IGZO thin film transistor and method for improving electrical property of IGZO thin film transistor

A thin-film transistor and electrical performance technology, which is applied in the direction of transistors, circuits, electrical components, etc., can solve the problems of reducing device performance, affecting IGZO thin-film metal Schottky contacts, and many oxygen vacancy defects, so as to improve mobility and improve Oxygen vacancy defects, the effect of increasing the driving current

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

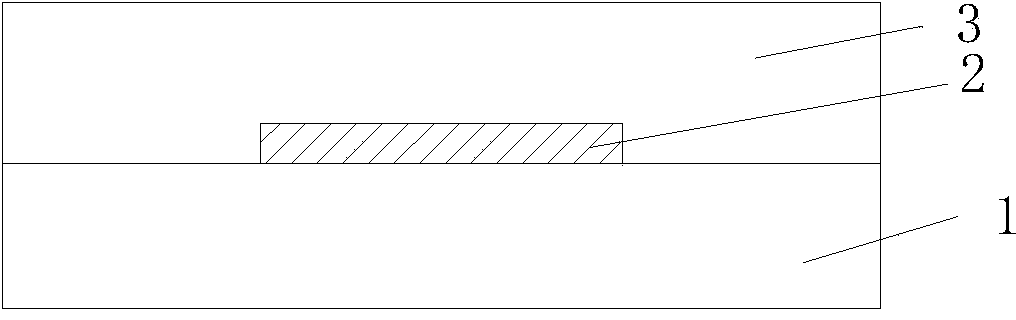

[0032] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

[0033] The invention provides a method for improving the electrical performance of an IGZO thin film layer transistor. In the process of preparing a display device containing an IGZO thin film, the IGZO thin film is treated by using a plasma treatment process to improve the oxygen atom content of the IGZO thin film layer. Improve the performance of the device; at the same time, the UV radiation treatment is performed at the same time as the plasma treatment, which can further accelerate the reaction and obtain a better process effect.

[0034] Specific steps are as follows:

[0035] Step S1: providing a substrate 1, preferably, the substrate 1 is a glass substrate; and cleaning the substrate 1, such as figure 1 shown.

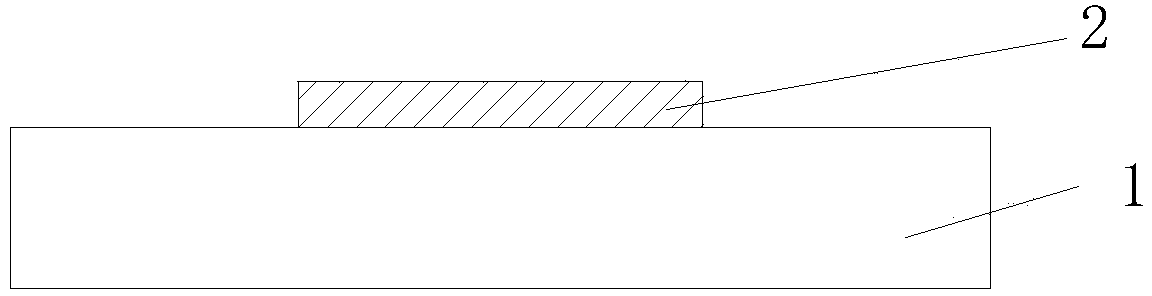

[0036] Step S2: Deposit a metal layer on the substrate 1, then perform a photolithography process and etch the metal layer, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com