Preparation method of polyelectrolyte-cladding LiNixCoyMn<1-x-y>O2 positive electrode material

A technology of polyelectrolyte and positive electrode material, which is applied to the preparation of high-voltage positive electrode materials for lithium ion batteries and the preparation of high-voltage nickel-cobalt-cobalt lithium manganate positive electrode materials on the surface, can solve the problem of cycle performance decline, rapid capacity decay, and easy dissolution. and other problems, to achieve the effect of excellent productivity and excellent pressing density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

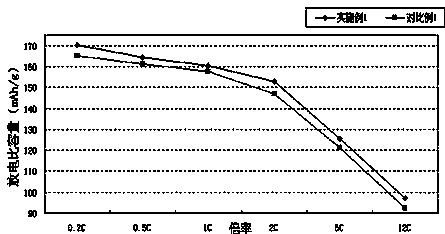

[0023] Weigh 100Kg of polyacrylic acid with an average molecular weight of 3000 into a 200L reactor, add LiOH solution (mass fraction 80-85%) into the reactor drop by drop through the liquid feeding port until the pH of the solution is 8, turn on the stirring motor, Disperse, the dispersion time is 30-60min, and then put the slurry into the vacuum dryer through the diaphragm pump, and filter and dry, the drying temperature is 80-140°C, and the drying time is 2-6 hours to obtain white PAALi powder. Vacuum packaged, stored in an environment with a relative humidity of 10%RH and a temperature of 25-28°C. Weigh LiNi x co y mn 1-x-y o 2 The finished product is 100Kg, and the corresponding PAALi is weighed according to the molar ratio of the coating component to the sum of nickel, cobalt and manganese in nickel-cobalt-lithium manganese oxide being 0.005. LiNi to be weighed x co y mn 1-x-y o 2 、PAALi is fully dissolved and mixed in absolute ethanol (solid-to-liquid ratio 1:3)...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com