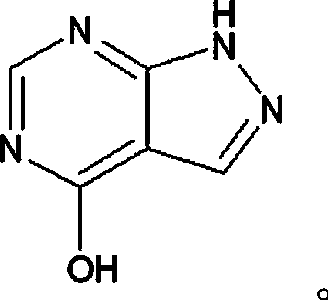

Purification method of allopurinol

A purification method and technology for allopurinol, applied in the field of purification of allopurinol, can solve the problems affecting product yield, quality, sample destruction, and complicated operation, and achieve the advantages of reducing production cost, improving equipment production capacity and simple process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

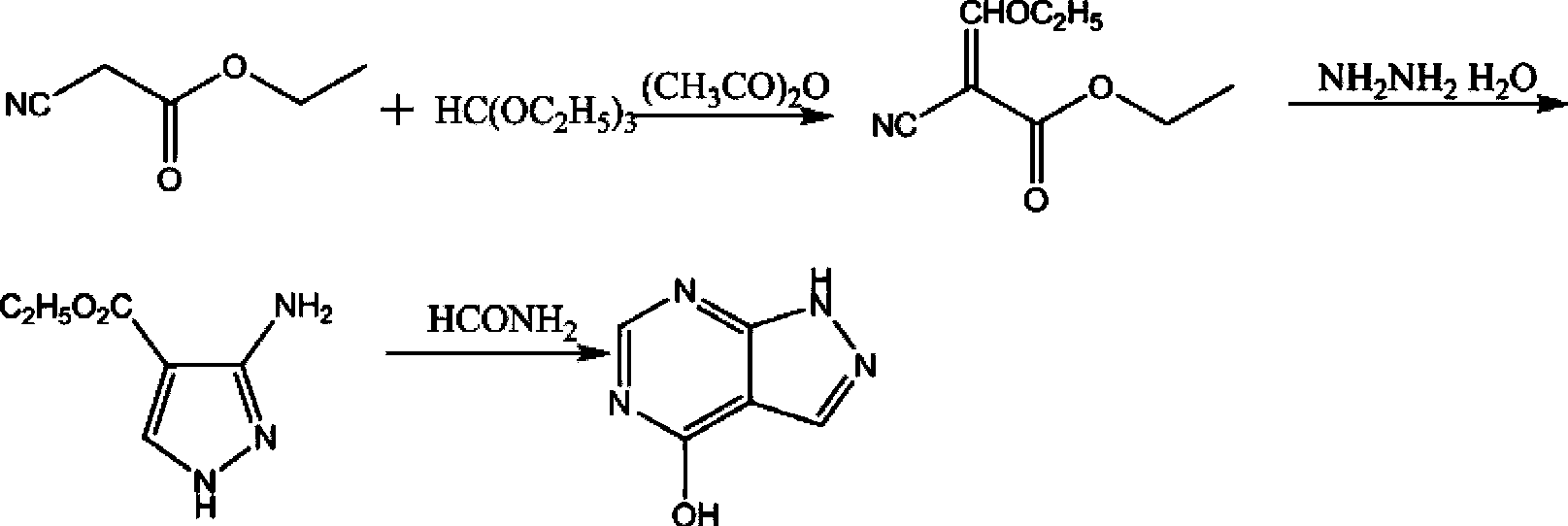

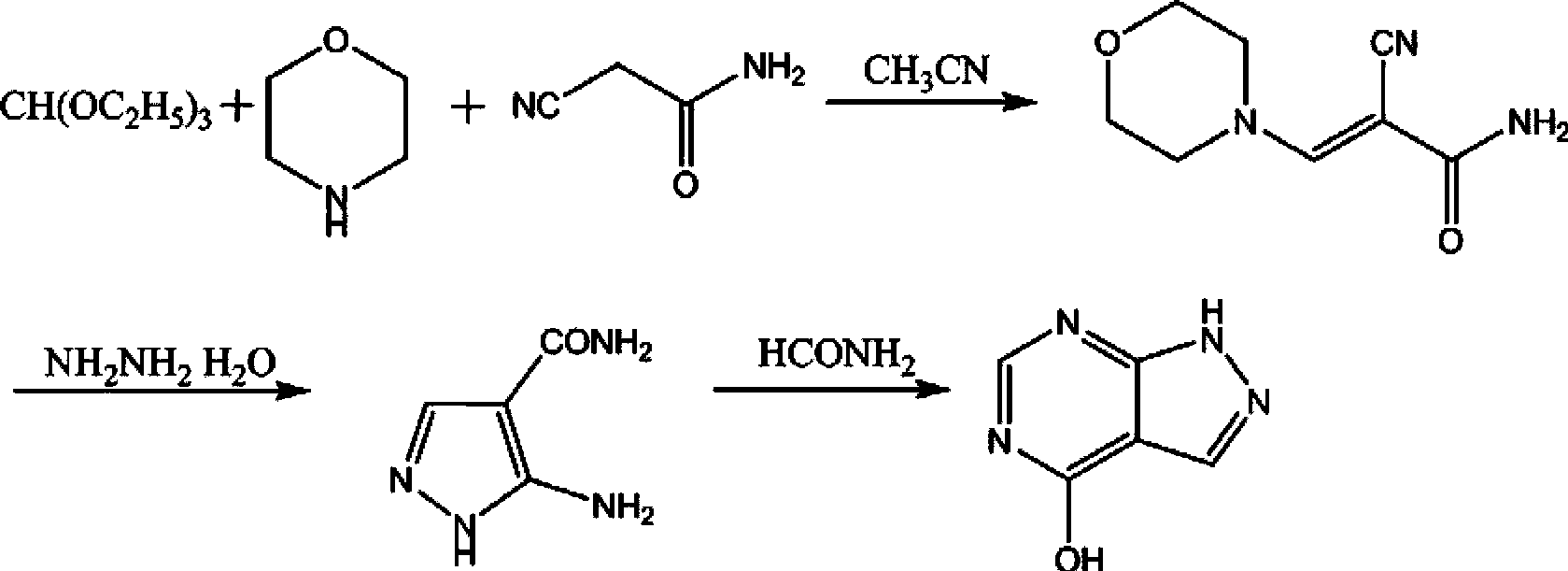

Method used

Image

Examples

Embodiment 1

[0061] Weigh 100g of the crude product of allopurinol, add 2100g of DMF, heat up to 150°C under stirring to dissolve the material, add 5g of activated carbon, decolorize under stirring for 15 minutes, filter while it is hot, and wash the carbon residue with 50g of DMF; cool the filtrate to room temperature, analyze The crystals were filtered out, and the filter cake was washed twice with 30 g of purified water, sucked dry, and dried at 80° C. to obtain 92.8 g of a white crystalline product.

[0062] Experimental results: the purity of the product is 99.979%, and the yield is 92.8%. The content of the largest single impurity is 0.021%, the content of the total impurities is 0.021%, and other indicators are in line with the pharmacopoeia standards.

Embodiment 2

