Preparation method and preprocessing method of biomaterial-embedded zero-valent-iron-ferroferric-oxide double-nanometer system

A kind of ferric oxide, biological material technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

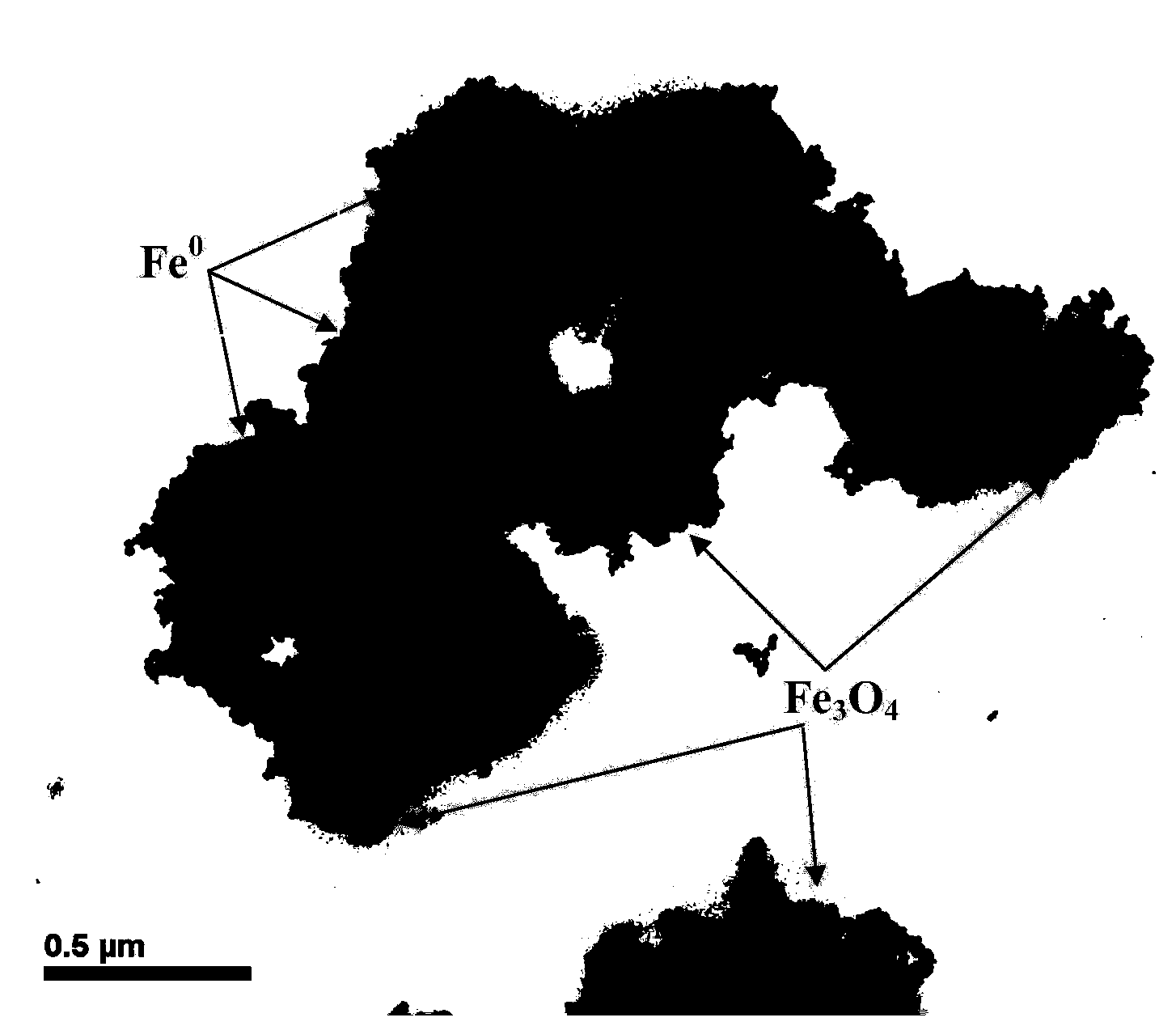

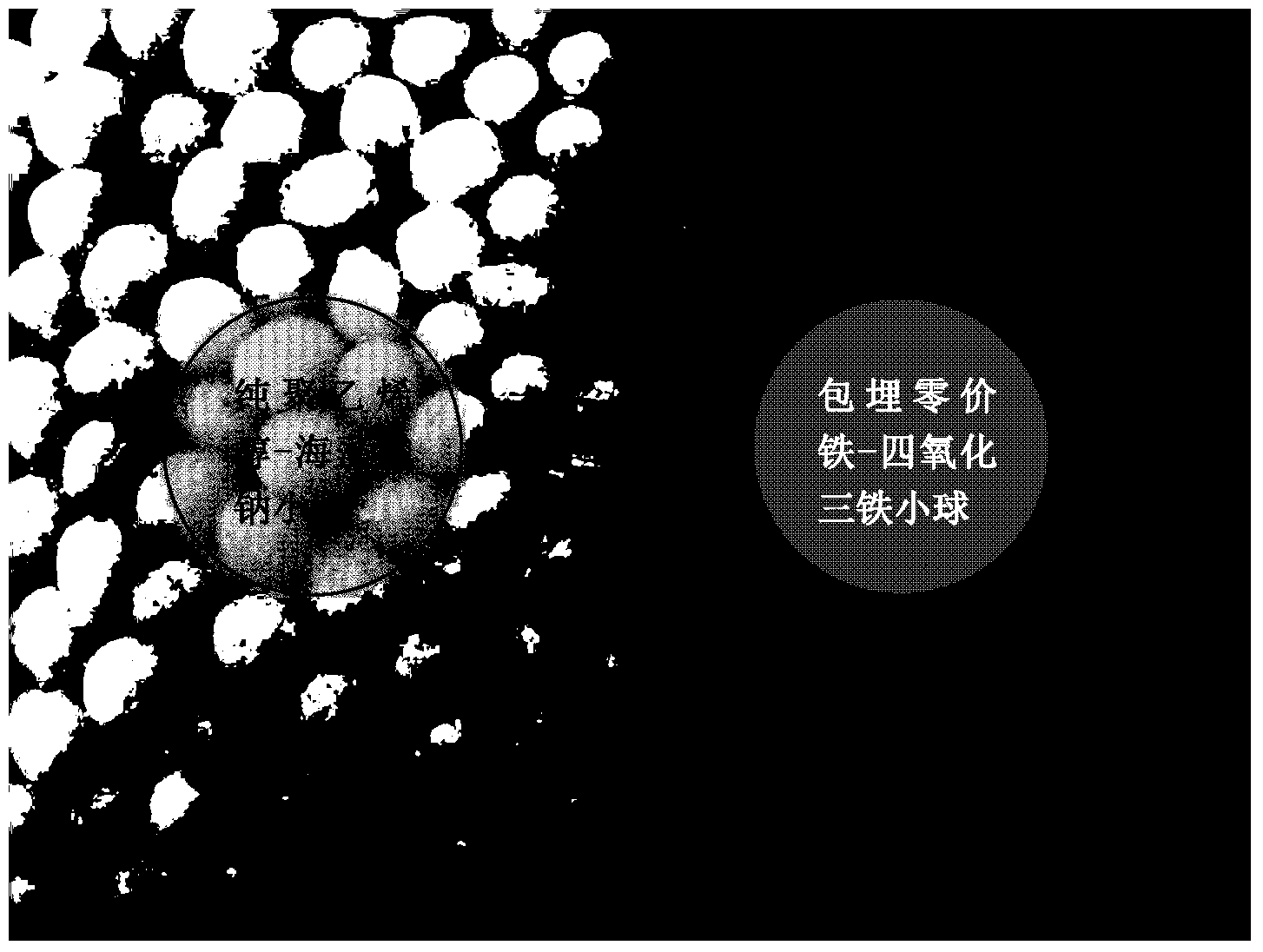

[0035] Using the method of the present invention to prepare polyvinyl alcohol-sodium alginate embedded zero-valent iron-ferric oxide embedded pellets, and apply it to the restoration of Cr(VI) polluted water, the steps are as follows:

[0036] (1) Weigh 0.745g FeCl 3 ·6H 2 O and 0.3825g FeSO 4 ·7H 2 O, put in a 250mL three-neck flask, add 100mL deionized water, and stir in a constant temperature water bath at 60°C. Under the protection of nitrogen at a flow rate of 150mL / min, 8mol / L ammonia water was added dropwise to make the reaction system alkaline to a pH above 11, and aged at a constant temperature for 2 hours to obtain nano-ferric oxide particles, which were separated and washed and then transferred to In a 1L three-neck flask, add 0.375g FeSO 4 ·7H 2 400mL deionized aqueous solution of O, stirring at constant temperature, dropwise add 0.35g NaBH 4 100mL of deionized aqueous solution, reacted for 1 hour, magnetically separated, washed with deionized water until neu...

Embodiment 2

[0051] When studying the preparation of polyvinyl alcohol-sodium alginate-embedded zero-valent iron-ferric oxide double nanosystem pellets by using the present invention, the influence of different preparation and pretreatment methods on the removal ability of the prepared pellets, specific steps as follows:

[0052] Examples 2-10 used different ratios of polyvinyl alcohol (PVA) and sodium alginate (SA) to prepare bi-nano material beads embedded with zero-valent iron-ferric oxide, and used to treat Cr(VI). Other operation steps are with embodiment 1, and raw material ratio and corresponding removal efficiency are as shown in table 3:

[0053] Table 3 The removal effect of different ratios of polyvinyl alcohol and sodium alginate to embed beads

[0054] Example

2

3

4

5

6

7

8

9

10

SA:PVA(wt%)

0.5:2

1.5:2

2.5:2

0.5:5

1.5:5

2.5:5

0.5:8

1.5:8

2.5:8

12 hours removal rate

60.2%

90....

