A functionalized synthetic fiber capable of removing formaldehyde and its preparation and application

A synthetic fiber and functionalization technology, which is applied in the field of functionalized synthetic fiber containing rod-shaped zinc oxide/bismuth oxyhalide and its preparation and application, can solve the problems of reducing photocatalytic efficiency, broaden the scope of application, solve the problem of recycling and recycling Exploiting difficult, cost-reducing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

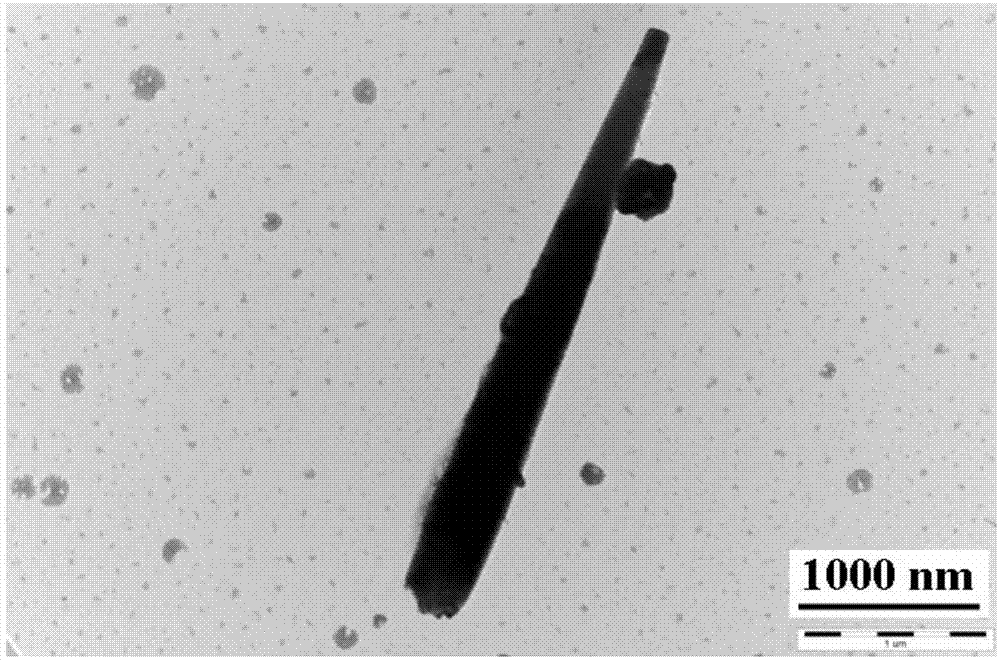

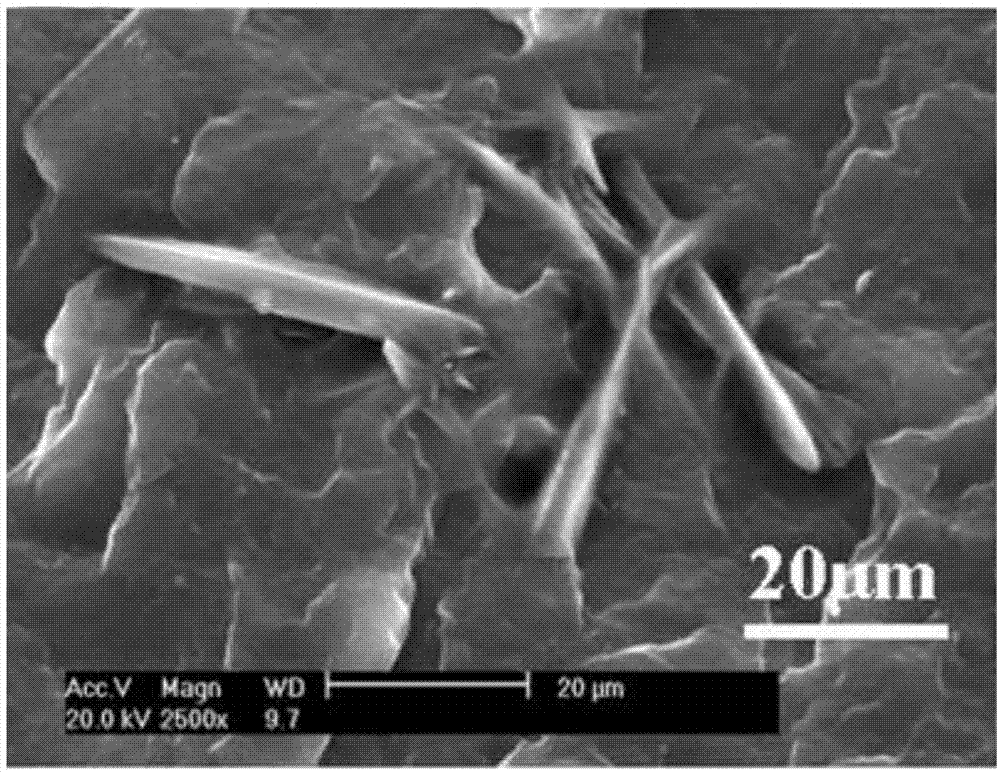

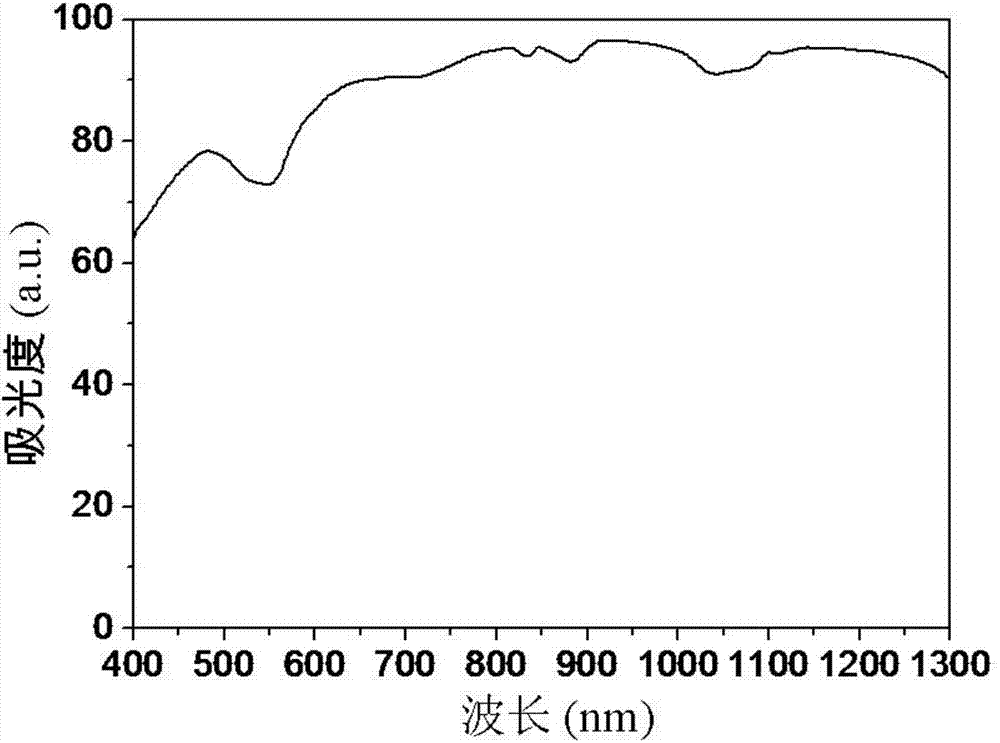

[0031] 1g Zn(Ac) 2 2H 2 O was dissolved in 40 mL of distilled water, then 2 mL of NH 3 ·H 2 O, get a white suspension, then transfer it to a 250mL round bottom flask, heat it in a water bath at 60°C for 10h, centrifuge, collect the white precipitate, wash it alternately with 50mL water or 50mL absolute ethanol for 4 times each time, and place it at 60°C The rod-shaped zinc oxide was obtained after drying for 48 hours; the length of the obtained rod-shaped zinc oxide was 2-3 μm, and the diameter was 200-400 nm; the weight loss at 900 ° C was 1 wt % (the thermal gravimetric analysis was carried out using the SDT-Q600 thermogravimetric analyzer of TA Company in the United States). Re-test, heating rate 10℃ / min, in N 2 atmosphere), has the advantages of rod-like structure and good thermal stability, and is an excellent carrier for various inorganic nanoparticles.

[0032] Will wait for 1mol of Bi(NO 3 ) 3 ·5H 2 O and 1mol of KCl were successively dissolved in 250mL of ethyl...

Embodiment 2

