A dust-proof and antistatic inorganic composite coating and its preparation method

An inorganic composite and antistatic technology, applied in the direction of antifouling/underwater coatings, coatings, paints containing biocides, etc., can solve the problem of no effect of dust adhesion, achieve the effect of improving durability and solving instability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

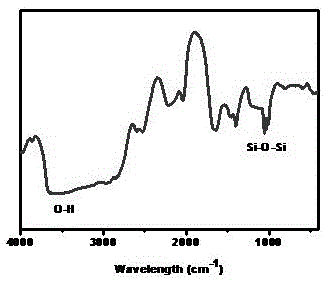

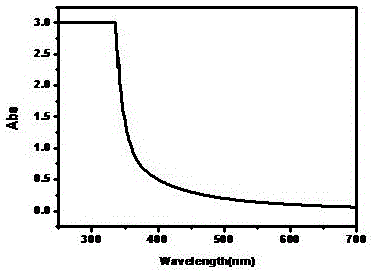

Image

Examples

Embodiment 1

[0033] 1) Add 1kg of tetramethoxysilane aqueous solution and 0.43kg of trimethoxysilane aqueous solution with a concentration of 10wt% to 28.57kg of methanol at room temperature, and stir for 10min to obtain a siloxane alcohol solution;

[0034] 2) Heat 10kg of oxalic acid aqueous solution with a concentration of 5wt% to 70°C, add a mixture consisting of 7.28kg of hydrogen peroxide and 24.93kg of metal Sn powder, and heat at 90°C for 1 hour to end the reaction to obtain SnO 2 Sol 50kg; To obtain SnO 2 Add 0.53kg of HF to the sol, adjust the pH to 10 with ammonia water, stir for 10 minutes, add it to the polytetrafluoroethylene sleeve, and then keep it at 150 ° C for 2 hours to prepare antistatic doped SnO 2 transparent aqueous solution;

[0035] 3) Combine 0.05kgNaOH and 1.45kgNa 2 SiO3 Add to 48.5kg of distilled water, stir for 1 hour, and prepare the inorganic binder;

[0036] 4) Add 3 kg of the siloxane alcohol solution prepared in step 1 to 87 kg of methanol, and then a...

Embodiment 2

[0042] 1) Add 2.44kg of tetraethoxysilane aqueous solution with a concentration of 20wt% to 97.56kg of ethanol at room temperature, and stir for 60min to obtain a siloxane alcohol solution;

[0043] 2) Heat 11.43kg of citric acid aqueous solution with a concentration of 10wt% to 70°C, add 4.64kg of hydrogen peroxide and 50.02kg of Sn(NO 3 ) 4 After heating the mixture at 90°C for 1h, the reaction was terminated to obtain SnO 2 Sol 80kg; To obtain SnO 2 Add 7.7kg of FNH to the sol 4 , and adjust the PH=10 with ammonia water, stir for 60min, add it into the polytetrafluoroethylene sleeve, and then keep it at 150℃ for 6h to obtain antistatic doped SnO 2 transparent aqueous solution;

[0044] 3) Combine 0.5kg of KOH and 0.15kg of K 2 SiO 3 Added into 8kg of distilled water, stirred for 3h, and prepared an inorganic binder;

[0045] 4) Add 10kg of the siloxane alcohol solution obtained in step 1 to 81kg of ethanol, and then add 8kg of the antistatic doped SnO obtained in ste...

Embodiment 3

[0047] 1) Add 0.97kg of 15wt% dimethyldimethoxysilane aqueous solution to 29.03kg of propanol at room temperature, and stir for 40min to obtain a siloxane alcohol solution;

[0048] 2) Heat 3.3kg of oxalic acid aqueous solution with a concentration of 8wt% to 70°C, add 1.38kg of hydrogen peroxide and 12.57kg of Sn(SO 4 ) 2 After heating the mixture at 90°C for 1h, the reaction was terminated to obtain SnO 2 Sol 20kg; in the obtained SnO 2 Add 0.63kg of HF to the sol, adjust the pH to 11 with ammonia water, stir for 40 minutes, add it to the polytetrafluoroethylene sleeve, and then keep it at 150°C for 4 hours to obtain antistatic doped SnO 2 transparent aqueous solution;

[0049] 3) Add 0.3kg of Ca(OH) 2 and 0.5kg of CaSiO 3 Add to 9.2kg of distilled water, stir for 2 hours to obtain an inorganic binder;

[0050] 4) Add 3kg of the siloxane alcohol solution obtained in step 1 to 94kg of propanol, and then add 2kg of the antistatic doped SnO obtained in step 2 2 Transpare...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com