Using 2-(p-formyl chloride phenyl)-5-amino-6-hydroxybenzoxazole as the method for raw material preparation of PBO polymer

A technology of hydroxybenzoxazole and formyl chloride phenyl, which is applied in the field of PBO polymer preparation, can solve the problems of large usage of corrosive raw materials and long reaction cycle, etc., to avoid poor solubility, reduce dosage, and high reaction active effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

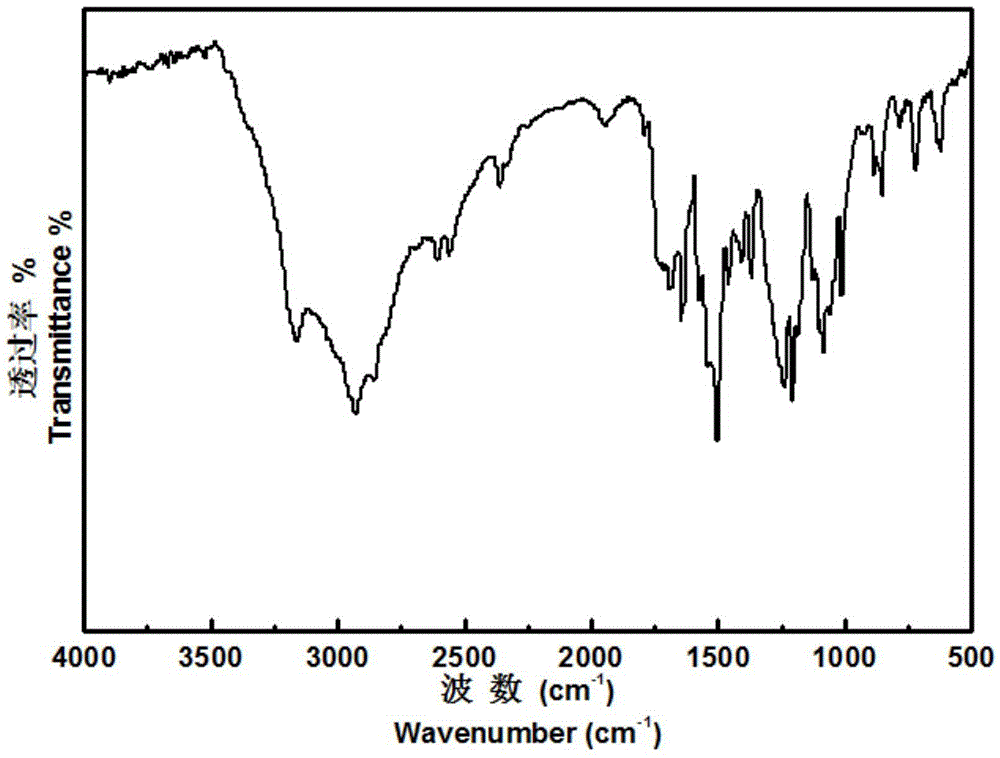

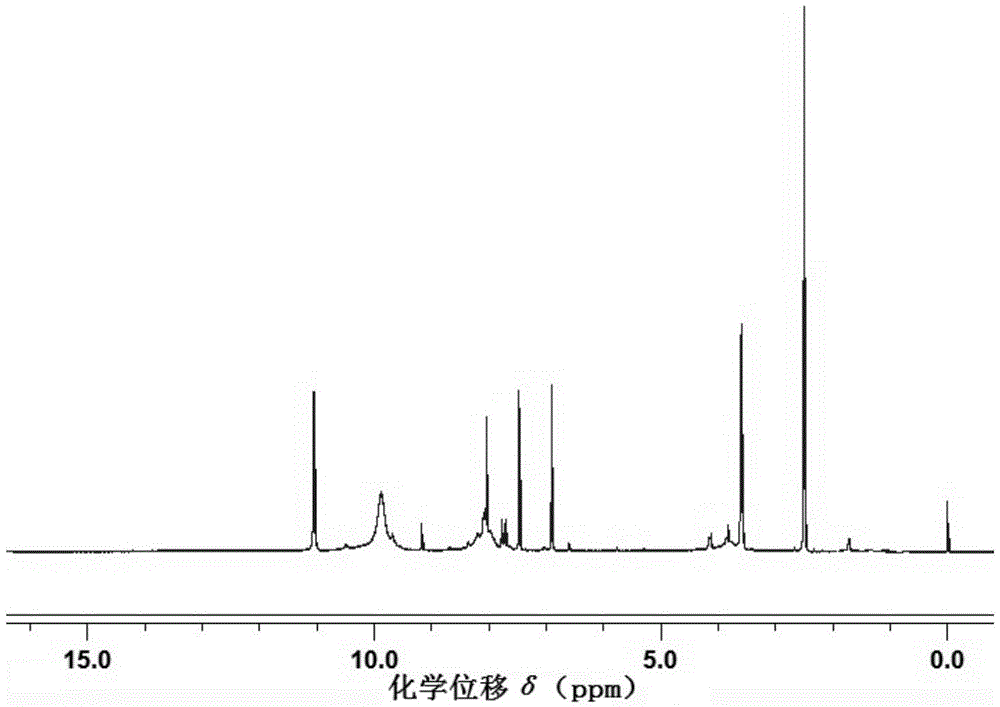

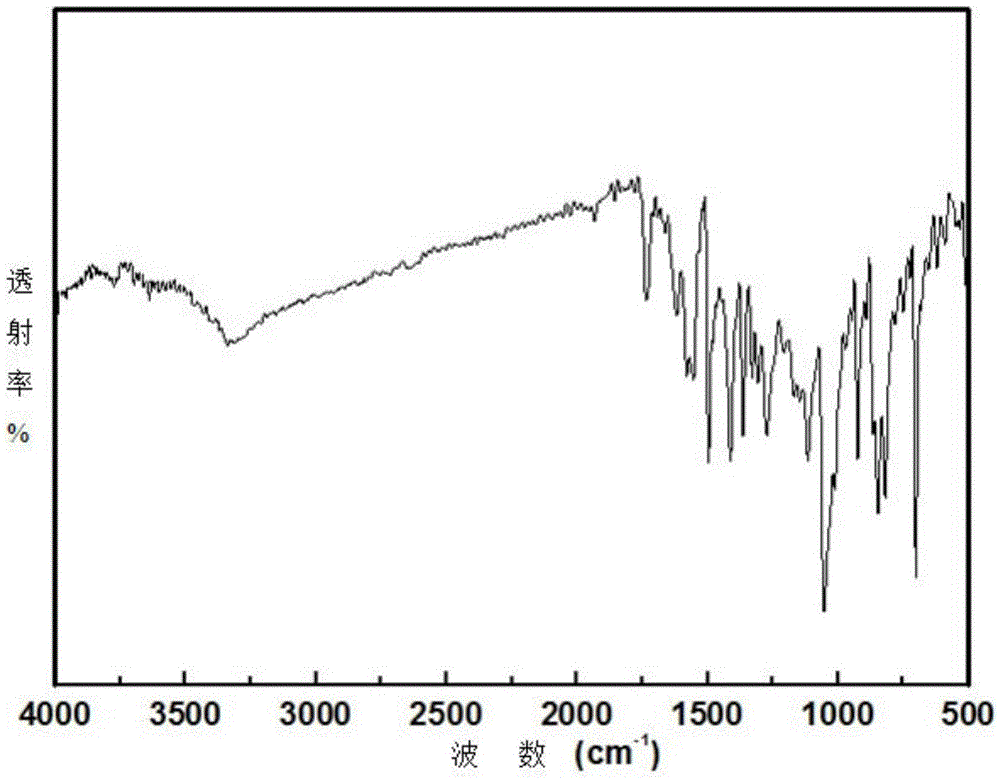

[0015] Specific embodiment one: the present embodiment takes 2-(p-formyl chloride phenyl)-5-amino-6-hydroxyl benzoxazole as the method for raw material preparation PBO polymer to implement according to the following steps:

[0016] 1. Under the protection of nitrogen, the P 2 o 5 Add it into the phosphoric acid solution, raise the temperature to 115-125°C, stir for 2 hours and cool down to 90°C to obtain a polyphosphoric acid solution;

[0017] 2. Under nitrogen protection, add AB type PBO monomer 2-(p-formyl chloride phenyl)-5-amino-6-hydroxybenzoxazole to the polyphosphoric acid solution in step 1 to prepare a PBO polymerization mixture , under full stirring, the PBO polymerization mixture was heated from 90°C to 120°C, and P was added continuously during the heating process. 2 o 5 , P in the control system 2 o 5 The mass percentage concentration is 80%~85%, obtains initial reaction liquid;

