A kind of bone cement and preparation method thereof

A technology of bone cement and ammonium phosphate, applied in medical science, prosthesis, etc., can solve problems such as difficulty in achieving the expected purpose, difficulty in removing auxiliary materials completely, and difficulty in obtaining porosity, etc., and achieves large adhesion surface and good mechanical properties. , the effect of excellent biocompatibility and bioactivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0061] Weigh 2.7g of magnesium oxide powder with a particle size of 10μm-80μm, 2.15g of ammonium dihydrogen phosphate powder, and 0.15g of sodium tetraborate powder. Grind and disperse the above three powders evenly in a mortar, add 0.4ml of normal saline, blend into a uniform mud mass with a dental knife, and then put it into a 37°C, 100% humidity environment for 2 hours to cure. The strength of the cured body is good.

Embodiment 2

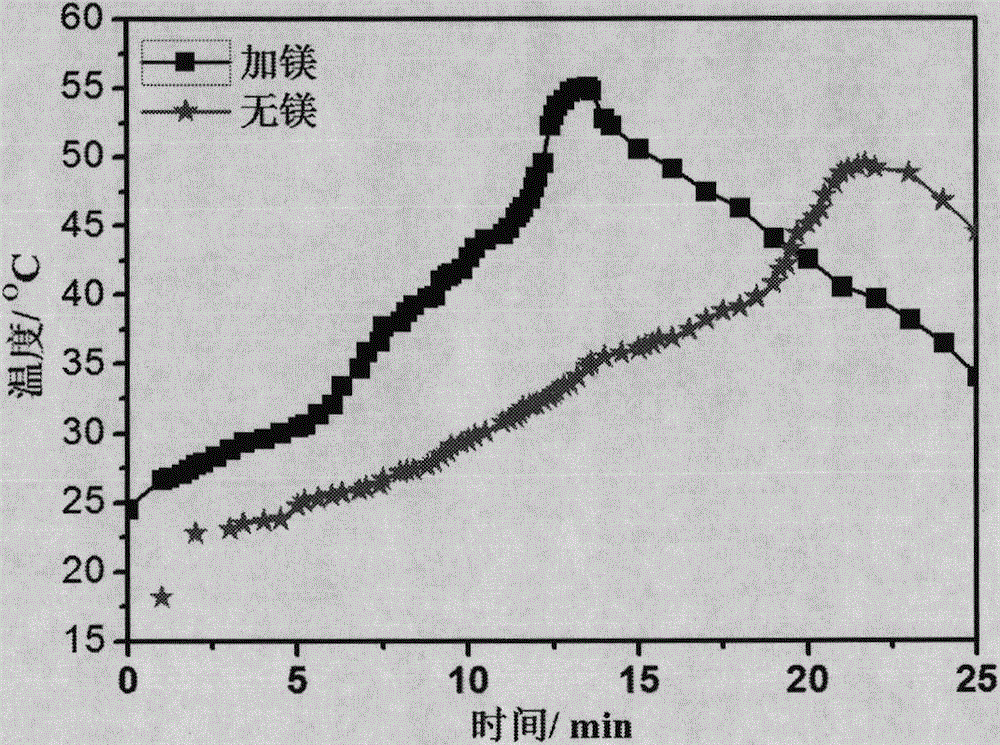

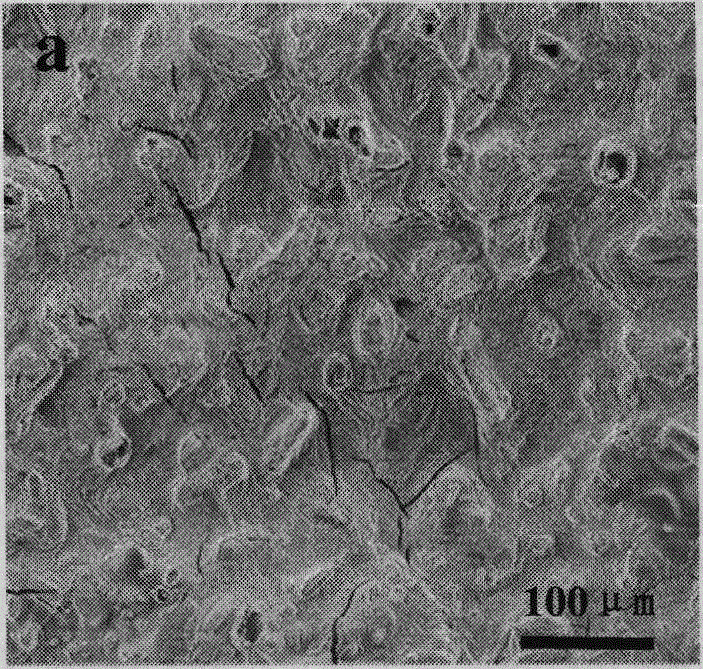

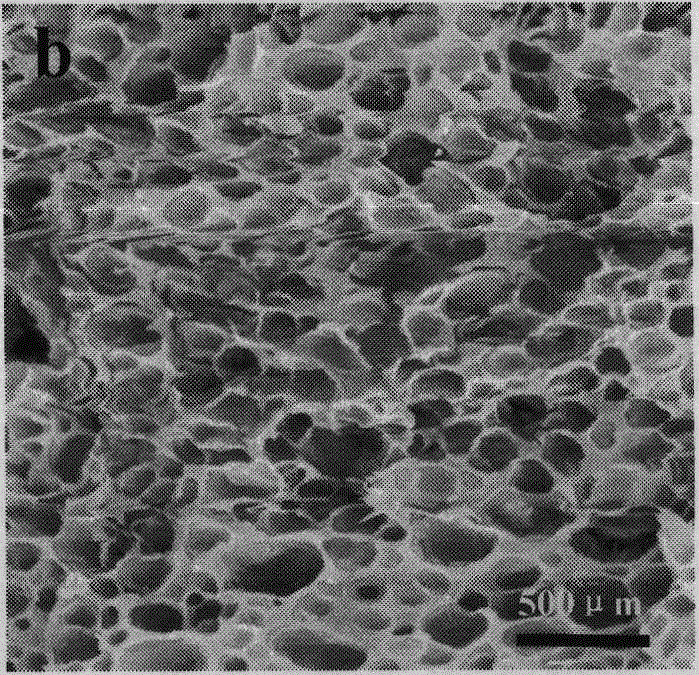

[0063] Weigh 2.585g (51.7%) of magnesium oxide powder with a particle diameter of 30 μm-50 μm, 2.355 g (47.1%) of ammonium dihydrogen phosphate powder, 0.059 g (1.18%) of boric acid powder, and 0.001 g (0.02%) of magnesium metal powder ). Grind and disperse the above four powders in a mortar evenly, add 3ml of magnesium chloride solution, use a dental knife to blend into a uniform mud mass, then put it in a 37°C 100% humidity environment for 2 hours, and use a microscope to detect the pore size distribution of the sample Uniform, the pore size is about 250+20μm, the porosity is 75%, and the compressive strength is about 8.8MPa. figure 1 The reaction exothermic temperature curves of the ordinary MPC prepared according to Example 1 and the MPC-Mg bone cement prepared according to Example 2 are shown. From figure 1 It can be seen that compared with ordinary MPC bone cement, the exothermic temperature of MPC bone cement mixed with metal magnesium powder is slightly higher than t...

Embodiment 3

[0067] Weigh 3.12g (60.89%) of magnesium oxide powder, 1.804g (35.2%) of diammonium hydrogen phosphate powder, 0.03g (0.59%) of sodium tetraborate powder, and 0.17g of magnesium metal powder with a particle size of 60 μm-80 μm (3.32%). Grind and disperse the above four powders in a mortar evenly, add 2ml of deionized water solution, use a dental knife to blend into a uniform mud mass, and then put it into a 370 (2100% humidity environment) to cure for 2 hours, and use a microscope to detect. The sample pore size The distribution is uniform, the pore size is about 150+20μm, the porosity is 55%, and the compressive strength is about 4.5MPa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| solidification time | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com