Patents

Literature

398 results about "Radiation induced" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Radiation-induced vasculopathy is caused by radiation treatment for another condition such as a brain tumor. The radiation causes the affected blood vessels to narrow and this limits the blood flow to the area. Therefore, patients who have had radiation treatment are at an increased risk of developing the condition.

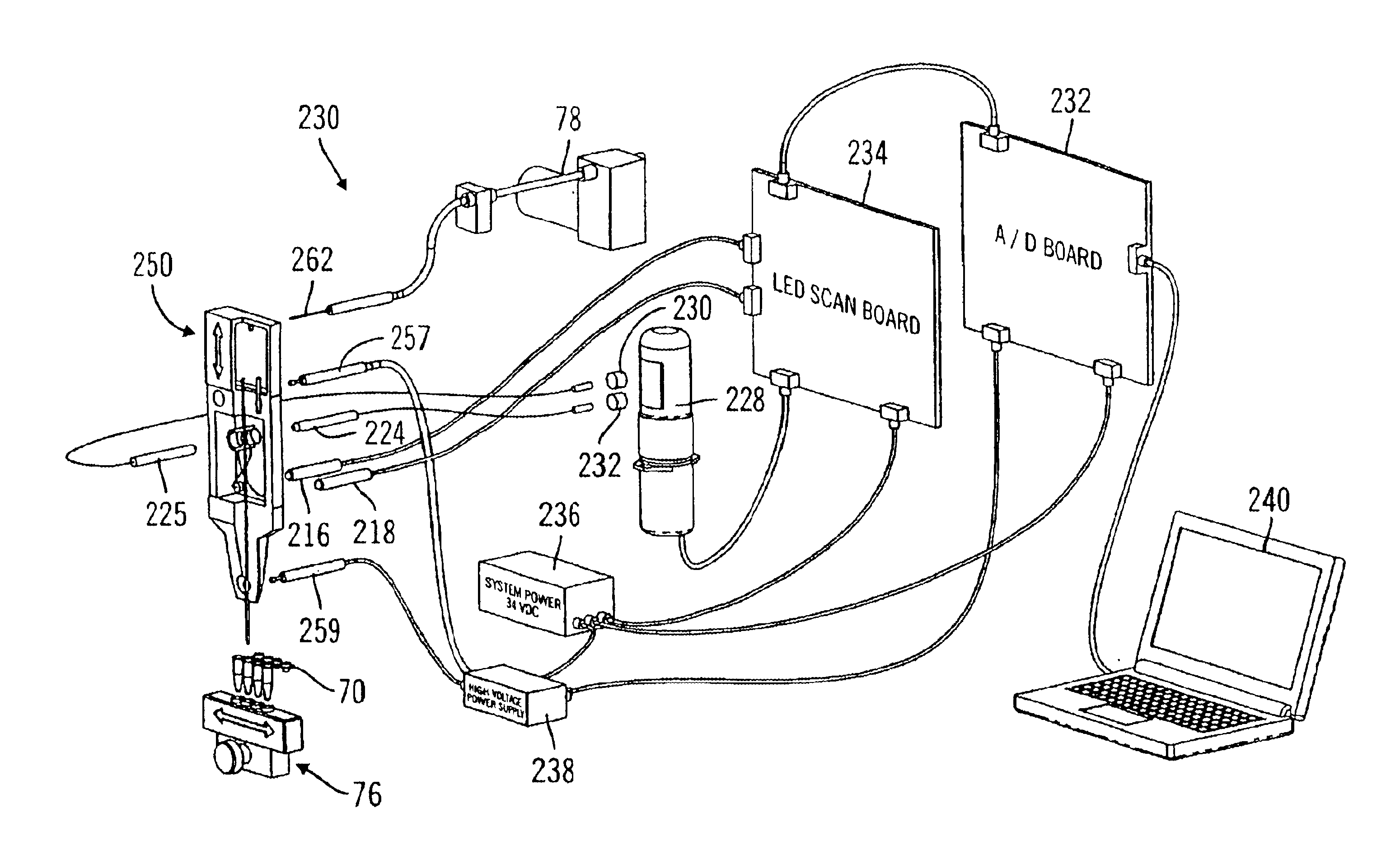

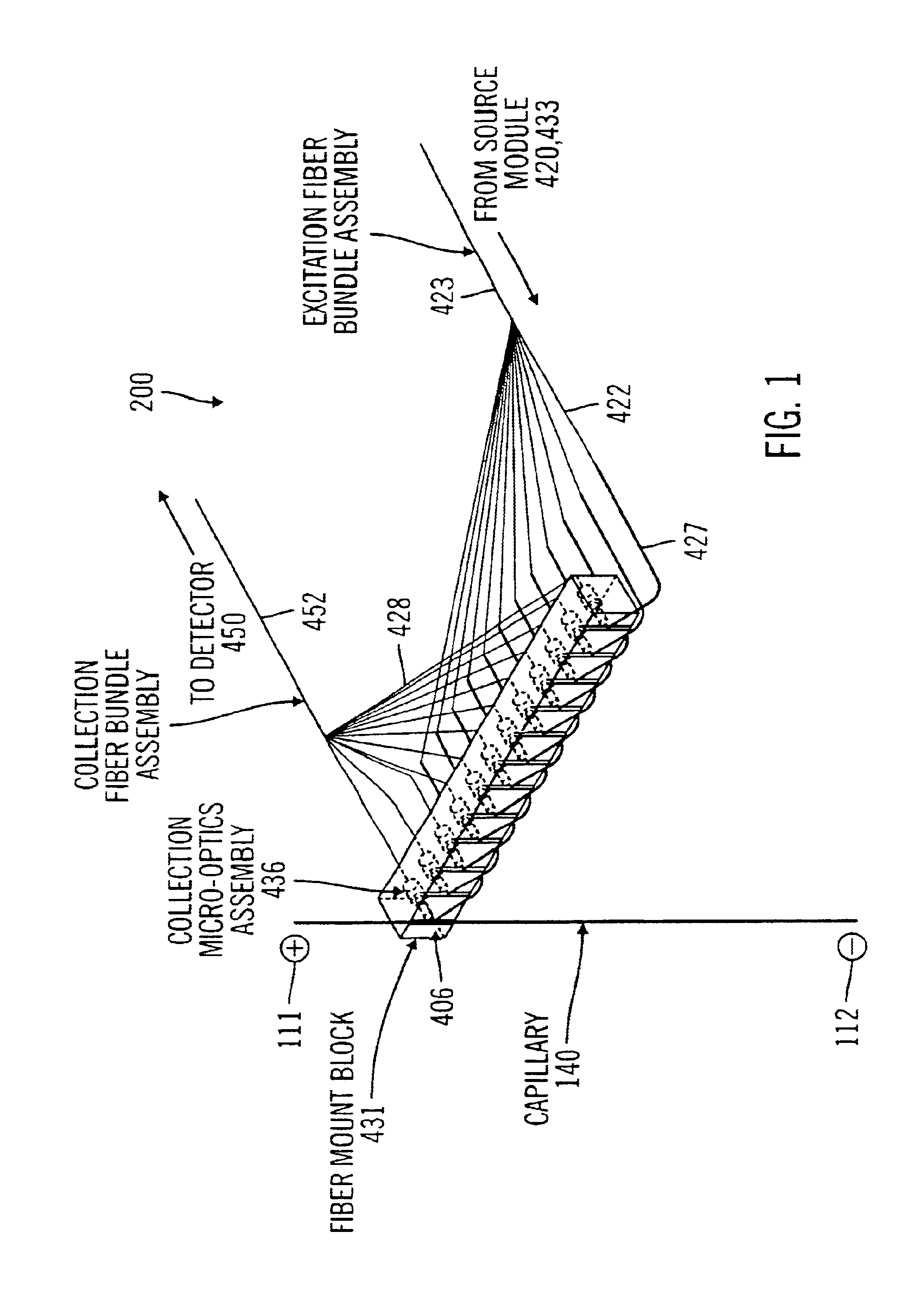

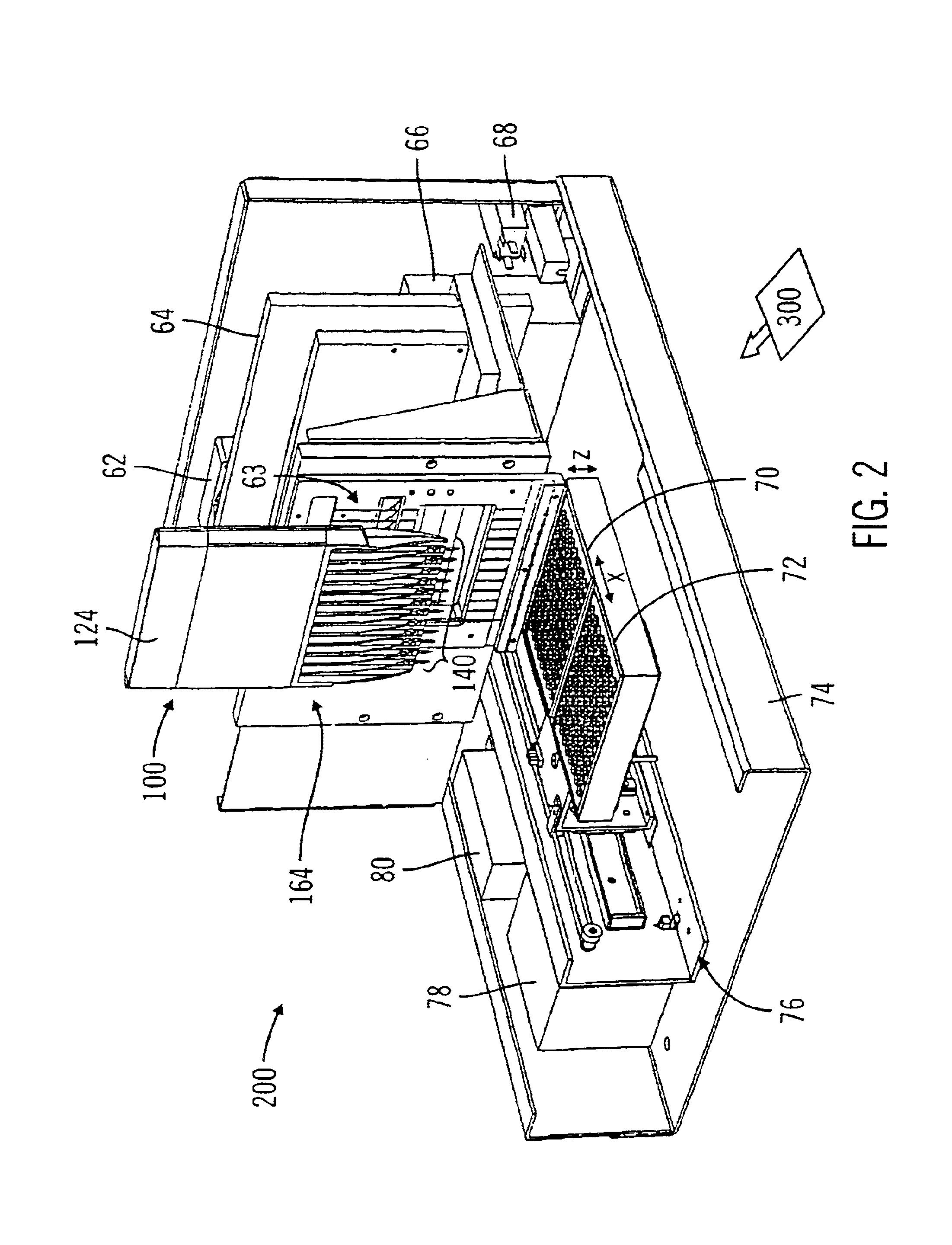

Multi-color multiplexed analysis in a bio-separation system

InactiveUS6870165B2Low costSensitive highOptical radiation measurementSludge treatmentCapillary electrophoresisFluorescence

A multi-channel and multi-color bio-separation detection method and apparatus in which a single detector is coupled to a plurality of radiation sources, in a one detector / many radiation sources configuration. Each radiation source directs radiation at a detection zone of a single separation channel, and a single detector is applied to detect light emissions from the detection zones associated with several radiation sources. The radiation sources are activated to direct radiation at the detection zone in a predetermined sequence and further in a cyclic manner, with the detector output synchronized to the radiation sources by a controller. Bio-separation may be conducted simultaneously in all the channels in parallel, with detection time-staggered and / or time multiplexed with respect to the light sources. In one embodiment, low cost light emitting diodes may be used as radiation sources. In another aspect, the detection scheme is configured for radiation induced fluorescence detection in an capillary electrophoresis instrument.