[0064] Weigh 100g of crude allopurinol, add 600g of DMSO, heat up to 150°C under stirring, dissolve the material, add 5g of activated carbon, decolorize under stirring for 15 minutes, filter while hot, wash the carbon residue with 50g of DMSO, cool the filtrate to room temperature, and crystallize , the crystals were filtered out, and the filter cake was washed twice with 30 g of purified water, sucked dry, and dried at 80° C. to obtain 89.6 g of a white crystalline product.

[0065] Experimental results: the purity of the product is 99.919%, and the yield is 89.6%. The content of the largest single impurity is 0.068%, the content of the total impurity is 0.081%, and other items are in line with the pharmacopoeia standards.

Embodiment 3

[0067] Weigh 100g of crude allopurinol, add 2500g of ethylene glycol, heat up to 150°C under stirring, and dissolve the material, add 10g of activated carbon, decolorize under stirring for 15 minutes, filter while hot, wash the carbon residue with 50g of ethylene glycol, and cool the filtrate Bring to room temperature, crystallize, and filter out the crystals. The filter cake was washed with 30 g of purified water for three times, sucked dry, and dried at 80° C. to obtain 88.2 g of off-white crystalline product.

[0068] Experimental results: the purity of the product is 99.875%, and the yield is 88.2%. The content of the largest single impurity is 0.087%, the content of the total impurities is 0.125%, and other indicators are in line with the pharmacopoeia standards.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com