Preparation technology of synthesizing rod-like zirconium oxide powder through water-quenching method

A technology of zirconia powder and preparation process, applied in zirconia and other directions, can solve the problem of no report of rod-shaped zirconia powder, and achieve the effects of high efficiency, simple and safe operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0013] Using water quenching method, using rod-shaped zirconium tetrachloride powder as raw material, the purity is greater than 99%, heating to 900 ° C for 1 h, water quenching, the water quenching solution is sodium hydroxide solution, the pH value of the water quenching solution is 10, The temperature of the water quenching solution is 0°C, and after water quenching, it is dried to obtain rod-shaped zirconia powder.

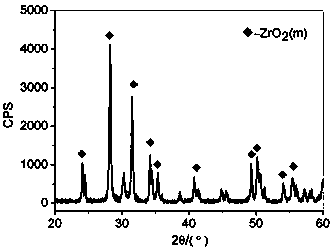

[0014] Through XRD test, it can be seen that the powder crystal type is monoclinic phase (see figure 1 ); through the SEM test, it can be seen that the zirconia powder is rod-shaped, with a diameter of about 10 μm and a length of about 200 μm (see figure 2 ).

Embodiment 2

[0016] Using water quenching method, using rod-shaped zirconium tetrachloride powder as raw material, the purity is greater than 99%, heating to 1100 ° C for 0.2h, water quenching, the water quenching solution is ammonia solution, the pH value of the water quenching solution is 8, water quenching The temperature of the solution is 30°C, quenched with water and then dried to obtain rod-shaped zirconia powder.

Embodiment 3

[0018] Using water quenching method, using rod-shaped zirconium tetrachloride powder as raw material, the purity is greater than 99%, heating to 1000 ° C for 0.5 h, water quenching, the water quenching solution is ammonia solution, the pH value of the water quenching solution is 9, water quenching The temperature of the solution is 20°C, quenched with water and then dried to obtain rod-shaped zirconia powder.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com