Owner:QIAGEN SCIENCES LLC

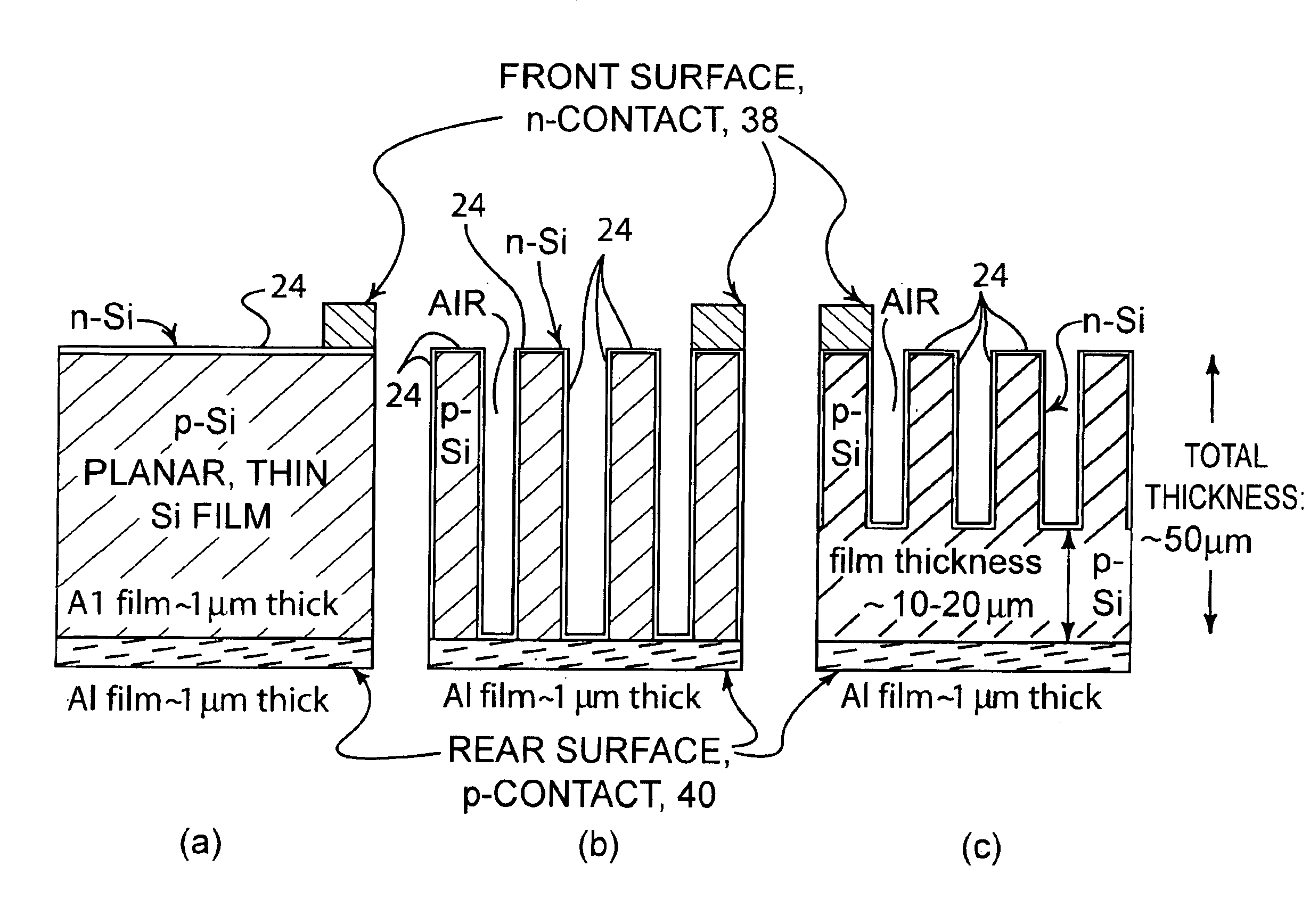

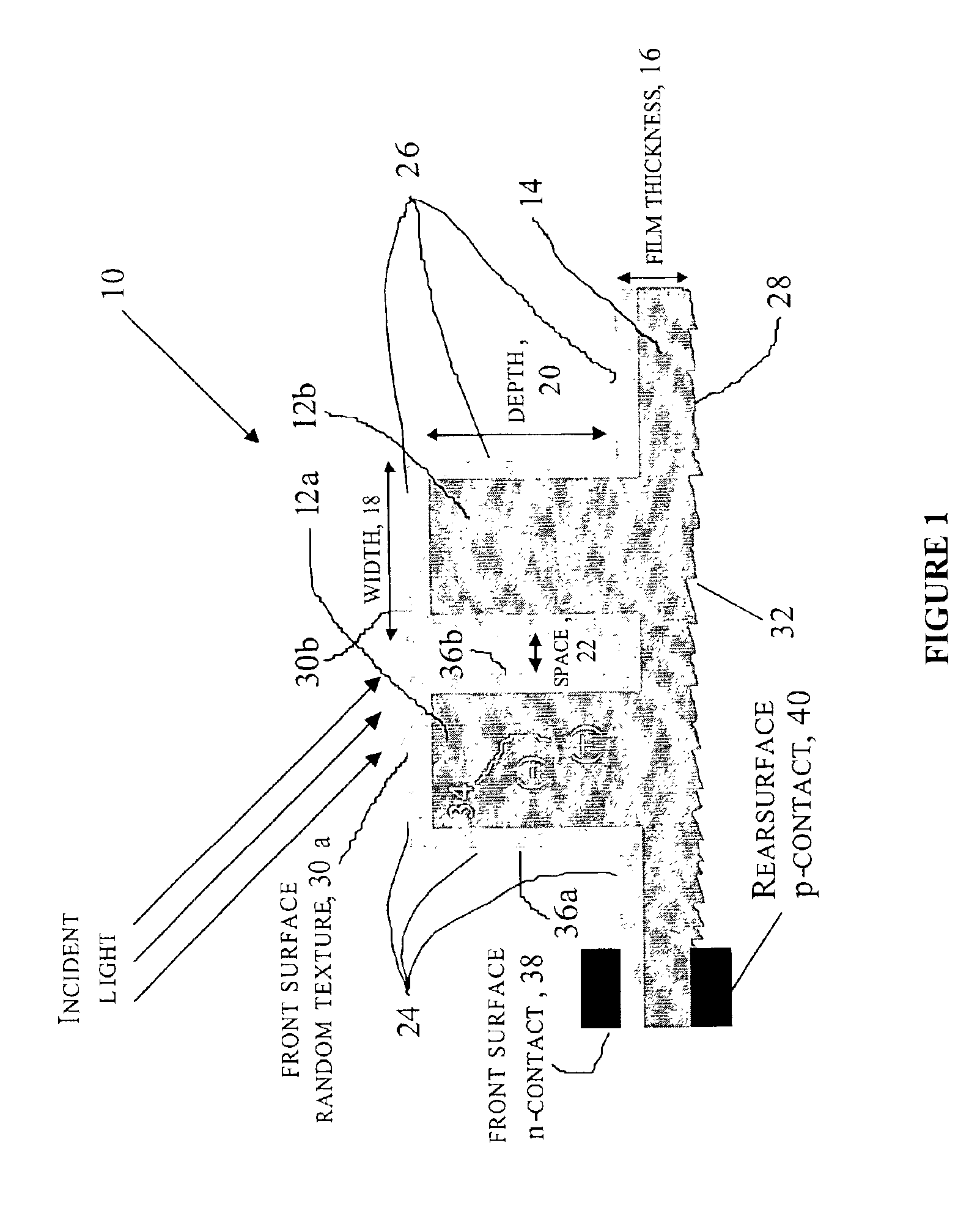

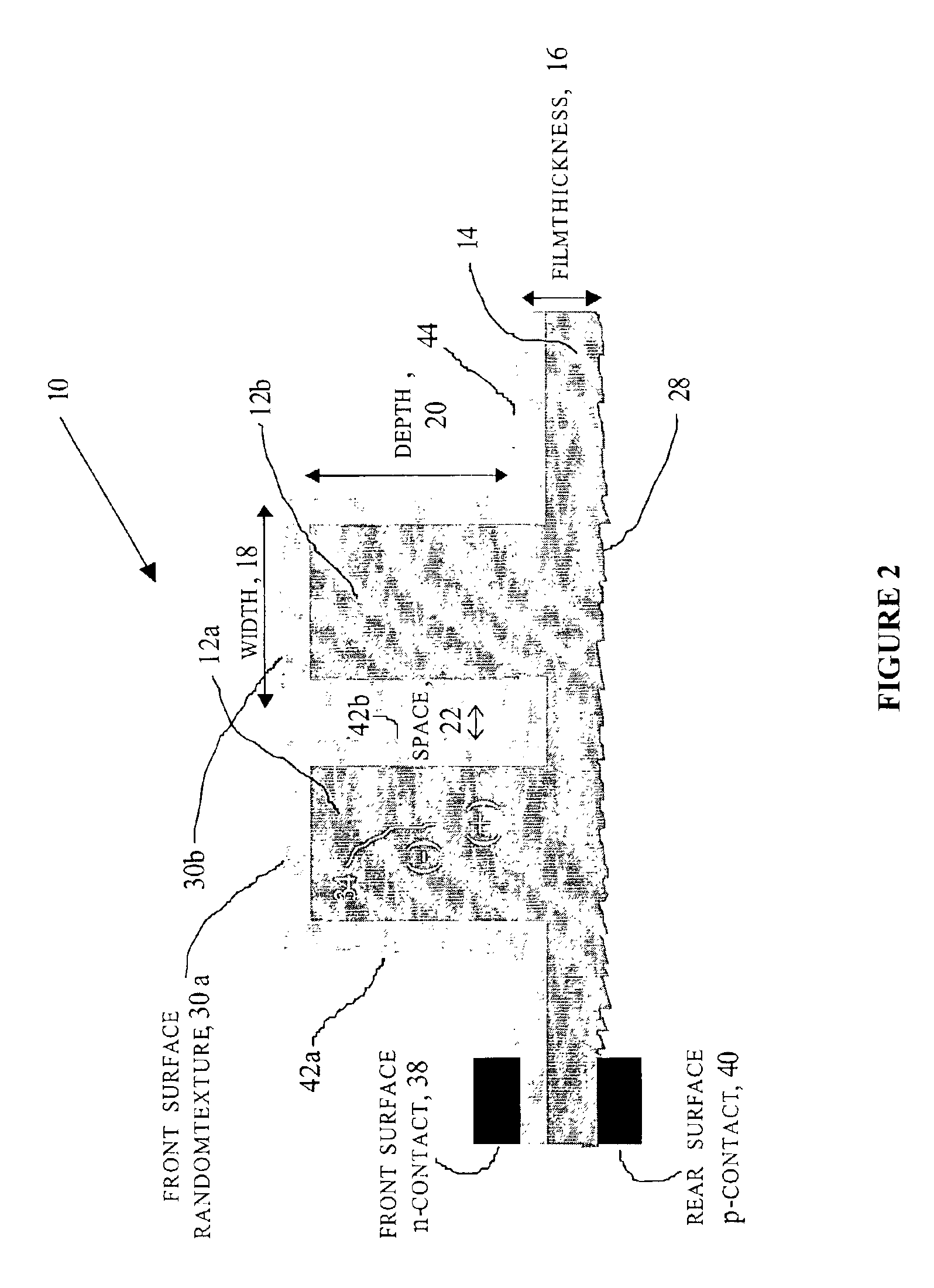

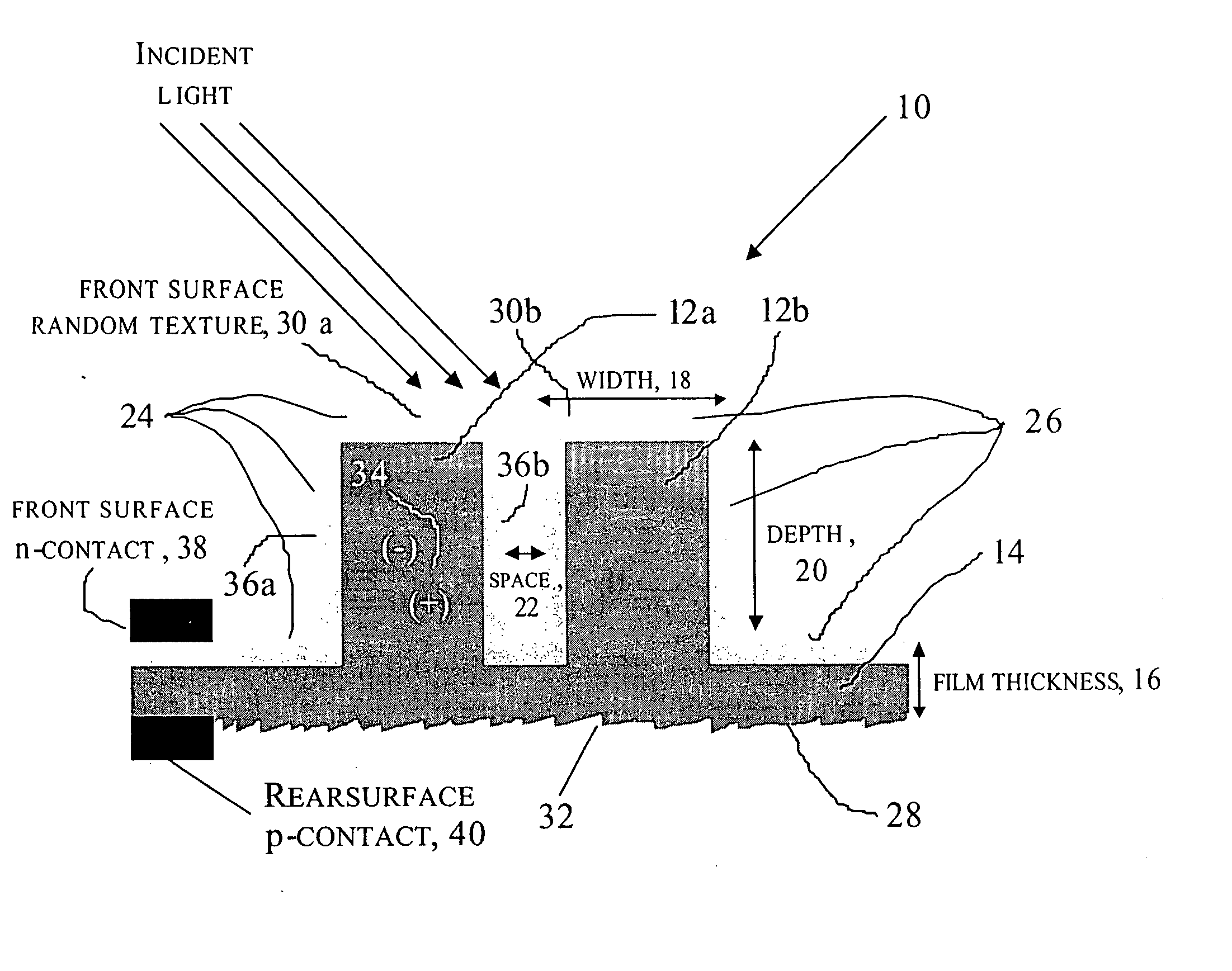

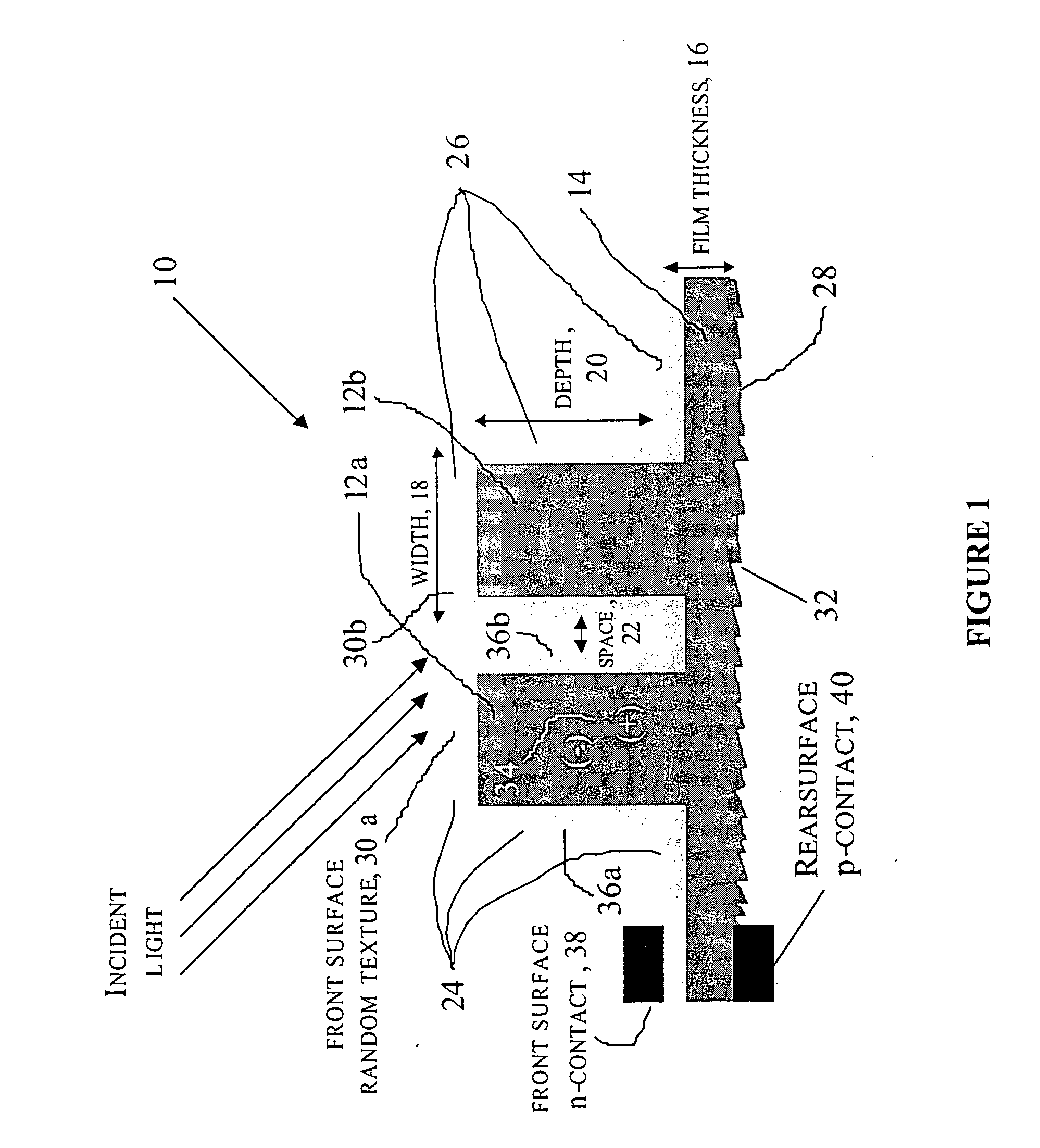

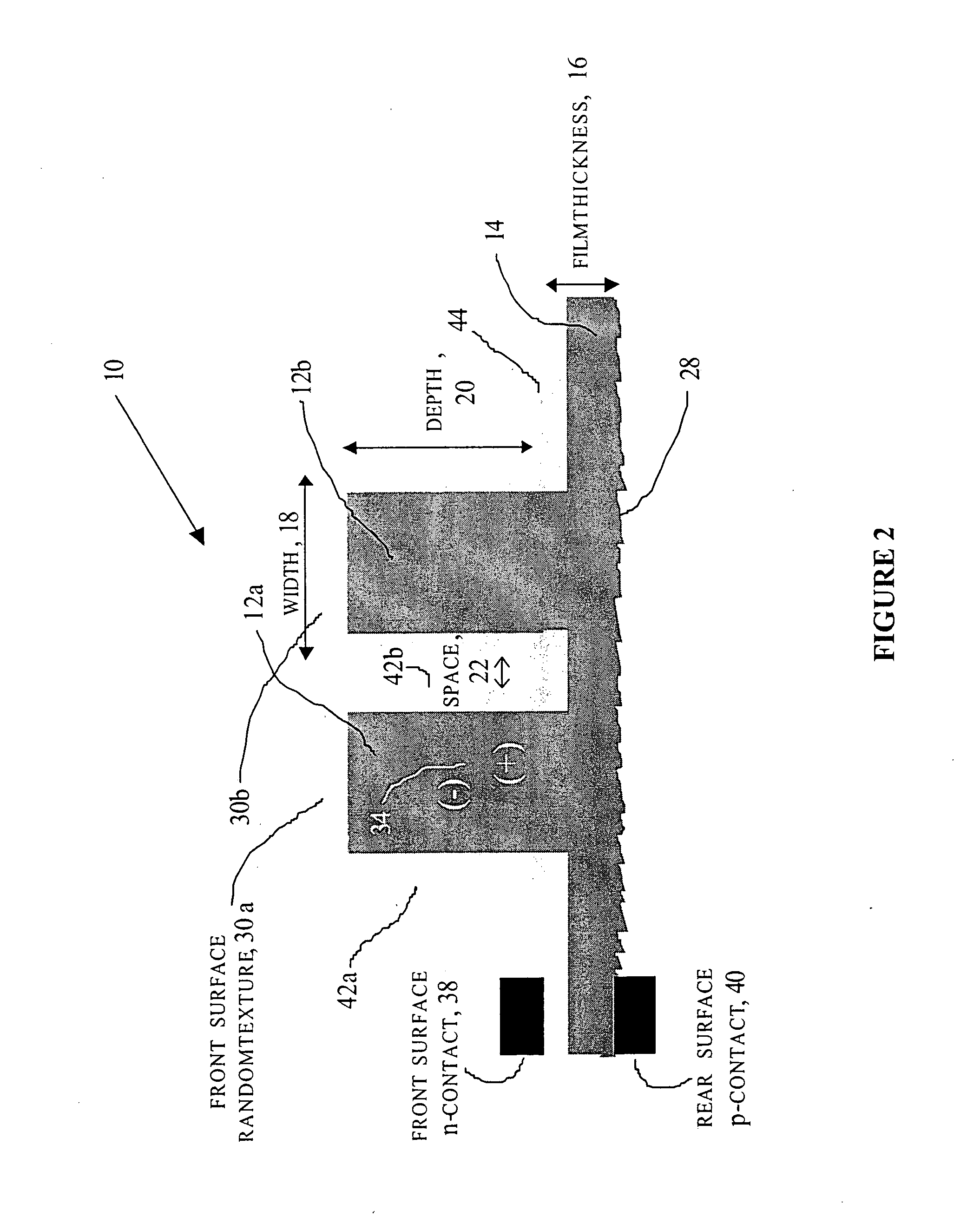

Method of making an enhanced optical absorption and radiation tolerance in thin-film solar cells and photodetectors

InactiveUS7109517B2Promote absorptionImprove toleranceFinal product manufacturePhotoelectric discharge tubesDiffraction orderPhotodetector

Subwavelength random and periodic microscopic structures are used to enhance light absorption and tolerance for ionizing radiation damage of thin film and photodetectors. Diffractive front surface microscopic structures scatter light into oblique propagating higher diffraction orders that are effectively trapped within the volume of the photovoltaic material. For subwavelength periodic microscopic structures etched through the majority of the material, enhanced absorption is due to waveguide effect perpendicular to the surface thereof. Enhanced radiation tolerance of the structures of the present invention is due to closely spaced, vertical sidewall junctions that capture a majority of deeply generated electron-hole pairs before they are lost to recombination. The separation of these vertical sidewall junctions is much smaller than the minority carrier diffusion lengths even after radiation-induced degradation. The effective light trapping of the structures of the invention compensates for the significant removal of photovoltaic material and substantially reduces the weight thereof for space applications.

Owner:ZAIDI SALEEM H

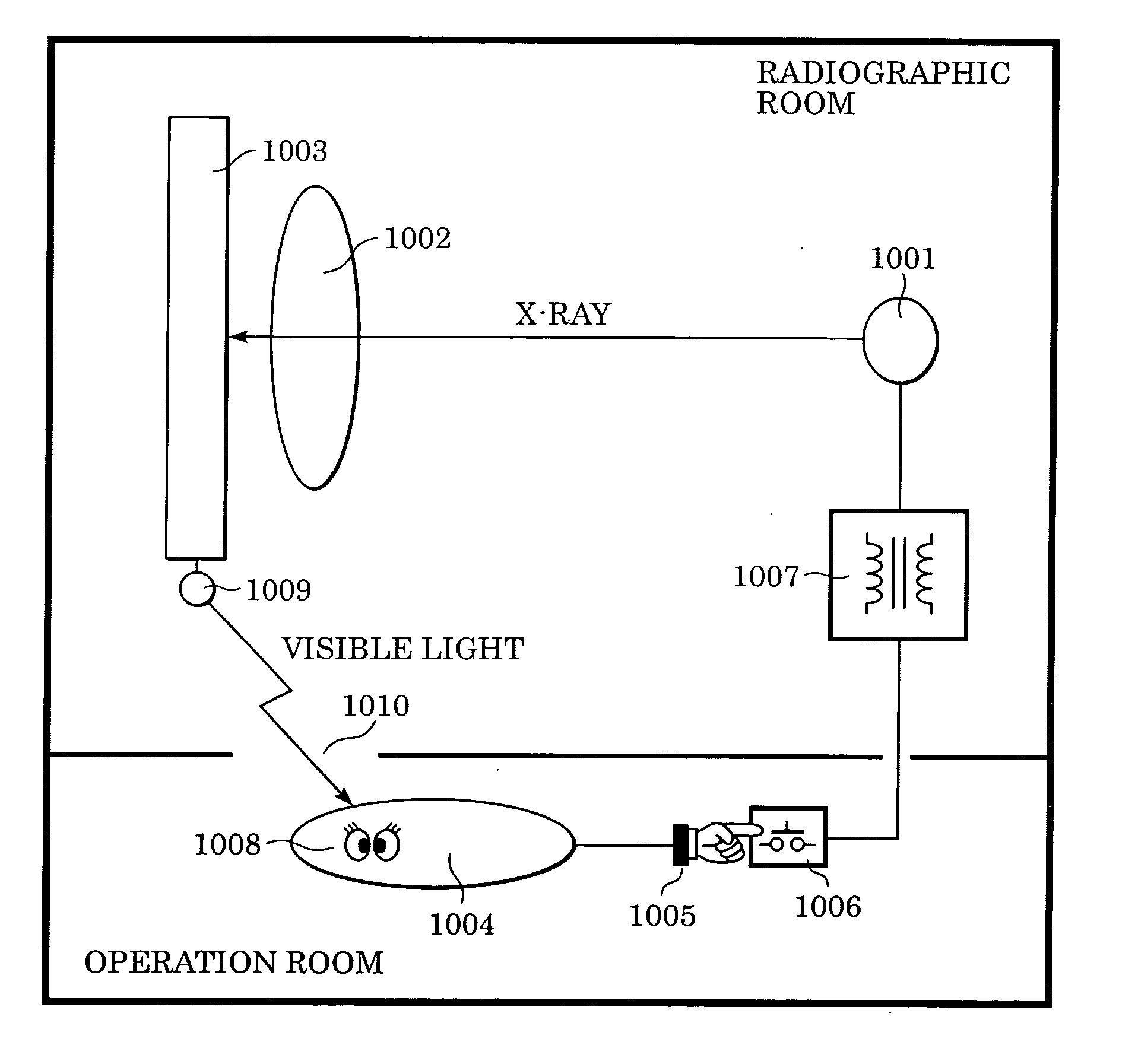

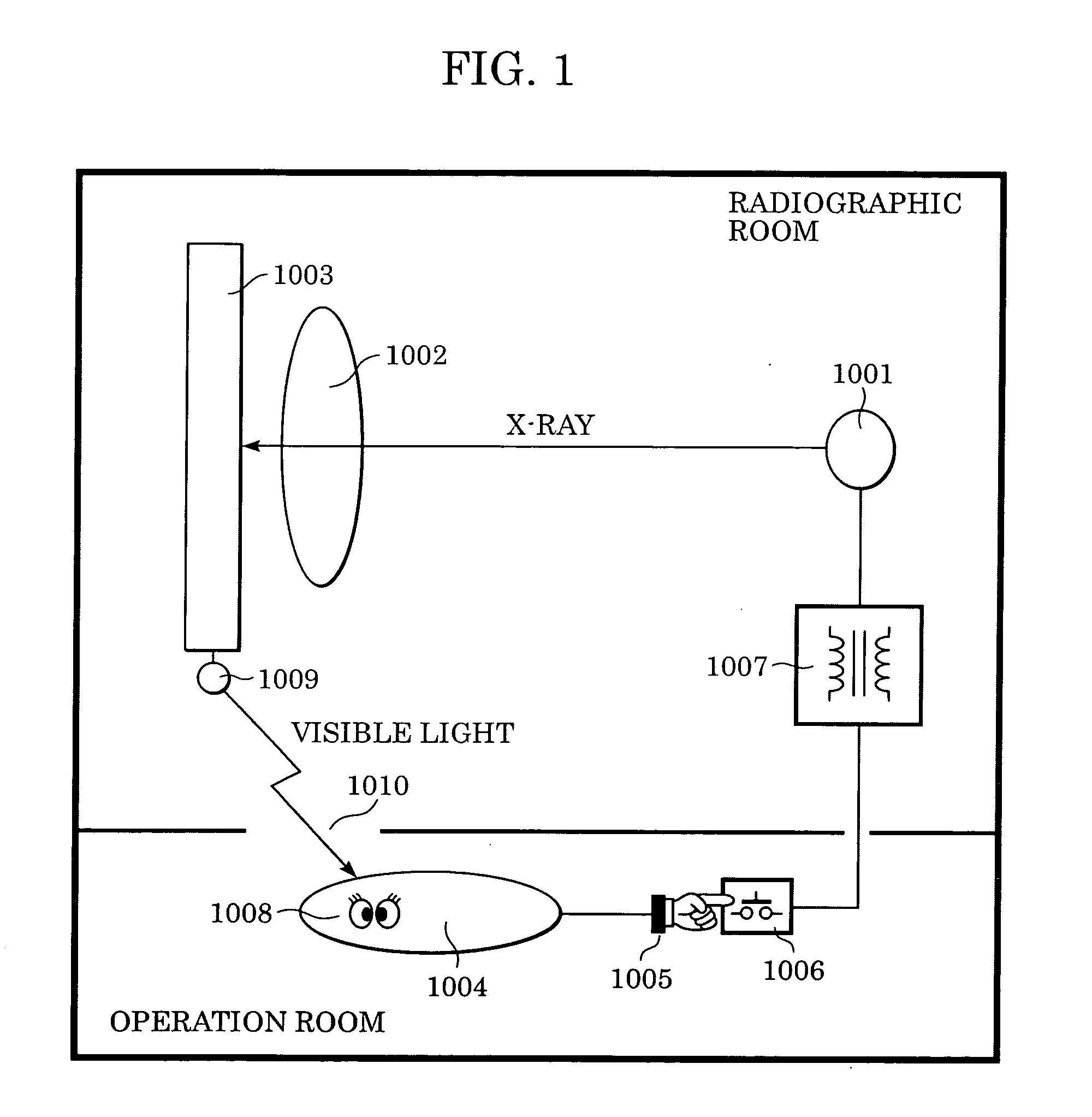

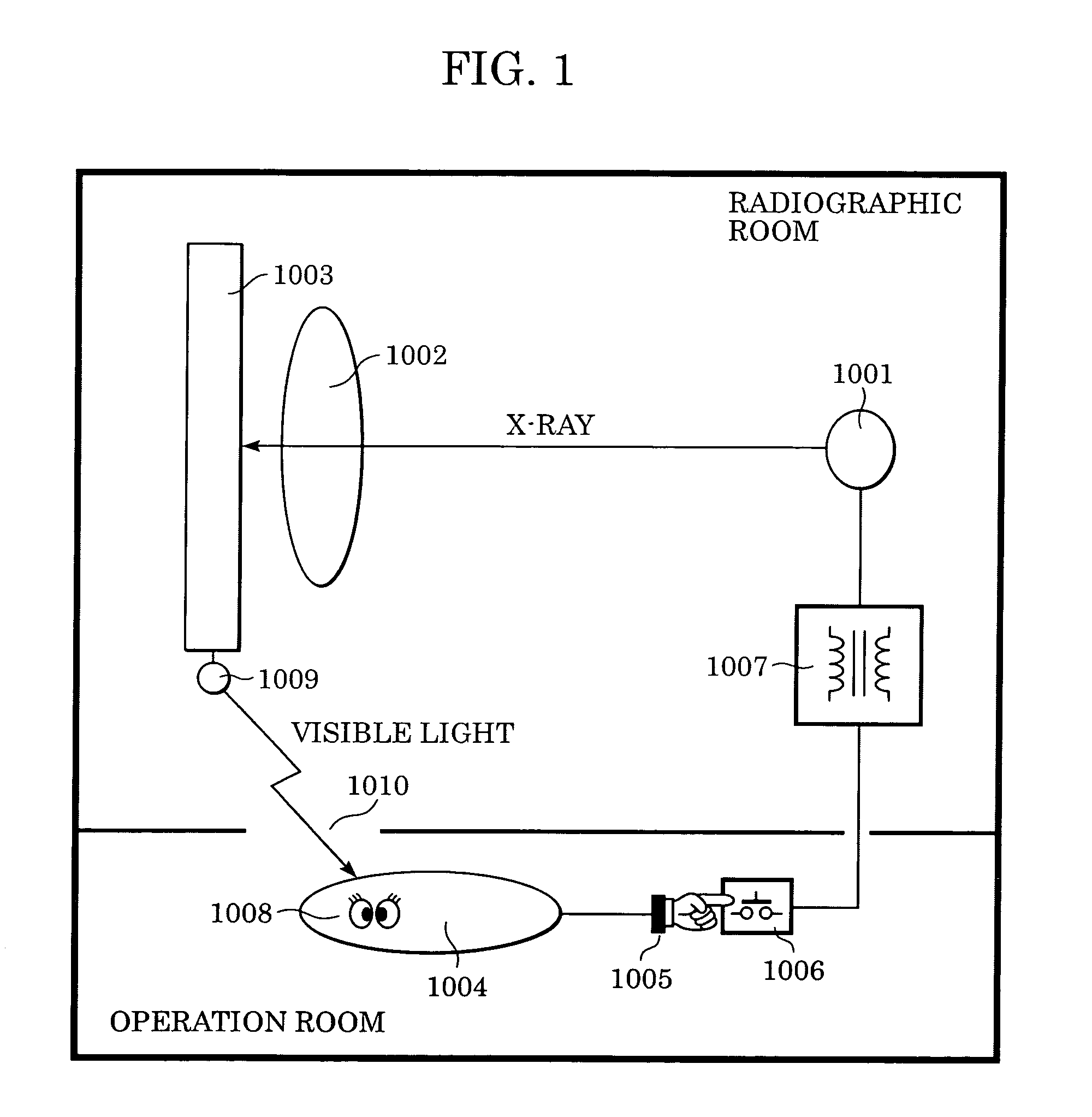

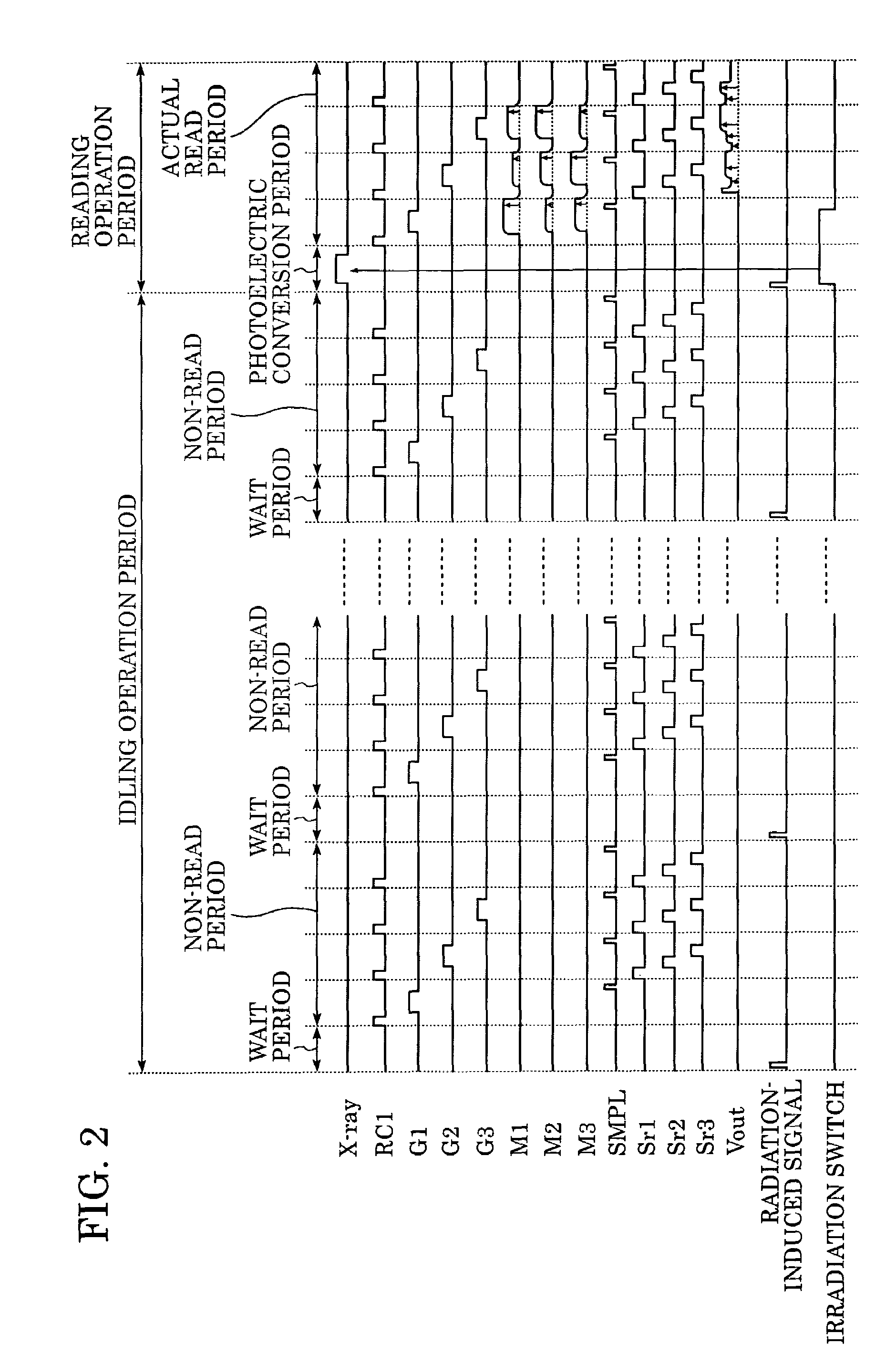

Radiation imaging apparatus and control method therefor

InactiveUS20050220269A1Stably performing radiographyAvoid delayX-ray apparatusRadiation diagnosticsX-rayOpto electronic

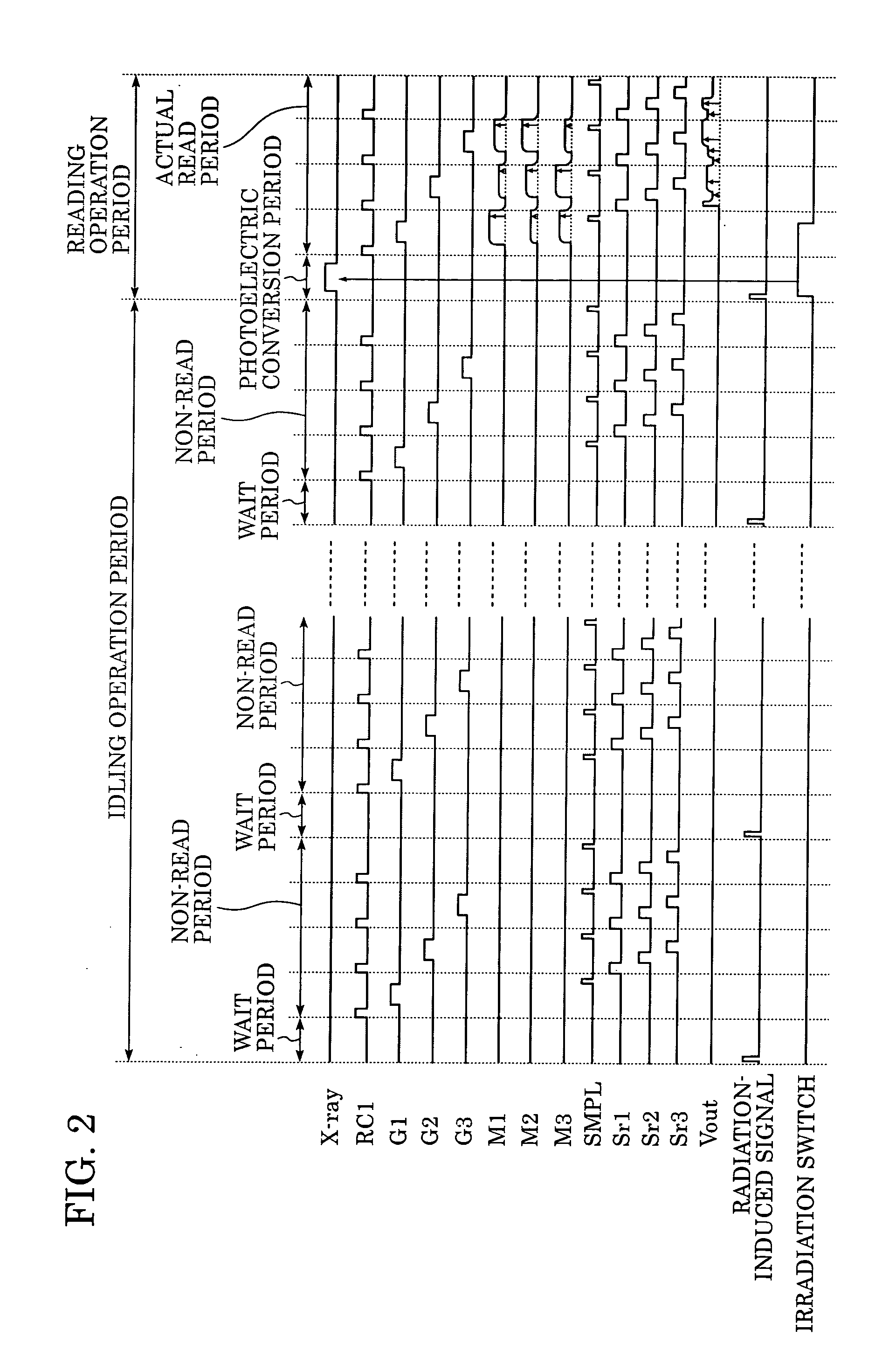

A lamp emits pulse-shaped visible light when a wait period begins. If a radiation emission switch is not pressed in the wait period, X-ray radiation is not emitted from an X-ray source, and no charges are accumulated in photoelectric conversion elements of an X-ray imaging apparatus. In a non-read period, although signals are sequentially read from the photoelectric conversion elements, an output signal does not change. When the radiation emission switch is pressed in synchronization with a radiation-induced signal in a certain wait period, the X-ray source emits X-rays. After irradiation of X-rays, a photoelectric conversion period transitions to an actual read period. In the photoelectric conversion period, X-rays are emitted and transmitted X-ray information of a patient are accumulated in the photoelectric conversion elements of the X-ray imaging apparatus. In the actual read period, the accumulated information is read.

