Multi-metal sulfide semiconductor photocatalytic material and preparation method thereof

A technology of photocatalytic materials and multiple metals, applied in chemical instruments and methods, physical/chemical process catalysts, chemical/physical processes, etc., can solve problems such as difficult promotion and application, long reaction time, etc., and achieve high practical value and low cost , The process is simple and easy to control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

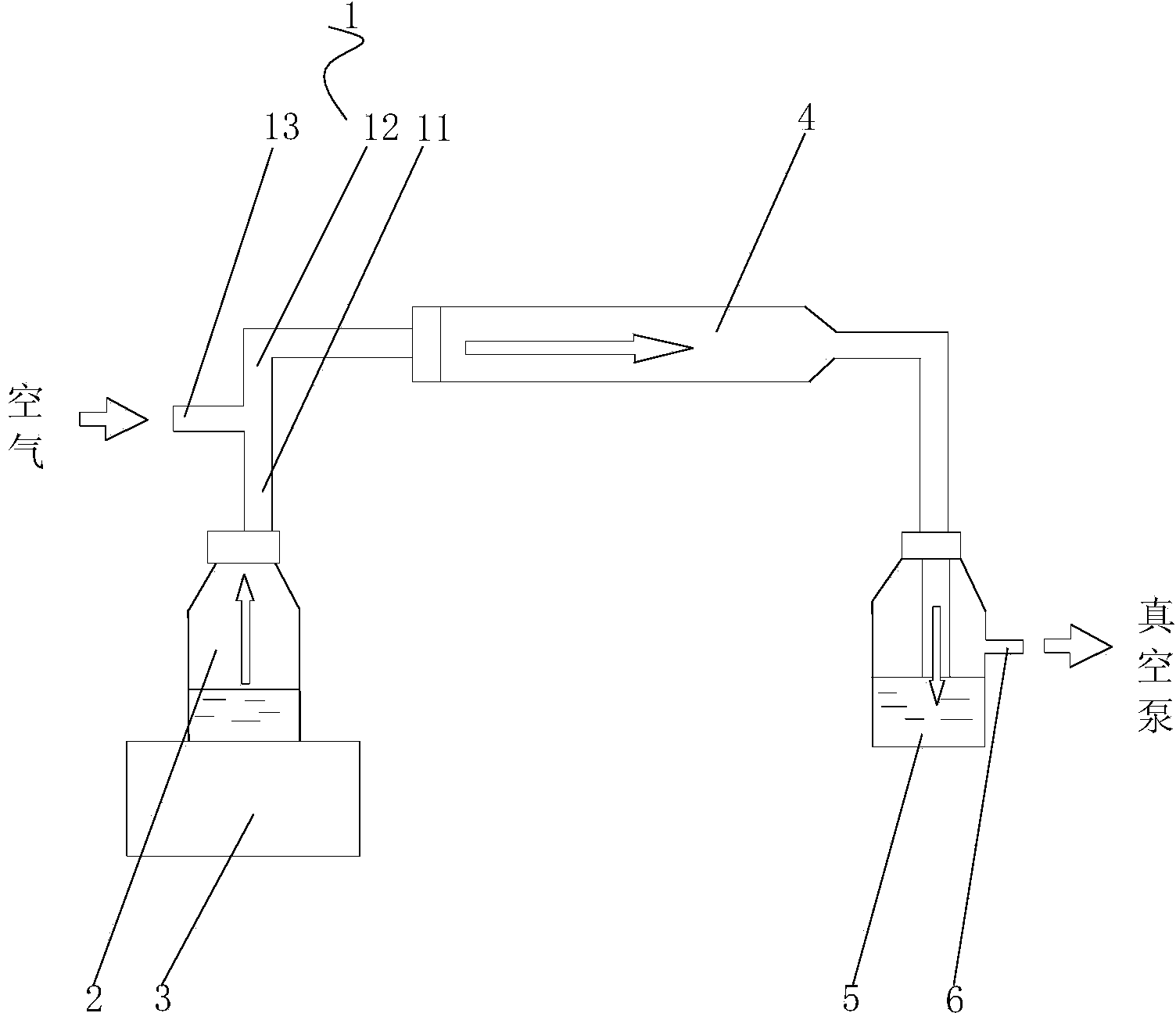

[0038] A preparation method of a multi-element metal sulfide semiconductor photocatalytic material, the preparation method is an ultrasonic atomization method, comprising the steps of:

[0039] 1) Dissolving excess thiourea and more than one soluble metal salt in distilled water simultaneously to obtain a transparent reaction precursor;

[0040] 2) The precursor solution is atomized in the reaction bottle under the action of an ultrasonic atomizer to generate an aerosol rich in tiny droplets;

[0041] 3) The aerosol enters the high-temperature tube furnace through the carrier gas, and each aerosol forms a microreactor in the tube furnace. The thiourea decomposes to generate hydrogen sulfide, and the hydrogen sulfide reacts with the metal ions in the soluble metal salt to form a multi-element metal sulfide semiconductor photocatalytic material;

[0042] 4) Driven by a vacuum pump, pump the photocatalytic material obtained in step 3) into a glass bottle filled with distilled wa...

