Solid oxide fuel cell control device and control method

A solid oxide and control device technology, applied in solid electrolyte fuel cells, fuel cells, fuel cell additives, etc., can solve problems affecting system performance, different manufacturing processes and operating conditions, unsatisfactory efficiency, safety and stability, etc. , to achieve the effect of strong versatility and simple device structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

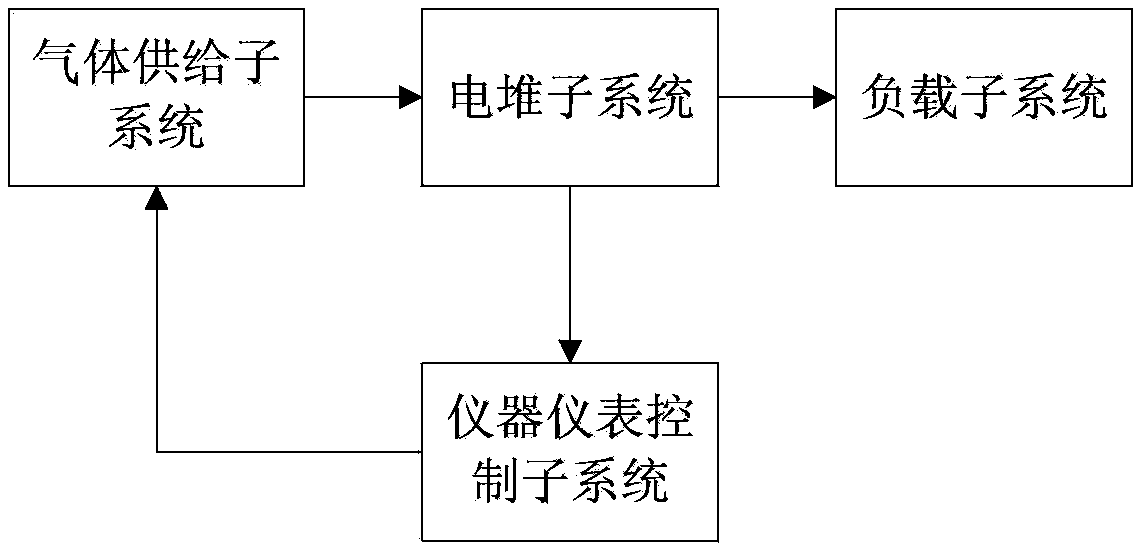

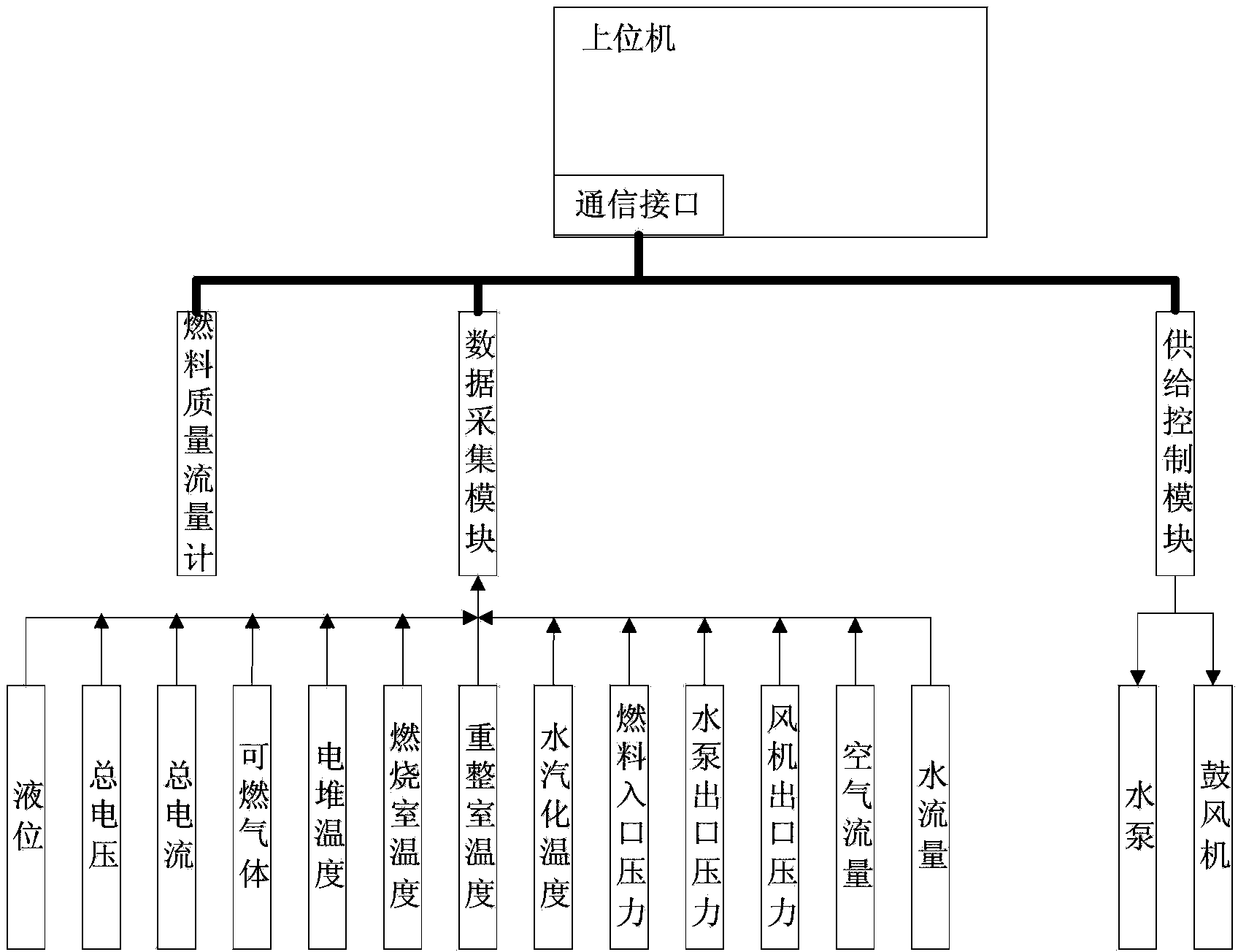

Method used

Image

Examples

Embodiment 1

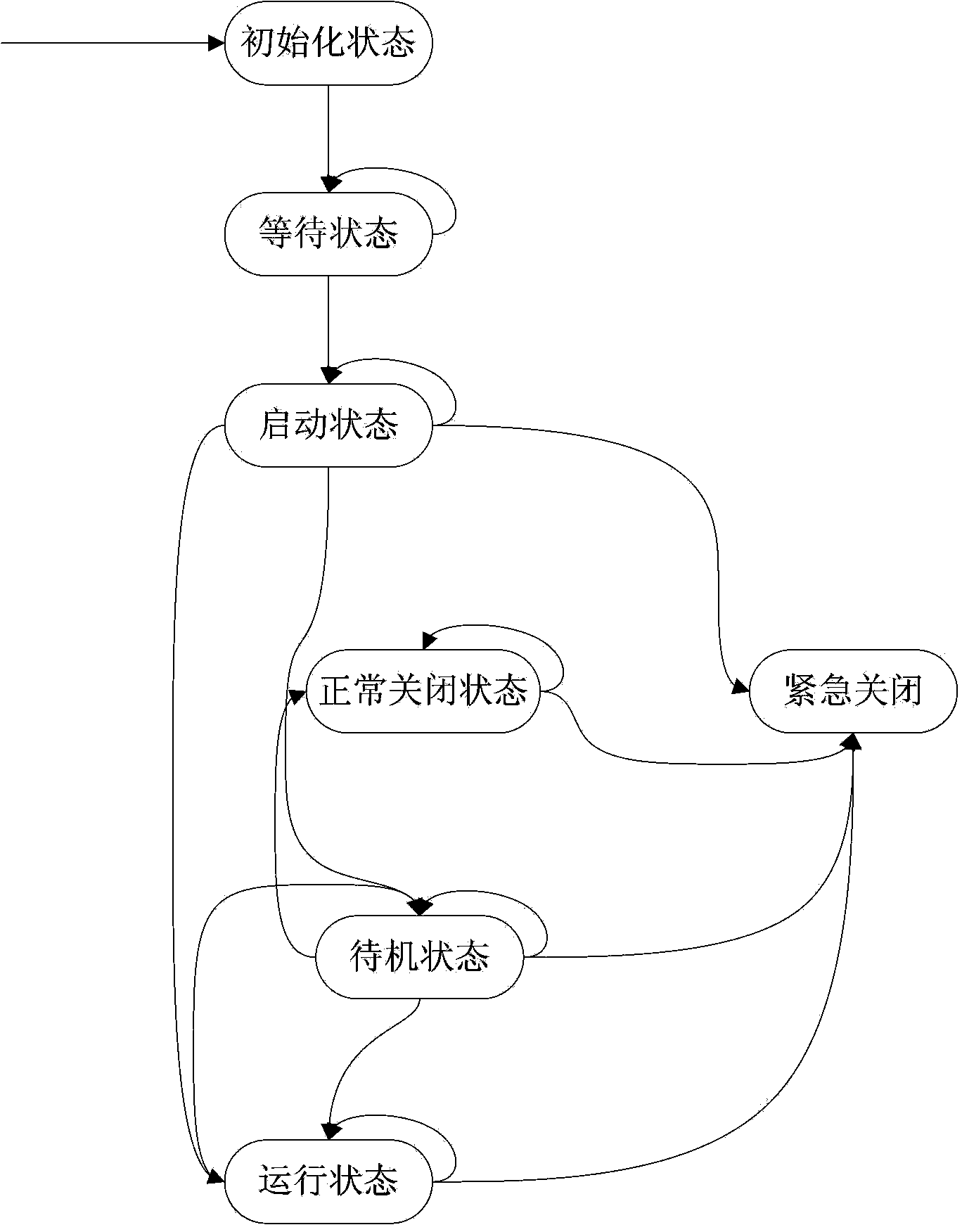

[0033] Embodiment 1: Define the state of the device and specify its operation steps to realize the control of each operation process

[0034] The device state is classified according to the device process, including at least initialization state, waiting state, start state, standby state, running state, normal shutdown state, and emergency shutdown state. The specified operation steps are executed in different states, and the difference