Application of oak barks, functional filter stick additives, preparation method for functional filter stick additives and application on the functional filter stick additives

A technology of oak bark and additives, applied in applications, smoke oil filter elements, tobacco, etc., to achieve simple preparation methods, reduce production costs, and meet the effects of industrial production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

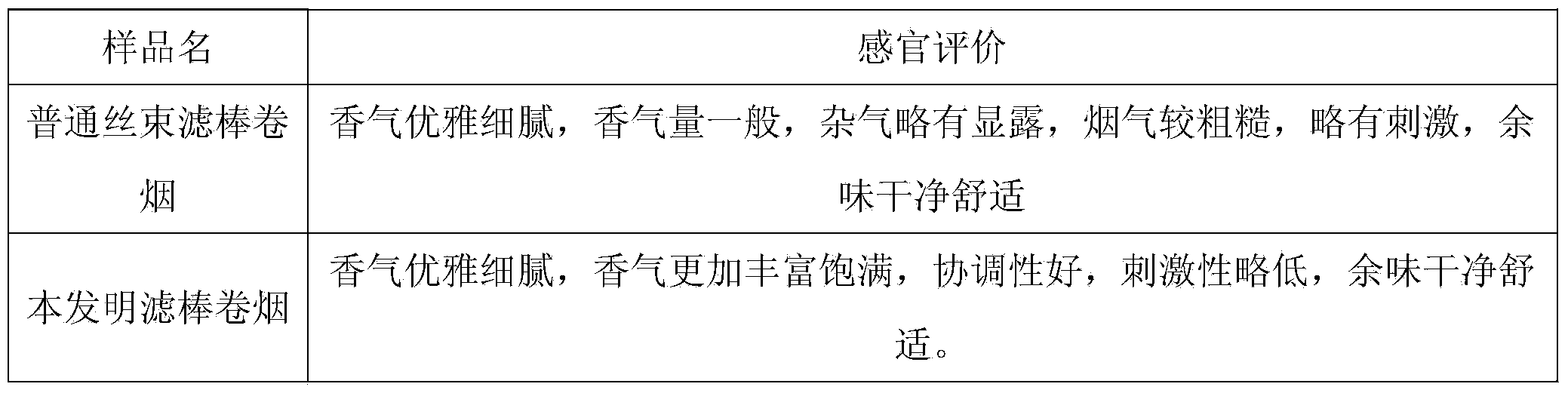

Embodiment 1

[0034] First prepare the filter rod particle additive: take 5KG oak bark to remove impurities and dry it, then physically and mechanically pulverize it, screen and get 80-120 mesh particles to get oak bark powder; take 3KG waste tobacco leaves, grind and grind to get a fine powder below 200 mesh for subsequent use; oak bark Particles and waste tobacco powder are uniformly mixed according to a certain weight ratio to obtain a dry mixed powder; appropriate amount of water-soluble chitosan and tobacco extract are dissolved in an appropriate amount of water to form an aqueous solution of a certain concentration, wherein, oak bark powder, waste tobacco leaf powder The mass ratio of chitosan and tobacco extract is 100:20:3:0.5; the powder and the aqueous solution are mixed and stirred evenly to form a slurry; the prepared slurry is put into a spray dryer for spray drying, and the control The water content of the particles is 6-12 wt%, and the obtained particles are sieved to get 30-6...