Owner:CANON KK

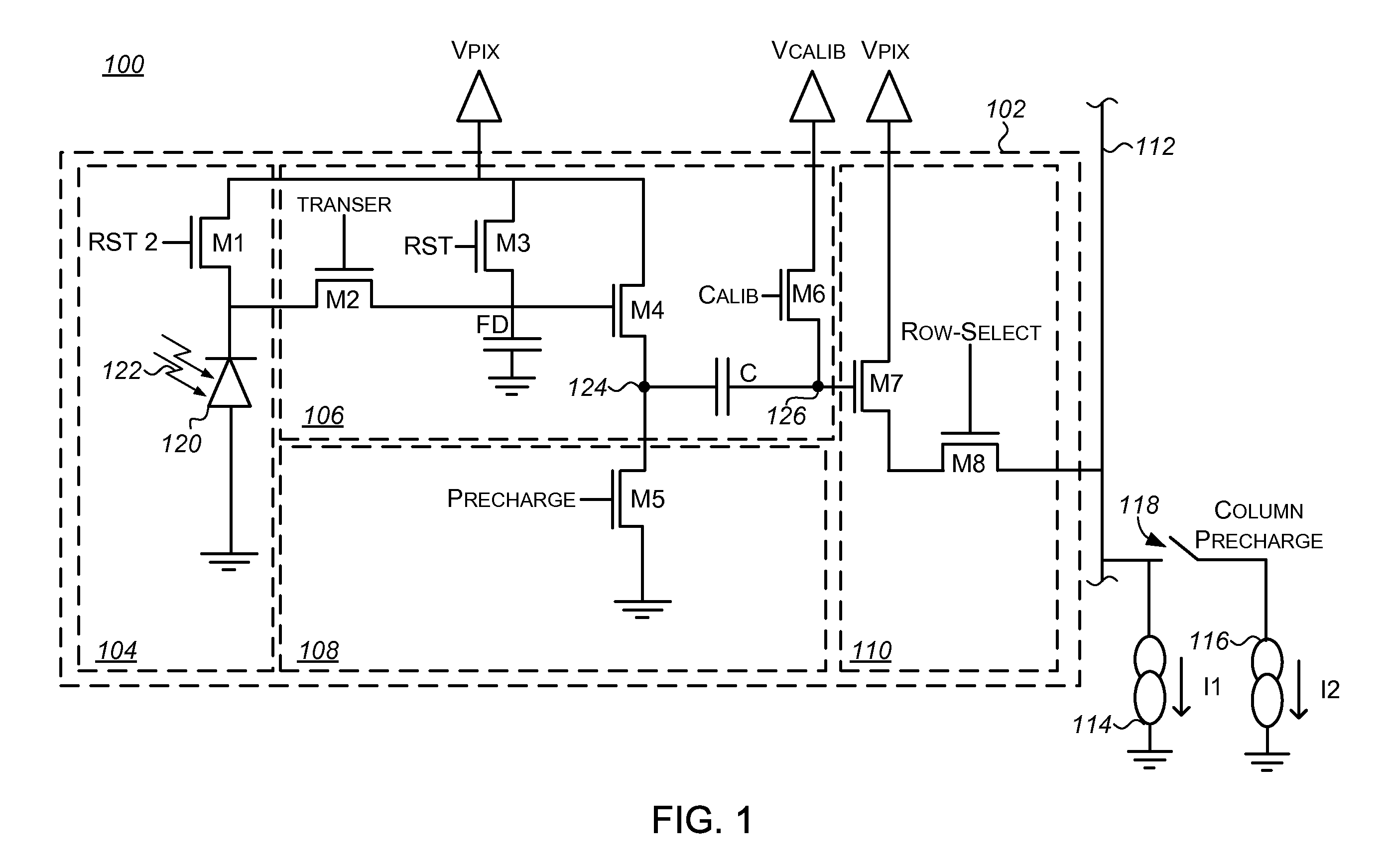

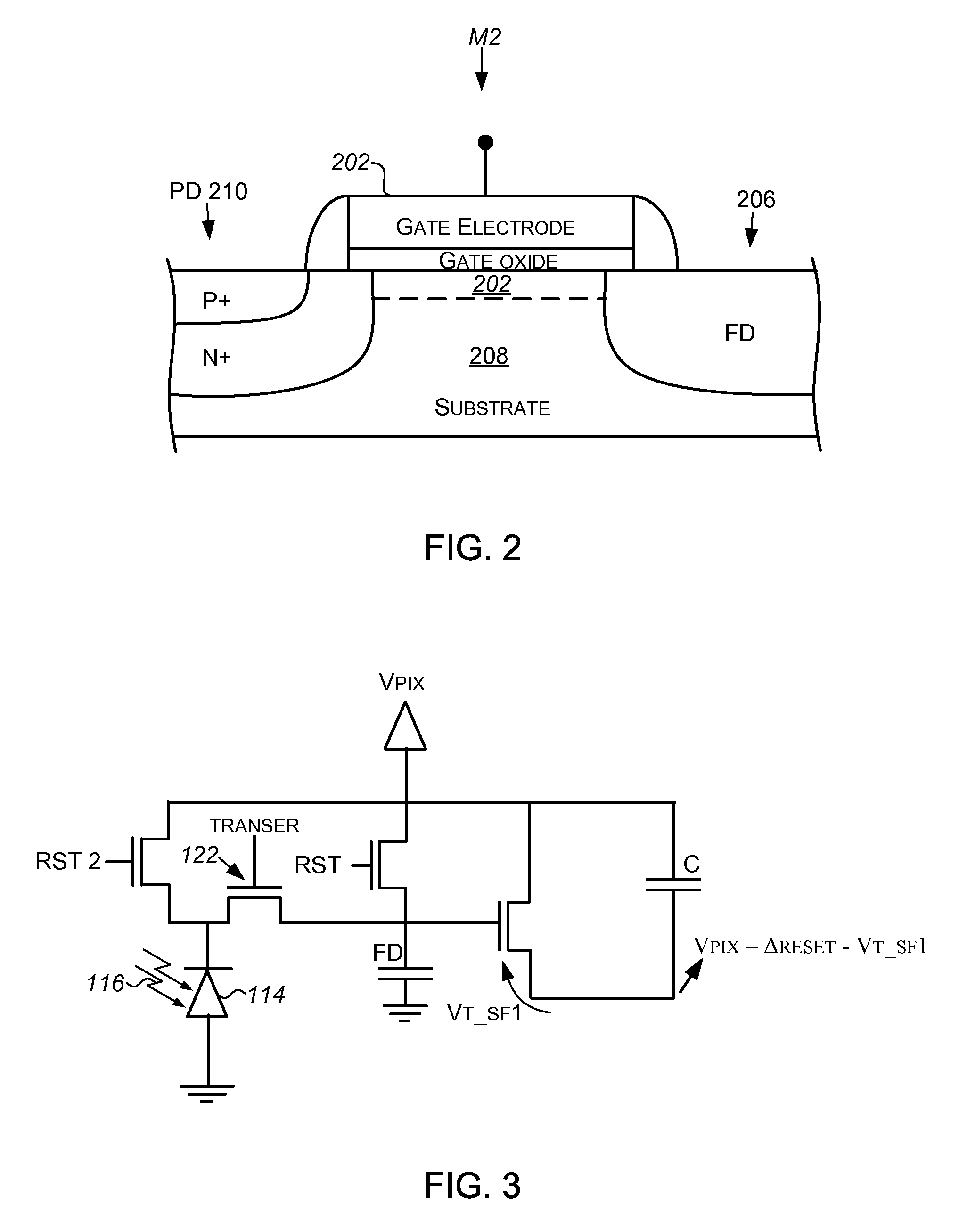

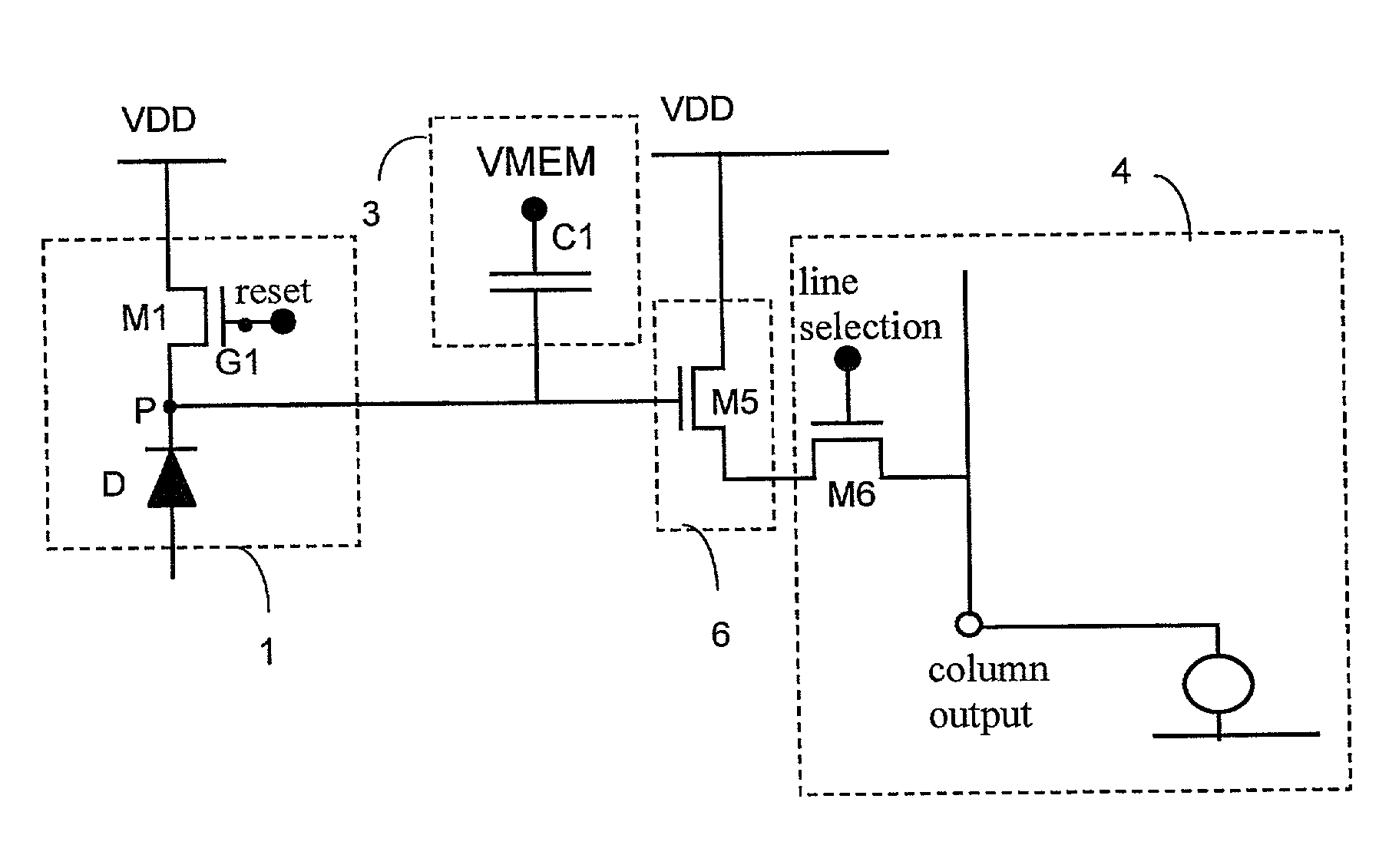

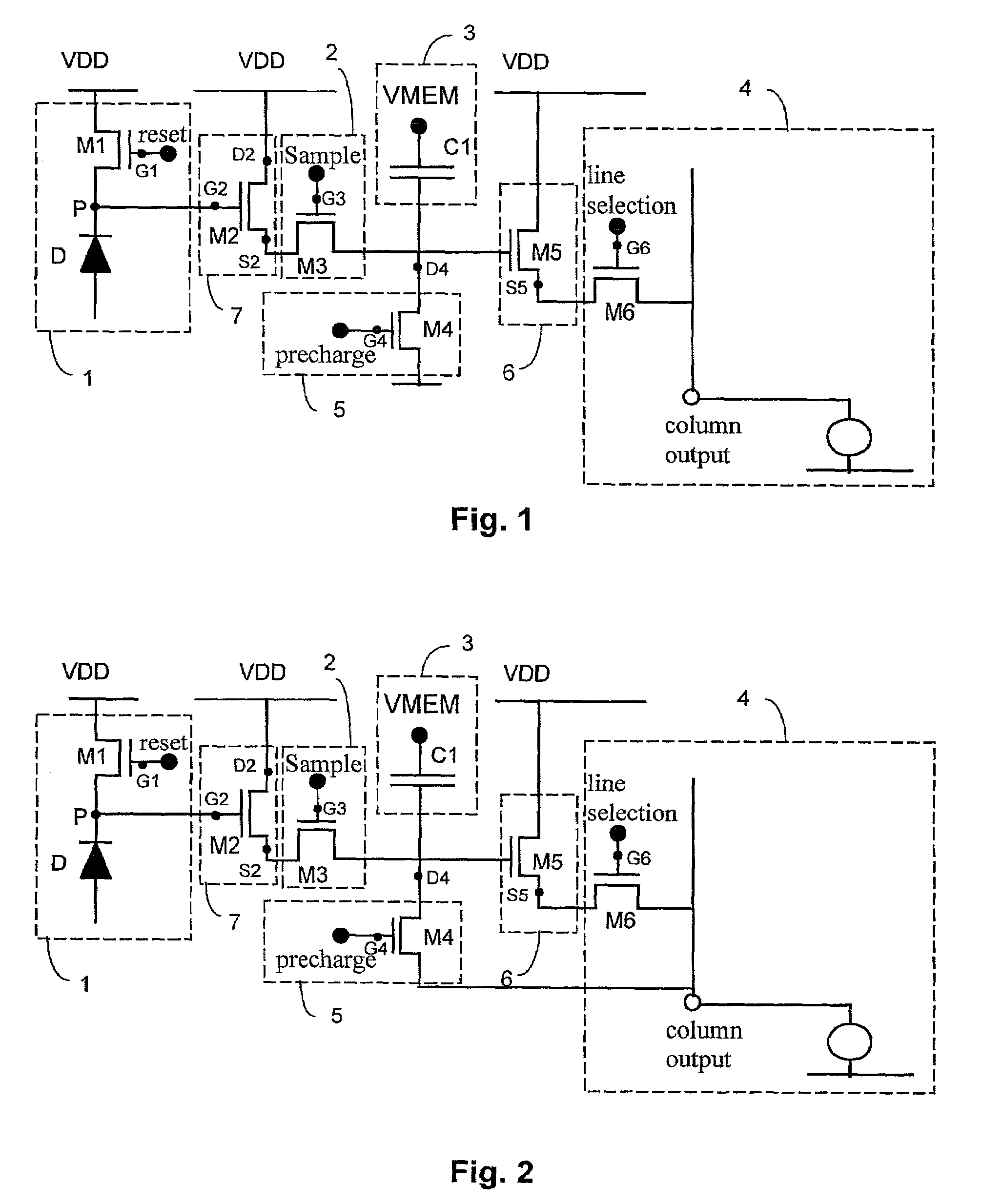

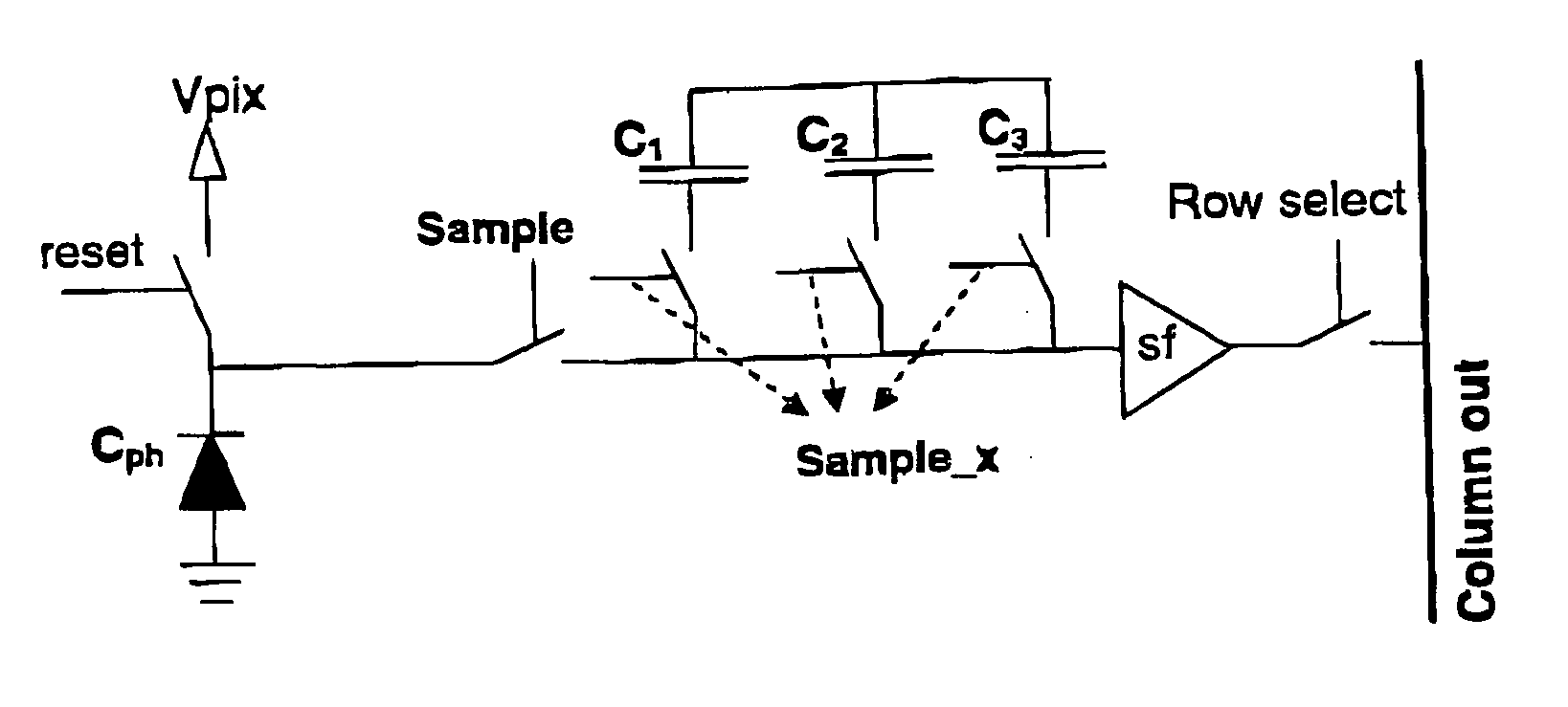

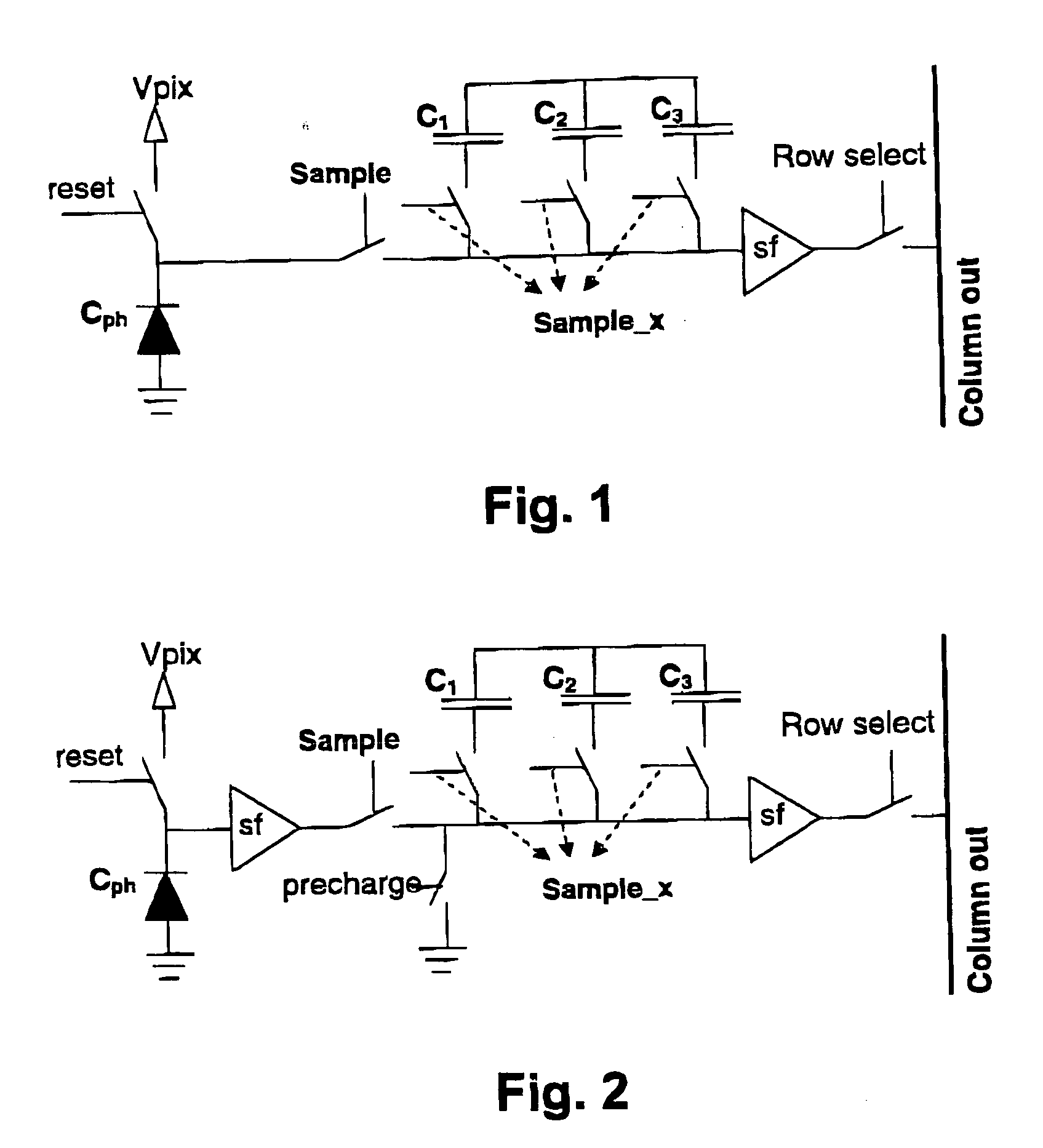

In-pixel correlated double sampling pixel

InactiveUS20100271517A1Television system detailsTelevision system scanning detailsAudio power amplifierPhotodetector

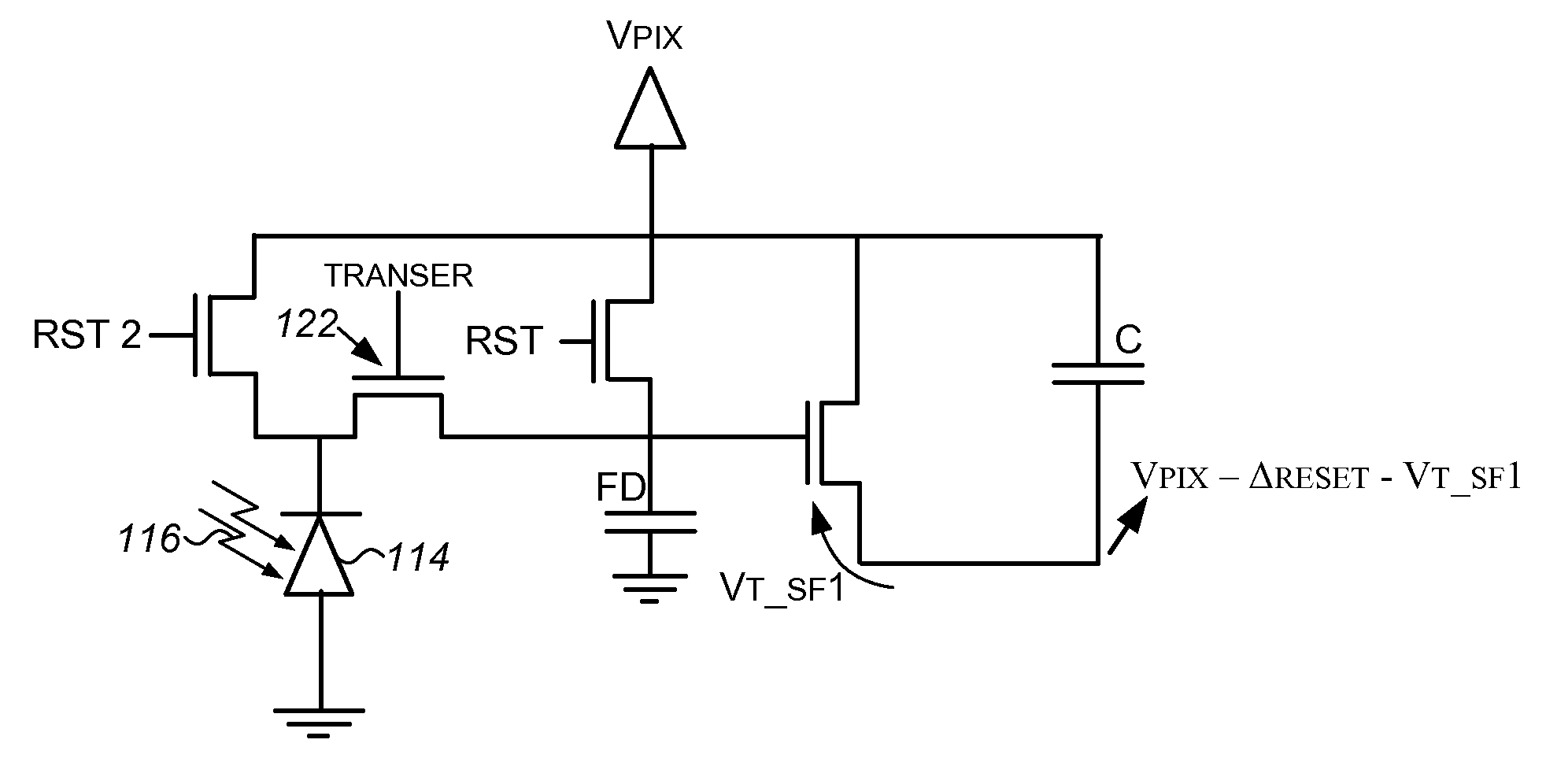

An in-pixel correlated double sampling (CDS) pixel and methods of operating the same are provided. The CDS pixel includes a photodetector to accumulate radiation induced charges, a floating diffusion element electrically coupled to an output of the photodetector through a transfer switch, and. a capacitor-element having an input node electrically coupled to an amplifier and through the amplifier to the floating diffusion element and an output node electrically coupled to an output of the pixel. The capacitor-element is configured to sample a reset value of the floating diffusion element during a reset sampling and to sample a signal value of the floating diffusion element during a signal sampling.

