Optical micro-cavity light-frequency comb generating system based on comb tooth feedback control and regulation

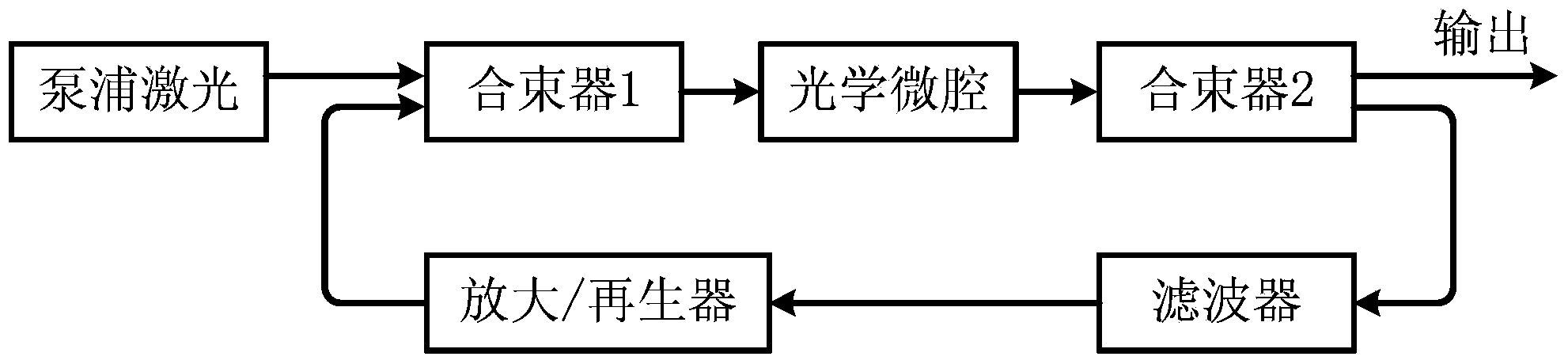

An optical microcavity and optical frequency comb technology, which is applied in the field of integrated photonics and nonlinear optics, can solve the problem that coherence and comb spacing cannot be controlled, hinder the popularization and application of optical microcavity optical frequency combs, and disadvantage the small size of the system. It can solve the problems of chemical and cost, and achieve the effect of simple structure, strong repeatability and controllable comb tooth spacing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The following describes the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention. Obviously, the described embodiments are only a part of the embodiments of the present invention, not all of them.