[0035] 1g Zn(Ac) 2 2H 2 O was dissolved in 200 mL of distilled water, and then 3 mL of NH 3 ·H 2 O, the white suspension was obtained, then transferred to a 250mL round bottom flask, heated in a water bath at 95°C for 9h, centrifuged, and the white precipitate was collected, washed alternately with 50mL of water or 50mL of absolute ethanol for 4 times, and washed at 95°C The rod-shaped zinc oxide was obtained after drying for 24 hours under the hood; the length of the obtained rod-shaped zinc oxide was 2-3 μm, and the diameter was 200-400 nm; the weight loss within 900 ° C was 2 wt % (the thermal gravimetric analysis was carried out using the SDT-Q600 thermogravimetric analyzer of TA Company in the United States). Re-test, heating rate 10℃ / min, in N 2 atmosphere), has the advantages of rod-like structure and good thermal stability, and is an excellent carrier for various inorganic nanoparticles.

[0036] Will wait for 1mol of Bi(NO 3 ) 3 ·5H 2 O and 1mol of KBr were suc...

Embodiment 3

[0039] 1g Zn(Ac) 2 2H 2 O was dissolved in 160 mL of distilled water, and then 4 mL of NH 3 ·H 2 O, the white suspension was obtained, then transferred to a 250mL round bottom flask, heated in a water bath at 90°C for 8h, centrifuged, and the white precipitate was collected, washed alternately with 50mL of water or 50mL of absolute ethanol for 4 times, and washed at 90°C The rod-shaped zinc oxide was obtained after drying for 24 hours; the length of the obtained rod-shaped zinc oxide was 2-3 μm, and the diameter was 200-400 nm; the weight loss at 900 ° C was 1 wt % (the thermal gravimetric analysis was carried out using the SDT-Q600 thermogravimetric analyzer of TA Company in the United States). Re-test, heating rate 10℃ / min, in N 2 atmosphere), has the advantages of rod-like structure and good thermal stability, and is an excellent carrier for various inorganic nanoparticles.

[0040] Will wait for 1mol of Bi(NO 3 ) 3 ·5H 2 O and 1mol of KI were successively dissolved ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com