Owner:SEMICON COMPONENTS IND LLC

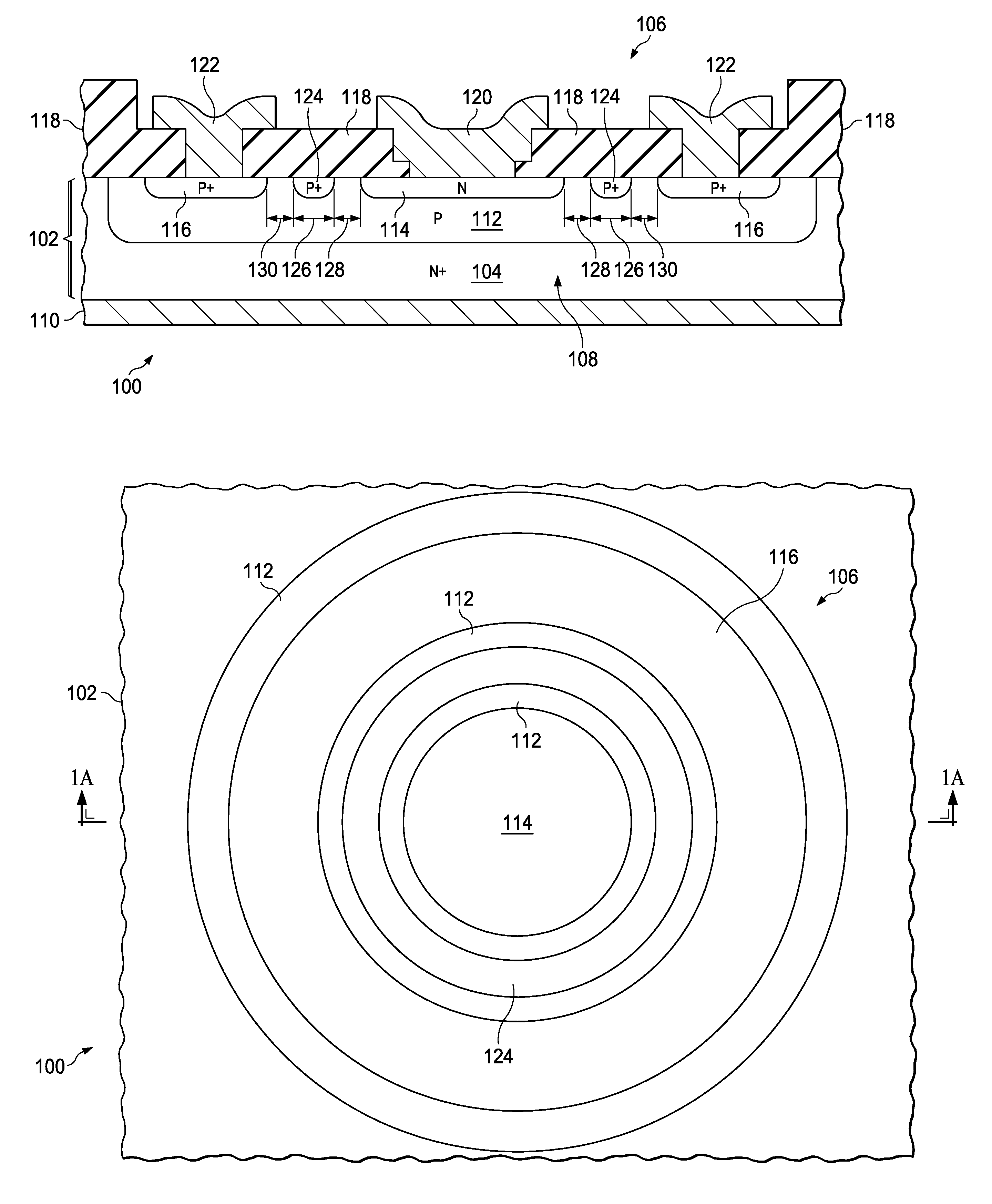

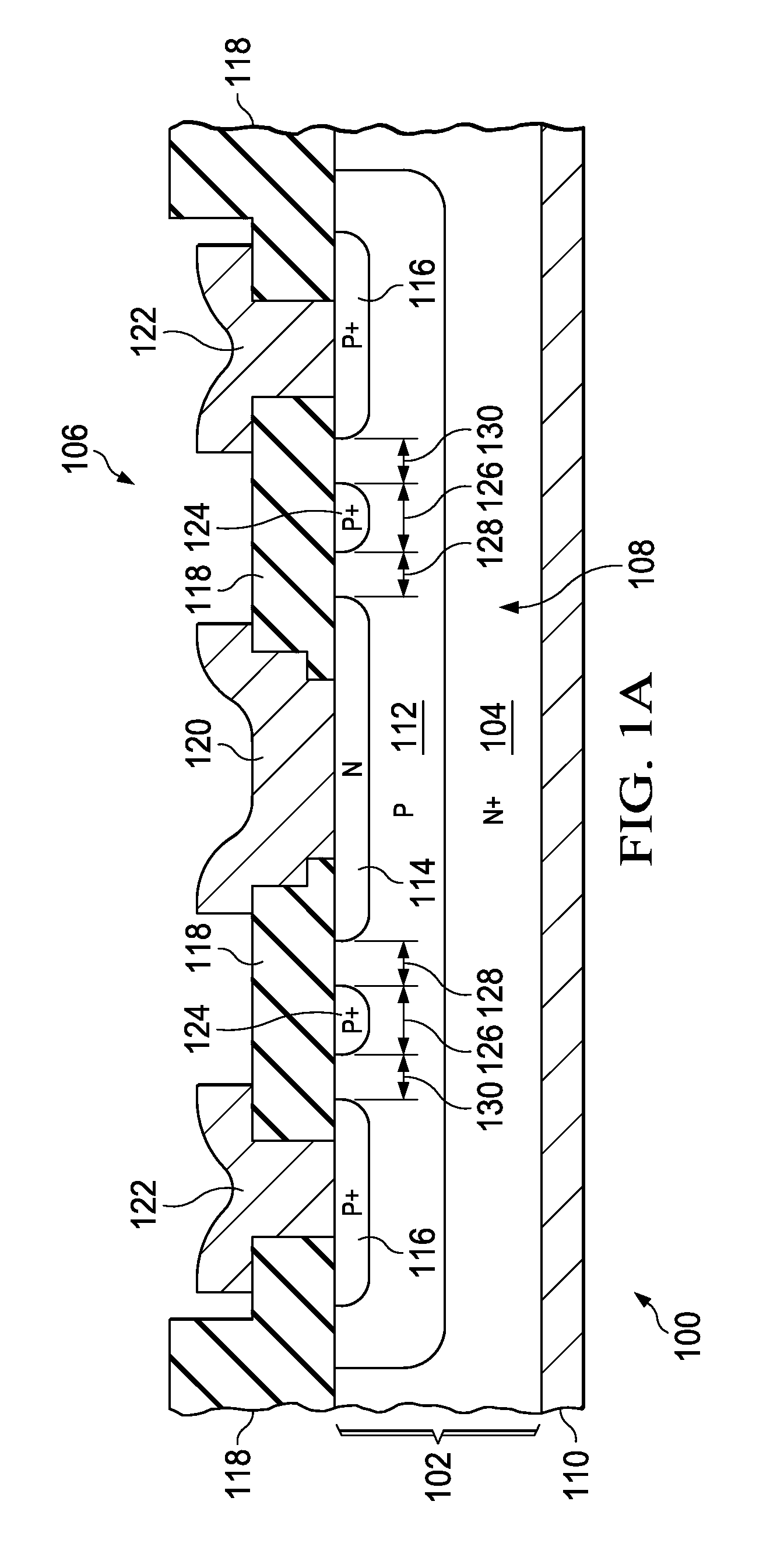

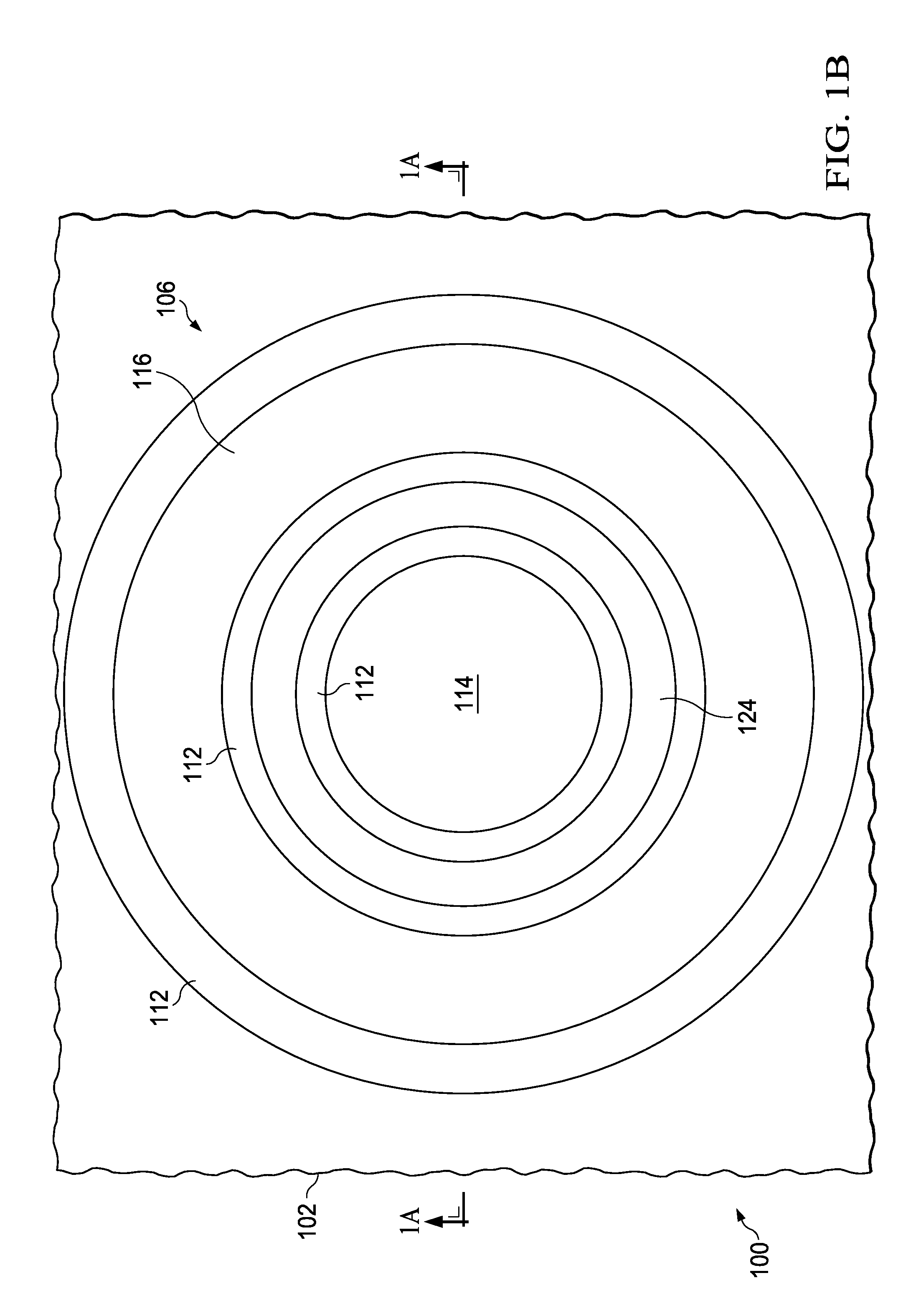

Radiation induced diode structure

ActiveUS20140124895A1TransistorSemiconductor/solid-state device manufacturingDielectric layerSemiconductor

A semiconductor device containing an NPN bipolar junction transistor may be formed by forming a p-type radiation induced diode structure (RIDS) region in an intrinsic p-type base region of the NPN bipolar junction transistor at a boundary of the intrinsic p-type base region with a dielectric layer over a substrate of the semiconductor device, between an emitter of the NPN bipolar junction transistor and an extrinsic p-type base region of the NPN bipolar junction transistor. The p-type RIDS region has a doping density high enough to prevent inversion of a surface of the p-type RIDS region adjacent to the dielectric layer when trapped charge is accumulated in the dielectric layer, while the intrinsic p-type base region may invert from the trapped charge forming the radiation induced diode structure. The p-type RIDS region is separated from the emitter and from the extrinsic base region by portions of the intrinsic base region.

Owner:TEXAS INSTR INC

Compositions and methods for treatment of mammalian skin

Compositions useful for treatment of a wide range of skin disorders including: pre-cancerous lesions, keratotic lesions, superficial basal cell carcinomae; squamous cell carcinomae; malignant melanoma, and radiation-induced burns. In some embodiments the treatments comprise contacting human or other mammalian skin with a composition according to the disclosure. In other embodiments, administration of compositions provided is by injection. Some embodiments provide for preventive use of compositions provided towards preventing some forms of skin cancer and skin cancer-related disorders by repeated application to healthy-looking skin. Methods for providing the compositions are disclosed.

Owner:BERRY PHARMA L L C

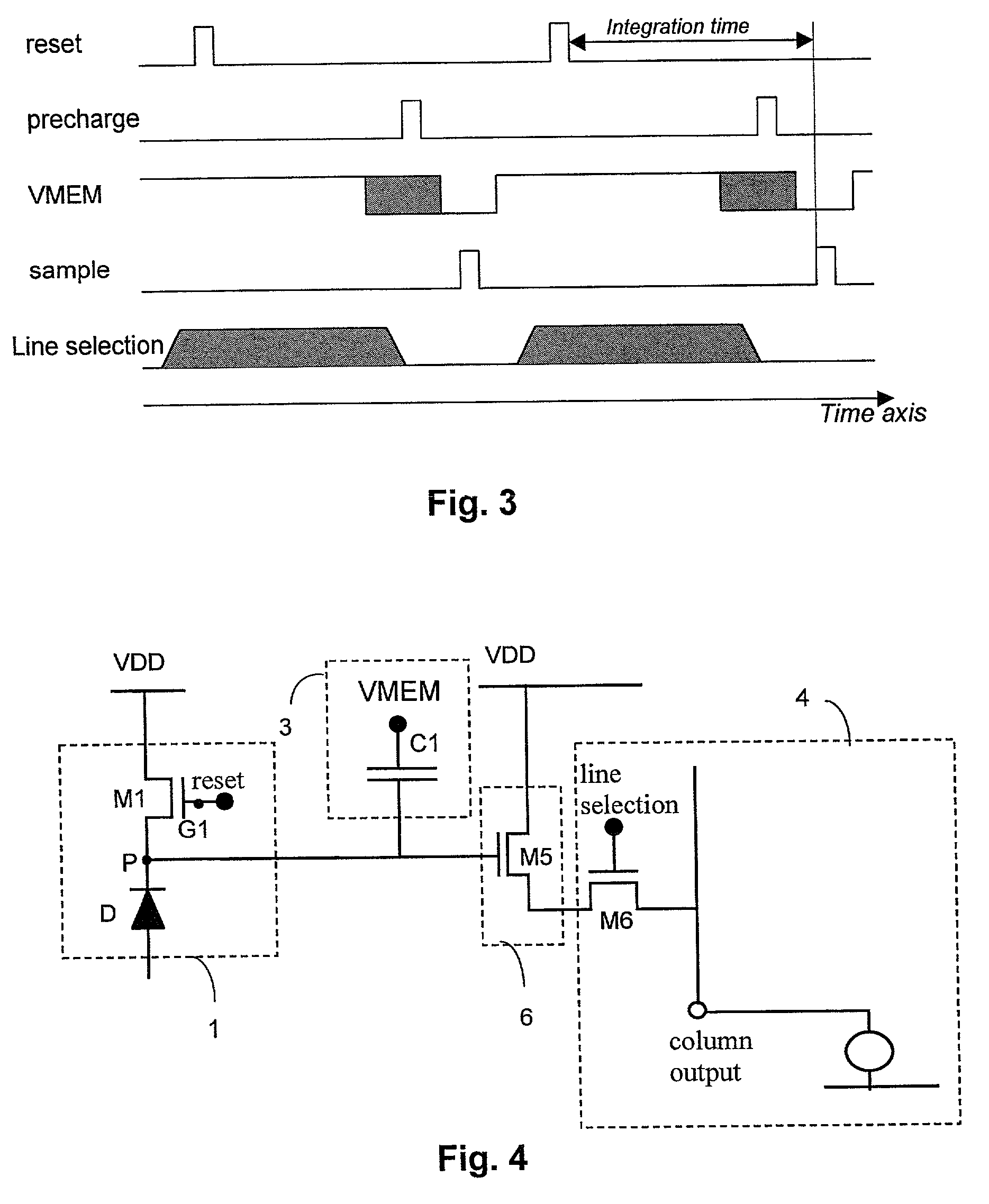

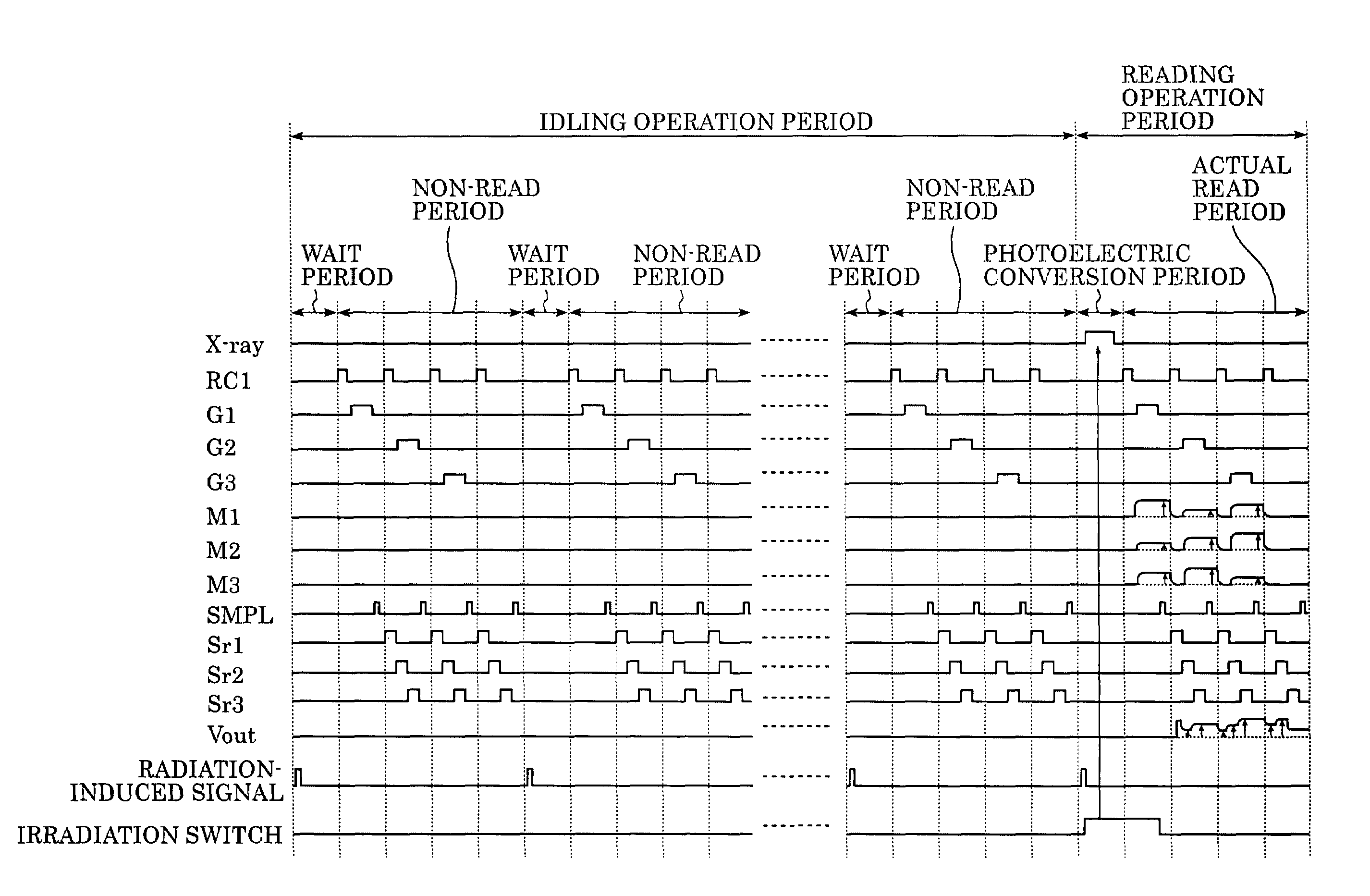

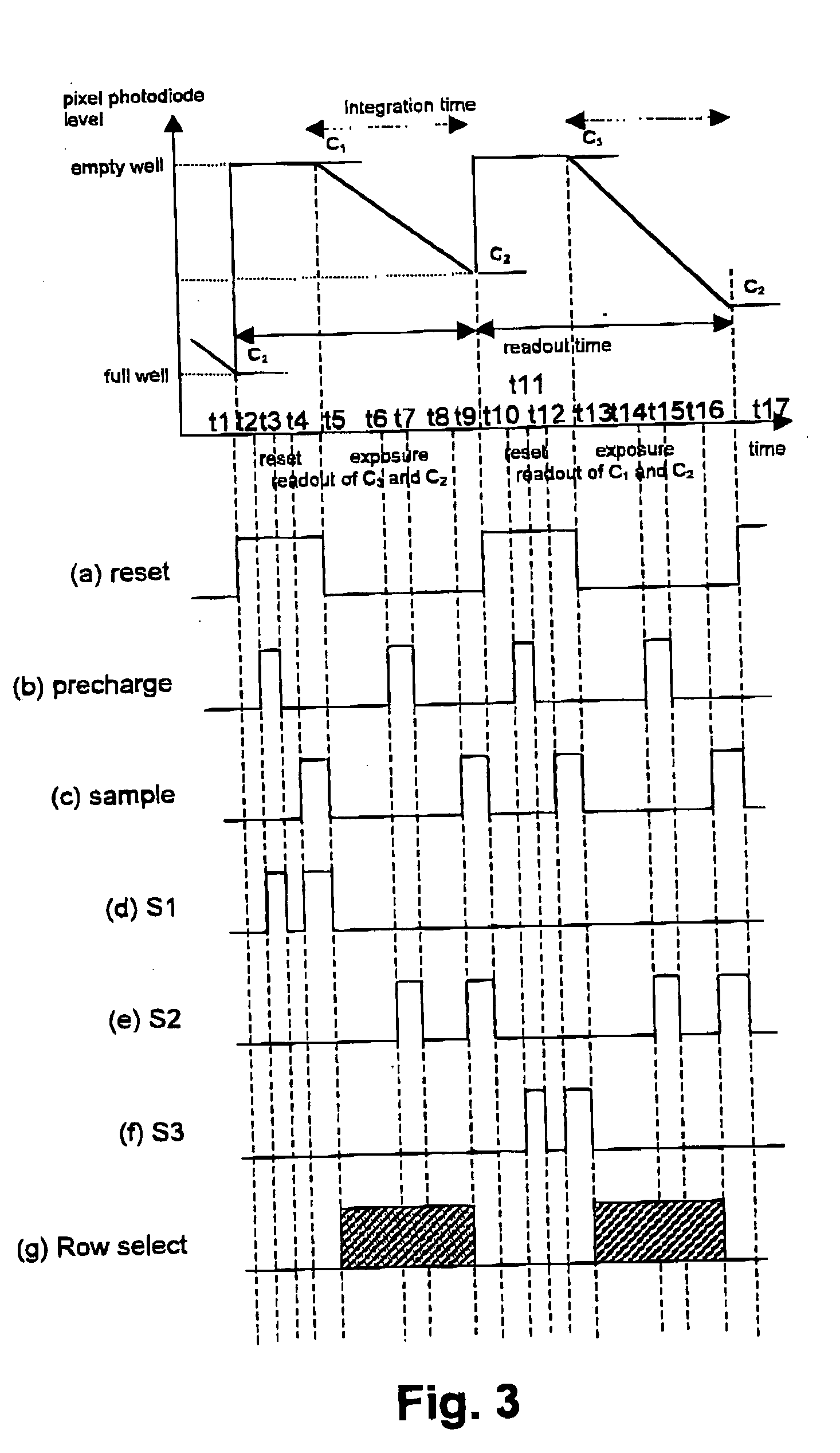

Method to adjust the signal level of an active pixel and corresponding active pixel

ActiveUS7224389B2Reduce signalingOvercome signal attenuationTelevision system detailsTelevision system scanning detailsEngineeringMemory circuits

An active pixel comprises a sensor circuit for collecting radiation induced charges and transducing them to a measurement signal corresponding to the amount of charge collected, and a capacitor element with two nodes, where the measurement signal is present on a node of the capacitor element. The memory circuit is clocked, i.e. driven by a pulsed signal. The pulse on the memory circuit will rise the reset level at the output, which is lowered due to threshold voltage losses in the active pixel circuit, thus restoring a large signal swing. Arrays of the pixels are described, as well as a method for reading out such a pixel.

Owner:SEMICON COMPONENTS IND LLC

Radiation imaging apparatus and control method therefor

InactiveUS7403594B2Stably performing radiographyAvoid delaySolid-state devicesMaterial analysis by optical meansSoft x rayX-ray

A lamp emits pulse-shaped visible light when a wait period begins. If a radiation emission switch is not pressed in the wait period, X-ray radiation is not emitted from an X-ray source, and no charges are accumulated in photoelectric conversion elements of an X-ray imaging apparatus. In a non-read period, although signals are sequentially read from the photoelectric conversion elements, an output signal does not change. When the radiation emission switch is pressed in synchronization with a radiation-induced signal in a certain wait period, the X-ray source emits X-rays. After irradiation of X-rays, a photoelectric conversion period transitions to an actual read period. In the photoelectric conversion period, X-rays are emitted and transmitted X-ray information of a patient are accumulated in the photoelectric conversion elements of the X-ray imaging apparatus. In the actual read period, the accumulated information is read.

