A highly transparent doped metal oxide dispersion that absorbs ultraviolet rays in a full band and its preparation method

An oxide and ultraviolet technology, applied in chemical instruments and methods, dyeing organosilicon compound treatment, inorganic pigment treatment, etc., can solve few problems, and achieve the effect of simple operation, broad application prospects and mild conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Embodiment 1: take by weighing 12.28gCe (NO 3 ) 3 ·6H 2 O and 0.12gFe(NO 3 ) 2 ·6H 2 Dissolve O in 40mL of ethanol, add 0.1mol / L NaOH ethanol solution to the above metal salt solution, and mix well, adjust the reaction temperature at 40°C, adjust the pH to 7, add 0.243g of vinyltriacetoxysilane, After fully reacting, the reaction solution was cooled to room temperature and then transferred to an autoclave at a controlled temperature of 120°C; the product was washed with deionized water and ethanol, dried and dispersed in water to obtain a highly transparent doped product with a solid content of 20wt%. Miscellaneous CeO 2 The dispersion has a light transmittance of 0.1% in the ultraviolet band of 100-400nm.

Embodiment 2

[0026] Embodiment 2: Weigh 7.11gTiCl 4 and 0.495gMnCl 2 4H 2Dissolve O in 40mL ethanol, add 0.5mol / L NaOH ethanol solution to the above metal salt solution, and mix well, adjust the reaction temperature at 60°C, adjust the pH to 9, add 0.60g 3-glycidyl ether oxypropyl trimethyl Oxysilane, after fully reacting, the reaction solution was cooled to room temperature, and transferred to an autoclave, the temperature was controlled at 140°C; the product was washed with deionized water and ethanol, dried and dispersed in ethyl acetate to obtain a solid Highly transparent doped TiO with a content of 20% 2 The dispersion has a light transmittance of 0.6% in the ultraviolet band of 100-400nm.

