Copper-based composite heat conduction material and manufacturing method thereof

A heat-conducting material, copper-based composite technology, applied in semiconductor/solid-state device manufacturing, metal material coating process, hot-dip plating process, etc., can solve the problems of doping price, material aging, high cost, etc. speed, not easy to liquefy or deform, and the effect of reducing the interface contact thermal resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

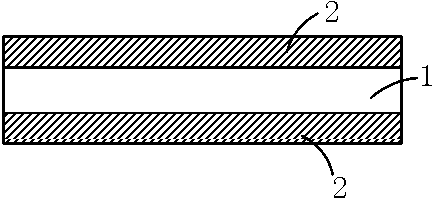

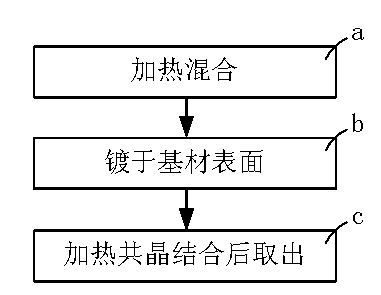

[0023] Such as figure 1 As shown, the first embodiment of the present invention provides a copper-based composite thermally conductive material, which includes a sheet-shaped copper substrate 1, and one or both sides of the sheet-shaped copper substrate are provided with The mixed metal material layer 2, the mixed metal material layer 2 is a eutectic mixed metal material formed by 6-12% silver, 8-3% gallium, and 80-91% tin; and the above-mentioned eutectic mixed metal material The silver mentioned in the layer is lead-free silver.

[0024] The copper-based composite heat-conducting material in this embodiment is generally arranged between the heat source surface and the heat sink when in use, so the copper base material in this embodiment is in the form of a sheet with a thickness of about 0.1 mm. There are eutectic mixed metal material layers on both sides. In this embodiment, the eutectic mixed metal material layer on each side is about 0.05mm, and the thickness of the base...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com