Preparation method of ceramic capacitor dielectric with high dielectric constant and ultra-wide working temperature

A technology with ultra-wide working temperature and high dielectric constant, applied in the field of ceramic compositions, can solve the problems of high working temperature environment mismatch, restricting the application of electronic equipment, etc., and achieve good application prospects, ultra-high working temperature range, and low sintering temperature. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The raw materials used in the present invention are commercially available analytical reagents.

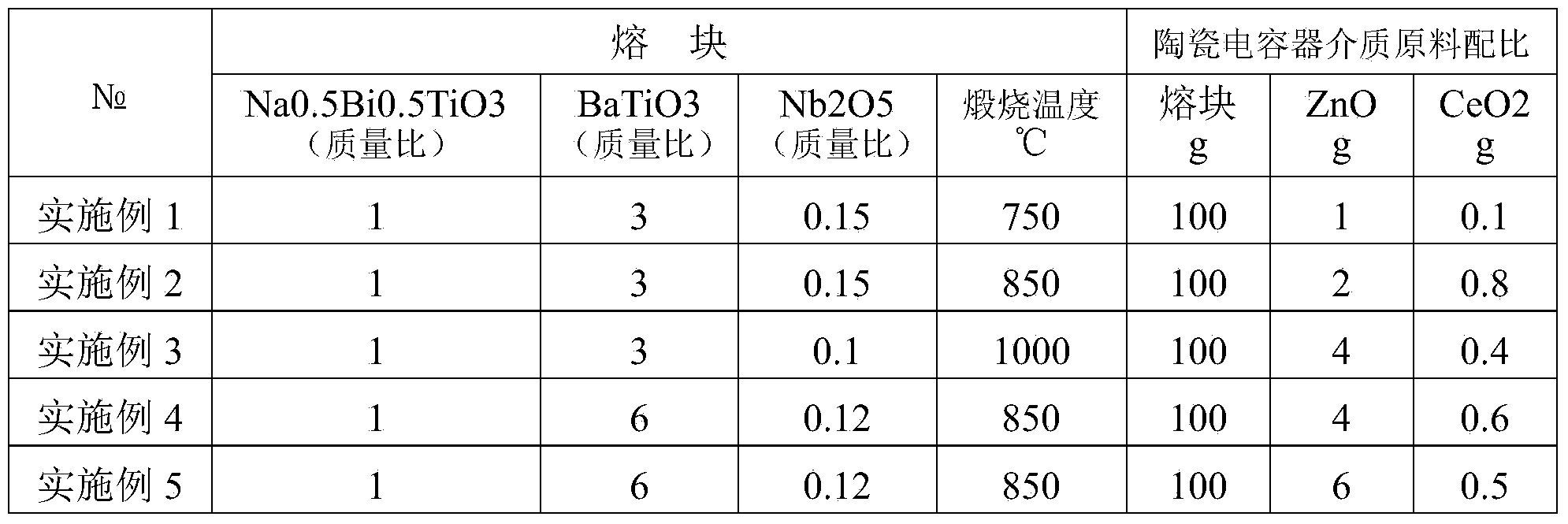

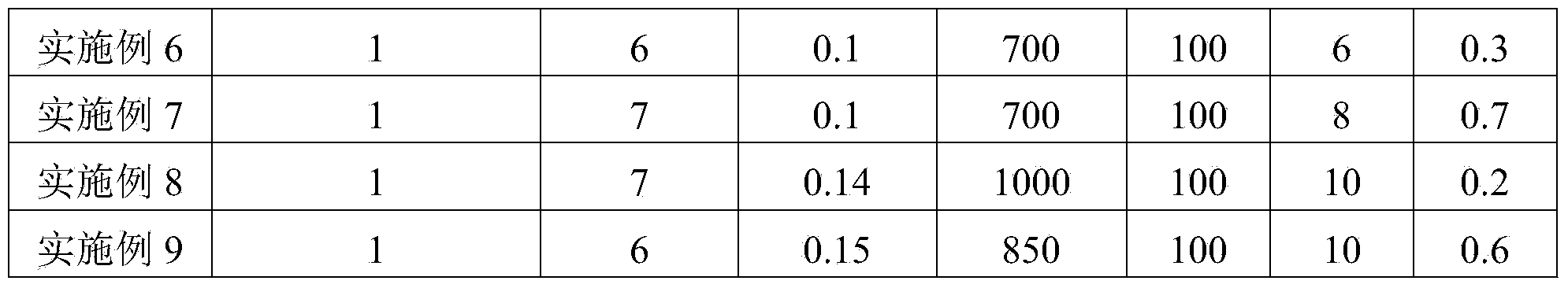

[0015] Na first 2 CO 3 、 Bi 2 o 3 、TiO 2 According to the mass ratio of 3:15:10, mixed with deionized water, ball milled for 6 hours, dried and calcined at 800°C to obtain Na 0.5 Bi 0.5 TiO 3 powder; press Na again 0.5 Bi 0.5 TiO 3 Powder and BaTiO 3 and Nb 2 o 5 The mass ratio is 1:3.0~7.0:0.1~0.15, mixed with deionized water and ball milled for 2~8 hours, dried and calcined at 750~1000℃ to obtain frit;

