Method for improving thermal degradation capacity of maleic anhydride grafted polypropylene plastic

A technique of grafting polypropylene and maleic anhydride, which is applied in the field of physical modification of maleic anhydride grafted polypropylene, can solve the problems of less active groups and poor blending compatibility, achieve low cost and improve crystallinity And the effect of crystallization ability and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

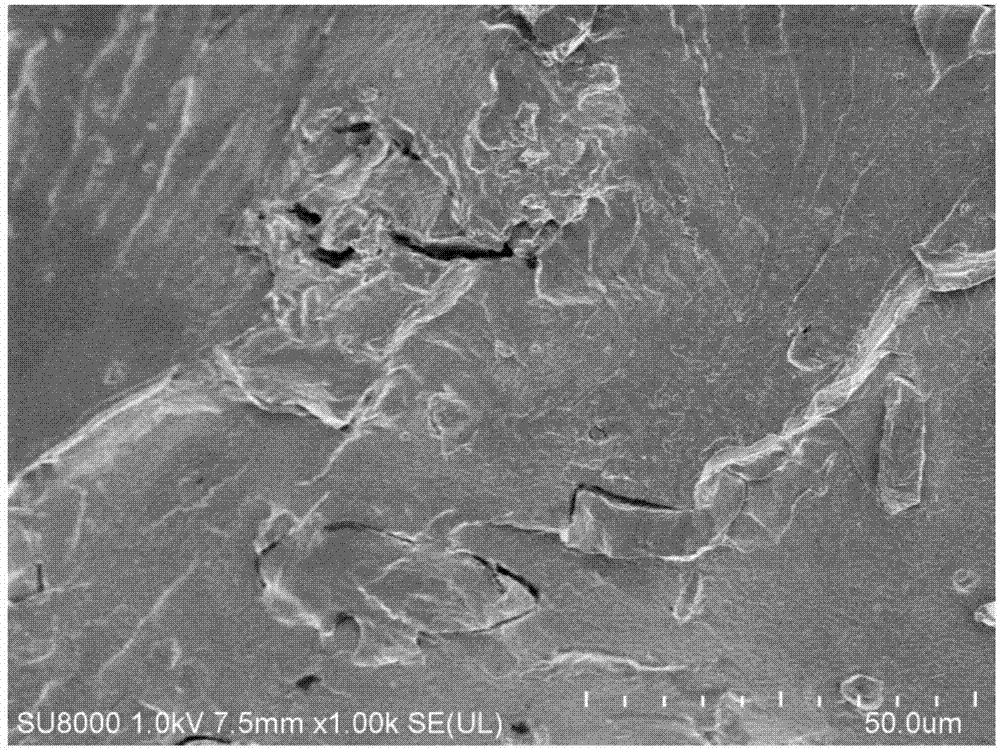

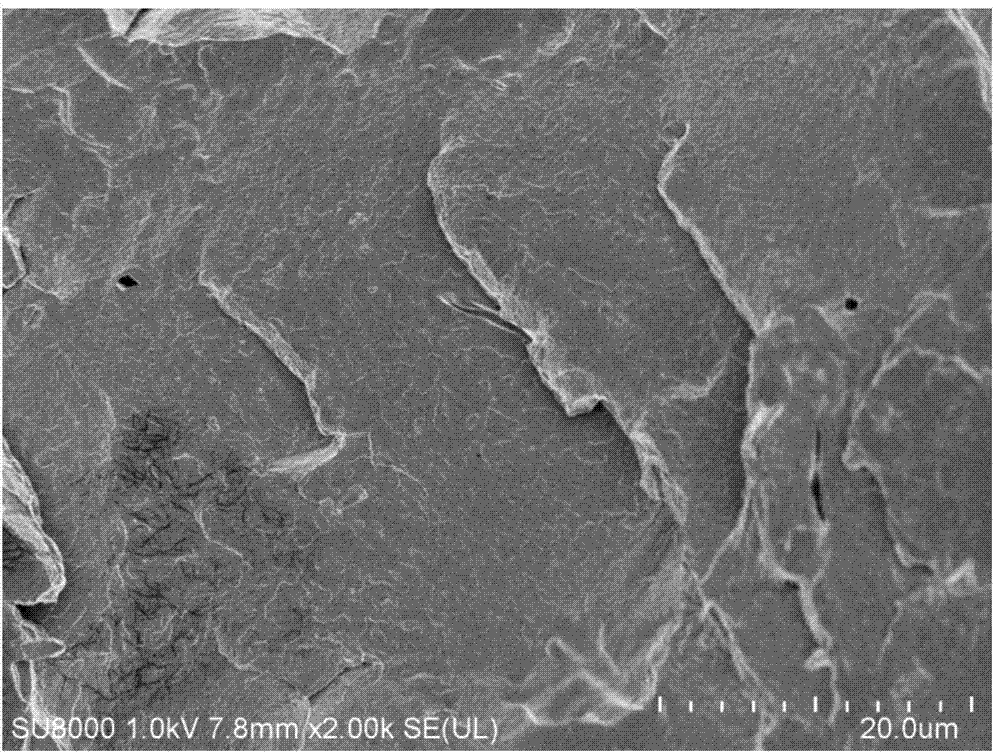

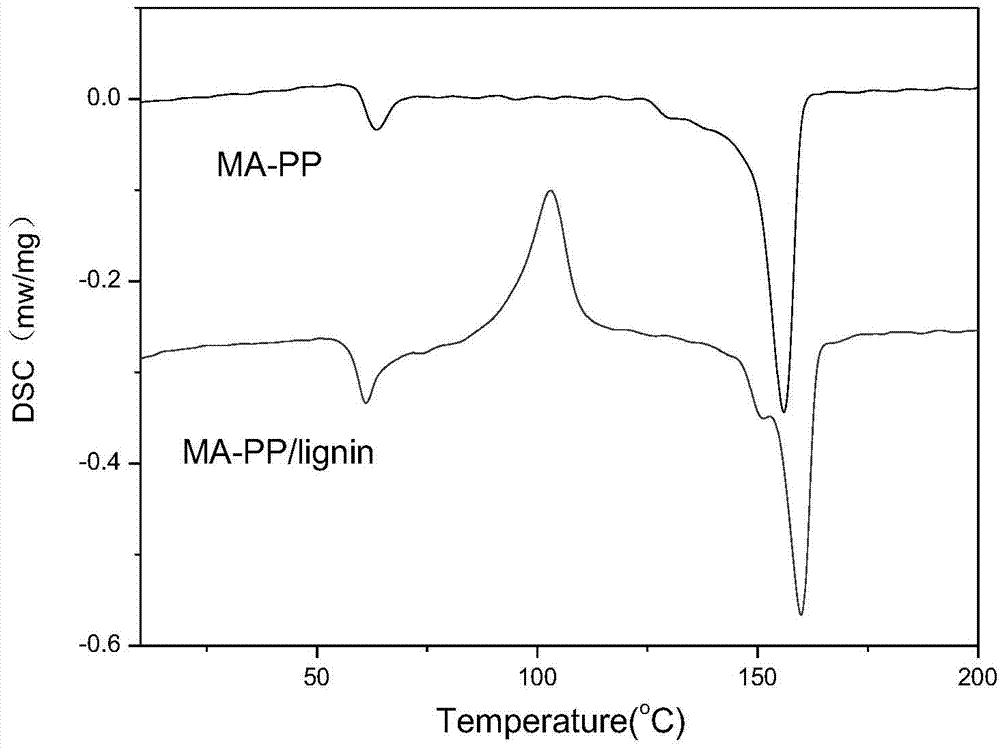

Embodiment 1

[0024] The lignin and maleic anhydride were grafted and modified according to the mass ratio of 95:5, the reaction solvent was acetic acid, and the reaction was carried out at 30°C for 30 minutes, washed with distilled water for 3 times and then dried to obtain the modified lignin after esterification. The modified lignin and maleic anhydride grafted polypropylene were mixed evenly in a high-speed mixer at a mass ratio of 10:90, and the mixed materials were melt-blended in a micro-blender at 180°C to obtain a uniformly mixed blend. Mixture; put the above blend into the feed hopper of the micro-injection molding machine and melt it at 190°C, and inject the mixture melt into the dumbbell-shaped mold under the pressure of the injection molding machine. A dumbbell-shaped blended spline is obtained. Among them, the crystallization performance of the blended spline is improved, the crystallinity is 50.3%, the thermal stability in nitrogen is improved, and the residual rate (12.73%) ...

Embodiment 2

