Electrophoretic coating liquid and electrophoretic display layer and preparation methods thereof

A coating liquid and electrophoresis technology, applied in electrophoretic coatings, coatings, protein coatings, etc., can solve problems such as poor mechanical properties, damage, and poor leveling, achieve good mechanical properties and leveling, and reduce surface tension. , the effect of improving mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0036] Two preparation methods of microcapsules for reference are provided below.

[0037] Reference method 1:

[0038] Step 1: Prepare 20ml of gelatin (natural water-soluble polymer compound A) solution with a mass fraction of 2% and 20ml of gum arabic (natural water-soluble polymer compound B) solution with a mass fraction of 2%;

[0039] Step 2: Add 5mg of disperse blue BF dye and 5mg of polybutene succinamide PIBI to 5ml of tetrachlorethylene, disperse under ultrasonic at around 50°C for 60min; add 20ml of the prepared gum arabic solution under stirring at 700rpm , continue to stir for 3 minutes; then adjust the speed to 300rpm, add 20ml of gelatin solution that has been prepared; then adjust the pH to about 4 with 10% acetic acid solution, slowly cool down to below 10°C, add 5ml of acetic acid solution with a mass fraction of 5 % glutaraldehyde solution, stirred for 1 h.

[0040] Step 3: introduce the microcapsules prepared in step 2 into a vibrating sieve, and wash the...

Embodiment 1

[0047] Embodiment 1 (this example is the preparation example of electrophoretic coating solution)

[0048] Prepare electrophoretic coating liquid, adopt following steps to prepare:

[0049] (1) Prepare microcapsules according to the microcapsule preparation method of reference method 2 mentioned above, wherein the natural water-soluble polymer compounds A and B are gelatin and gum arabic respectively;

[0050] (2) Weigh 100 g of the microcapsules prepared in step (1) with a centrifuged solid content of 45%, and set aside;

[0051] (3) Dissolve 0.6g of gelatin (component A) in 2.4g of water, filter to obtain a gelatin solution, mix it with the microcapsules in step (2), stir at 250rpm for 1.0h, and mix well to get a preliminary Electrophoretic coating solution;

[0052] (4) Weigh 20 g of aqueous polyurethane solution (component B) into the preliminary electrophoretic coating solution prepared in step (3), and stir for 1.0 h to obtain the electrophoretic coating solution.

[...

Embodiment 26

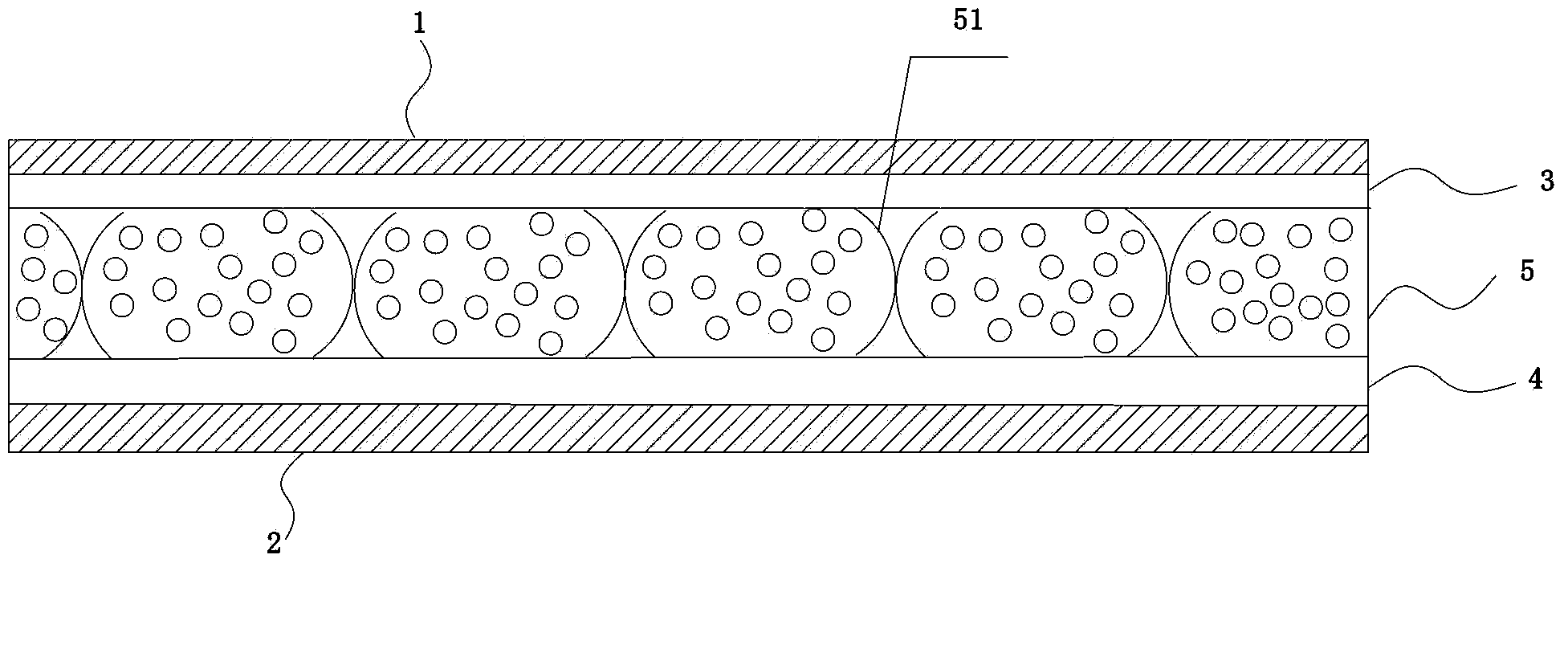

[0058] Embodiment 26 (this example is the preparation example of electrophoretic display layer, see figure 1 )

[0059] The electrophoretic display layer is prepared by the following steps:

[0060] The prepared electrophoretic coating solution is coated on the ITO (indium tin oxide) transparent conductive layer 3 of the PET film 1 by using a coater, dried and cured to form the electrophoretic display layer 5 . A substrate 2 with several pixel electrodes is covered on the electrophoretic display layer 5, and the pixel electrodes on the substrate 2 and the electrophoretic display layer 5 are thermally pressed or glued together with transparent glue. In this embodiment, transparent glue is used to bond the pixel electrodes on the substrate 2 and the electrophoretic display layer 5 together, and a glue layer 4 is formed between the substrate 2 and the electrophoretic display layer 5 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com