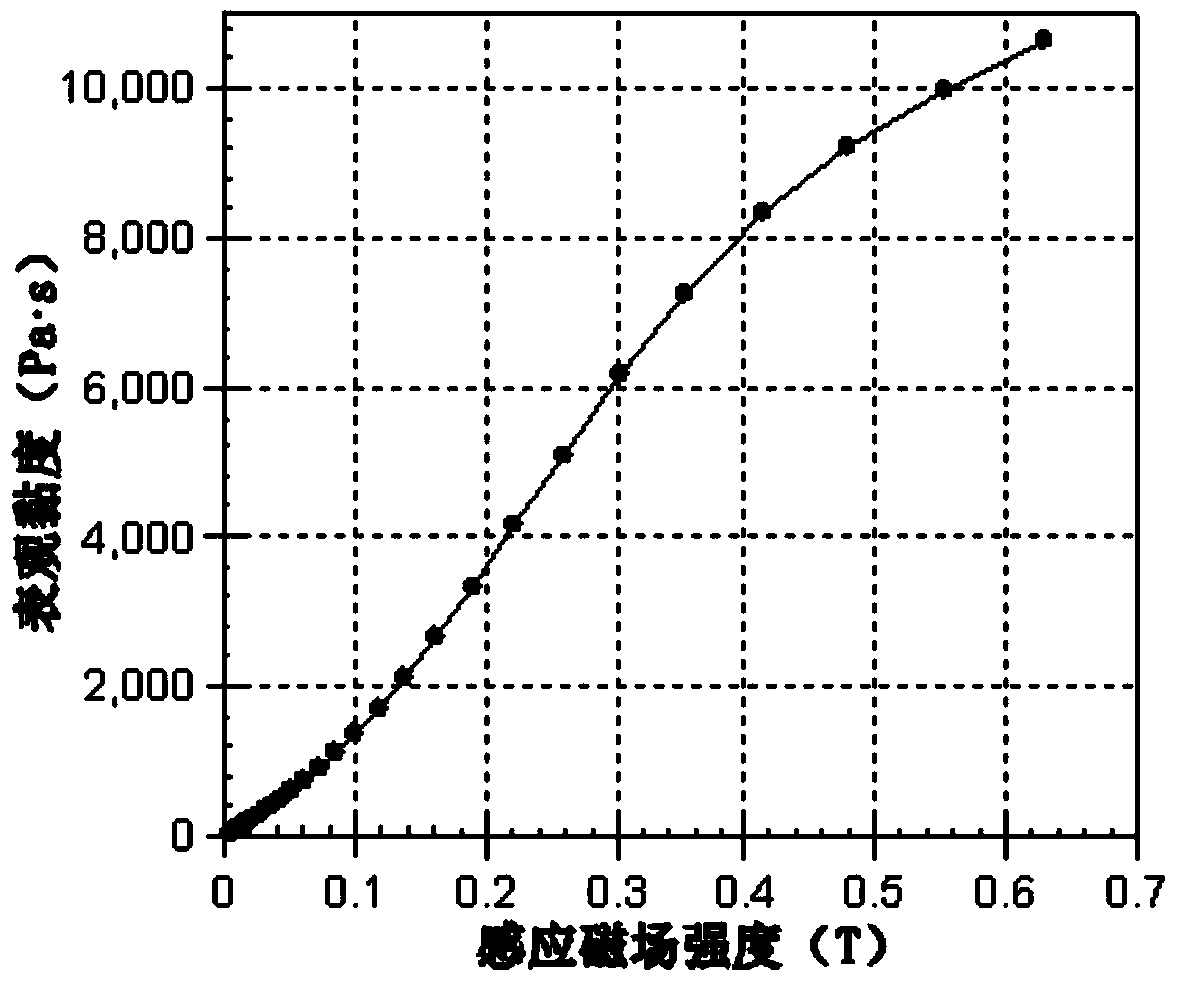

Magnetorheological fluid comprising macromolecular composite magnetic powder and preparation method thereof

A composite magnetic and magnetorheological fluid technology, applied in the direction of lubricating compositions, etc., can solve the problems of magnetorheological fluids such as easy sedimentation, and achieve low equipment requirements, wide range of zero-field viscosity and saturated shear viscosity, and simple operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] (1) Under stirring conditions, dissolve 1g of polyethersulfone in 20g of N,N-dimethylformamide, stir up the liquid with a pick knife after 12 hours, and drop the liquid into drops to obtain a polyethersulfone solution; under stirring conditions Next, 10g of iron powder is added to the polyethersulfone solution, and the stirring rate is 2000r / min to suspend it; then, the polyethersulfone is evenly coated on the surface of the magnetic powder by solvent evaporation and drying, and the obtained The composite magnetic powder coated with polyethersulfone was washed and filtered with distilled water and absolute ethanol for 3 times, and subjected to magnetic field separation; vacuum-dried at 50°C for 24 hours, and ground to obtain polyethersulfone composite magnetic powder;

[0029] (2) Add 0.1g of nano-silica with a particle size of 15±5nm to 6g of silicone oil with a viscosity of 100±8mPa·s and stir for 2 hours to fully disperse it into the silicone oil with a viscosity of 1...

Embodiment 2

[0032] (1) Replace 1g polyethersulfone with 1g polyarylethersulfone, replace 5g iron powder with 5g carbonyl iron powder, replace 20g N,N-dimethylformamide with 30g chloroform, stir at 3000r / min, repeat Example 1 (1) to obtain polyarylethersulfone composite magnetic powder;

[0033] (2) Add 0.1g of nano-silica with a particle size of 15±5nm to 6g of silicone oil with a viscosity of 100±8mPa·s and stir for 2 hours to fully disperse it into the silicone oil with a viscosity of 100±8mPa·s. The higher the stirring rate, the better, to obtain a mixed carrier liquid; add the 4g polyarylether sulfone composite magnetic powder to the mixed carrier liquid, ultrasonically disperse for 6 hours and then stir for 12 hours to obtain a polyarylether sulfone composite magnetic powder Body magnetorheological fluid.

Embodiment 3

[0035] (1) Replace 1g polyethersulfone with 2g polyetherimide, replace 20g N,N-dimethylformamide with 40g N,N-dimethylformamide, replace 10g iron powder with 4g ferric oxide, The stirring rate was 2500r / min, and (1) in Example 1 was repeated to obtain polyetherimide composite magnetic powder;

[0036] (2) Add 0.05g of nano-silica with a particle size of 15±5nm to 6g of silicone oil with a viscosity of 100±8mPa·s and stir for 2 hours to fully disperse it into the silicone oil with a viscosity of 100±8mPa·s. The higher the stirring rate, the better, to obtain a mixed carrier liquid; add the 4g polyetherimide composite magnetic powder into the mixed carrier liquid, ultrasonically disperse for 6 hours, and then stir for 12 hours to obtain a polyetherimide composite magnetic powder. Magnetorheological fluid for magnetic powder.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com