Method for manufacturing dry-pressing heterosexual permanent-magnetic material

A technology of permanent magnet material and manufacturing method, which is applied to the manufacturing field of dry-pressed anisotropic permanent-magnet materials, can solve the problems of low performance of dry-pressed permanent-magnet materials, unable to obtain good orientation degree and density, etc. Degree of orientation, density, and performance improvement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

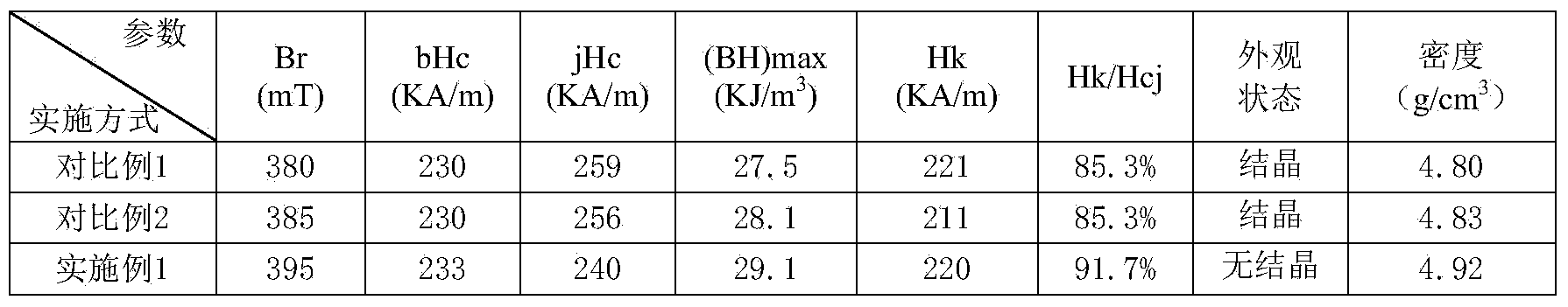

Examples

Embodiment 1

[0025] The pre-fired material uses the following raw materials:

[0026] Fe 2 o 3 Powder: (purity≥99.2wt%, original average particle size of particles: 1.0μm), 85.5~86.5wt%;

[0027] SrCO 3 Powder: (purity≥98.0wt%, original average particle size of particles: 2.0μm), 13.4~14.1wt%;

[0028] Silicon oxide powder: (purity ≥ 98.0wt%, original average particle size of particles: 2.0μm), 0.1-0.4wt%;

[0029] Weigh Fe 2 o 3 Powder, SrCO 3 and silicon oxide powder, and the obtained raw material powder was wet-mixed for 2 hours, dried, and calcined in air at 1250° C. for 2 hours to obtain a calcined material.

[0030] The calcined material is broken into a coarse powder, using a known crushing method, weighing 300g of the coarse powder prepared in the above-mentioned way, adding 0.3wt% SiO 2 , 0.1wt% boric acid; add 600mL tap water as a ball milling medium, and grind for 10 hours until the average particle size of the particles is 0.75-1.0μm; the resulting slurry is centrifugal...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com