsion; after centrifugation at 10,000 rpm for 5 min, the extractant precipitated at the bottom of the test tube. The volume of the precipitated phase was measured with a 100 μL microsyringe and transferred to a chromatography vial for liquid chromatography analysis.

[0030] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com