Embodiment 1

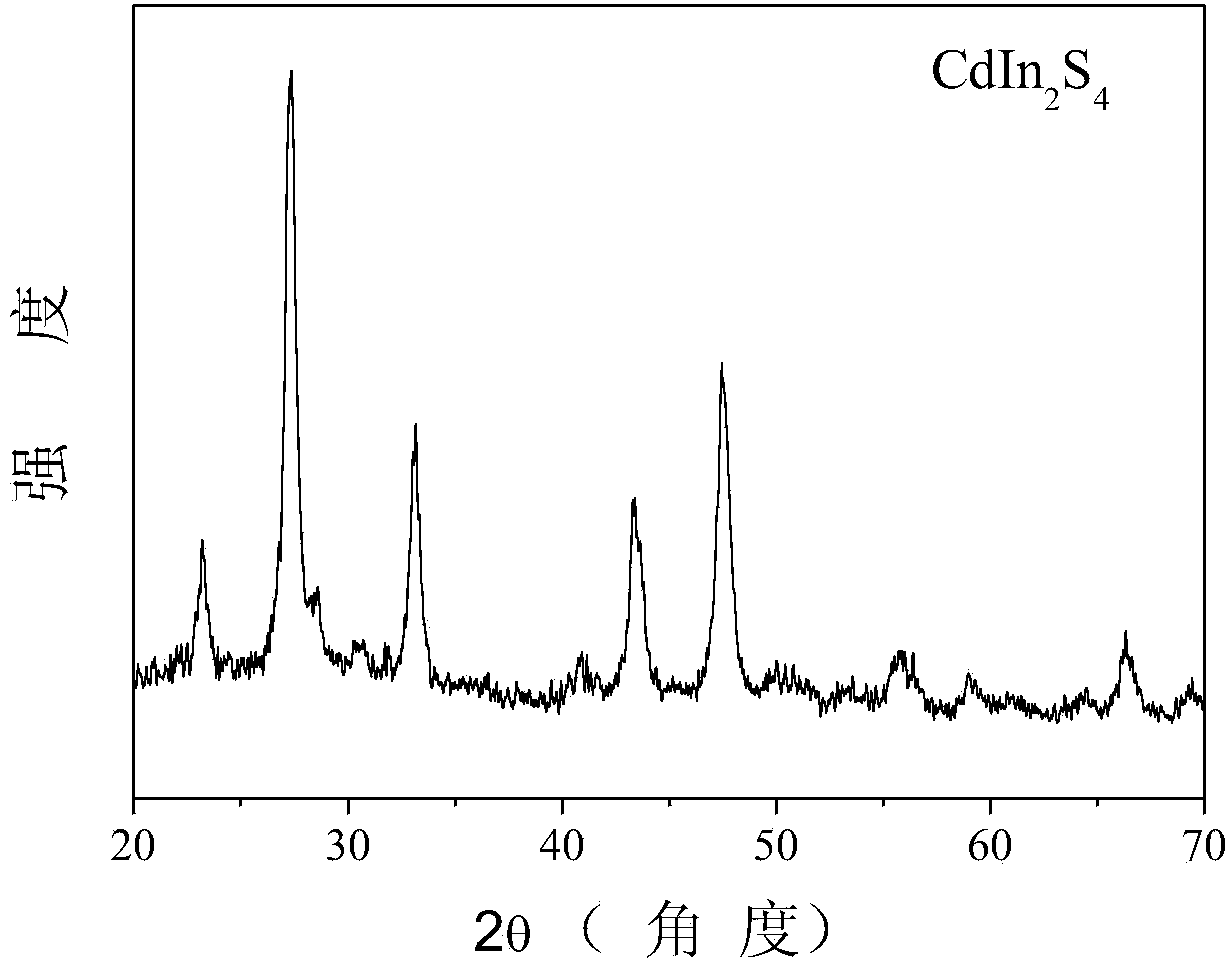

[0047] 0.532 g of cadmium acetate (Cd(AC) 2 (H 2 O) 2 ), 1.172 g of indium chloride (InCl 3 (H 2 O) 4 ) and 0.76 g of thiourea (CH 4 N 2 S ) Dissolve in 150 mL of distilled water and stir until completely dissolved to obtain a transparent reaction precursor; the reaction precursor is atomized under the action of an ultrasonic nebulizer to form an aerosol, and the aerosol is carried into the high-temperature tube by the carrier gas (air). Furnace (800 o C) Reaction; the flow rate of the carrier gas is 10 L / min. After the reaction in the tube furnace, the generated photocatalytic material is collected with distilled water, washed and centrifuged, and placed at 75 o C drying to obtain the metal sulfide semiconductor photocatalytic material CdIn 2 S 4 .