[0018] 3. Under the protection of nitrogen, the initial reaction liquid obtai...

specific Embodiment approach 2

[0023] Specific embodiment two: the difference between this embodiment and specific embodiment one is that the P in the polyphosphoric acid solution obtained in step one 2 o 5 The mass fraction is 80% to 85%. Other steps and parameters are the same as those in Embodiment 1.

[0024] The mass fraction described in this embodiment is by P 2 o 5 count.

specific Embodiment approach 3

[0025] Specific embodiment three: the difference between this embodiment and specific embodiment one or two is the AB type PBO monomer 2-(p-formyl chloride phenyl)-5-amino-6-hydroxybenzoxazole described in step two The preparation method is implemented according to the following steps:

[0026] 1. Under the protection of an inert gas, add 4,6-diaminoresorcinol hydrochloride to the ionic liquid at a molar ratio of 1: (2 to 4) to obtain a mixed solution A, and heat the obtained mixture to 50 After stirring at ℃~90℃ for 100min~150min, the liquid mixture A is obtained;

[0027] Wherein, the ionic liquid described in step 1 is a disubstituted imidazole type N-methylimidazolium tetrafluoroborate ionic liquid;

[0028] 2. Under the protection of an inert gas, add terephthaloyl dichloride to the liquid mixture A obtained in step 1 to obtain a mixture B, raise the temperature of the mixture B to 100°C to 140°C and stir for 10h to 18h, then Cool to room temperature to obtain a mixed s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com