Owner:CANON KK

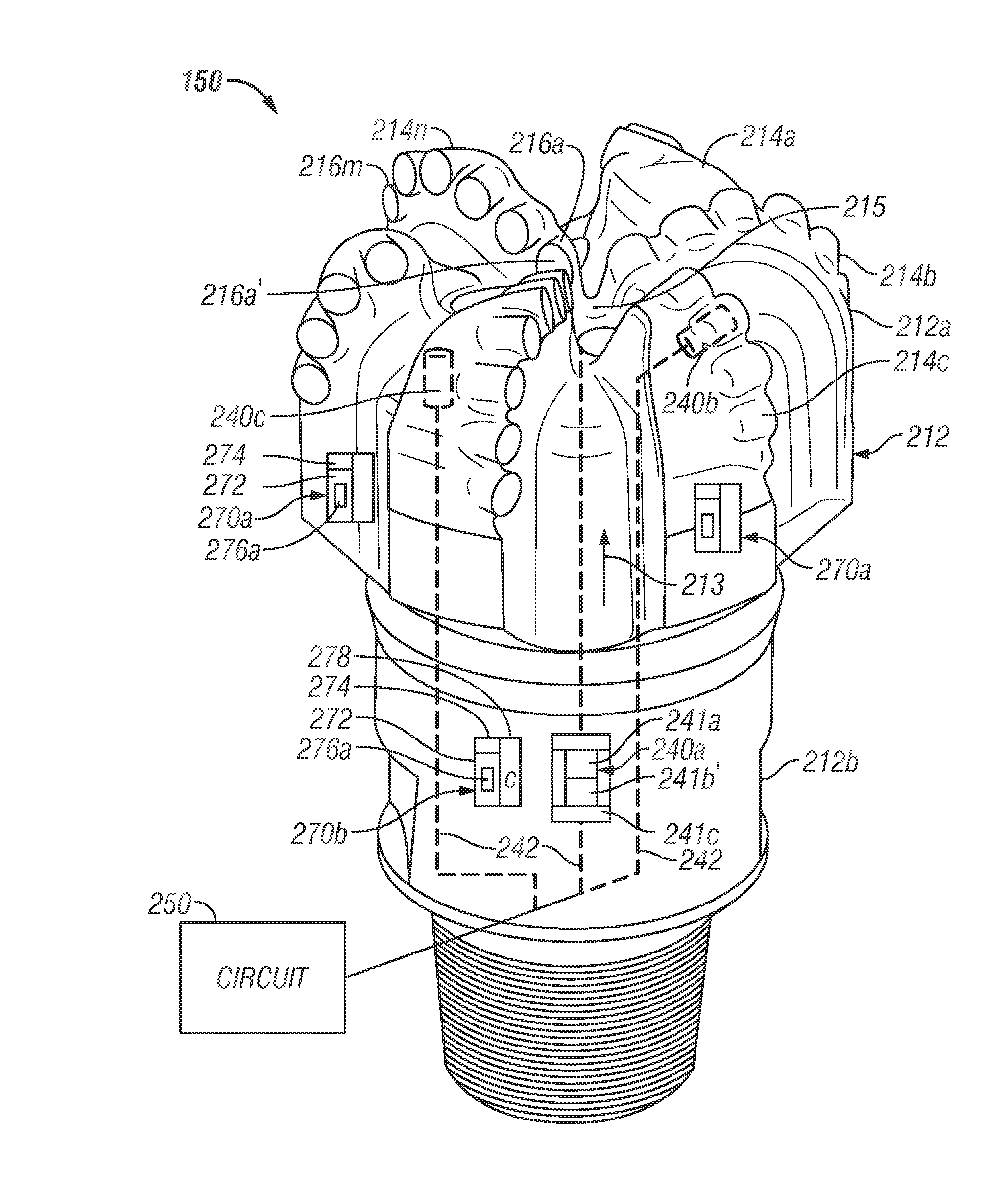

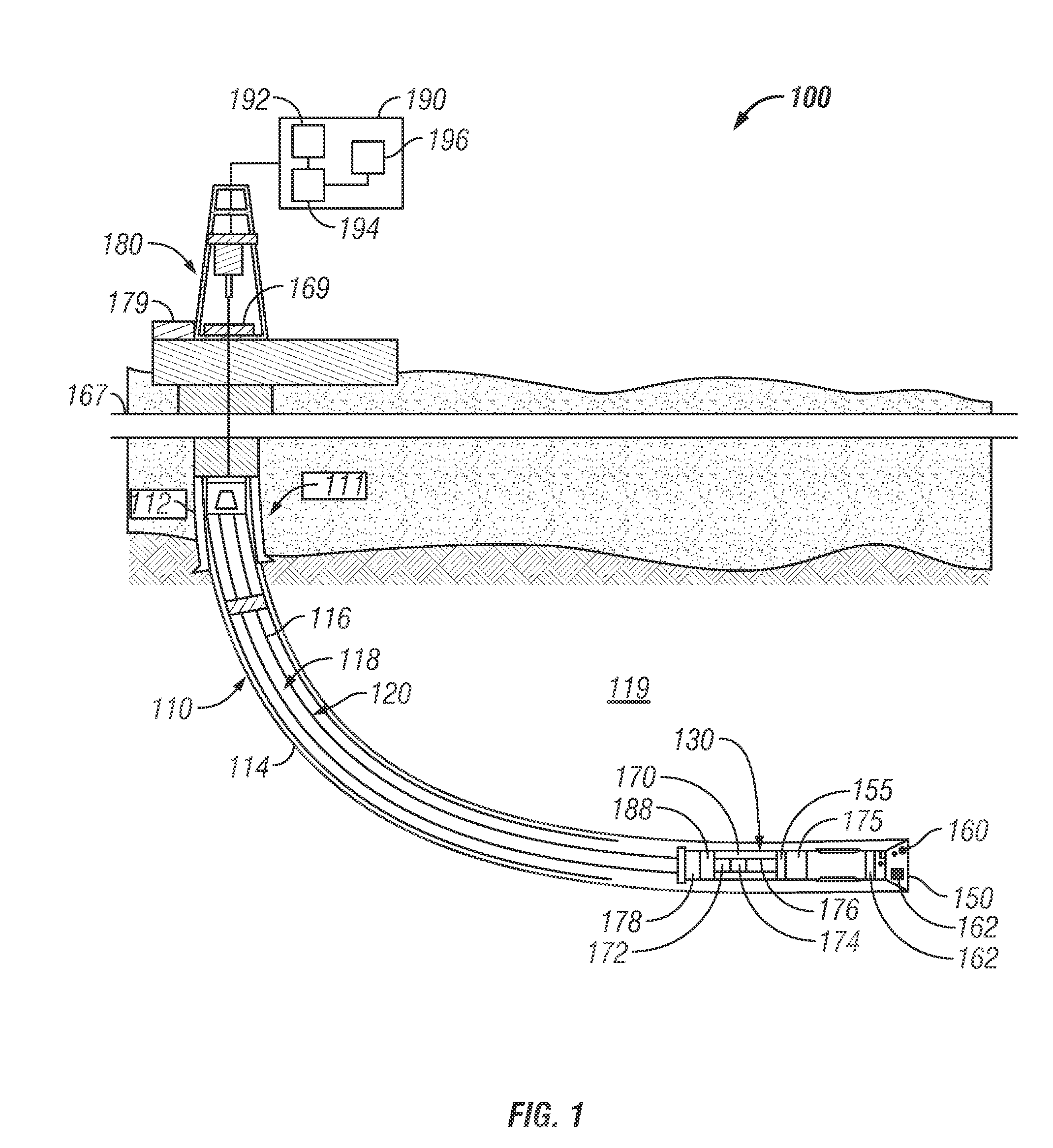

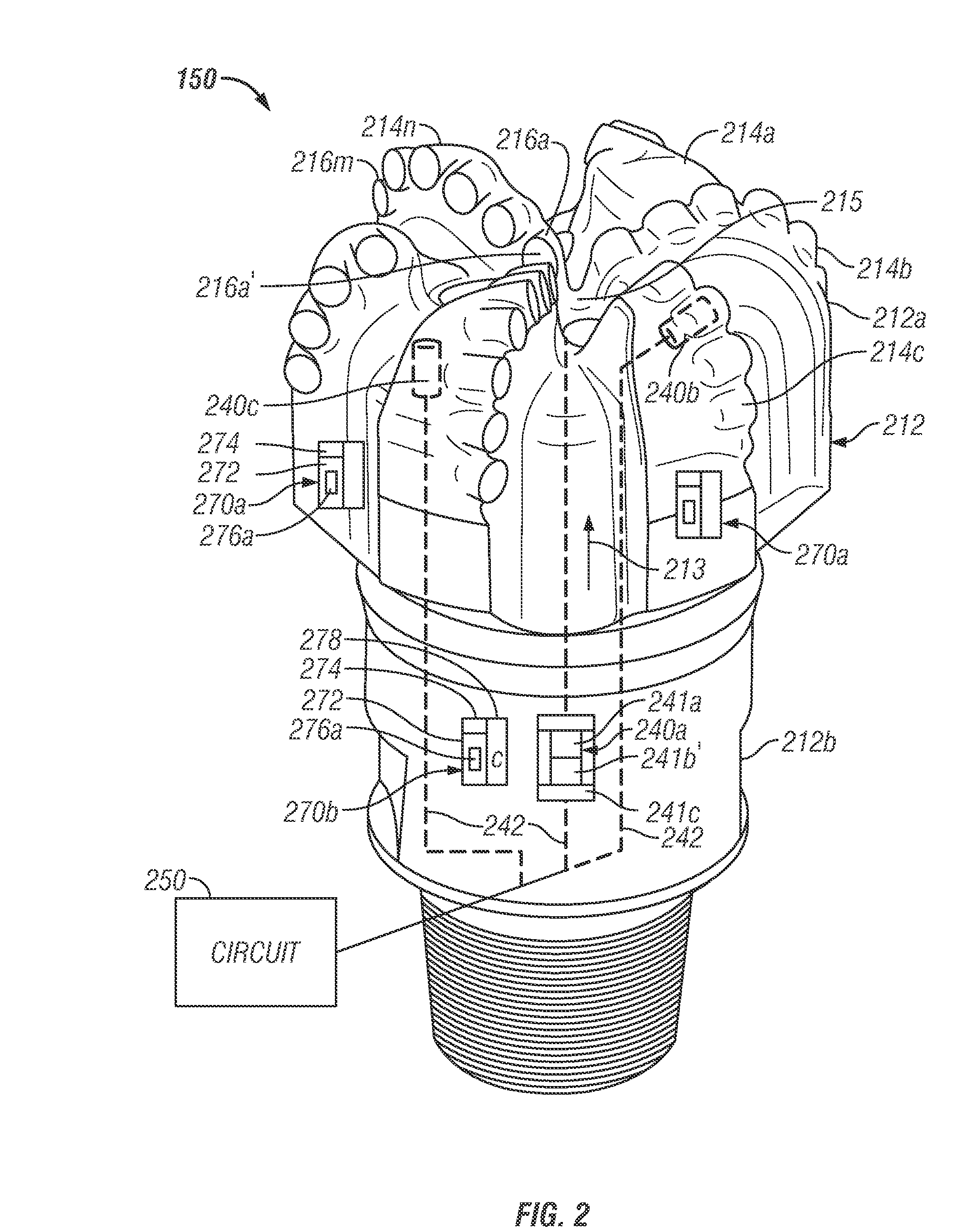

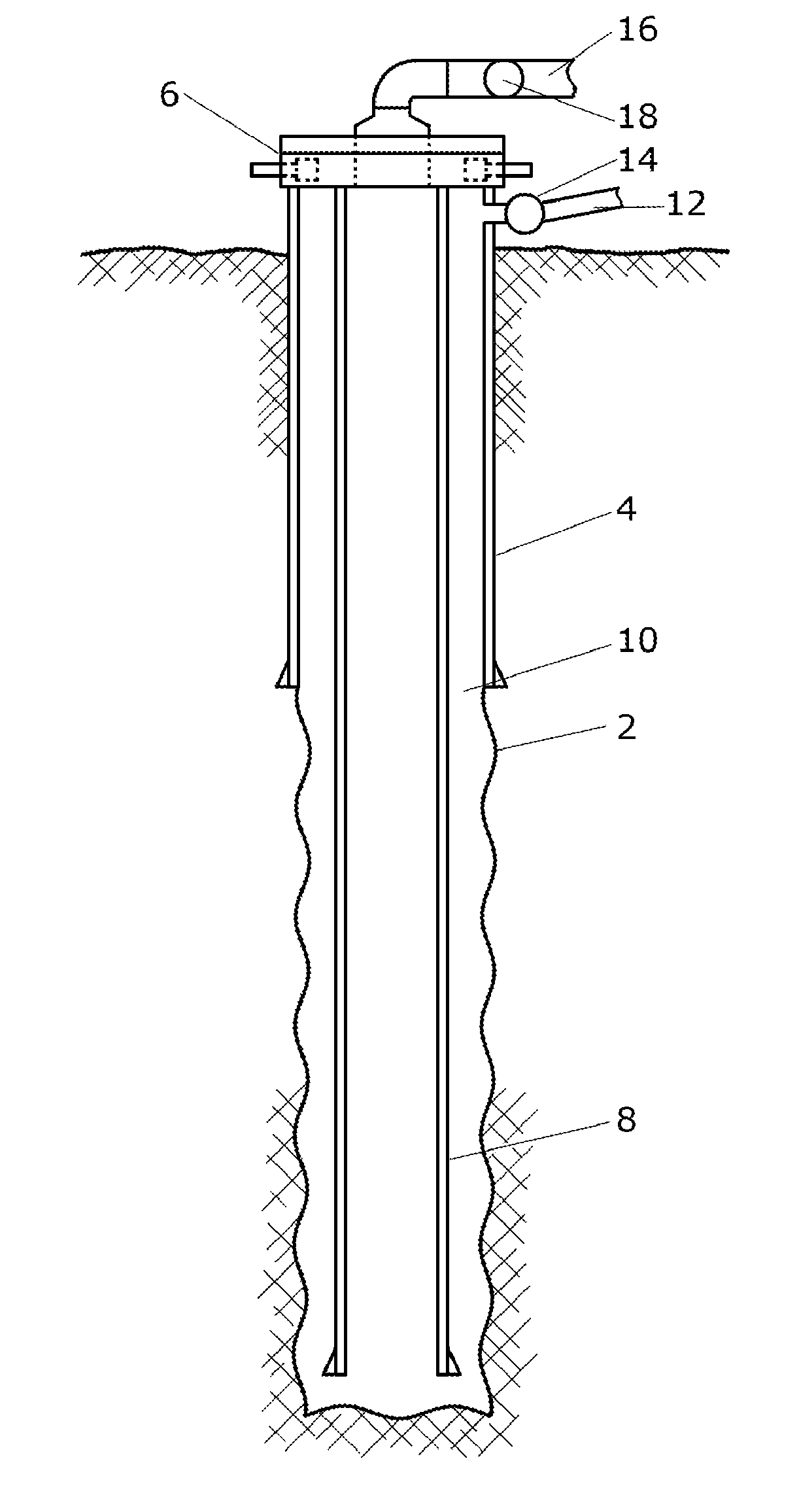

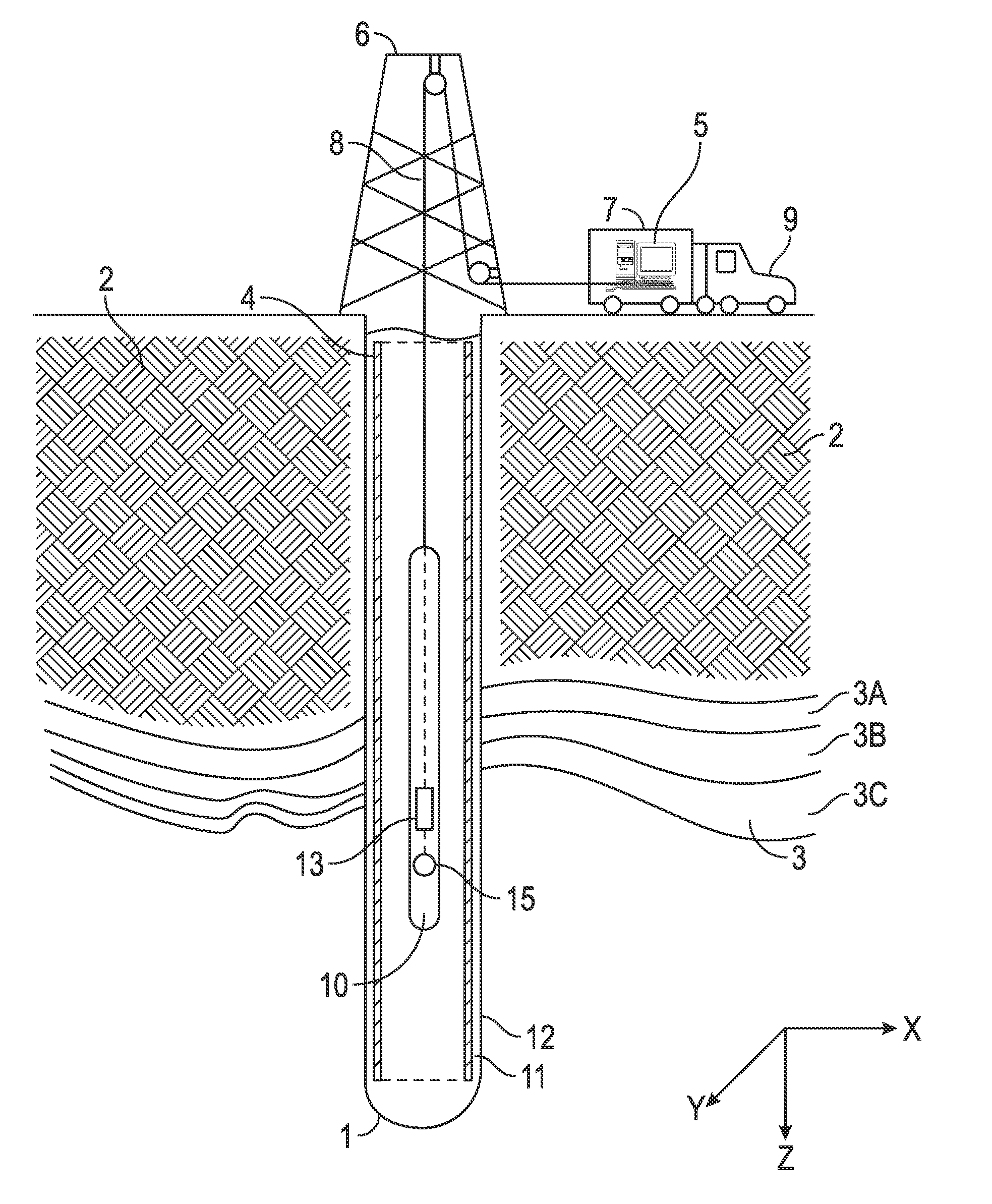

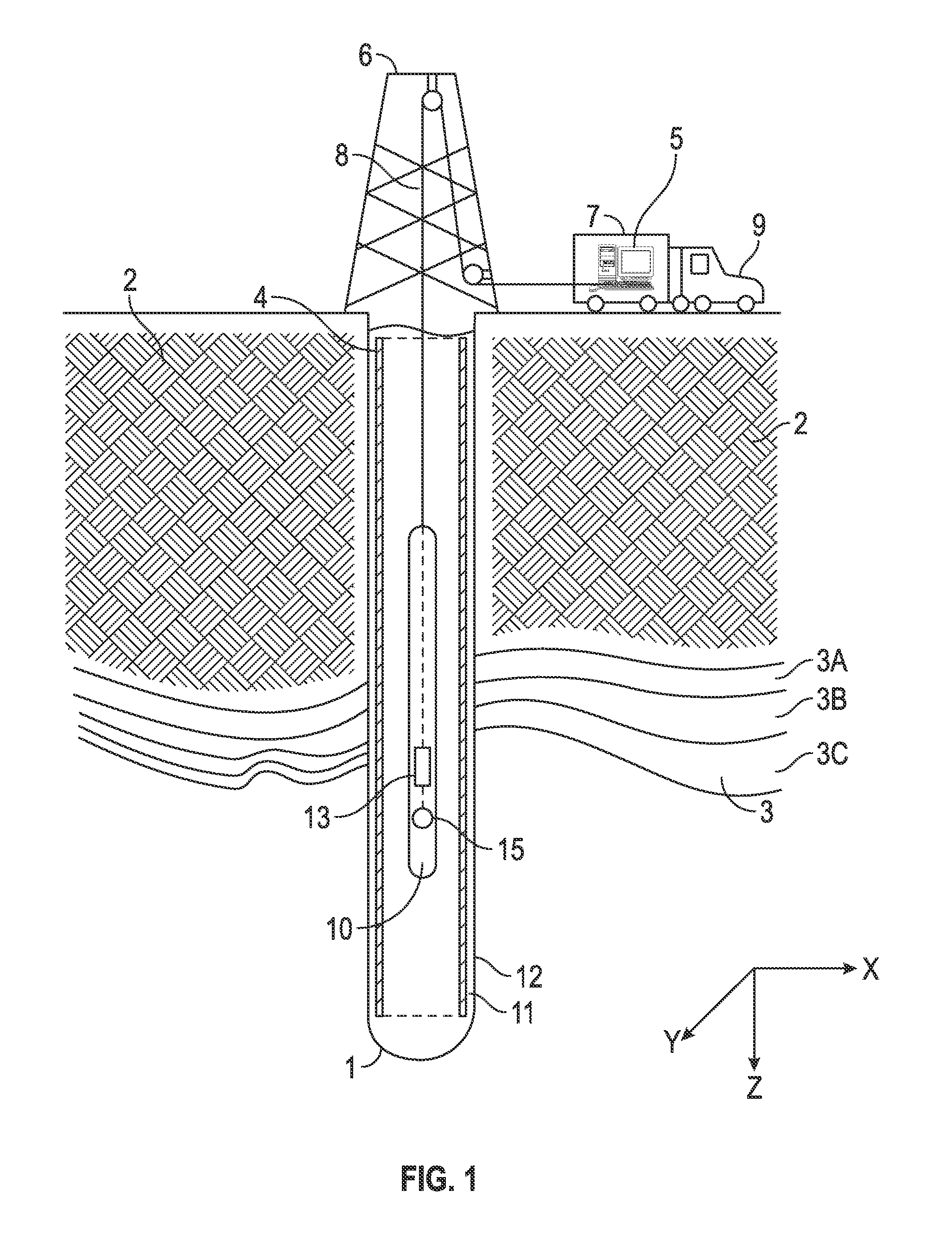

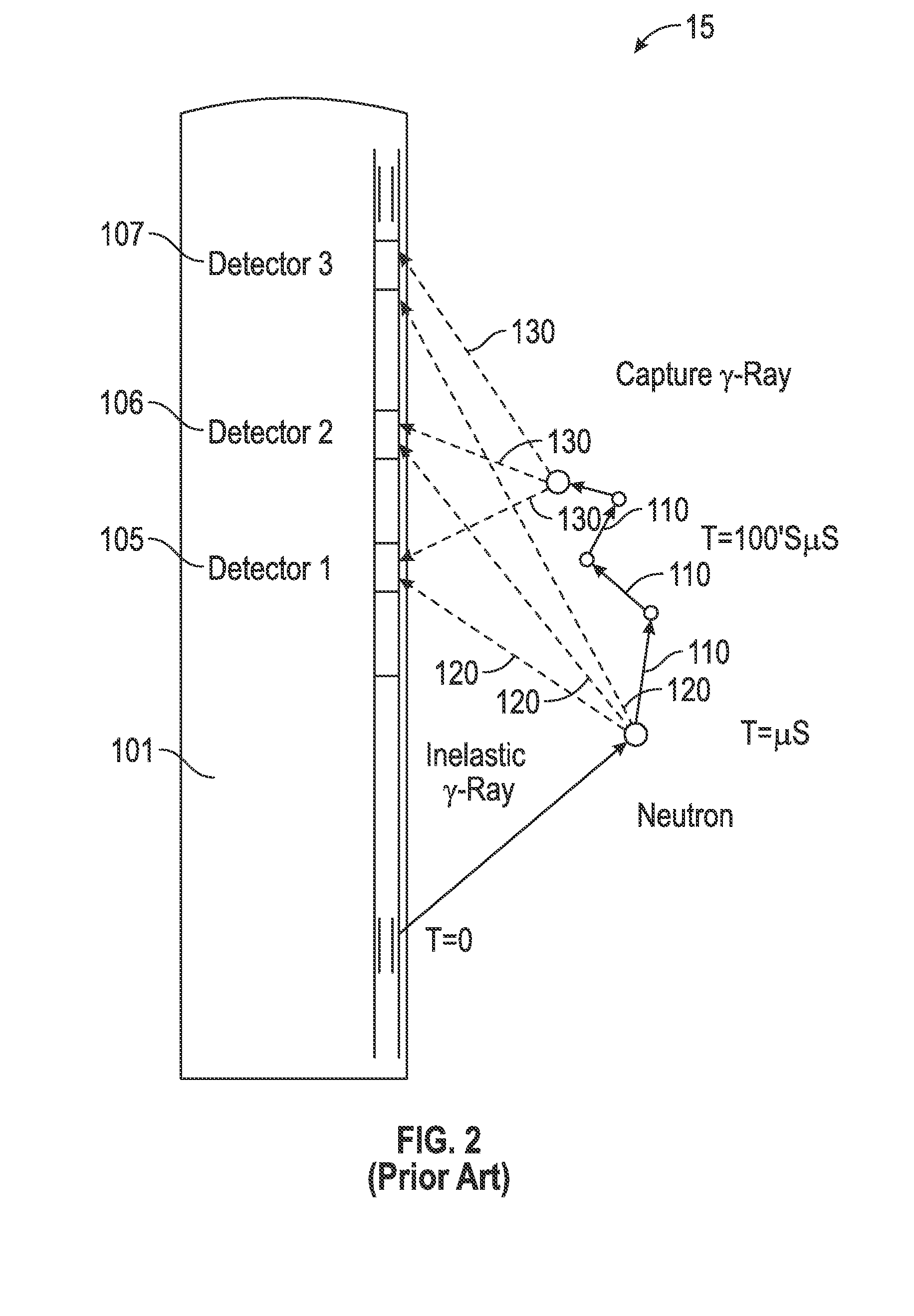

Formation Evaluation Using a Bit-Based Active Radiation Source and a Gamma Ray Detector

A drill bit made according to one embodiment includes a source configured to induce radiation into a formation during drilling of a wellbore and a sensor in the drill bit configured to detect radiation from the formation responsive to the radiation induced by the source. The drill bit may further include a circuit configured to process signals received from the sensor to estimate a property of the formation.