Embodiment 2

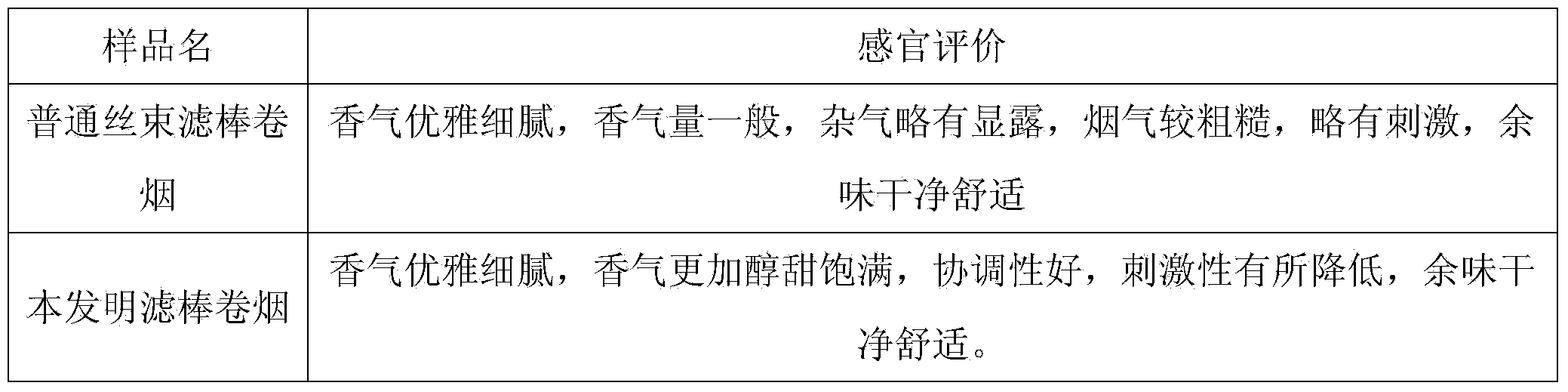

[0038] First prepare the filter rod particle additive: take 5KG oak bark to remove impurities and dry it, then physically and mechanically pulverize it, sieve and get 80-120 mesh particles to get the required oak bark powder for later use; take 3KG waste tobacco stems, grind and grind to get a fine powder below 200 mesh Standby; mix oak bark particles and waste tobacco powder uniformly according to a certain weight ratio to obtain a dry mixed powder; take appropriate amount of sodium alginate and yunyan absolute and dissolve them in an appropriate amount of water to form an aqueous solution of a certain concentration, wherein the oak bark powder, The mass ratio of waste tobacco powder, sodium alginate, and yunyan absolute is 100:30:5:0.8; the powder and aqueous solution are mixed and stirred evenly to form a slurry with a certain concentration; the prepared slurry is spray-dried The machine is used for spray drying, the water content of the particles is controlled to 6-12wt%, a...

Embodiment 3

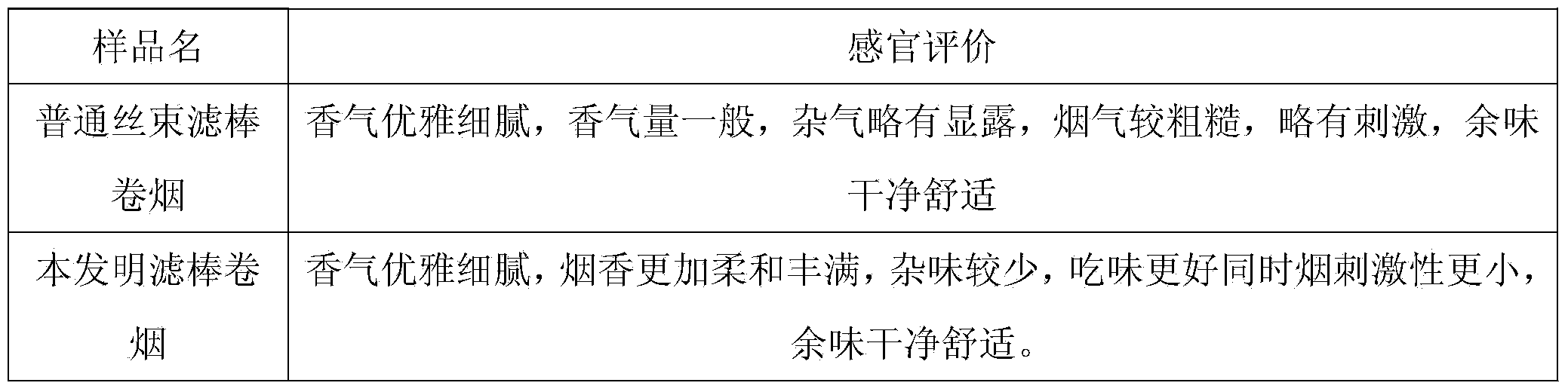

[0042]First prepare the filter rod particle additive: take 5KG oak bark to remove impurities and dry it, then pulverize it physically and mechanically, and screen to get 80-120 mesh particles to obtain oak bark powder for later use; take 3KG waste tobacco leaves and tobacco stems (each 1.5KG) to grind and grind to get less than 200-mesh fine powder for use; mix oak bark particles and waste tobacco powder according to a certain weight ratio to obtain dry mixed powder; take appropriate amount of modified starch, vanilla absolute, and macrostigmatrienone dissolved in appropriate amount of water to prepare a certain concentration aqueous solution, wherein the mass ratio of oak bark powder, waste tobacco powder, modified starch, vape absolute, and macrostigmatrienone is 100:10:8:0.5:0.1; the powder and aqueous solution are mixed and stirred evenly to form A certain concentration of slurry; put the prepared slurry into a spray dryer for spray drying, control the particle moisture to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com