[0026] The lignin and maleic anhydride were grafted and modified according to the mass ratio of 95:5, the reaction solvent was acetic acid, and the reaction was carried out at 30°C for 30 minutes, washed with distilled water for 3 times and then dried to obtain the modified lignin after esterification. The modified lignin and maleic anhydride-grafted polypropylene were mixed evenly in a high-speed mixer at a mass ratio of 15:85, and the mixed materials were melt-blended in a micro-blender at 185°C to obtain a well-mixed blend Mixture; put the above blend into the feed hopper of the micro-injection molding machine and melt it at 190°C, and inject the mixture melt into the dumbbell-shaped mold under the pressure of the injection molding machine. A dumbbell-shaped blended spline is obtained. Among them, the crystallization performance of the blended spline is improved, the crystallinity is 53.1%, the thermal stability in nitrogen is improved, and the residual rate (13.24%) in the...

Embodiment 3

[0028] The lignin and maleic anhydride were grafted and modified according to the mass ratio of 90:10, the reaction solvent was acetic acid, and the reaction was carried out at 30° C. for 40 minutes, washed with distilled water for 3 times and then dried to obtain the modified lignin after esterification. The modified lignin and maleic anhydride-grafted polypropylene were mixed evenly in a high-speed mixer at a mass ratio of 10:90, and the mixed materials were melt-blended in a micro-blender at 175°C to obtain a well-mixed blend Mixture; put the above blend into the feed hopper of the micro-injection molding machine and melt it at 185°C, and inject the mixture melt into the dumbbell-shaped mold under the pressure of the injection molding machine. A dumbbell-shaped blended spline is obtained. Among them, the crystallization performance of the blended spline is improved, the crystallinity is 53.6%, the thermal stability in nitrogen is improved, and the residual rate (13.62%) in ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com