Use of isopropyl acetate as leaching solvent in leaching vegetable oil and method for leaching oil using it

A technology of isopropyl acetate and vegetable oil, which is applied in the direction of fat oil/fat production and fat generation, can solve the problems of insufficient attention to toxicity, lack of understanding, and large loss of ethanol solvent, so as to achieve stable supply and quality, prolong service life, The effect of increasing business efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

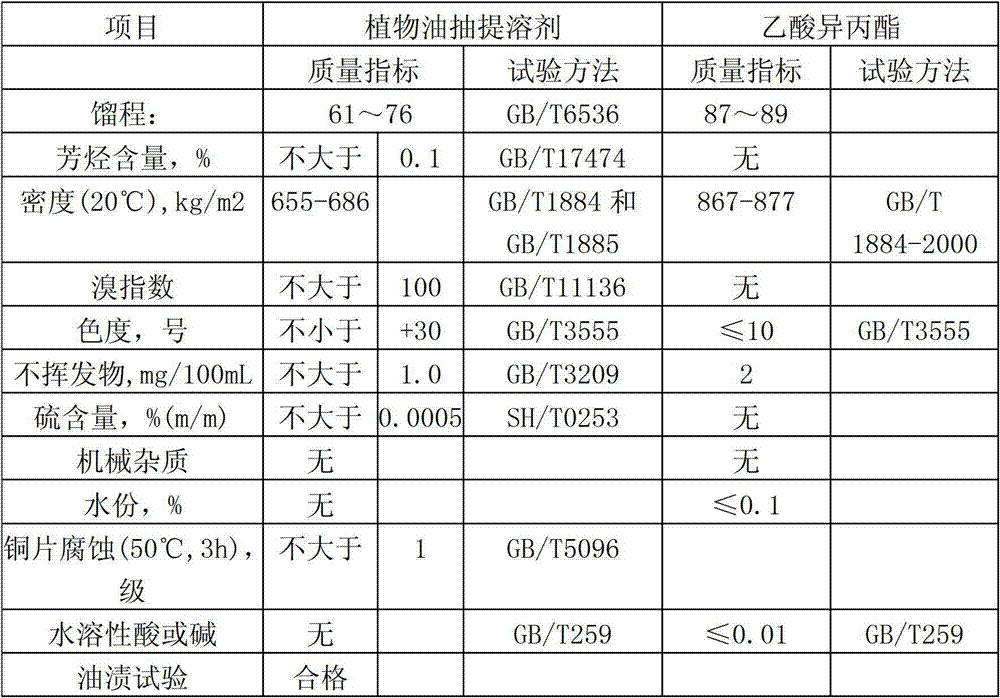

Image

Examples

Embodiment 1

[0055] Example 1 (comparative example)

[0056] Soybean is selected as the oil, and the vegetable oil extraction solvent is the extraction solvent to extract soybean oil. The process is as follows:

[0057] The raw soybeans are cleaned, dried, crushed and peeled, and then heated to 78°C to soften and bind the billet. The thickness of the billet is about 0.3mm; the prepared billet is leached in a flat rotary extractor with vegetable oil extraction solvent , The solvent and the material embryo are in countercurrent contact with immersion and spray mixing. The ratio of the leaching solvent to the oil is 0.8:1 by weight; the leaching time is 60min; the temperature is 78℃, filtered and separated to obtain 30wt% mixed oil and solvent content It is 35wt% wet meal. A high-temperature desolventization process is used to desolve the wet meal, and the residual oil content of the meal is about 0.8wt% after the desolventizing process. Pass the mixed oil into an evaporator for evaporation, the...

Embodiment 2

[0059] Soybean is used as oil and isopropyl acetate is used as extraction solvent to extract soybean oil. The process is as follows:

[0060] The raw soybeans are cleaned, dried, crushed and peeled, and then heated to 78°C to soften and roll the billet. The thickness of the billet is about 0.3mm; the prepared billet is leached in a flat-rotating extractor with isopropyl acetate , The solvent and the raw material are contacted by immersion, spray mixing and countercurrent flow. The ratio of the leaching solvent to the oil is 0.8:1 by weight; the leaching time is 60min; the temperature is 78℃, filtered and separated to obtain 48wt% mixed oil and solvent content It is 30wt% wet meal. A high-temperature desolventization process is used to desolve the wet meal, and the residual oil content of the meal after desolventizing is about 0.6wt%. The mixed oil is passed into an evaporator for evaporation, the outlet solvent gas temperature is 88°C; the once-evaporated mixed oil is re-evapora...

Embodiment 3

[0062] Using peanut as the oil and isopropyl acetate as the extraction solvent to extract peanut oil, the process is as follows:

[0063] The raw peanuts are cleaned, dried, crushed and peeled, and then heated to 74°C to soften and roll the billet. The thickness of the billet is about 0.3mm; then the oil billet is heated to 120°C for extruding and puffing, and it is heated by a dryer. Dry the preform to 3% moisture at 75°C; use isopropyl acetate to leaching the prepared preform in a flat-rotation extractor. The solvent and the preform are in countercurrent contact with immersion and spray mixing. The oil-to-feed ratio is 0.4:1 by weight; the leaching time is 80min; the temperature is 85°C to obtain 49% mixed oil and 25% solvent content wet meal. A high-temperature desolventization process is used to desolve the wet meal, and the residual oil content of the meal after desolventizing is about 0.6wt%. The mixed oil is passed into an evaporator for evaporation, the outlet solvent ga...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| flash point | aaaaa | aaaaa |

| flash point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com