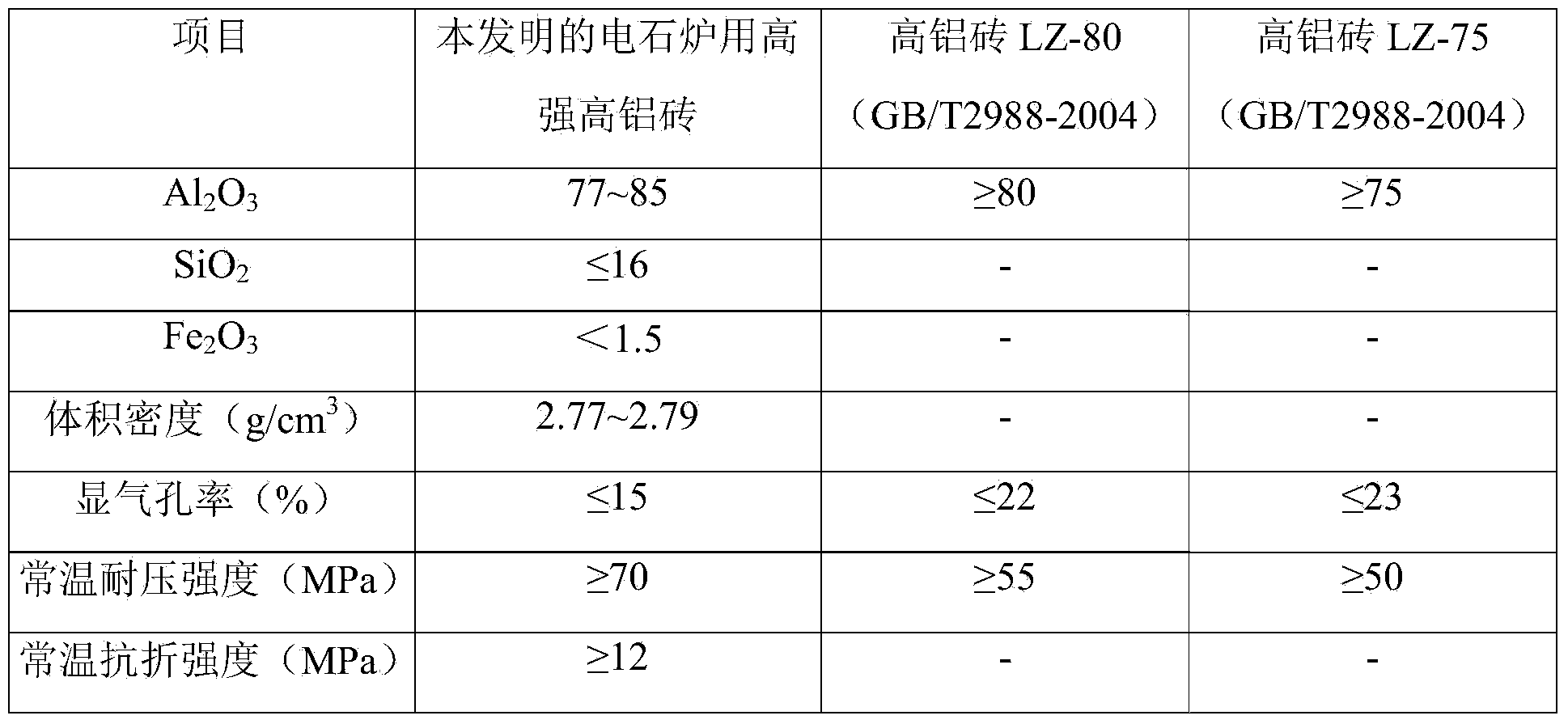

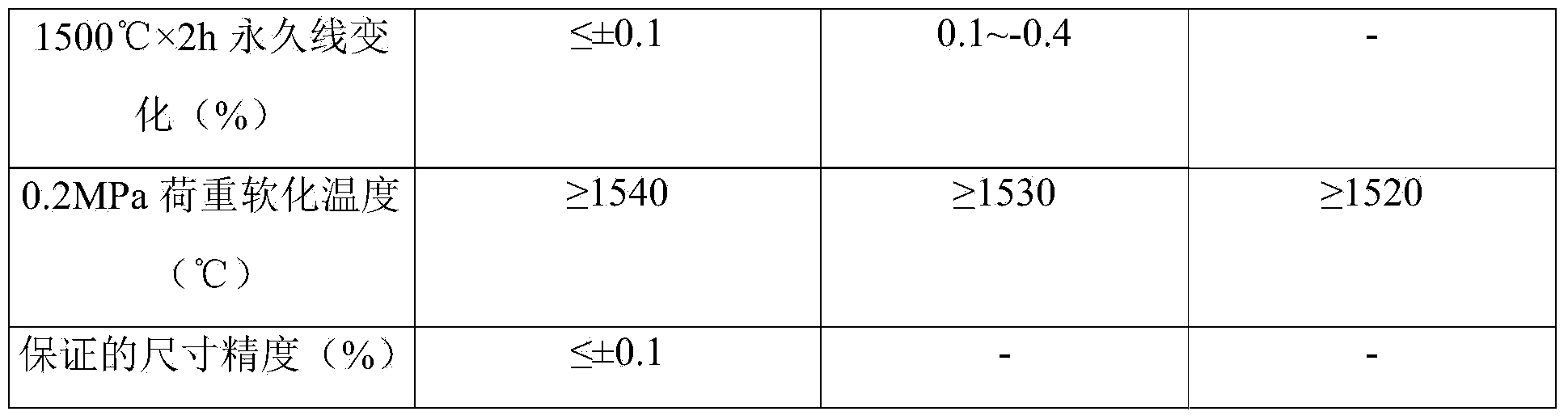

High-strength high-alumina brick prepared from homogenized alumina for calcium carbide furnace and preparation method thereof

A technology for homogenizing bauxite and calcium carbide furnaces, applied in the field of refractory materials, can solve the problems of insufficient carbon graphitization and