[0016] Bi 2 o 3 , Pb 3 o 4 , ZnO, H 3 BO 3 According to the mass percentage of 5:4:8:3, it is mixed with alcohol and ball milled for 10 hours, dried, melted and quenched, ground and sieved to obtain glass powder;

[0017] Then put the frit into 100g, add 1~10g ZnO, 8g glass powder, and 0.1~0.8g CeO 2 Ingredients; then mix the raw materials with deionized water and ball mill for 2-8 hours and dry;

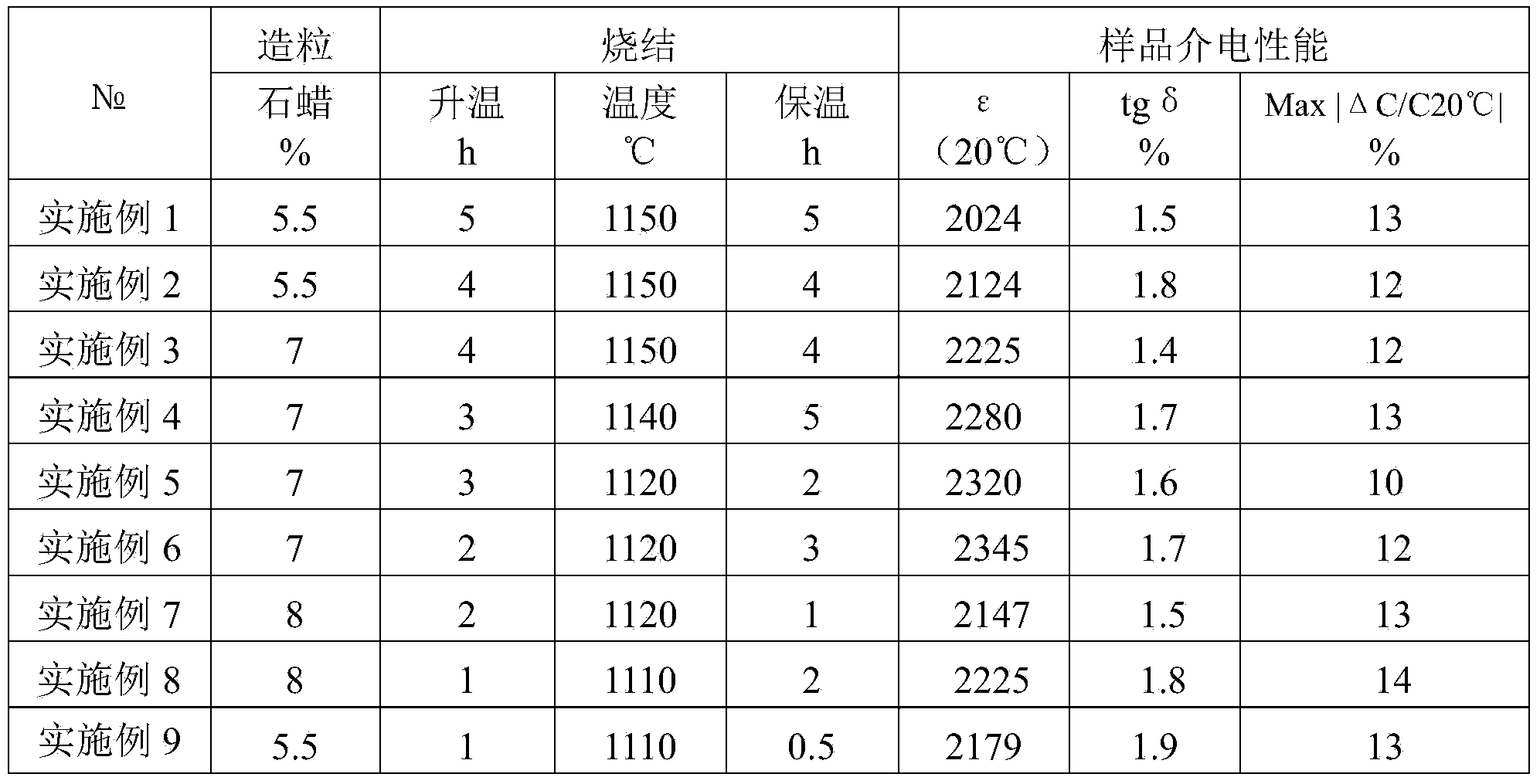

[0018] Then add paraffin wax with a mass percentage o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com