Owner:BAKER HUGHES INC

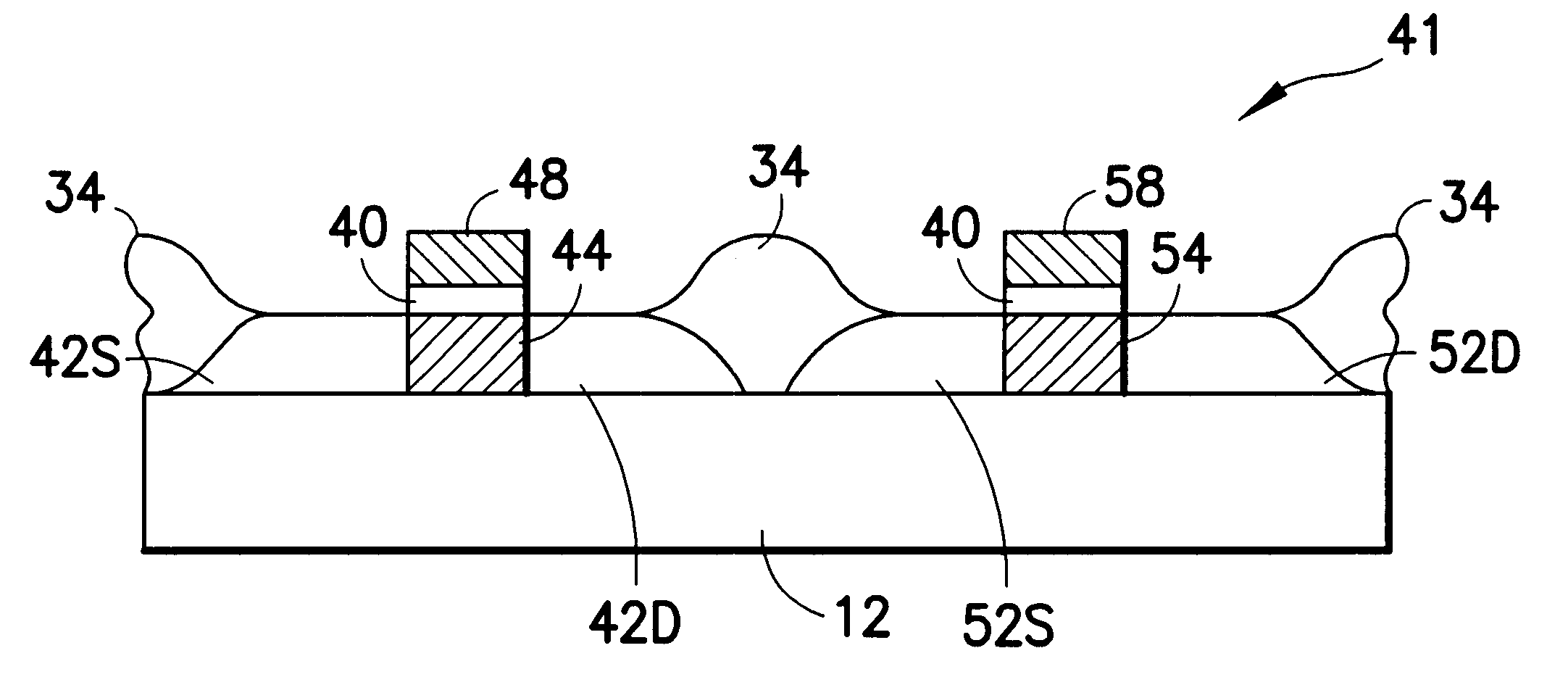

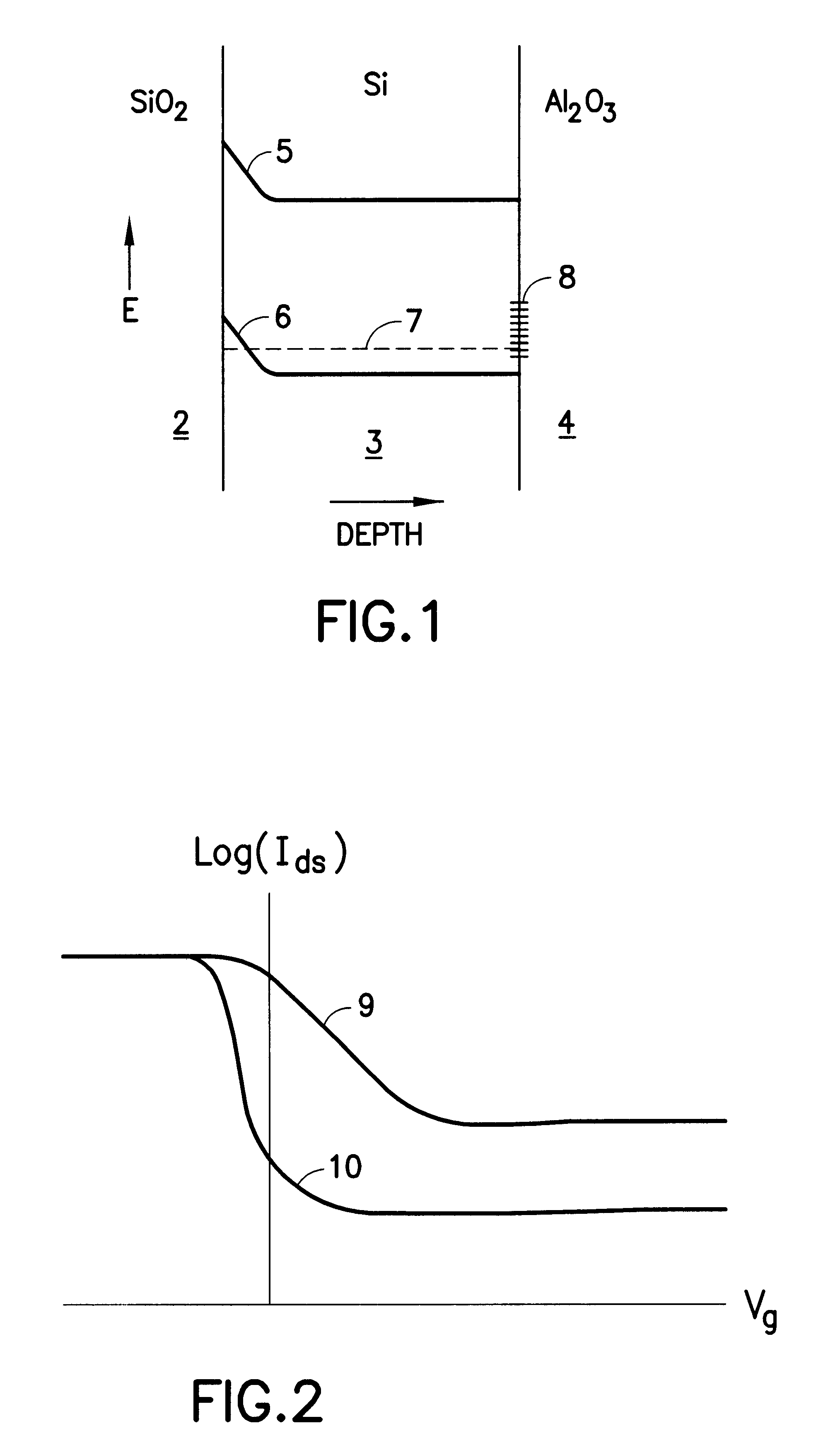

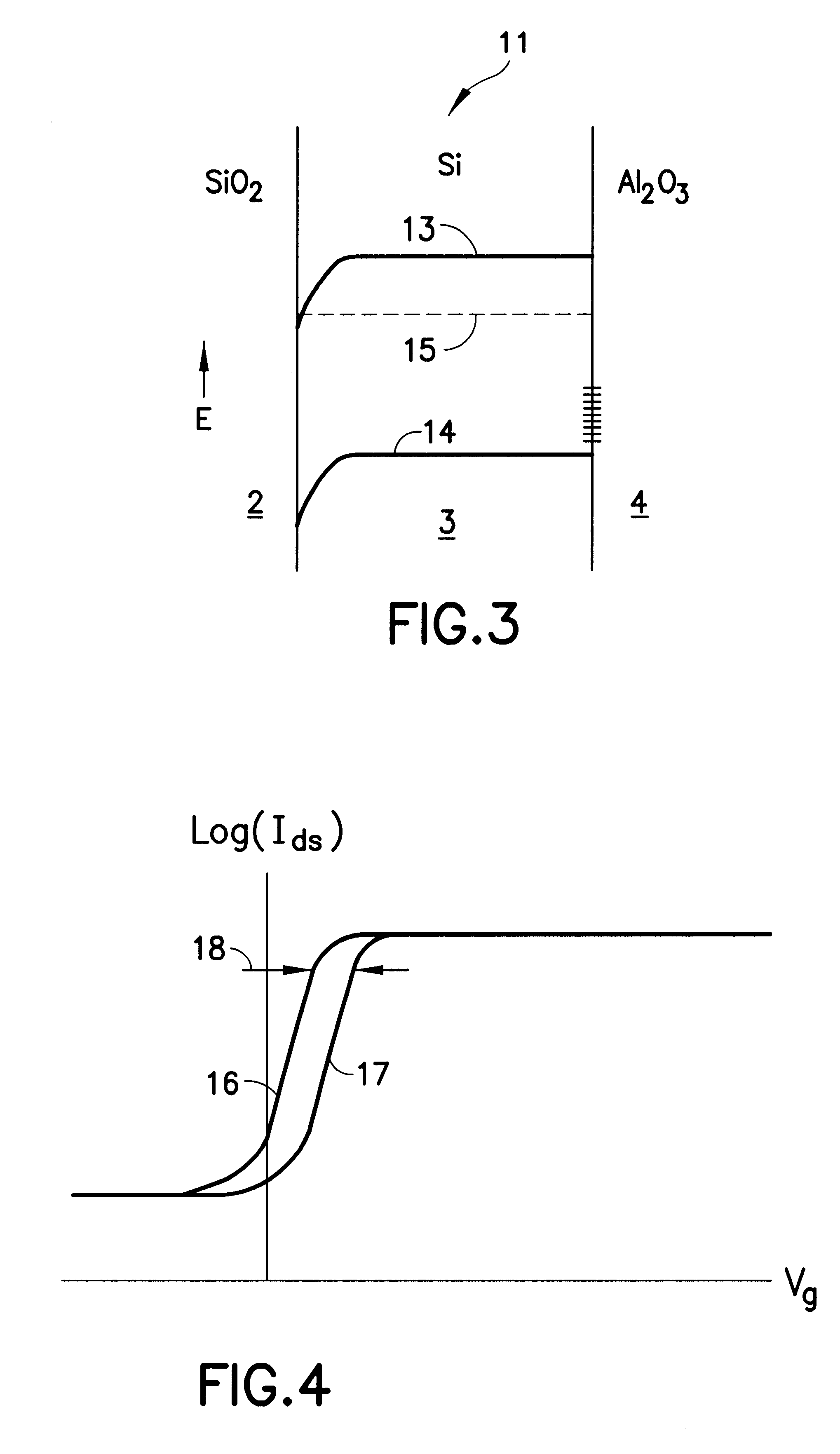

Radiation-hardened silicon-on-insulator CMOS device, and method of making the same

A method for eliminating the radiation-induced off-state current in the P-channel ultrathin silicon-on-sapphire transistor, by providing a retrograde dopant concentration profile that has the effect of moving the Fermi level at the back of the device away from that part of the bandgap where the interface states are located. When the Fermi level does not swing through this area in any region of operation of the device, subthreshold stretchout of the I-V curves does not occur.

Owner:PSEMI CORP

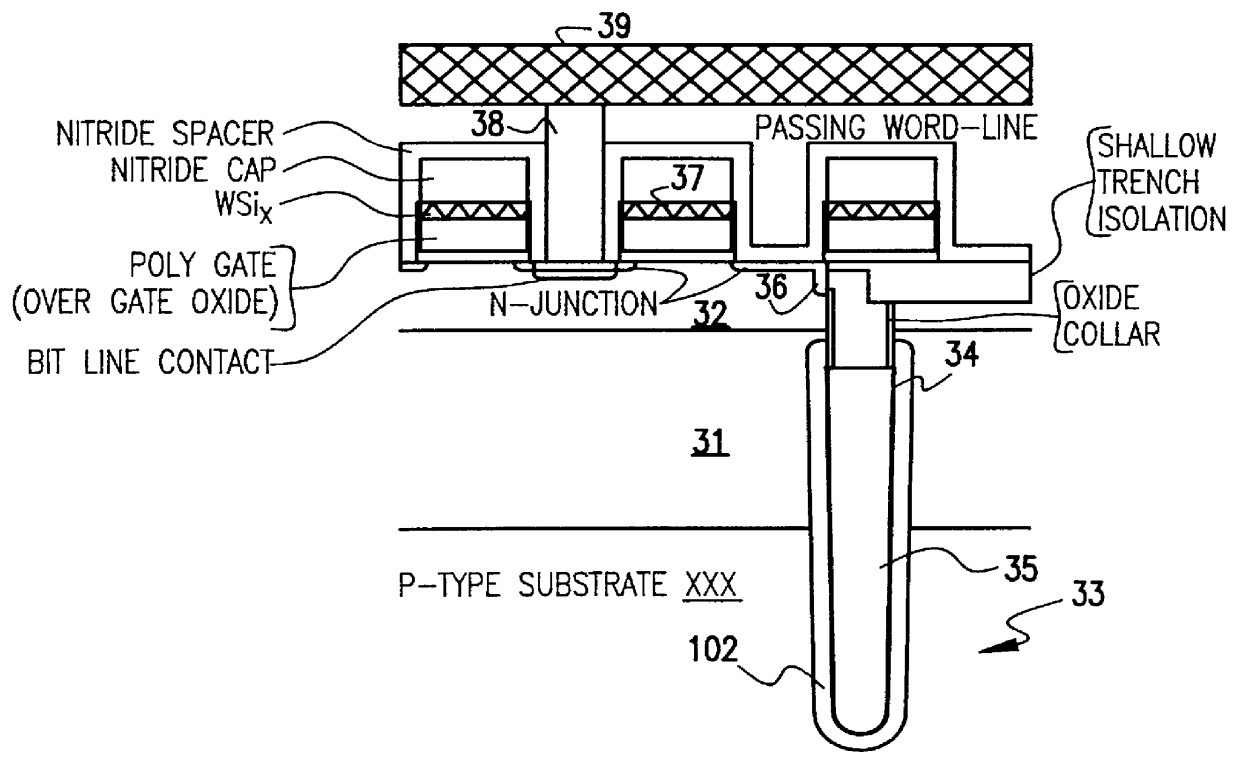

Trench capacitor structures

An optimized trench capacitor structure which is useful as a decoupling capacitor or a storage capacitor can be manufactured without added process complexity. As an on-chip decoupling trench capacitor structure, the structure reduces the series resistance to outer and inner plates and results in an acceptable RC delay, while maintaining a high capacitance per unit area. As a storage capacitor with a buried shield, the trench capacitor structure exhibits high immunity to alpha particle and cosmic radiation induced failures. The trench capacitor structure which includes a buried n-well in a silicon substrate. A trench is formed in the substrate and extends through the buried n-well. A dielectric film is formed on an inner surface of the trench, and an inner plate formed as a polysilicon fill within the trench is connected to a surface n+ film formed during definition of peripheral source / drain contacts of the integrated circuit. An outer plate of the capacitor in the form of an out diffusion from the trench provides a low resistance electrical contact with the substrate. A number of these capacitors can be combined in a very efficient X-Y array of decoupling capacitors.

Owner:IBM CORP

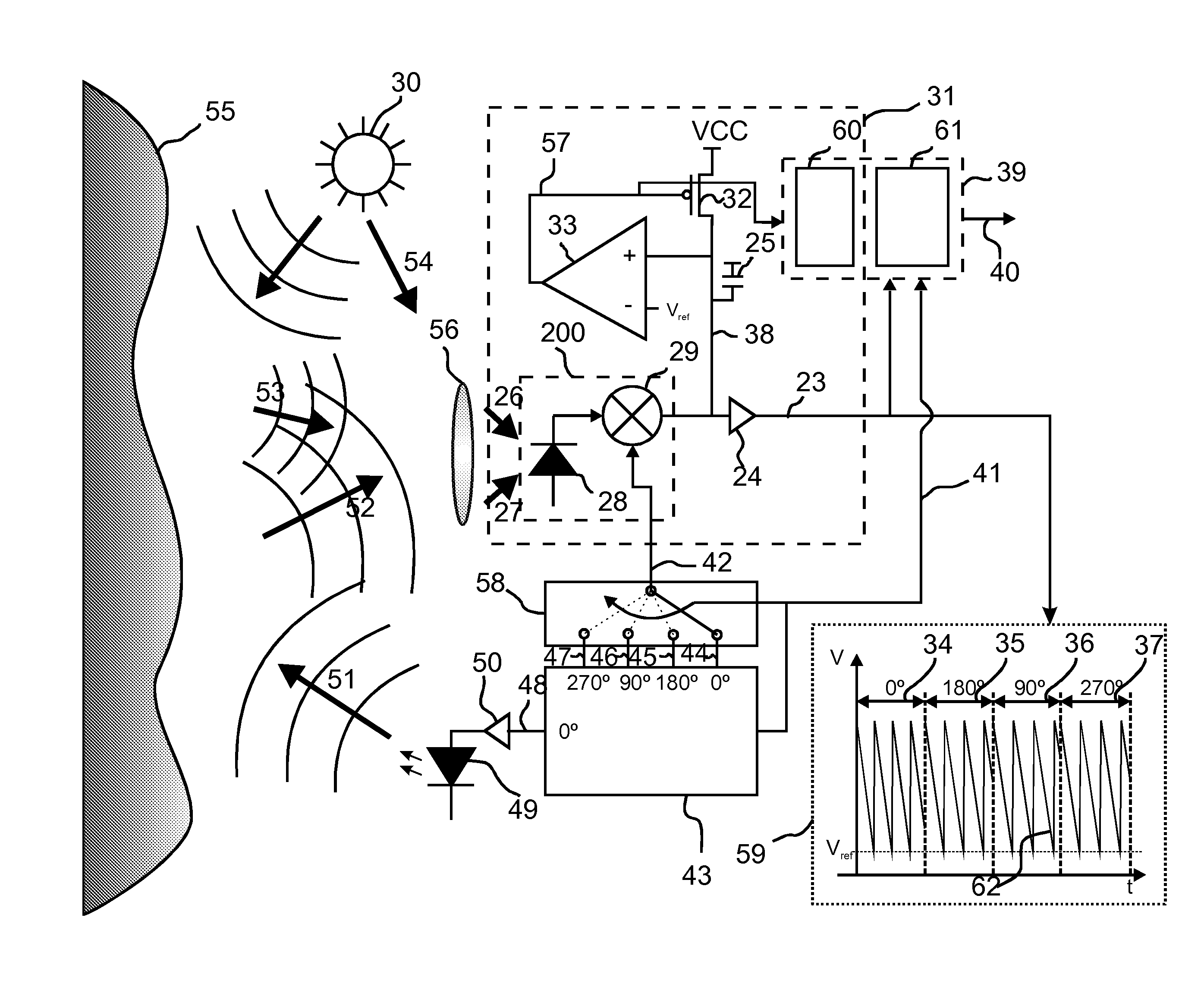

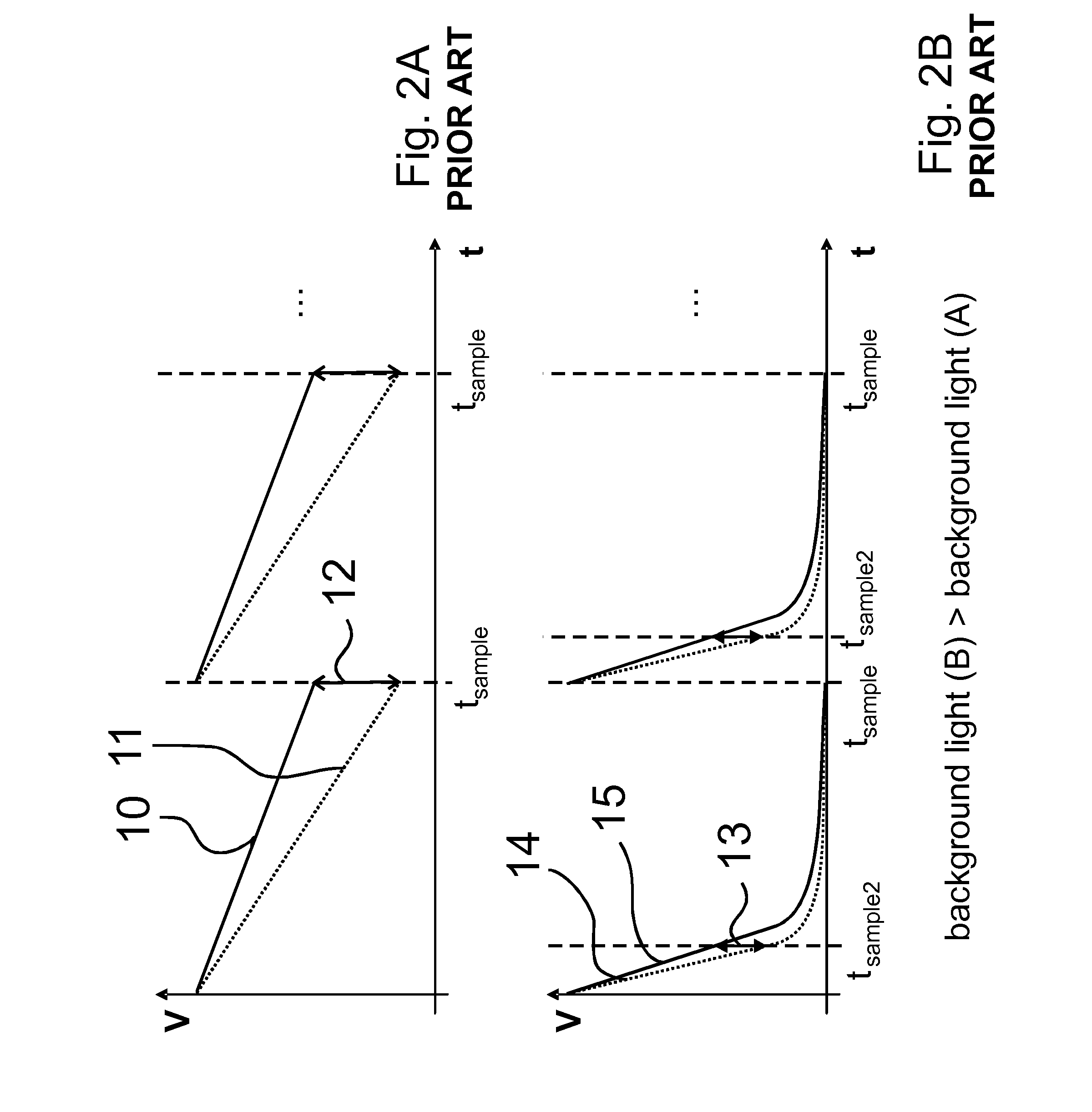

TOF Range Finding With Background Radiation Suppression

ActiveUS20110058153A1Reduce lightTelevision system detailsRadiation pyrometryElectric signalTime of flight

A method for measuring time of flight of radiation includes emitting modulated radiation (51) in response to a first modulation signal, projecting the modulated radiation (51) onto a scene (55), and receiving radiation, the received radiation including at least modulated radiation reflected by the scene (55). The received radiation (26, 27) is converted into a radiation induced electrical signal. The radiation induced electrical signal is mixed with a second modulation signal, thus generating a mixed signal, which is integrated, thus generating an integrated signal. When the integrated signal exceeds a threshold value (Vref), charge is injected into the integrated signal. The method includes applying changes to the first and / or second modulation signal at one or more moments in time, and measuring the integrated signal at one or more moments in time, thus obtaining at least one TOF pair difference signal (62). The measuring includes using a single detector node (38) and associated memory element (25), to obtain a TOF pair difference signal (62). The method furthermore includes using one or more TOF pair difference signals to determine time of flight of radiation.

Owner:SOFTKINETIC SENSORS

Method and topical formulation for treating skin conditions associated with aging

A composition and method are provided for alleviating the dermatological signs of intrinsic and extrinsic aging. A topical formulation containing a cosmeceutically active base, wherein the formulation provides a pH in the range of about 8.0 to 13.0 at the skin surface, is applied to the skin in order to prevent or treat aging-related skin conditions such as wrinkles, dry skin, age spots, sun damage (particularly UV radiation-induced oxidative stress), blemishes, hyperpigmented skin, age spots, increased skin thickness, loss of skin elasticity and collagen content, dry skin, lentigines and melasmas. The cosmeceutically active base is either an inorganic base, such as an inorganic hydroxide, an inorganic oxide, or a metal salt of a weak acid, or an organic base, particularly a nitrogenous base such as may be selected from primary amines, secondary amines, tertiary amines, amides, oximes, nitrites, aromatic and non-aromatic nitrogen-containing heterocycles, urea, and mixtures thereof.

Owner:DERMATRENDS INC

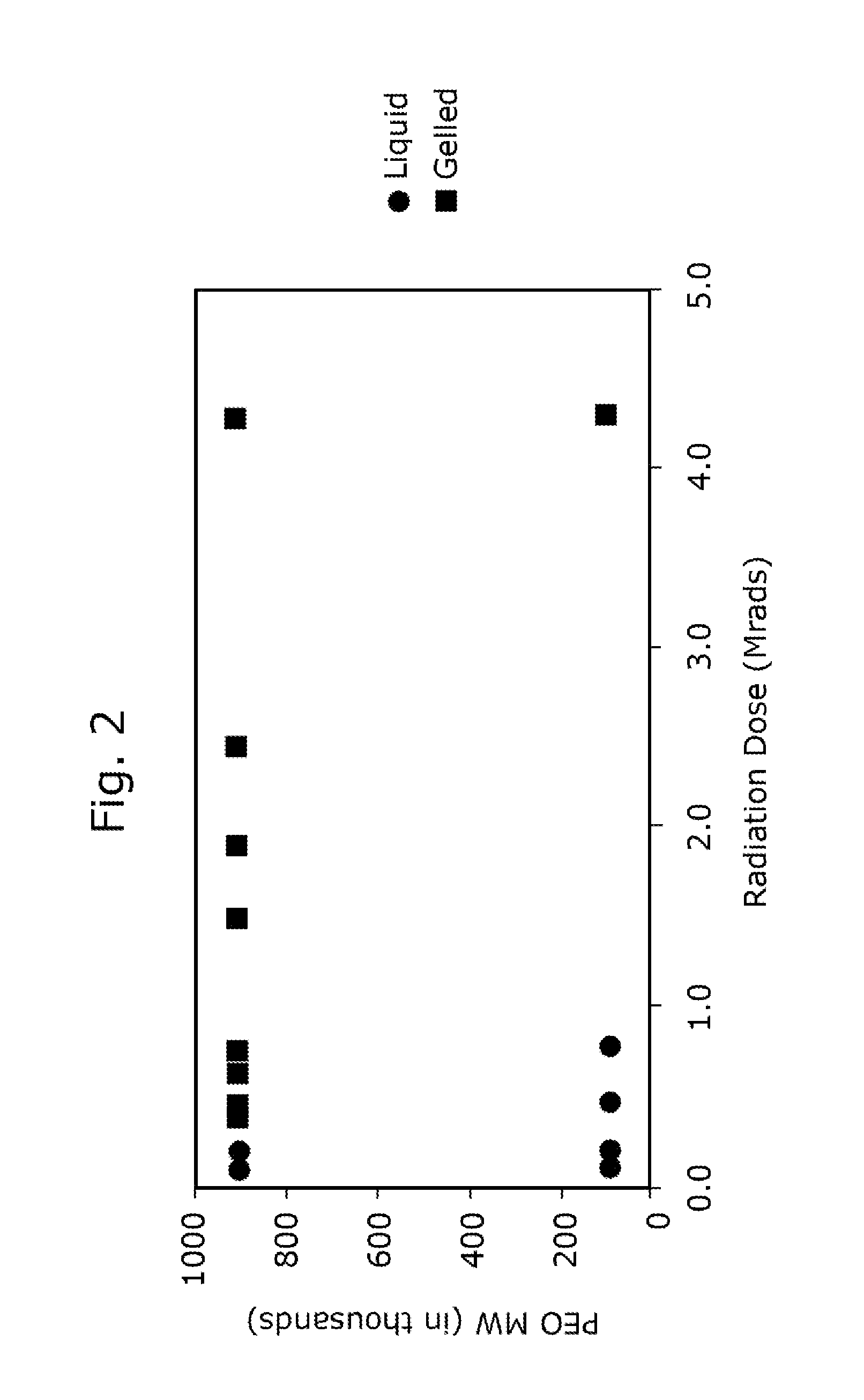

Radiation-Induced Thickening and Radiation-Induced Triggering for Set-On-Command Sealant Compositions and Methods of Use

The present invention includes methods and compositions relating to the setting of fluids or slurries in a wellbore. In one embodiment, a method of isolating a portion a wellbore includes preparing a sealant composition having a fluid component, a polymeric additive constituent, and a set modifier component. The sealant composition is placed into a wellbore and subjected to ionizing radiation. The ionizing radiation can cause bonding between polymeric additive constituents and create a polymer matrix within the sealant composition that increases the mechanical strength of the sealant composition. The ionizing radiation also alters the set modifier component, triggering the thickening of the sealant composition.

Owner:HALLIBURTON ENERGY SERVICES INC

In vivo panning for ligands to radiation-induced molecules

InactiveUS20030130190A1Increase choiceReduced flexibilityPeptide/protein ingredientsMicrobiological testing/measurementIn vivoTargeting ligands

A method for identifying a molecule that binds an irradiated tumor in a subject and molecules identified thereby. The method includes the steps of: (a) exposing a tumor to ionizing radiation; (b) administering to a subject a library of diverse molecules; and (c) isolating from the tumor one or more molecules of the library of diverse molecules, whereby a molecule that binds an irradiated tumor is identified. Also provided are therapeutic and diagnostic methods using targeting ligands that bind an irradiated tumor.