damage to the carbon brick layer, and achieve the effects of reducing electrostatic repulsion, promoting sintering, and high forming density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

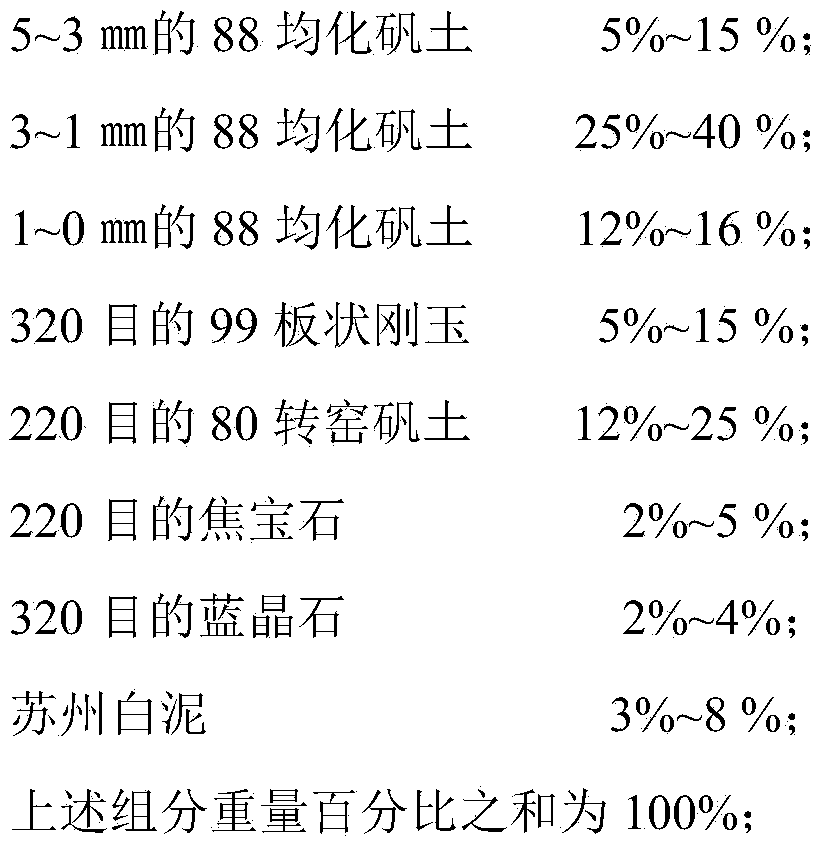

[0032] The formula (weight percentage) of high-strength high-alumina bricks for calcium carbide furnaces prepared by homogenized bauxite is as follows:

