Pyrotechnic composition oxidant

A technology of oxidant and pyrotechnic powder, which is applied to explosives and other directions, can solve the problems of high product reactivity, low price and cost, and cannot satisfy the safety of production process at the same time, and achieves the effects of low price, high safety and high reactivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

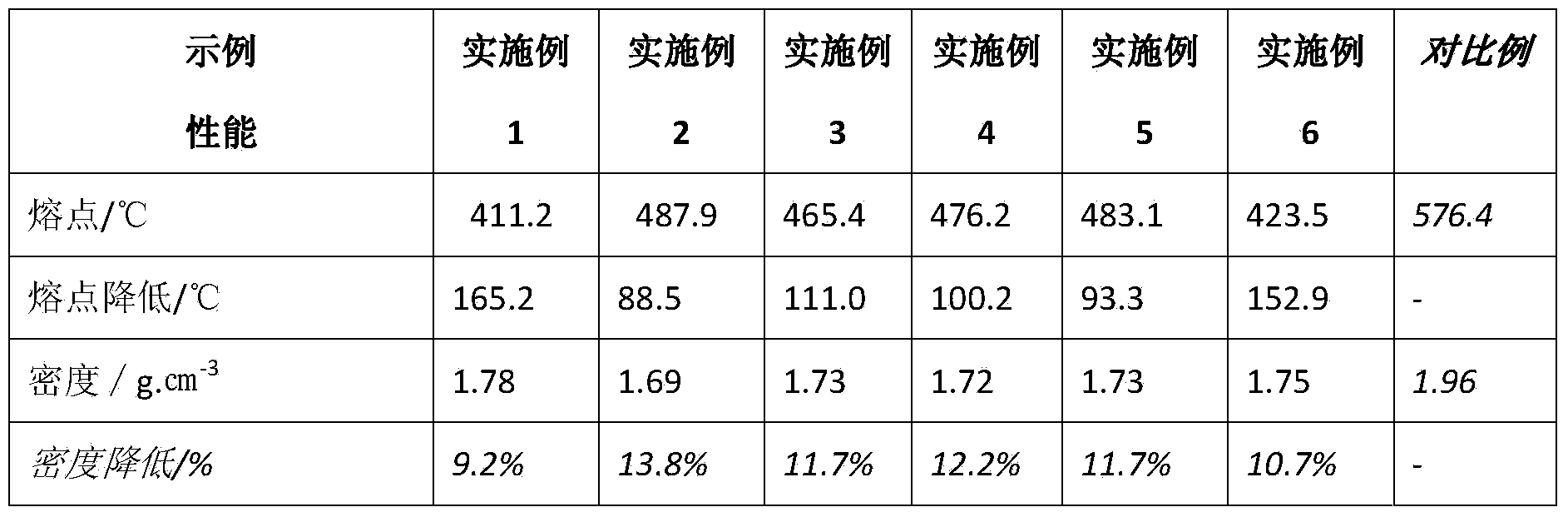

Embodiment 1

[0047] The formula of pyrotechnic powder safety oxidant is: modified barium nitrate: potassium perchlorate=0.6:0.4, mass ratio, the same below.

[0048] The production process of safe oxidant for pyrotechnic powder is as follows: ① Preparation of barium nitrate solution, ② Adding swelling agent to barium nitrate solution, ③ Evaporation and crystallization, ④ Drying and expansion, ⑤ Grinding and refining, ⑥ Preparation of active agent, ⑦ Blending of active agent , ⑧ mixed with potassium perchlorate.

[0049] The raw material for preparing barium nitrate solution is industrial barium nitrate.

[0050] The consumption of barium nitrate swelling agent is 5% of barium nitrate quality; The formula of swelling agent is: ammonium oxalate (NH 4 ) 2 C 2 o 4 75%, potassium oxalate K 2 C 2 o 4 10%, ferric ammonium oxalate (NH 4 ) 3 [Fe(C 2 o 4 ) 3 ] 10%, 5% of catalytic functional expansion agent; catalytic functional expansion agent is iron oxalate Fe 2 (C 2 o 4 ) 3 .

...

Embodiment 2

[0056] The formula of the pyrotechnic powder safety oxidant is: modified barium nitrate: potassium perchlorate=0.9:0.1.

[0057] The production process of safe oxidant for pyrotechnic powder is as follows: ① Preparation of barium nitrate solution, ② Adding swelling agent to barium nitrate solution, ③ Evaporation and crystallization, ④ Drying and expansion, ⑤ Grinding and refining, ⑥ Preparation of active agent, ⑦ Blending of active agent , ⑧ mixed with potassium perchlorate.

[0058] The raw materials for preparing barium nitrate solution are industrial nitric acid and industrial barium carbonate.

[0059] The consumption of barium nitrate swelling agent is 15% of barium nitrate quality; The formula of swelling agent is: ammonium oxalate (NH 4 ) 2 C 2 o 4 80%, potassium oxalate K 2 C 2 o 4 10%, ferric ammonium oxalate (NH 4 ) 3 [Fe(C 2 o 4 ) 3 ] 10%, catalytic functional expansion agent 0.

[0060] The operating temperature for drying and puffing is 450°C, and the...

Embodiment 3

[0065] The formula of the pyrotechnic powder safety oxidant is: modified barium nitrate: potassium perchlorate=0.7:0.3.

[0066] The production process of safe oxidant for pyrotechnic powder is as follows: ① Preparation of barium nitrate solution, ② Adding swelling agent to barium nitrate solution, ③ Evaporation and crystallization, ④ Drying and expansion, ⑤ Grinding and refining, ⑥ Preparation of active agent, ⑦ Blending of active agent , ⑧ mixed with potassium perchlorate.

[0067] The raw material for preparing barium nitrate solution is industrial barium nitrate.

[0068] The consumption of barium nitrate swelling agent is 10% of barium nitrate quality; The formula of swelling agent is: ammonium oxalate (NH 4 ) 2 C 2 o 4 80%, potassium oxalate K 2 C 2 o 4 5%, ferric ammonium oxalate (NH 4 ) 3 [Fe(C 2 o 4 ) 3 ]10%, catalytic functional expansion agent 5%; catalytic functional expansion agent is barium oxalate BaC 2 o 4 ﹑Copper oxalate CuC 2 o 4 equal mixture...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com