Owner:VANDERBILT UNIV

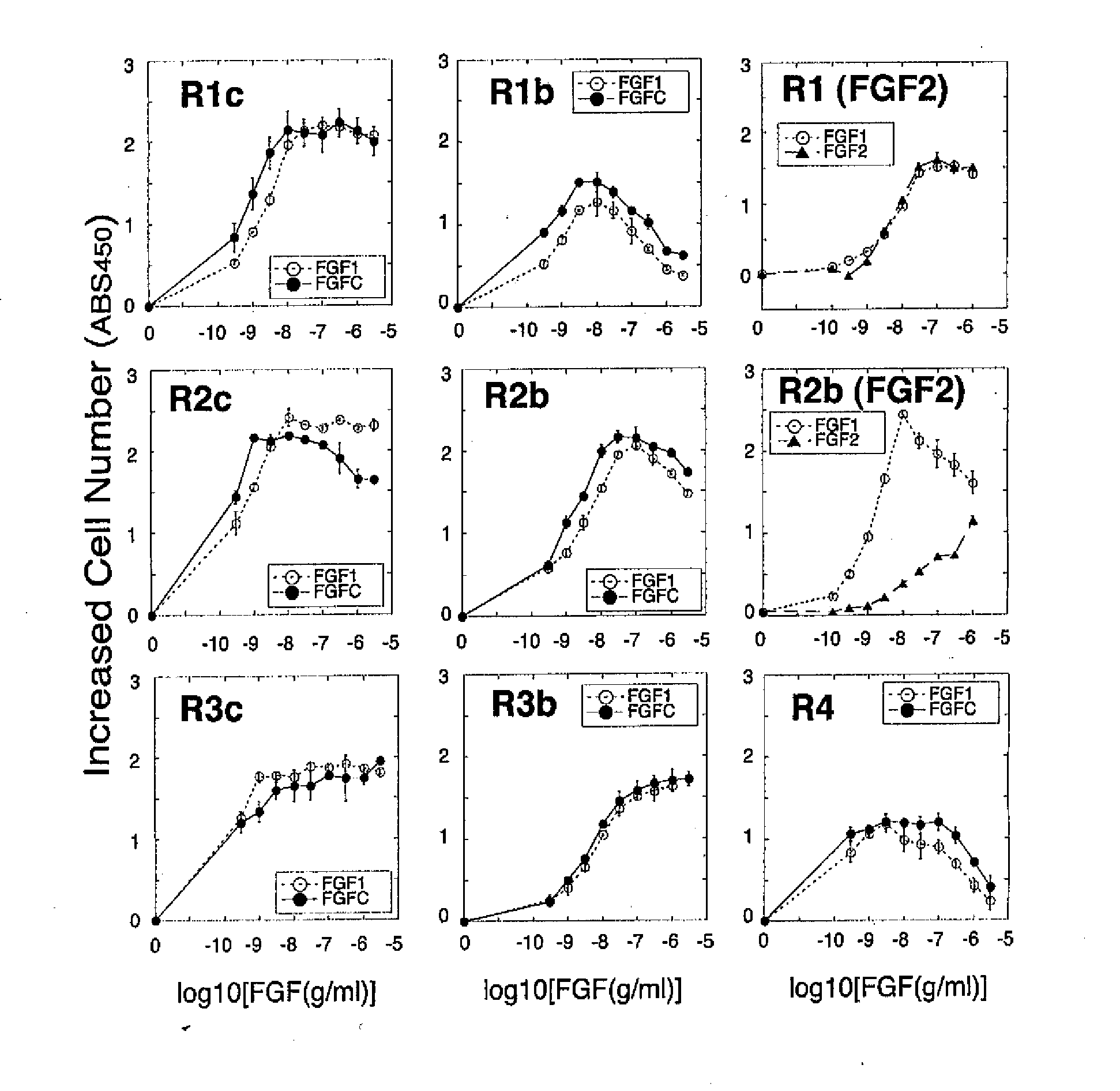

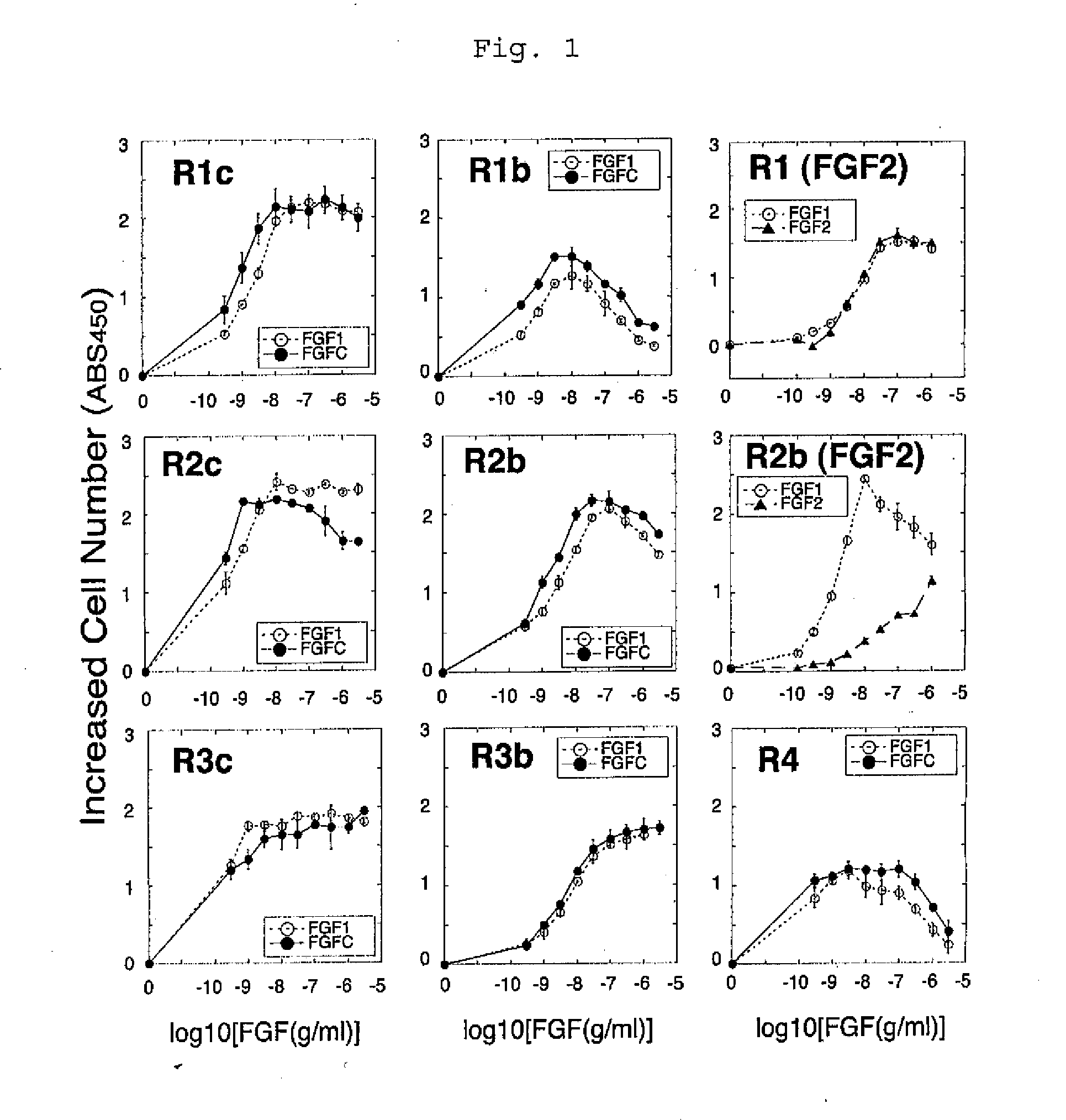

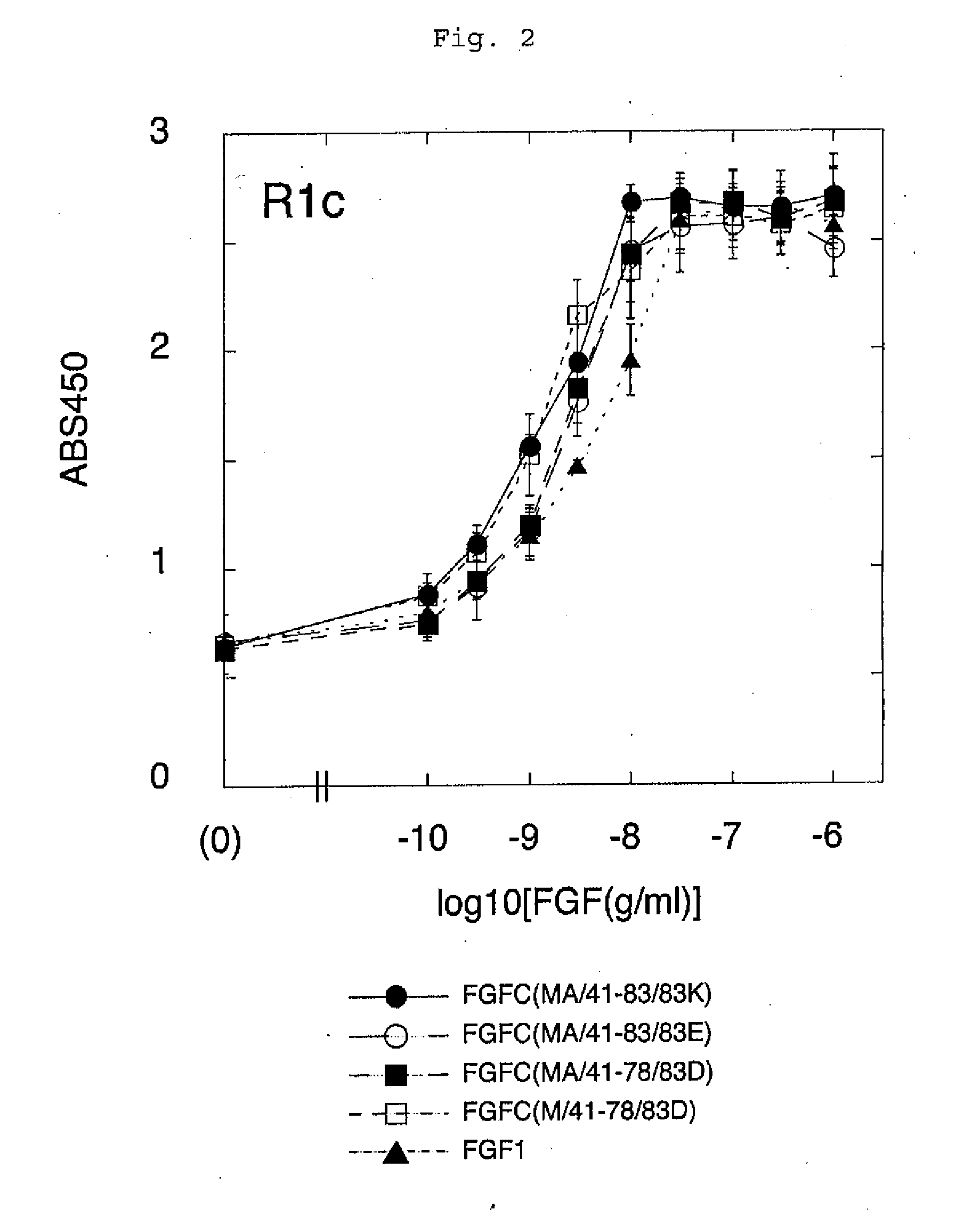

Medicinal Composition Containing Highly Functionalized Chimeric Protein

InactiveUS20100286042A1Facilitated DiffusionPromote wound healingPeptide/protein ingredientsAntibody mimetics/scaffoldsWound healingBULK ACTIVE INGREDIENT

There is provided an FGF2 substitute containing medicinal composition which comprises, as an active ingredient, a chimeric protein comprising the amino acid sequence of an FGF1 protein in which a partial sequence including a sequence of at least positions 62-83 within a sequence of positions 41-83 is substituted with a partial sequence at the corresponding positions in the amino acid sequence of an FGF2 protein; and the remaining region is formed of the amino acid sequence of FGF1. In particular, this medicinal composition is used for wound healing and for the prevention and treatment of radiation-induced damage, and it exhibits a pharmacological action superior to that of an FGF2 medicinal composition, and further, it can be easily formulated into a preparation.

Owner:NAT INST OF ADVANCED IND SCI & TECH

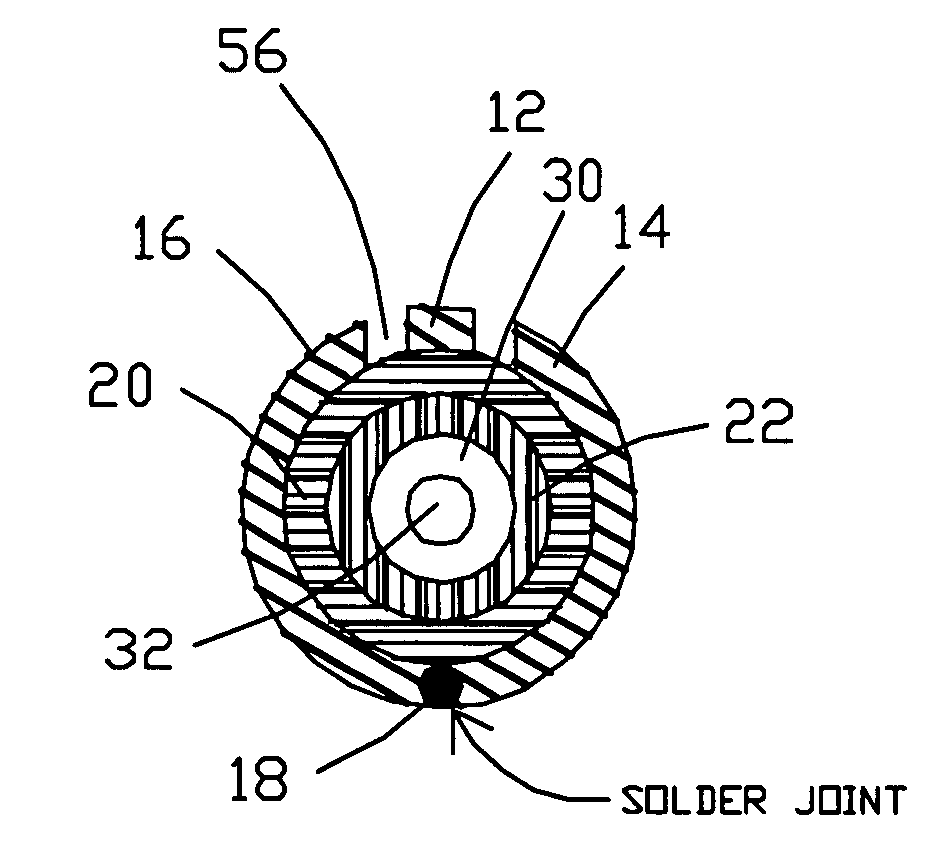

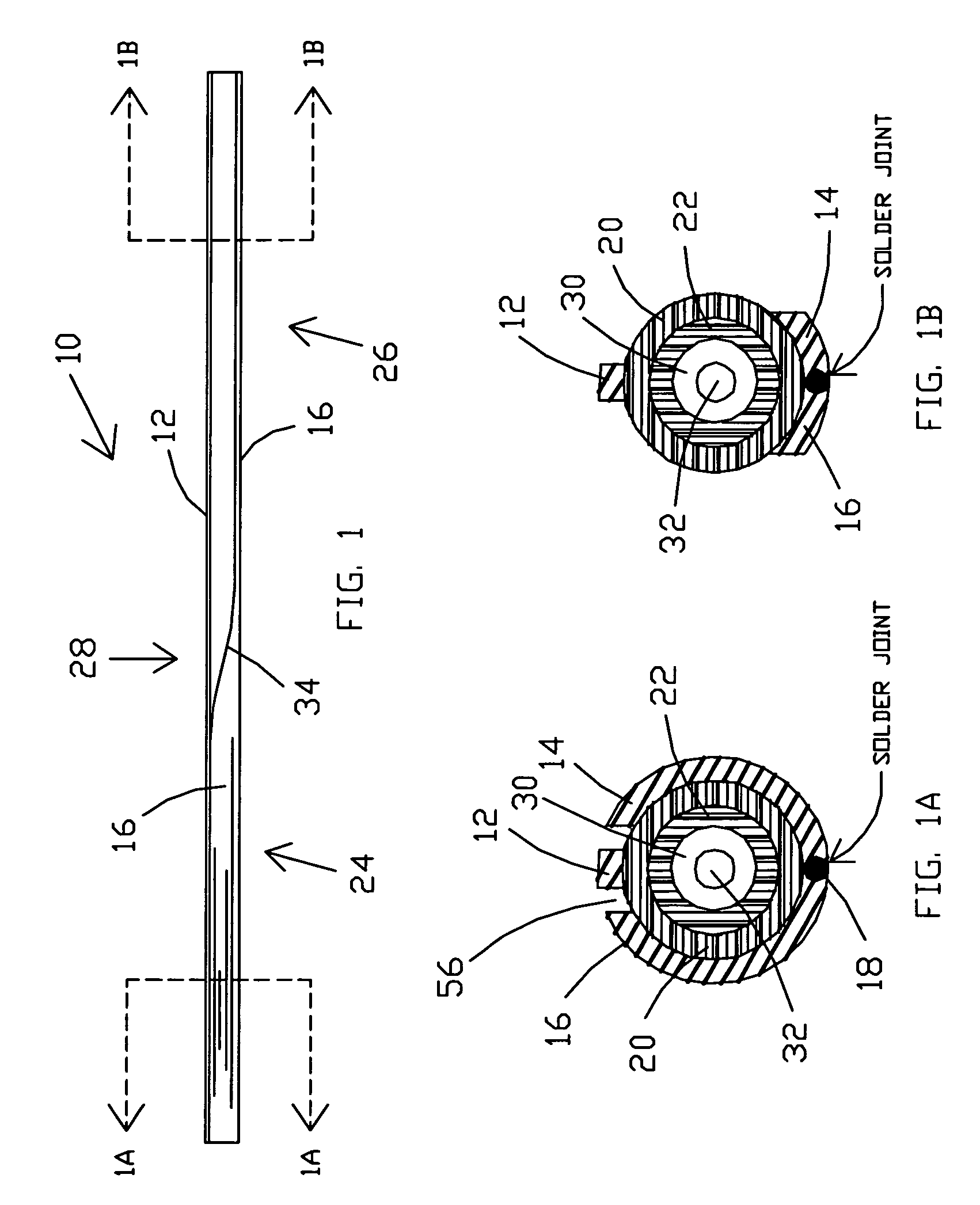

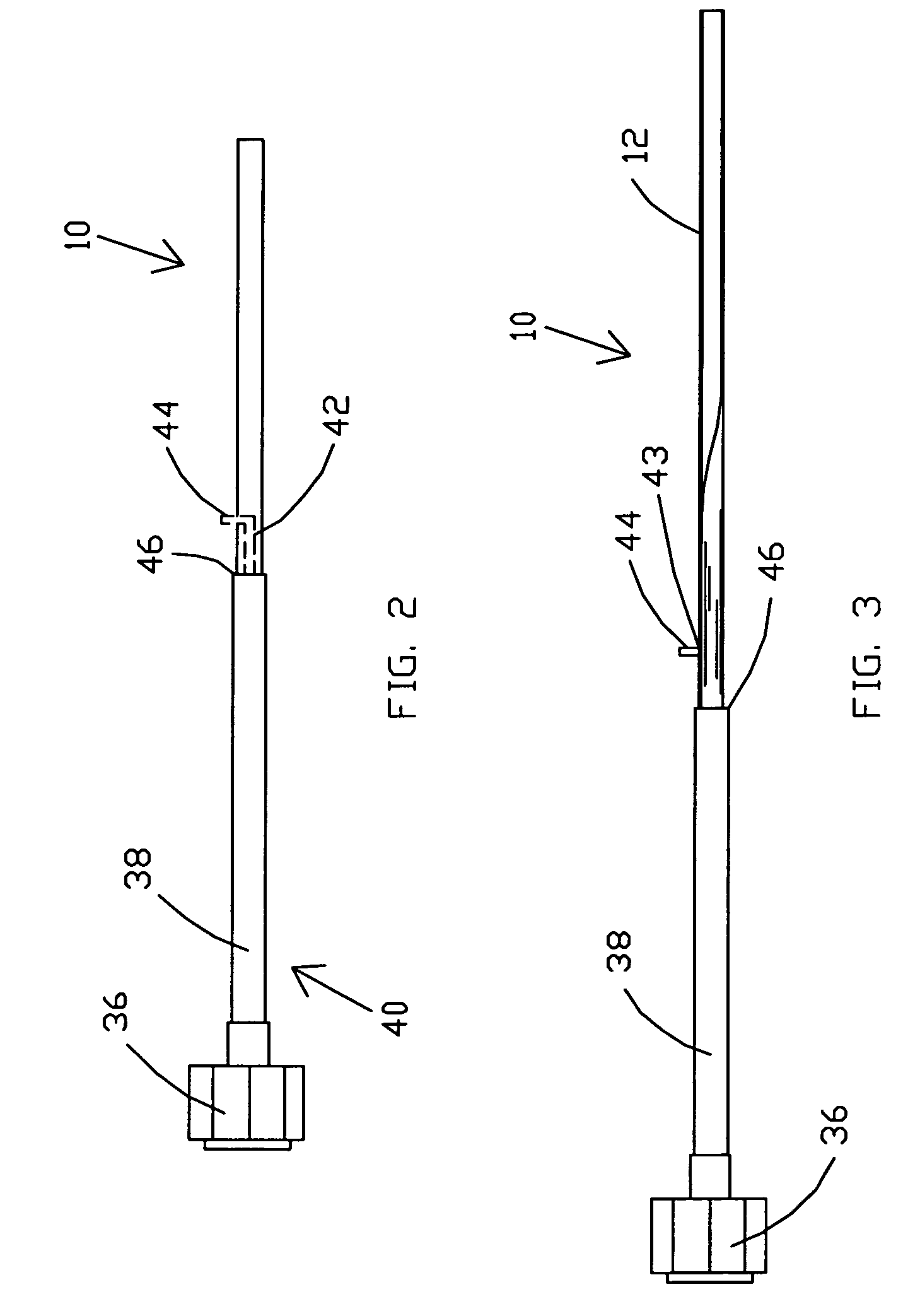

Directional microwave applicator and methods

ActiveUS7410485B1Efficiently provideElectrotherapySurgical instruments for heatingAzimuth directionBiomedical engineering

A miniature microwave antenna is disclosed which may be utilized for biomedical applications such as, for example, radiation induced hyperthermia through catheter systems. One feature of the antenna is that it possesses azimuthal directionality despite its small size. This directionality permits targeting of certain tissues while limiting thermal exposure of adjacent tissue. One embodiment has an outer diameter of about 0.095″ (2.4 mm) but the design permits for smaller diameters.

