Surface anti-oxidation protective coating of platinum wire-drawing crucible as well as preparation method and application of surface anti-oxidation protective coating

A protective coating and anti-oxidation technology, applied in glass manufacturing equipment, manufacturing tools, etc., can solve the problems of low coating adhesion, loss of platinum-rhodium alloy, and reduced use loss of platinum. Oxidative volatilization loss, easy operation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Weigh 150 grams of a-calcined alumina powder, 120 grams of quartz powder, 36 grams of boron nitride powder, and 294 grams of kaolin, put them into a stirrer, and mix them evenly. Use a graduated cylinder to measure 295ml of distilled water, pour it into the mixed material, and stir until it becomes viscous. Let stand at room temperature for 30 minutes.

[0033] Application of anti-oxidation protective coating on the surface of platinum wire drawing crucible:

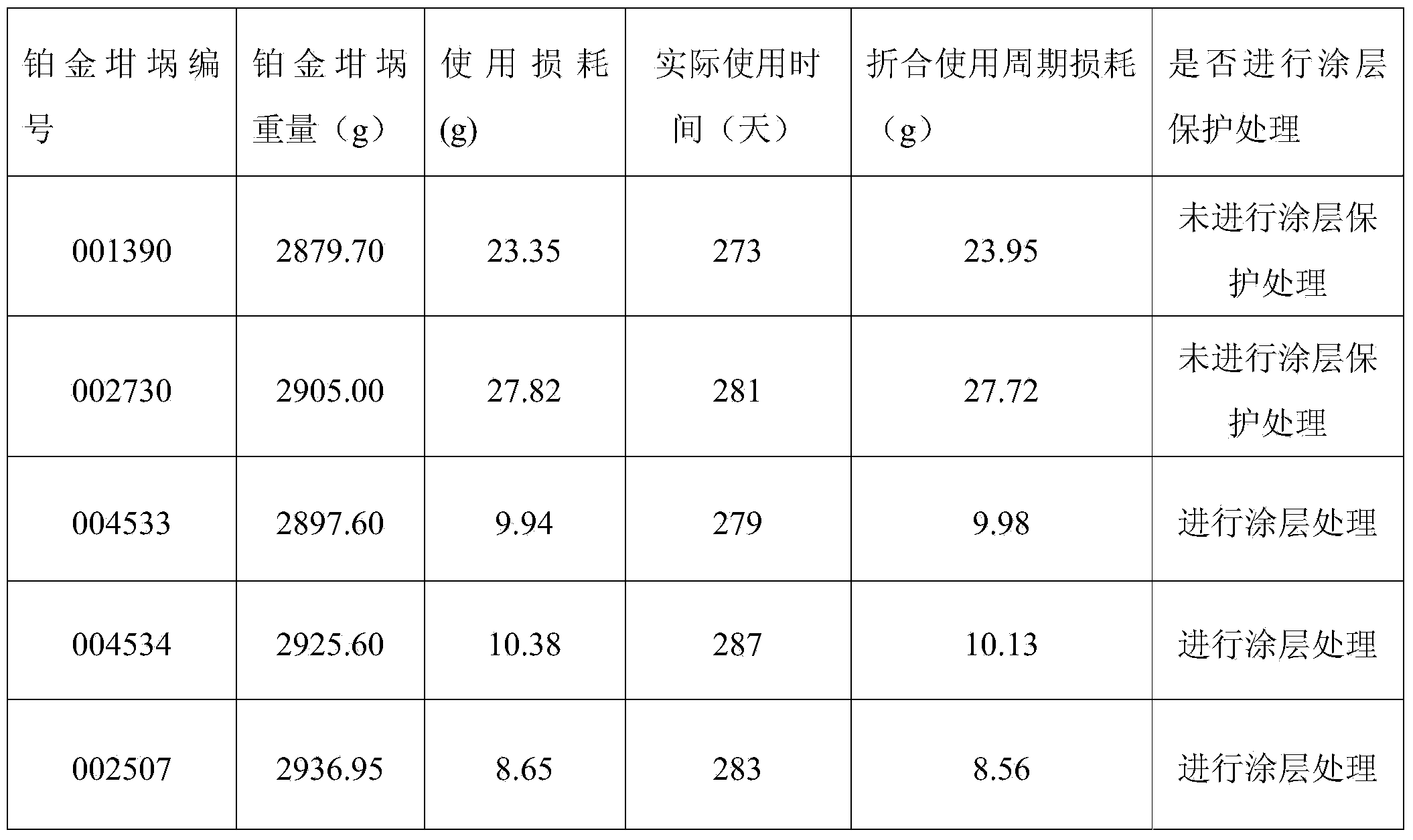

[0034] Clean the surface of the platinum wire drawing crucible and wipe it with a cotton cloth dipped in absolute ethanol to ensure that there is no impurity on the surface of the platinum wire drawing crucible; use plastic tape to seal the injection nozzle, air exhaust port and leak nozzle of the platinum wire drawing crucible; Apply the coating evenly on the surface of the cleaned platinum wire drawing crucible (No. 004533), the thickness of the coating is 2mm, and at the same time apply the coating evenly on t...

Embodiment 2

[0038] Weigh 192 grams of a-calcined alumina powder, 156 grams of quartz powder, 48 grams of boron nitride powder, and 204 grams of kaolin, put them into a blender, and mix them evenly. Measure 305ml of distilled water with a measuring cylinder, pour it into the mixed material, stir evenly until viscous, and let it stand at room temperature for 30 minutes.

[0039] Application of anti-oxidation protective coating on the surface of platinum wire drawing crucible:

[0040] Clean the surface of the platinum wire drawing crucible, and wipe it with a cotton cloth dipped in absolute ethanol to ensure that there is no impurity on the surface of the platinum wire drawing crucible; use plastic tape to seal the injection nozzle, air exhaust port, and leak nozzle of the platinum wire drawing crucible; then apply the coating Apply evenly on the surface of the cleaned platinum wire drawing crucible (No. 004534), the thickness of the coating is 1.5mm. 2.5mm, install the platinum wire drawi...

Embodiment 3

[0044] Weigh 224 grams of a-calcined alumina powder, 184 grams of quartz powder, 56 grams of boron nitride powder, and 336 grams of kaolin, put them into the mixer, and mix them evenly. Measure 416ml of distilled water with a measuring cylinder, pour it into the mixed material, stir evenly until viscous, and let stand at room temperature for 30 minutes.

[0045] Application of anti-oxidation protective coating on the surface of platinum wire drawing crucible:

[0046] Clean the surface of the platinum wire drawing crucible, and wipe it with a cotton cloth dipped in absolute ethanol to ensure that there is no impurity on the surface of the platinum wire drawing crucible; use plastic tape to seal the injection nozzle, air exhaust port, and leak nozzle of the platinum wire drawing crucible; then apply the coating Apply evenly on the surface of the cleaned platinum wire drawing crucible (No. 002507), the thickness of the coating is 1.8mm. 2.0mm, install the platinum wire drawing ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com