[0033] 88 homogenized bauxite in 5~3㎜, 6%

[0034] 3~1㎜ 88 homogenized bauxite, 26%

[0035] 88 homogenized bauxite in 1~0㎜, 16%

[0036] 320 mesh 99 tabular alumina, 15%

[0037] 220 mesh 80 rotary kiln bauxite, 25%

[0038] 220 mesh dense coke gemstone, 5%

[0039] 320 mesh kyanite, 4%

[0040] Suzhou white clay, 3%

[0041] Plus:

[0042] Yellow dextrin, 0.4%

[0043] Surfactant (1:1 mixture by weight of sulfonated naphthol formaldehyde polymer and polycarboxylic acid), 0.15%

[0044] Water, 3%.

[0045] The specific process includes the following parts:

[0046] (1) Pre-mix fine powder. Accurately weigh according to the proportion; 320 mesh 99 tabular corundum, 220 mesh 80 rotary kiln alumina, 220 mesh dense burnt gemstone, 320 mesh kyanite, Suzhou white mud, add them together to a dry powder mixer and stir for...

Embodiment 2

[0055] The formula (weight percentage) of high-strength high-alumina bricks for calcium carbide furnaces prepared by homogenized bauxite is as follows:

[0056] 5~3㎜ 88 homogenized bauxite, 10%

[0057] 3-1㎜ 88 homogenized bauxite, 35%

[0058] 88 homogenized bauxite in 1~0㎜, 12%

[0059]320 mesh 99 tabular alumina, 12%

[0060] 220 mesh 80 rotary kiln bauxite, 18%

[0061] 220 mesh dense coke gemstone, 4%

[0062] 320 mesh kyanite, 3%

[0063] Suzhou white clay, 6%

[0064] Plus:

[0065] Yellow dextrin, 0.5%

[0066] Surfactant (1:1 mixture by weight of sulfonated naphthol formaldehyde polymer and polycarboxylic acid), 0.2%

[0067] Clear water, 2.5%

[0068] The specific process includes the following parts:

[0069] (1) Pre-mix fine powder. Accurately weigh according to the proportion; 320 mesh 99 tabular corundum, 220 mesh 80 rotary kiln bauxite, 220 mesh dense burnt gemstone, 325 mesh kyanite, Suzhou white clay, add them together to a dry powder mixer and stir...

Embodiment 3

[0075] The formula (weight percentage) of high-strength high-alumina bricks for calcium carbide furnaces prepared by homogenized bauxite is as follows:

[0076] 5~3㎜ 88 homogenized bauxite, 15%

[0077] 3~1㎜ 88 homogenized bauxite, 40%

[0078] 88 homogenized bauxite in 1~0㎜, 15%

[0079] 320 mesh 99 tabular alumina, 5%

[0080] 220 mesh 80 rotary kiln bauxite, 12%

[0081] 220 mesh dense coke gemstone, 3%

[0082] 320 mesh kyanite, 2%

[0083] Suzhou white clay, 8%

[0084] Plus:

[0085] Yellow dextrin, 0.6%

[0086] Incorporated surfactant (1:1 mixture by weight of sulfonated naphthol formaldehyde polymer and polycarboxylic acid), 0.25%

[0087] Clear water, 2%

[0088] The specific process includes the following parts:

[0089] (1) Pre-mix fine powder. Accurately weigh according to the proportion; 320 mesh 99 tabular corundum, 220 mesh 80 rotary kiln bauxite, 220 mesh dense burnt gemstone, 325 mesh kyanite, Suzhou white mud, add them together to the dry powder m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com