Zinc-oxide-base amorphous oxide semiconductor thin film transistor and manufacturing method thereof

A technology of amorphous oxide and thin film transistors, which is applied in semiconductor/solid-state device manufacturing, transistors, semiconductor devices, etc., and can solve the problem of light transmittance of double-layer active layer structure, display circuit failure, and device electrical stability No high problems, to achieve the effect of improving mobility and working current, high local homogeneity of the film, and good stress balance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

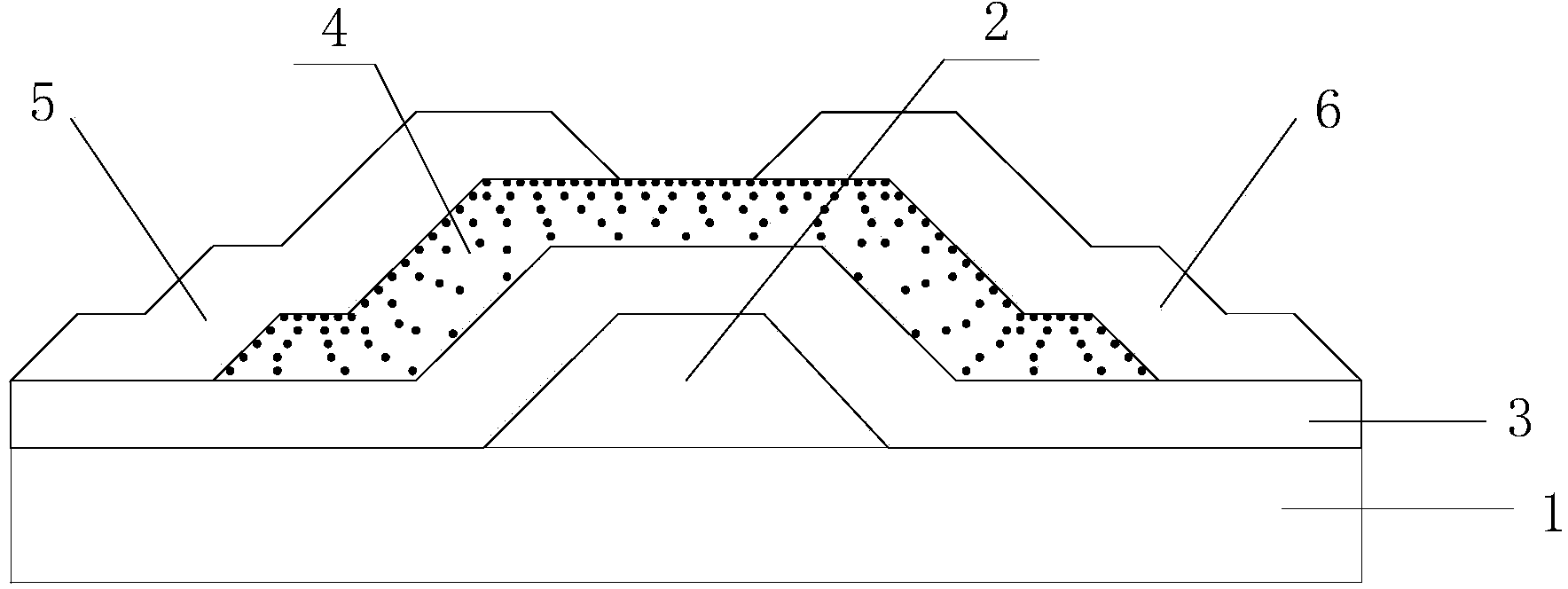

[0034] A method for manufacturing a zinc oxide-based amorphous oxide semiconductor thin film transistor comprises the following steps:

[0035](1) Deposit a layer of Mo with a thickness of 150 nm on a clean glass substrate by direct current sputtering, and etch to form a gate.

[0036] (2) PECVD grows a layer of SiO with a thickness of 50nm 2 A gate insulating layer covering the gate and the substrate.

[0037] (3) Simultaneously magnetron sputtering indium zinc oxide target (indium zinc molar ratio is 1:9) and gallium zinc oxide target ( The molar ratio of gallium to zinc is 9:1), the sputtering power applied to the indium zinc oxide target gradually decreases from 30W at the beginning to 0W at the end, and the sputtering power applied to the gallium zinc oxide target is determined by The 0W at the beginning gradually increased to 30W at the completion, the substrate rotation speed was 5rpm, and a 20nm-thick zinc oxide-based amorphous oxide semiconductor active layer doped ...

Embodiment 2

[0040] A method for manufacturing a zinc oxide-based amorphous oxide semiconductor thin film transistor comprises the following steps:

[0041] (1) Deposit a layer of Mo with a thickness of 150 nm on a clean glass substrate by direct current sputtering, and etch to form a gate.

[0042] (2) PECVD grows a layer of SiO with a thickness of 50nm 2 A gate insulating layer covering the gate and the substrate.

[0043] (3) Simultaneously magnetron sputtering indium zinc oxide target (indium zinc molar ratio is 9:1) and gallium zinc oxide target ( The ratio of gallium to zinc is 1:9), the sputtering power applied to the indium zinc oxide target gradually decreases from 400W at the beginning to 0W at the end, and the sputtering power applied to the gallium zinc oxide target starts from 0W at the time of completion gradually increased to 400W at the time of completion, the substrate rotation speed was 20rpm, and a layer of zinc oxide-based amorphous oxide semiconductor active layer do...

Embodiment 3

[0046] (1) Deposit a layer of Mo with a thickness of 150 nm on a clean glass substrate by direct current sputtering, and etch to form a gate.

[0047] (2) PECVD grows a SiO2 gate insulating layer with a thickness of 50nm, covering the gate and the substrate.

[0048] (3) Simultaneously magnetron sputtering indium zinc oxide target (indium zinc molar ratio is 4:3) and gallium zinc oxide target ( The ratio of gallium to zinc is 3:2), the sputtering power applied to the indium zinc oxide target gradually decreases from 300W at the beginning to 0W at the end, and the sputtering power applied to the gallium zinc oxide target starts from The 0W at the time of completion gradually increased to 300W at the time of completion, the substrate rotation speed was 10rpm, and a layer of zinc oxide-based amorphous oxide semiconductor active layer doped with indium and gallium was deposited with a thickness of 50nm.

[0049] (4) Deposit a layer of indium tin oxide with a thickness of 40 nm on...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com