[0048]

Embodiment 2

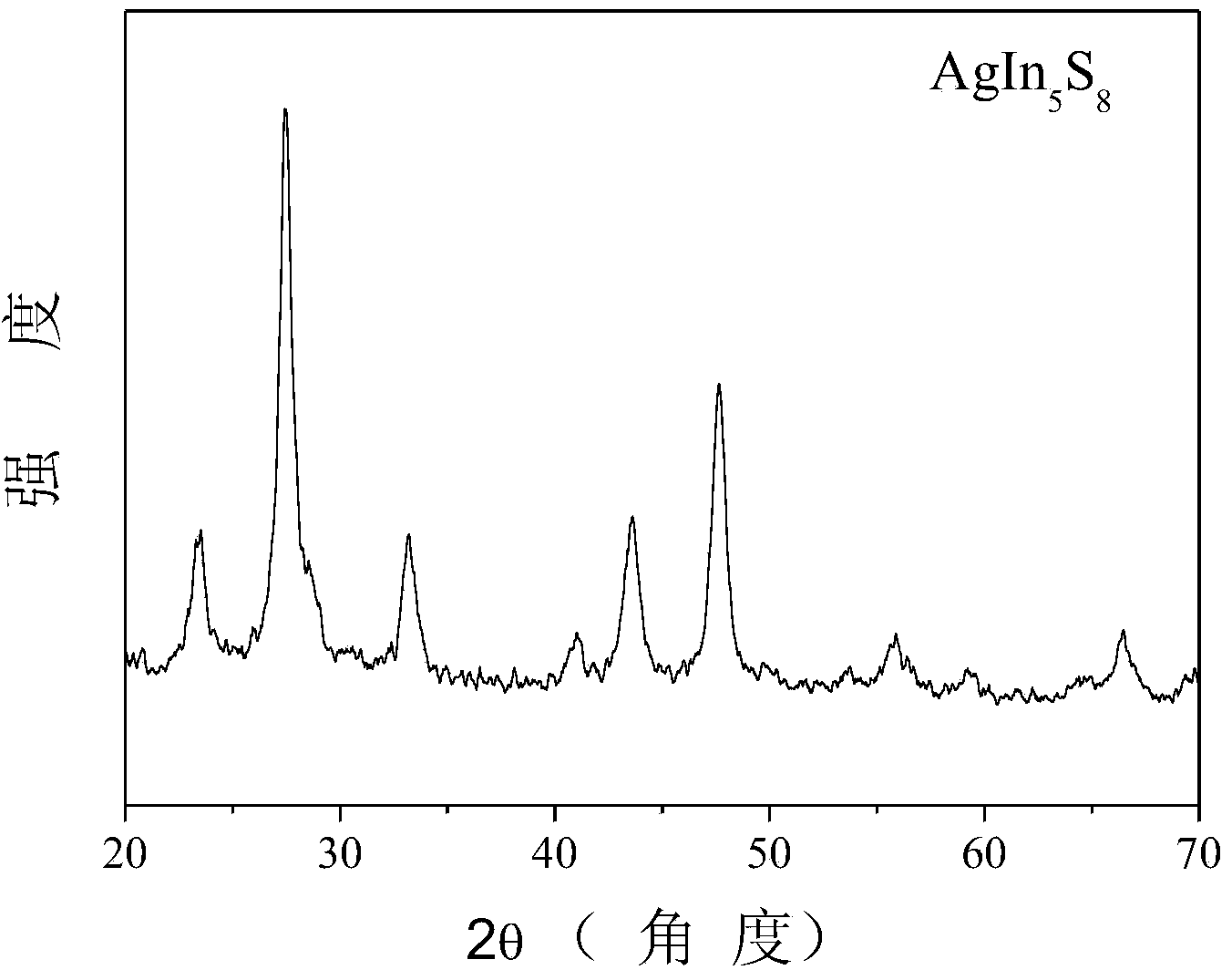

[0050] 0.34 g of silver nitrate (AgNO 3 ), 3.01 g of indium chloride (InCl 3 (H 2 O) 4 ) and 1.60 g of thiourea (CH 4 N 2 S ) Dissolve in 150 mL of distilled water and stir until completely dissolved to obtain a transparent reaction precursor; the reaction precursor is atomized under the action of an ultrasonic nebulizer to form an aerosol, and the aerosol is carried into the high-temperature tube by the carrier gas (air). Furnace (600 o C) Reaction; the flow rate of the carrier gas is 20 L / min. After the reaction in the tube furnace, the generated photocatalytic material is collected with distilled water, washed and centrifuged, and placed at 80 o C is dried to obtain the metal sulfide semiconductor photocatalytic material AgIn 5 S 8 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com