Embodiment 18

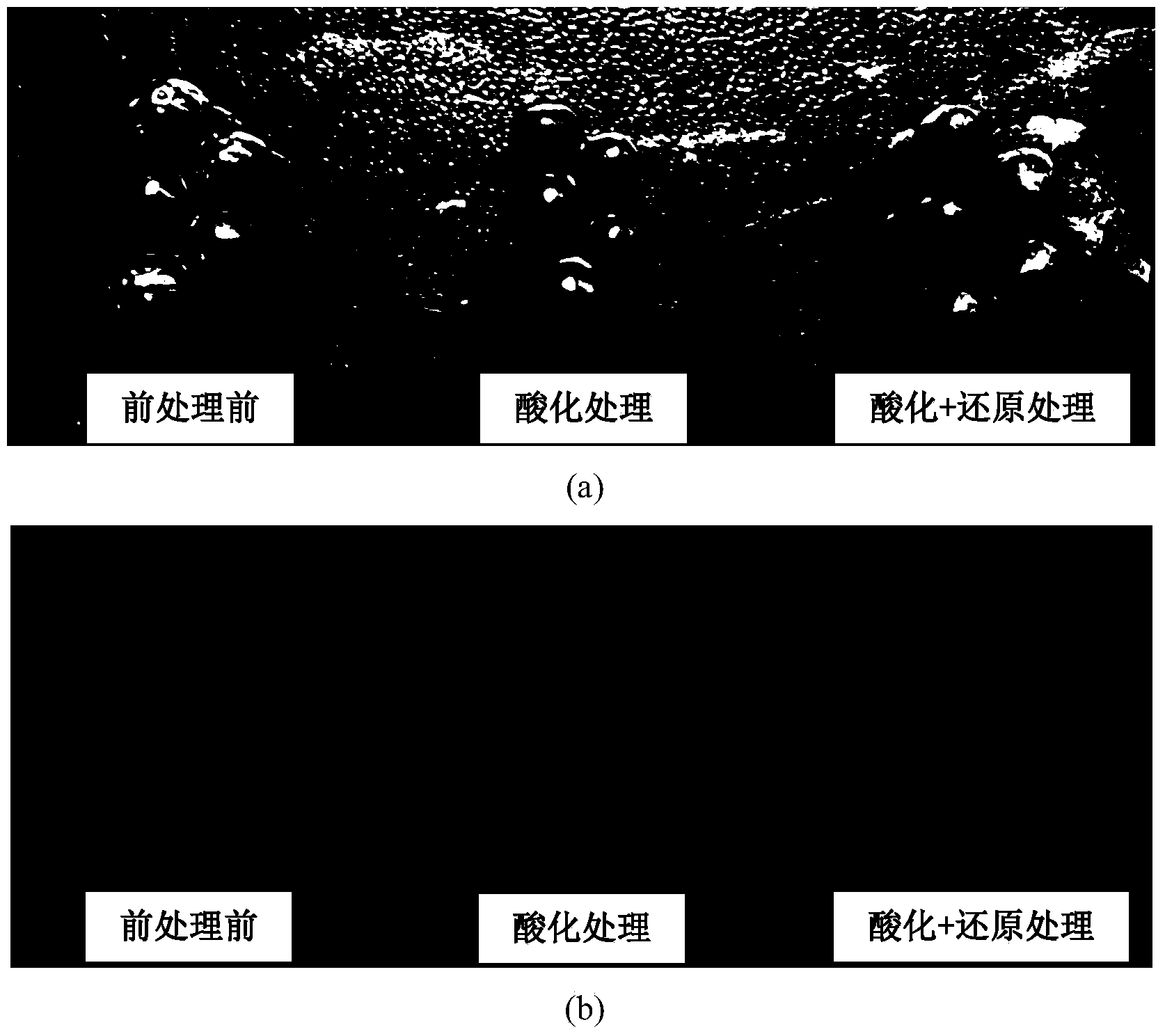

[0060] To study the influence of the pretreatment step on the performance of the pellets and the percolation of iron during the use of the pellets when preparing polyvinyl alcohol-sodium alginate-embedded zero-valent iron-ferric oxide double nanosystem pellets by using the present invention And the reuse situation, the specific steps are as follows:

[0061] 1) Place the pellets prepared in the steps of Example 1 without pretreatment, only acidified pellets, and acidified + reduced pellets in a constant temperature water bath at 30°C and 150 rpm for oscillation Cultivate in the box, and study the breakage rate during the process to characterize its mechanical strength. At the same time, another group of small balls was air-dried under natural conditions, and the changes of the small balls were studied during the process;

[0062] 2) Add 8.0 g of pretreated polyvinyl alcohol-sodium alginate embedded zero-valent iron-ferric oxide pellets to 100 mL of Cr(VI) aqueous solution con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com