Embodiment 3

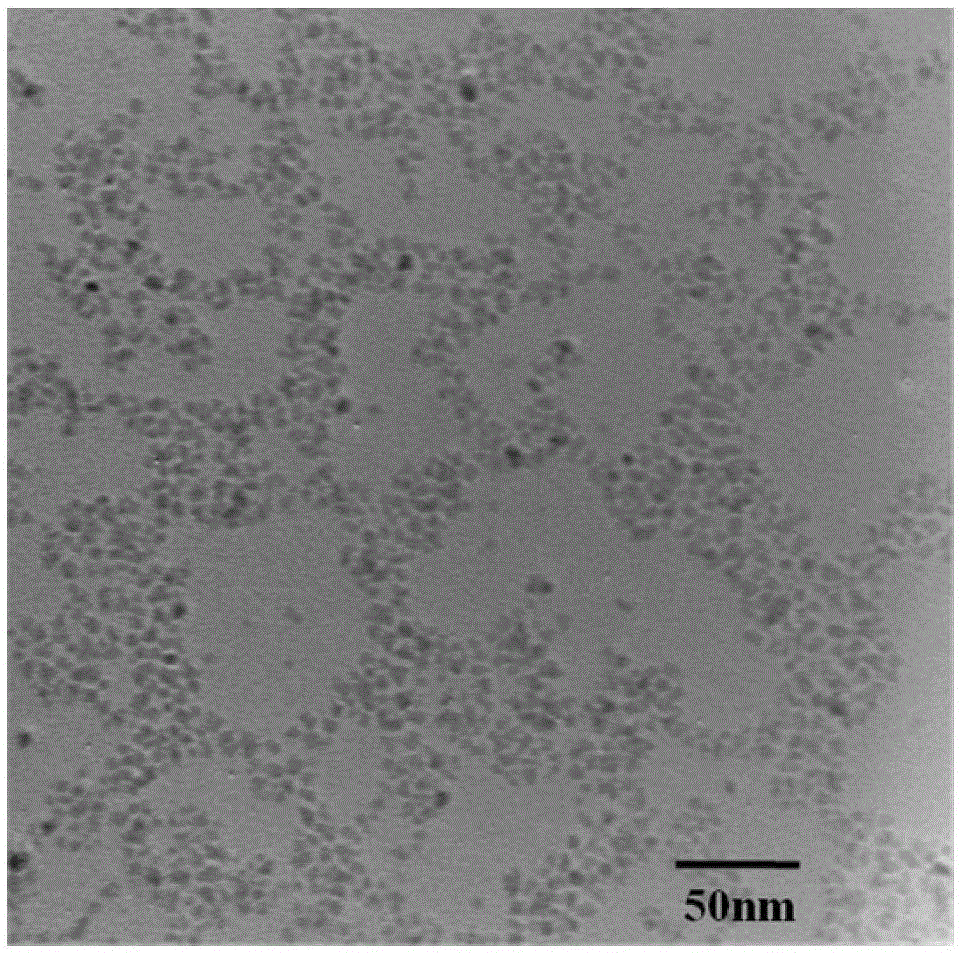

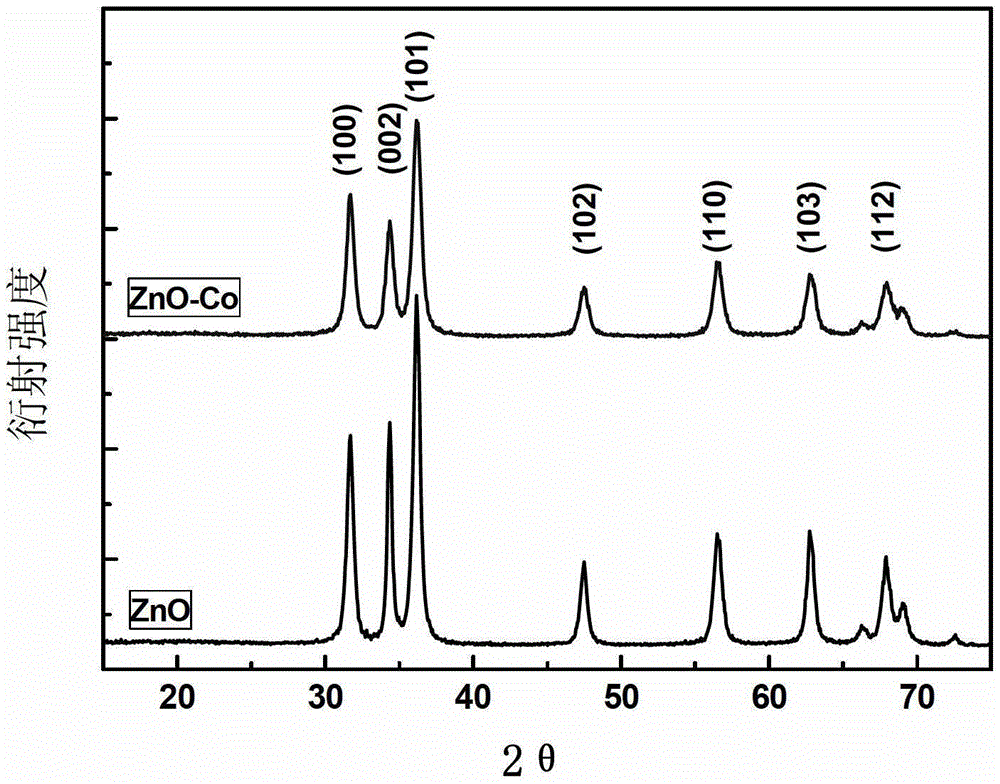

[0027] Embodiment 3: take by weighing 7.67gZn (CH 3 COO) 2 2H 2 O and 1.25gCo(CH 3 COO) 2 4H 2 Dissolve O in 40mL ethanol, add 0.3mol / L NaOH ethanol solution to the above metal salt solution, and mix well, adjust the reaction temperature at 50°C, adjust the pH to 8, add 1.25g n-octyltrimethoxysilane, After fully reacting, the reaction solution was cooled to room temperature and then transferred to an autoclave at a controlled temperature of 100°C; the product was washed with deionized water and ethanol, dried and dispersed in ethanol to obtain a highly transparent product with a solid content of 40%. The ZnO-doped dispersion has a light transmittance of 0.5% in the ultraviolet band of 100-400nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com