A preparation method of ultra-stable and highly weather-resistant water-in-water imitation granite colorful coating

A technology of imitating granite and multi-color paint, applied in multi-color effect paint, coating and other directions, can solve the problems of inelastic crack resistance, poor storage stability, poor weather resistance, etc., and achieve low production cost, stable storage, and weather resistance. good effect

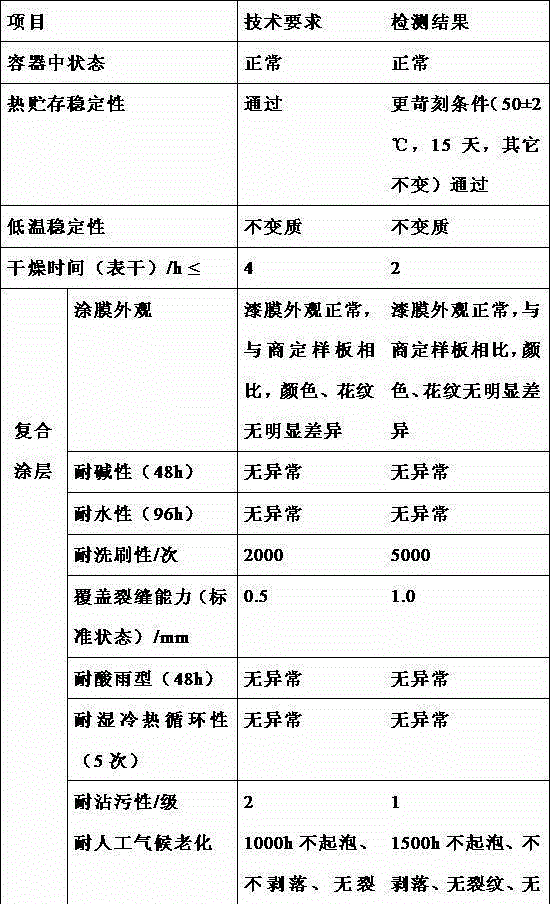

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] The preparation method embodiment 1 of this product is as follows:

[0035] Step 1: Preparation of protective colloid solution

[0036] The raw materials and mass ratio of the protective colloid solution are 3% of industrial-grade sodium pyrophosphate, 7% of liquid granite additive (using LaponiteRDS of Lockwood Company), 90% of water, and the above-mentioned sodium pyrophosphate, liquid granite Additives and water are dispersed for 20 minutes under the stirring condition of 800r / min, and the density of the protective colloid solution is about 1.003g / cm 3 , until the solution has no particles and is translucent, it is left to age for 24 hours and then it is used for later use.

[0037] Step 2: Preparation of white base paint

[0038] The raw materials and mass ratio of the white base paint are 35% water, 0.8% cellulose (hydroxyethyl cellulose ether ER30M of Dow Company or cellulose Natrosol250HBR of Ashland Company), 0.6% dispersant (Nopco Company Polycarboxylate typ...

Embodiment 2

[0047] The preparation method embodiment 2 of this product is as follows:

[0048] Step 1: Preparation of protective colloid solution

[0049] The raw materials and mass ratio of the protective colloid solution are 2% of industrial grade sodium pyrophosphate, 5% of liquid granite additive (using LaponiteRDS of Lockwood Company), 93% of water, and the above mass parts of sodium pyrophosphate, liquid granite Additives and water are dispersed for 20 minutes under the stirring condition of 1000r / min, and the density of the protective colloid solution is about 1.005g / cm 3 , until the solution has no particles and is translucent, it is left to age for 24 hours and then it is used for later use.

[0050] Step 2: Preparation of white base paint

[0051] The raw materials and mass ratio of the white base paint are 40% water, 0.5% cellulose (hydroxyethyl cellulose ether ER30M of Dow Company or cellulose Natrosol250HBR of Ashland Company), 0.5% dispersant (Nopco Company Polycarboxylat...

Embodiment 3

[0060] The preparation method embodiment 3 of this product is as follows:

[0061] Step 1: Preparation of protective colloid solution

[0062] The raw materials and mass ratio of the protective colloid solution are 0.5% of industrial grade sodium pyrophosphate, 3.5% of liquid granite additive (using LaponiteRDS of Lockwood Company), and 96% of water. Additives and water are dispersed for 20 minutes under the stirring condition of 1200r / min, and the density of the protective colloid solution is about 1.006g / cm 3 , until the solution has no particles and is translucent, it is left to age for 24 hours and then it is used for later use.

[0063] Step 2: Preparation of white base paint

[0064] The raw materials and mass ratio of the white base paint are 45% water, 0.3% cellulose (hydroxyethyl cellulose ether ER30M of Dow Company or cellulose Natrosol250HBR of Ashland Company), 0.4% dispersant (Nopco Company Polycarboxylate-type low-foaming dispersant SN5040 or Corning low-foami...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com