between different device states state transitions are possible. The state transition can be performed according to user actions such as executing the action of starting the electric stack, or according to the measured value of the device such as the temperature is greater than a specified value, and the relevant transition operation steps are executed.

[0035] The initialization state is to detect whether the measured value of the device and its connection state are abnormal; the waiting state is to wait for user operation instructions and set...

Embodiment 2

[0047] Embodiment 2: Programmable Table Setting of Sequence Control Flow

[0048] The sequential control process of the fuel cell device, such as start-up and shutdown, and different device processes will result in different control quantities at different times. The control quantities include temperature and different gas supply quantities, which correspond to different instruments and equipment, and the adjustment is complicated. The programmable parameter table is used for setting, and the setting is uniform. The setting content includes the time period, temperature period, and different gas supply volumes. The gas supply types include methane, hydrogen, nitrogen, water and air. The corresponding table items when the gas is not used set to 0. Combination settings of parameters can be carried out, and operations such as creating, saving and loading the parameter table can be performed.

Embodiment 3

[0049] Embodiment 3: Programmable Table Setting of Fault Judgment Parameters During the operation of the fuel cell device, the types of faults and their fault definitions are different in different states, and different users are concerned about different faults. The programmable table is used to set the fault judgment parameters. Including that the user can add the fault item by himself, and the fault item is the measurement item parameter of the sensor, and can define its upper and lower limits by himself, and can set the fault judgment parameters of one or more states in the table at the same time.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com