Method and device for the preparation of a sample for microstructure diagnostics

A microstructure and sample technology, applied in the preparation of test samples, discharge tubes, electrical components, etc., can solve problems such as inability to penetrate into bulk materials, damage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

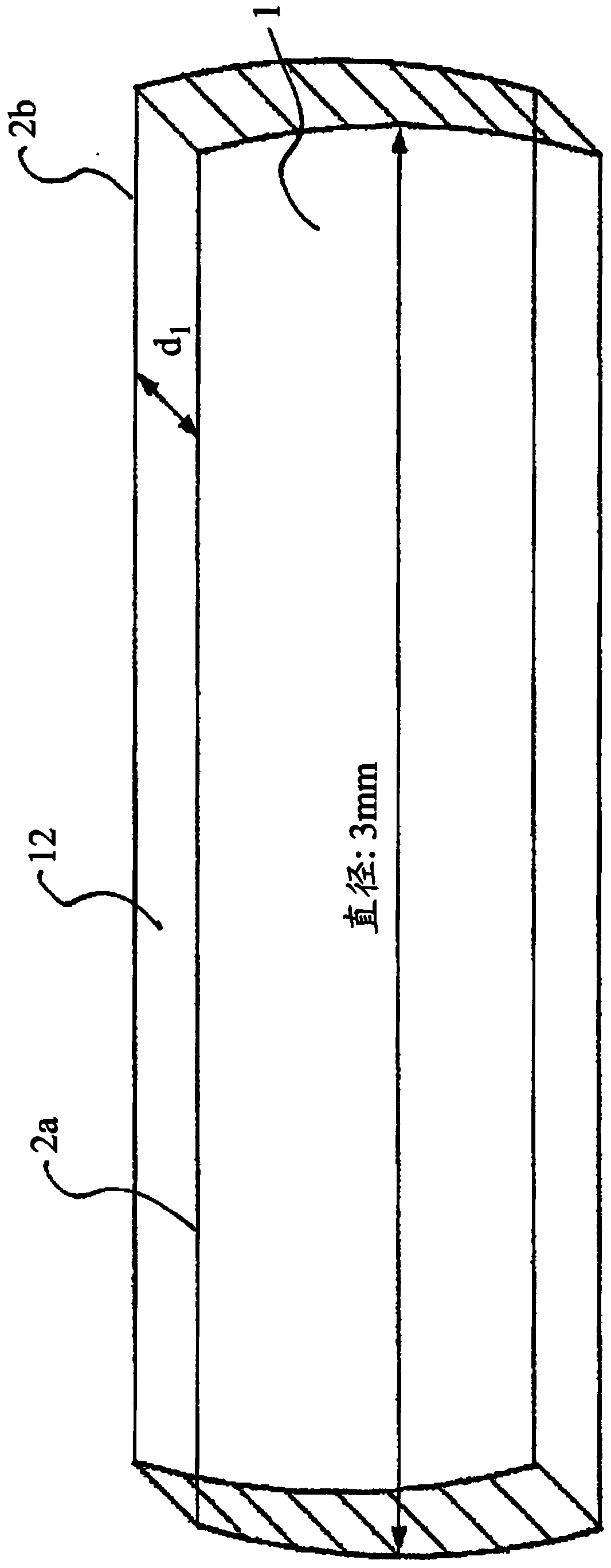

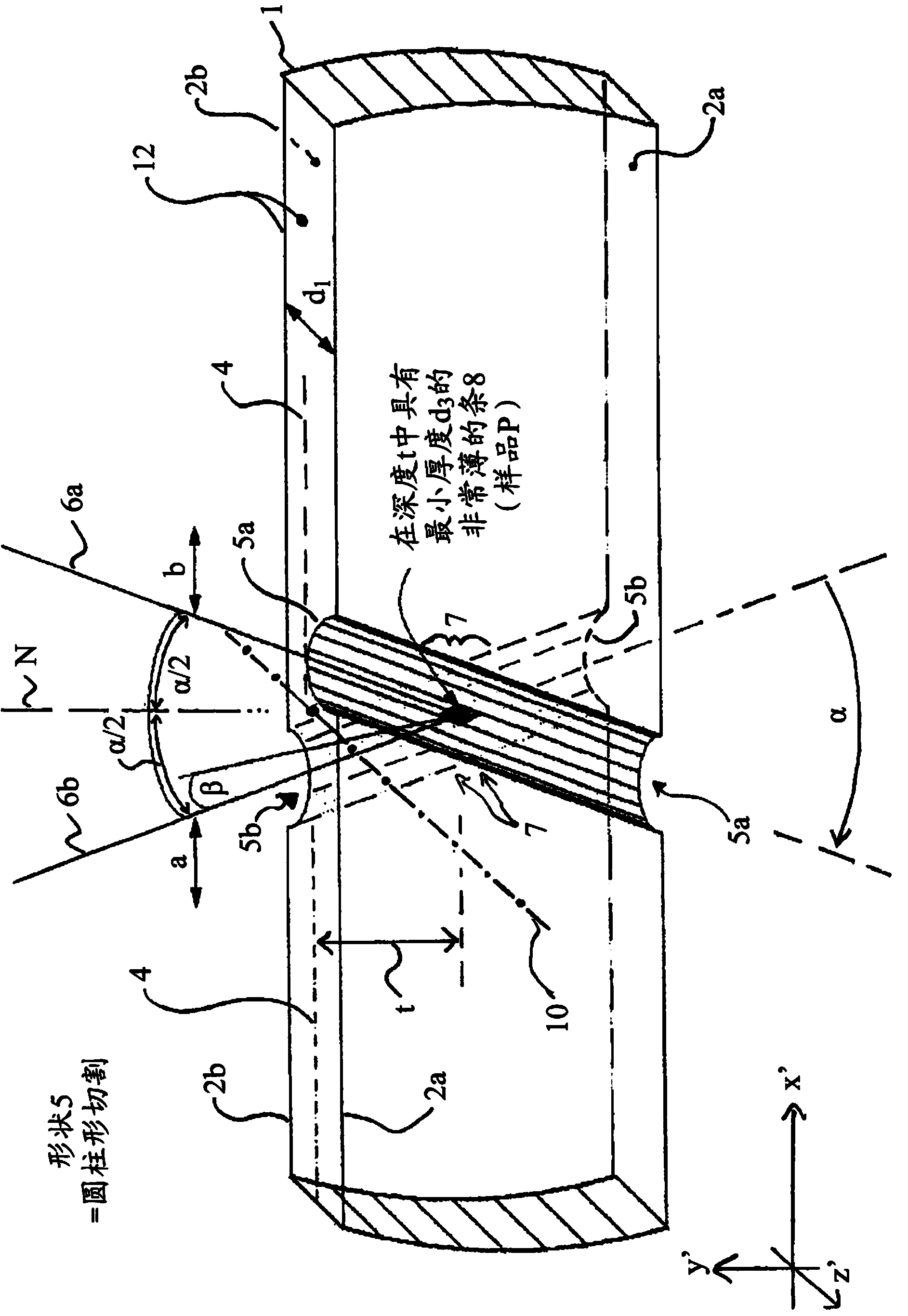

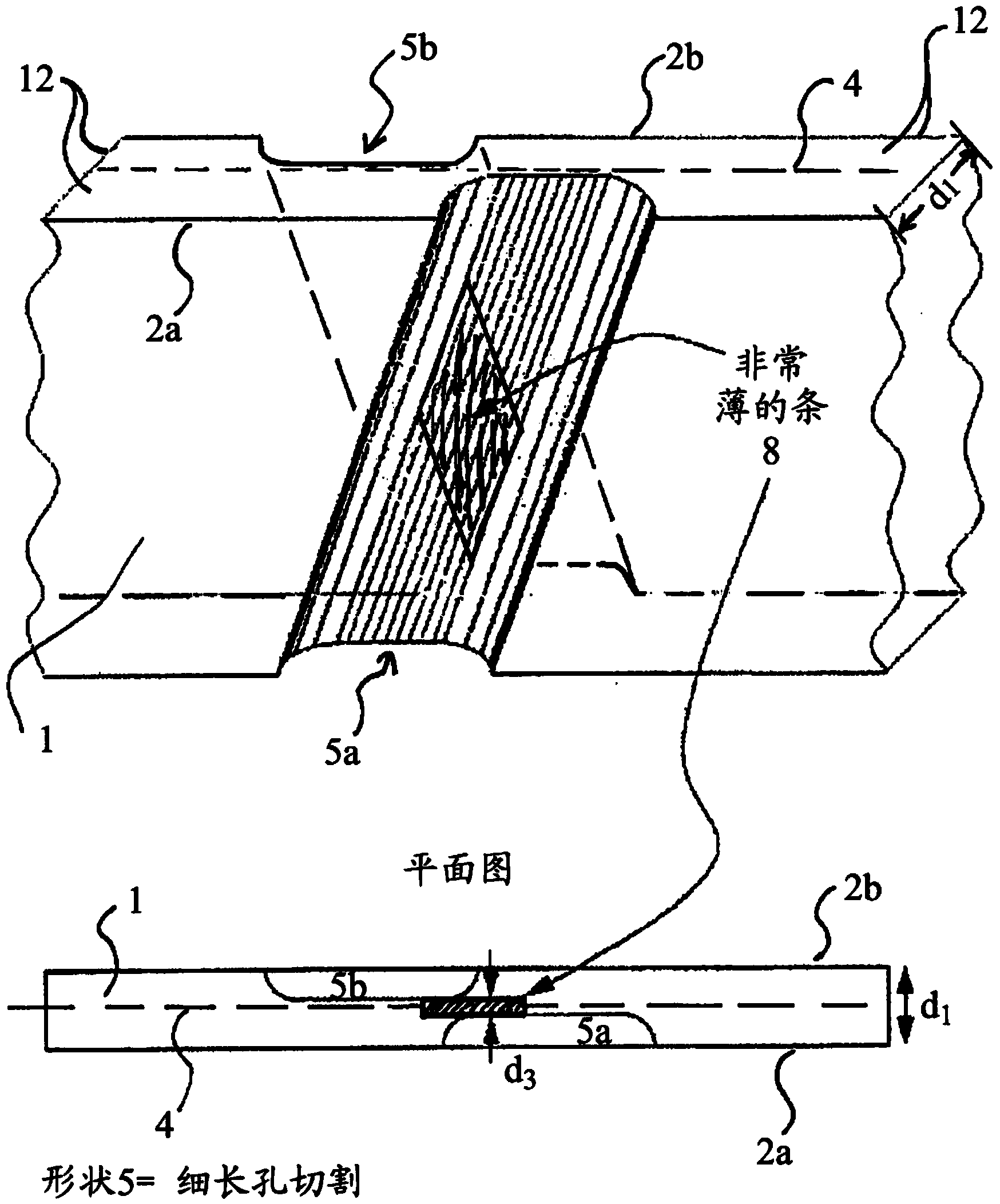

[0048] figure 1 Shown is a disc 1 which is thinned to a thickness d of 100 μm in an extensive plane-parallel manner as a starting basis for the method according to the invention 1 . Produced using mechanical grinding, laser etching or plasma spark erosion or other processing techniques known from the prior art, the disc is fabricated so that it can be accommodated in a standard TEM holder due to its diameter of 3 mm middle. Dimensioning of the disk 1 to a diameter of 3 mm can also be easily achieved with a laser micromachining system which is also used for the introduction of the depressions according to the invention (see for example DE 10 2008 000 306 A1 or Figure 4 ). Here, the surface of the disc oriented towards the viewer is denoted by 2a and the back side of the disc oriented away from the viewer is denoted by reference numeral 2b. In both surfaces, as described in more detail below, recesses are constructed internally. For better illustration, the disc 1 is only ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com