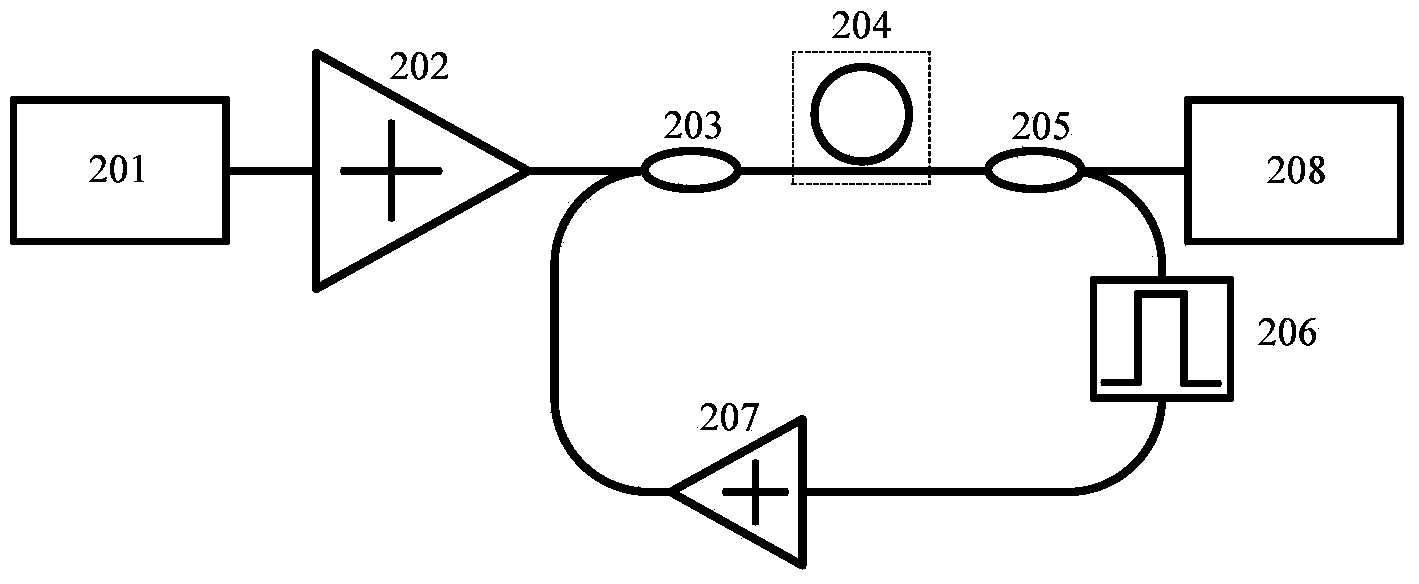

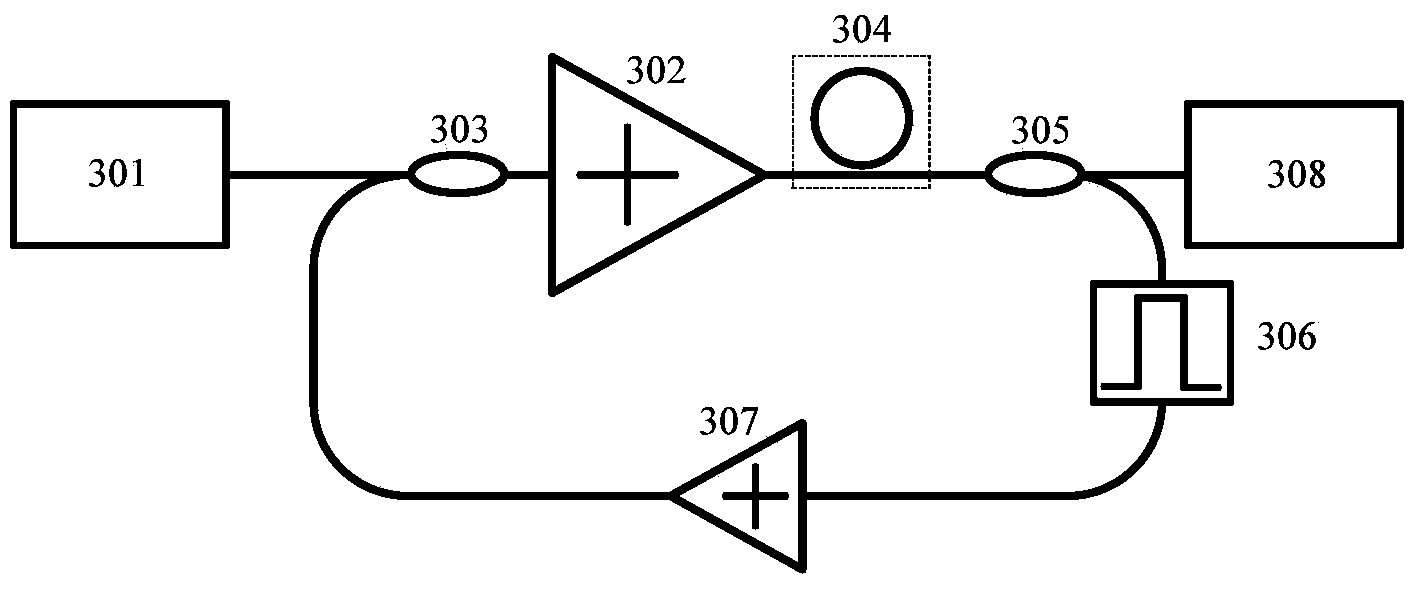

[0032] (1) The first embodiment:

[0033] figure 2 As shown, 201 provides single-frequency laser, and 202 amplifies optical power to provide pump laser for the system. The pump laser enters 204 through 203, and the output of 204 passes through 205, part of which becomes the output of the system and connected to 208, and part of which becomes a feedback control signal. The feedback control signal selects a comb tooth through 206, and then amplifies it by 207 and returns to 203, and injects it into 204 together with the pump laser. 208 is connected to a spectrometer to measure optical frequency comb spectral lines under different conditions.

[0034] The central wavelength of 206 is succe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com