Owner:NASA

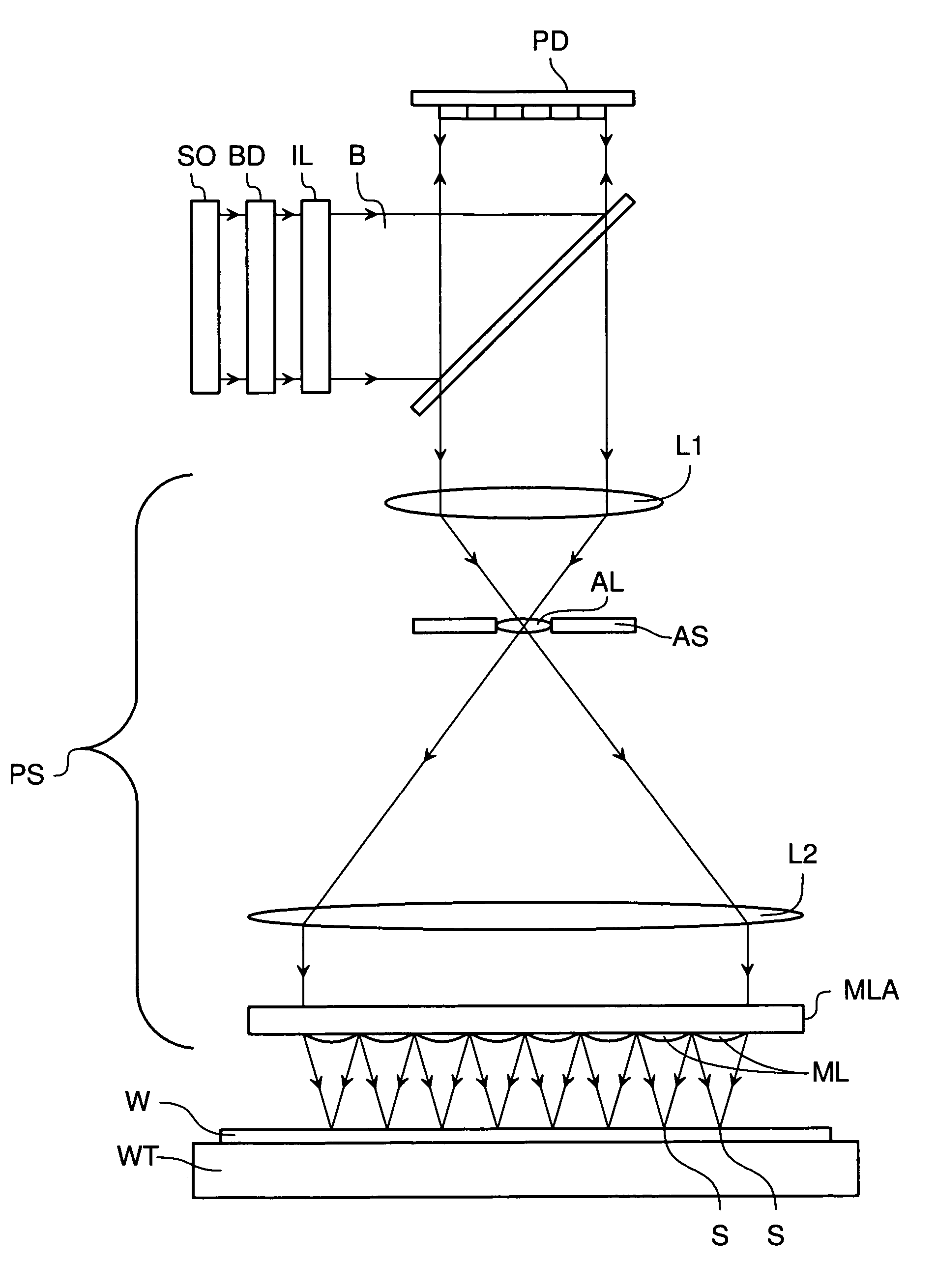

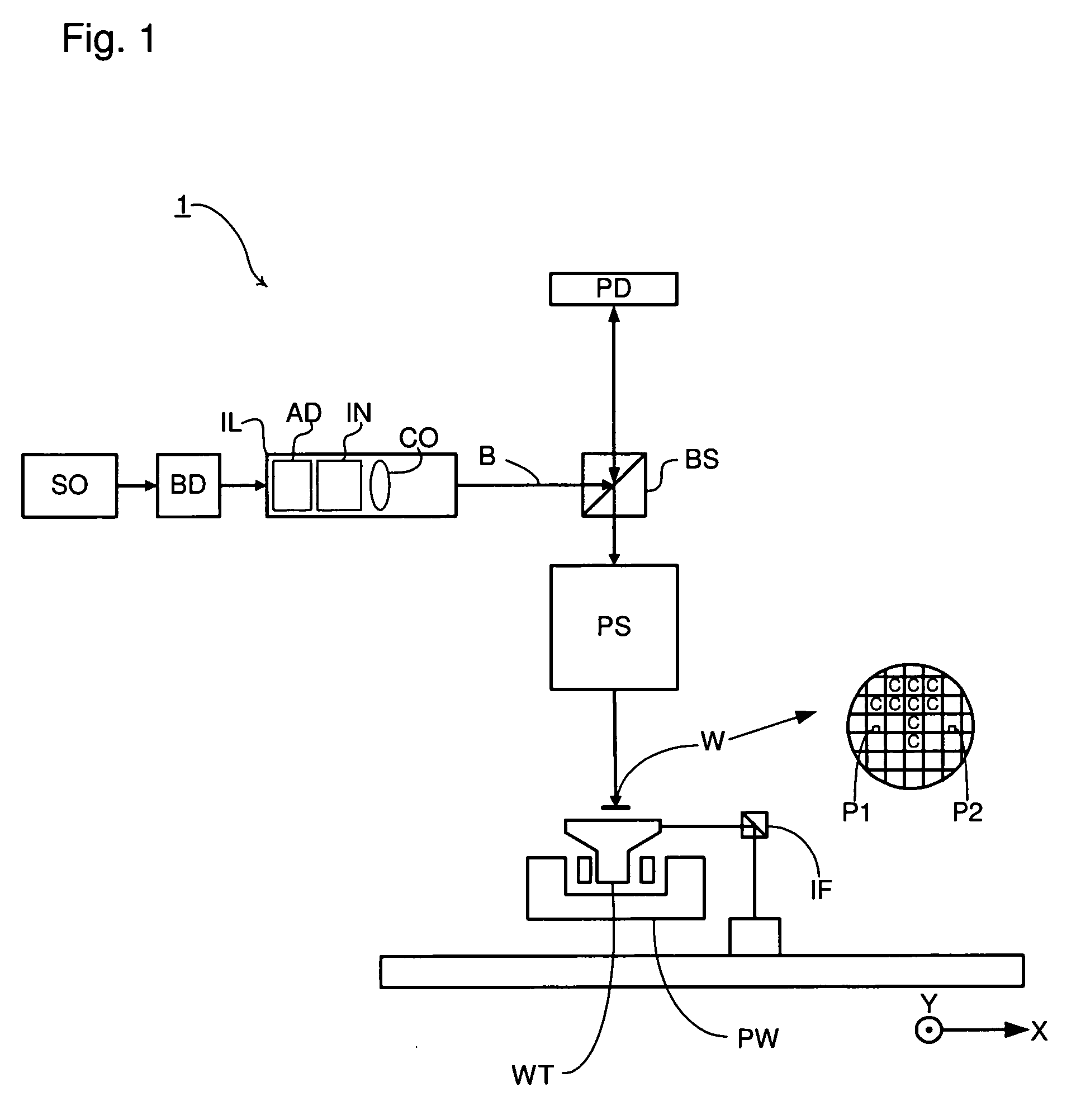

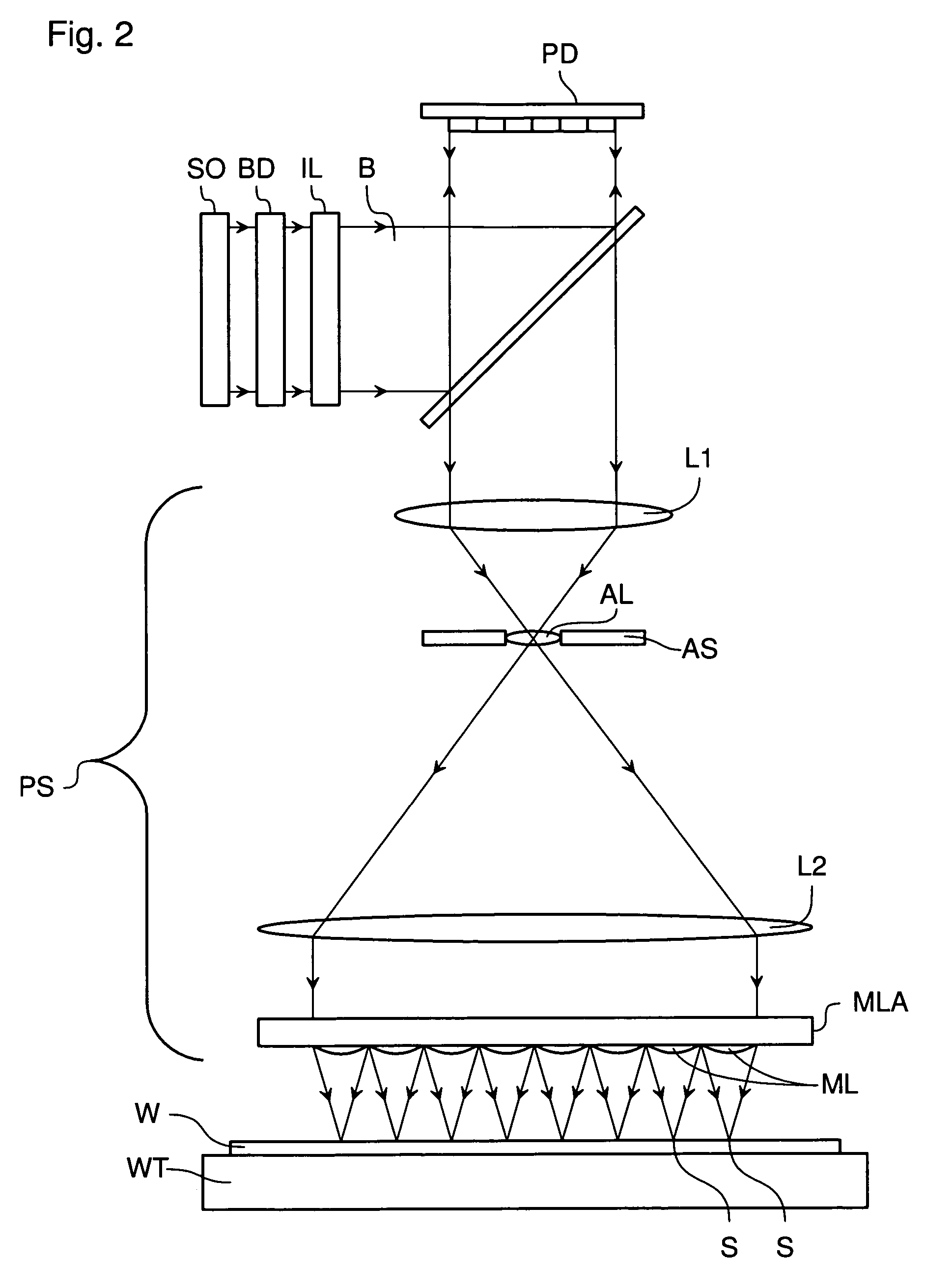

System and method for compensating for radiation induced thermal distortions

ActiveUS20070076180A1Distortion of can arisePhotomechanical apparatusPhotographic printingProjection systemThermal effect

A system and method are used to compensate for thermal effect on a lithographic apparatus. The system comprises a patterning device, a projection system, a substrate position controller, and a substrate-position-based expansion-compensator. The patterning device modulates a radiation beam. The projection system projects the modulated radiation beam onto a target portion of a substrate. The substrate position controller moves the substrate relative to the projection system sequentially through a plurality of exposure positions. The substrate-position-based expansion-compensator interacts with the substrate position controller to modify the exposure positions in order at least partially to compensate for thermally-induced geometrical changes of at least one of the substrate and projection system.

Owner:ASML NETHERLANDS BV

Thin-film solar cells and photodetectors having enhanced optical absorption and radiation tolerance

InactiveUS20070084505A1Promote absorptionImprove toleranceFinal product manufacturePhotoelectric discharge tubesDiffraction orderPhotodetector

Subwavelength random and periodic microscopic structures are used to enhance light absorption and tolerance for ionizing radiation damage of thin film and photodetectors. Diffractive front surface microscopic structures scatter light into oblique propagating higher diffraction orders that are effectively trapped within the volume of the photovoltaic material. For subwavelength periodic microscopic structures etched through the majority of the material, enhanced absorption is due to waveguide effect perpendicular to the surface thereof. Enhanced radiation tolerance of the structures of the present invention is due to closely spaced, vertical sidewall junctions that capture a majority of deeply generated electron-hole pairs before they are lost to recombination. The separation of these vertical sidewall junctions is much smaller than the minority carrier diffusion lengths even after radiation-induced degradation. The effective light trapping of the structures of the invention compensates for the significant removal of photovoltaic material and substantially reduces the weight thereof for space applications.

Owner:ZAIDI SALEEM H

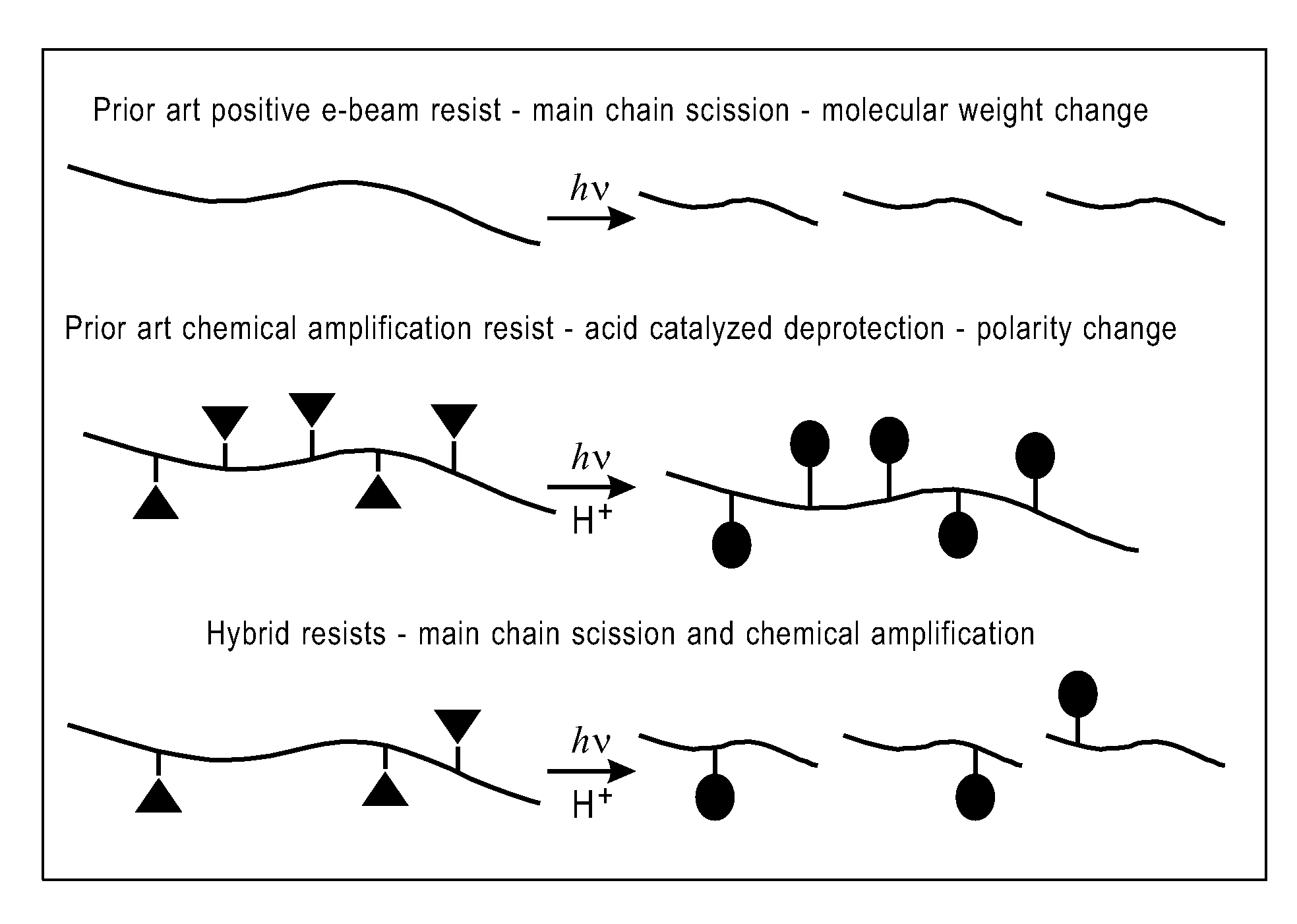

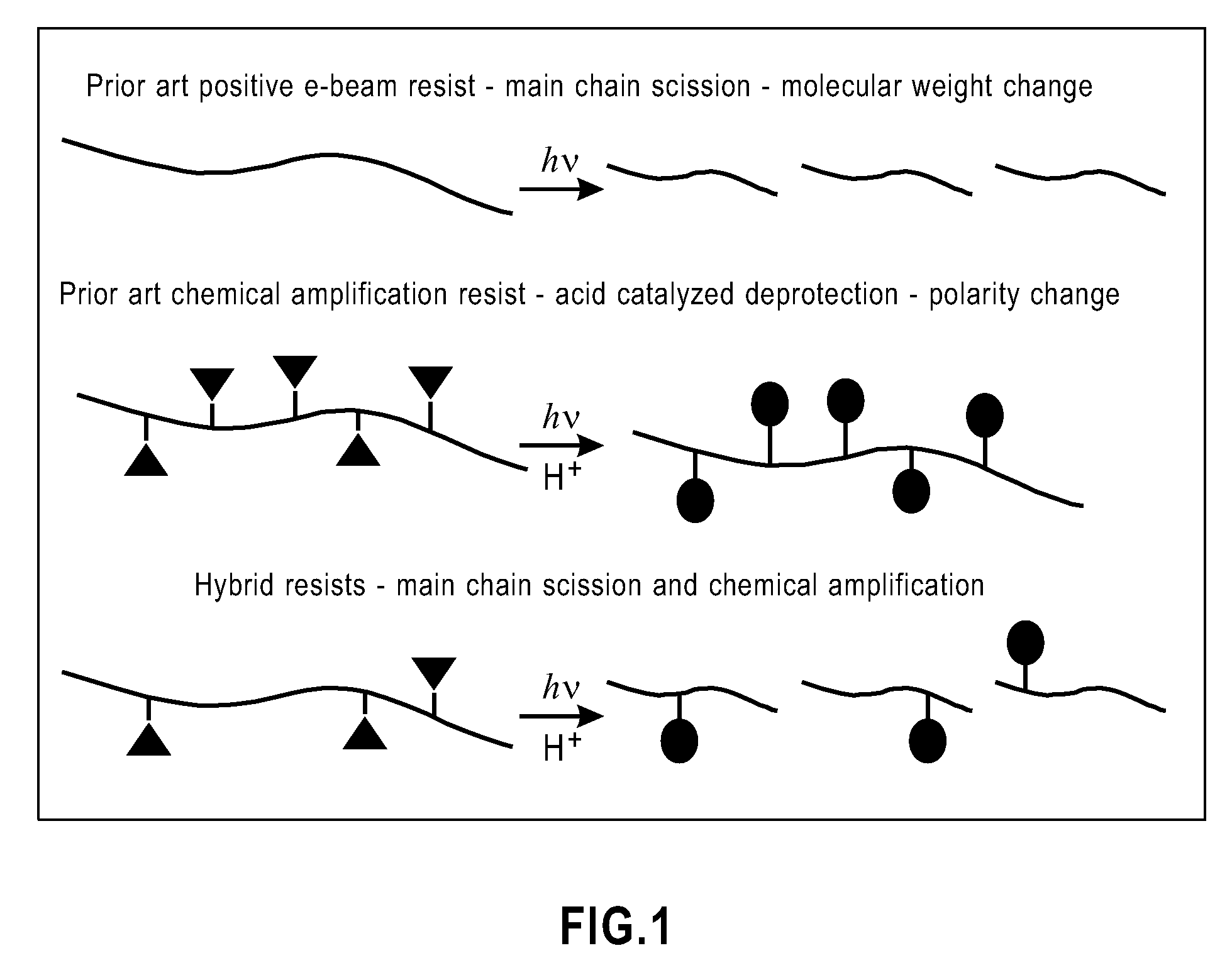

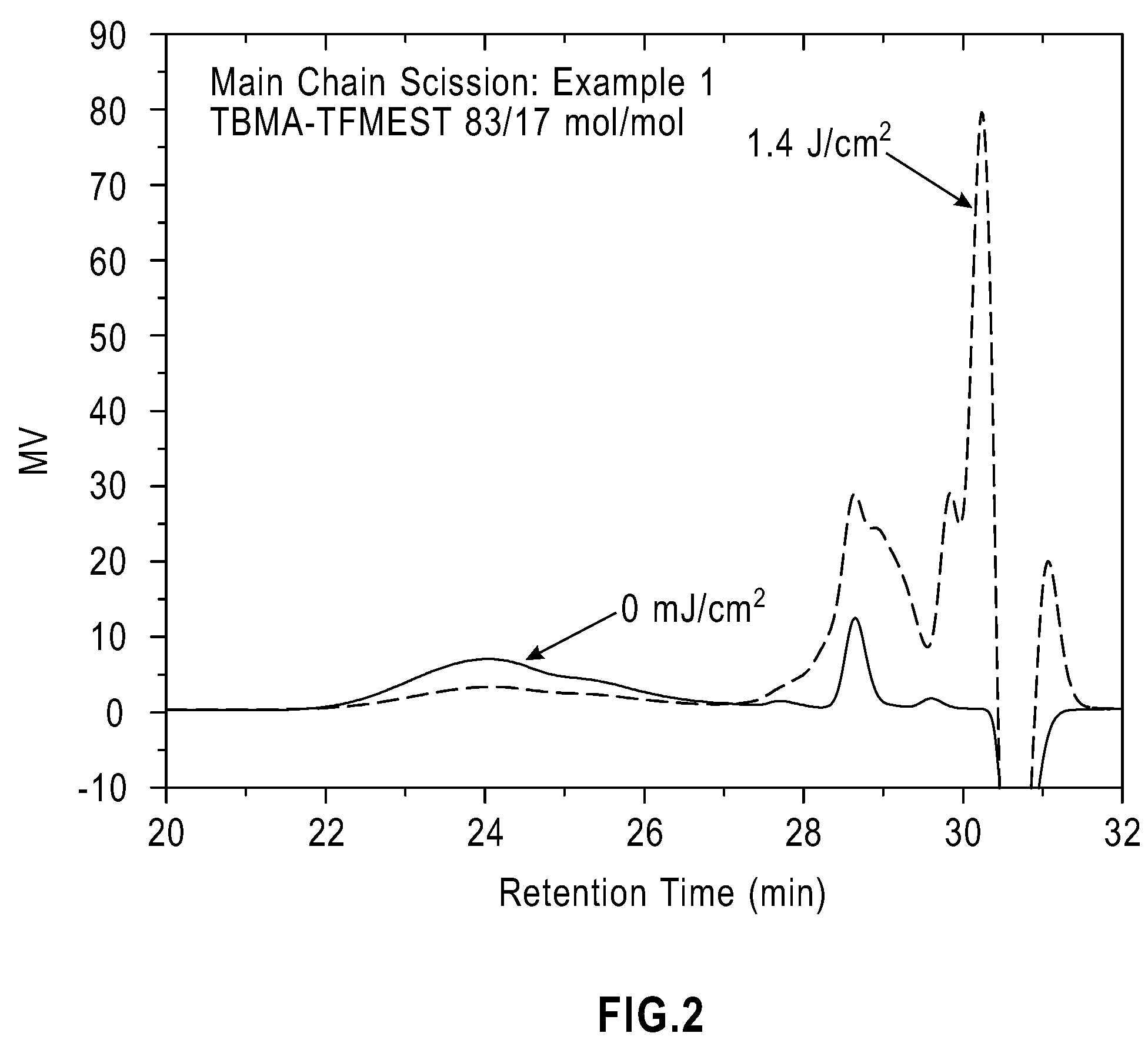

Photoresist compositions and methods of use

InactiveUS20100203450A1Photosensitive materialsPhotomechanical exposure apparatusChain scissionAcid catalyzed

A photoresist composition comprises a polymer capable of radiation induced main chain scission and acid-catalyzed deprotection, wherein the polymer is derived by free radical polymerization of two or more monomers, each having an alpha-substituent on a polymerizable vinyl group; and a photochemical acid generator.

Owner:CENT GLASS CO LTD +1

Downhole cement evalution using pulsed neutron measurements

Estimating cement voids in between a casing and a borehole wall of a borehole penetrating the earth formation includes forming with a computing device an actual ratio of radiation induced by a neutron source and measured by a first detector and a second detector when the tool is at two or more different locations in the borehole. A relationship between the actual ratio and the porosity at each of the two or more different locations is used and compared to two different cases of estimates of the ratio. Based on the comparison, an estimate of the cement voids at the two or more locations.

Owner:BAKER HUGHES INC

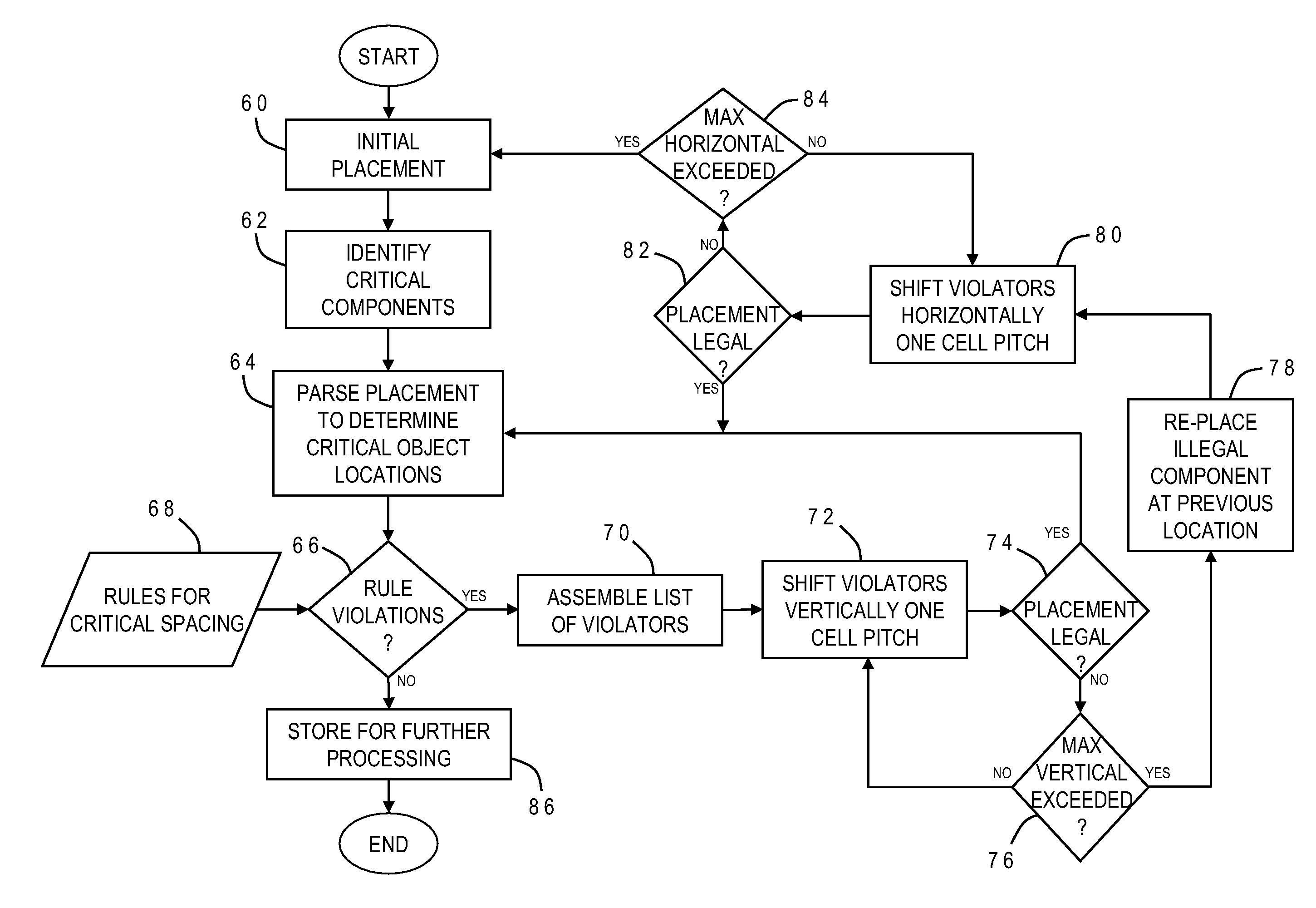

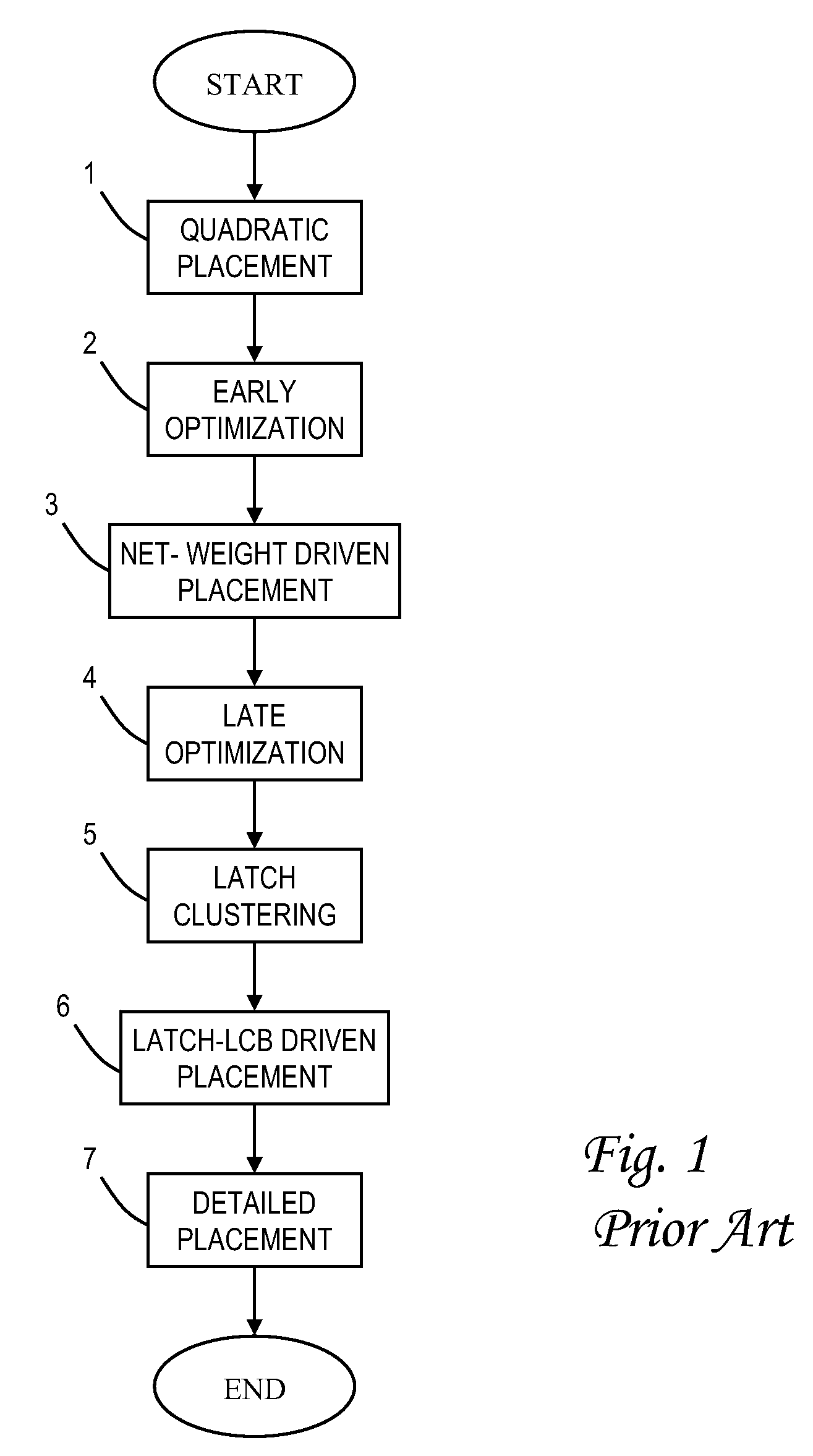

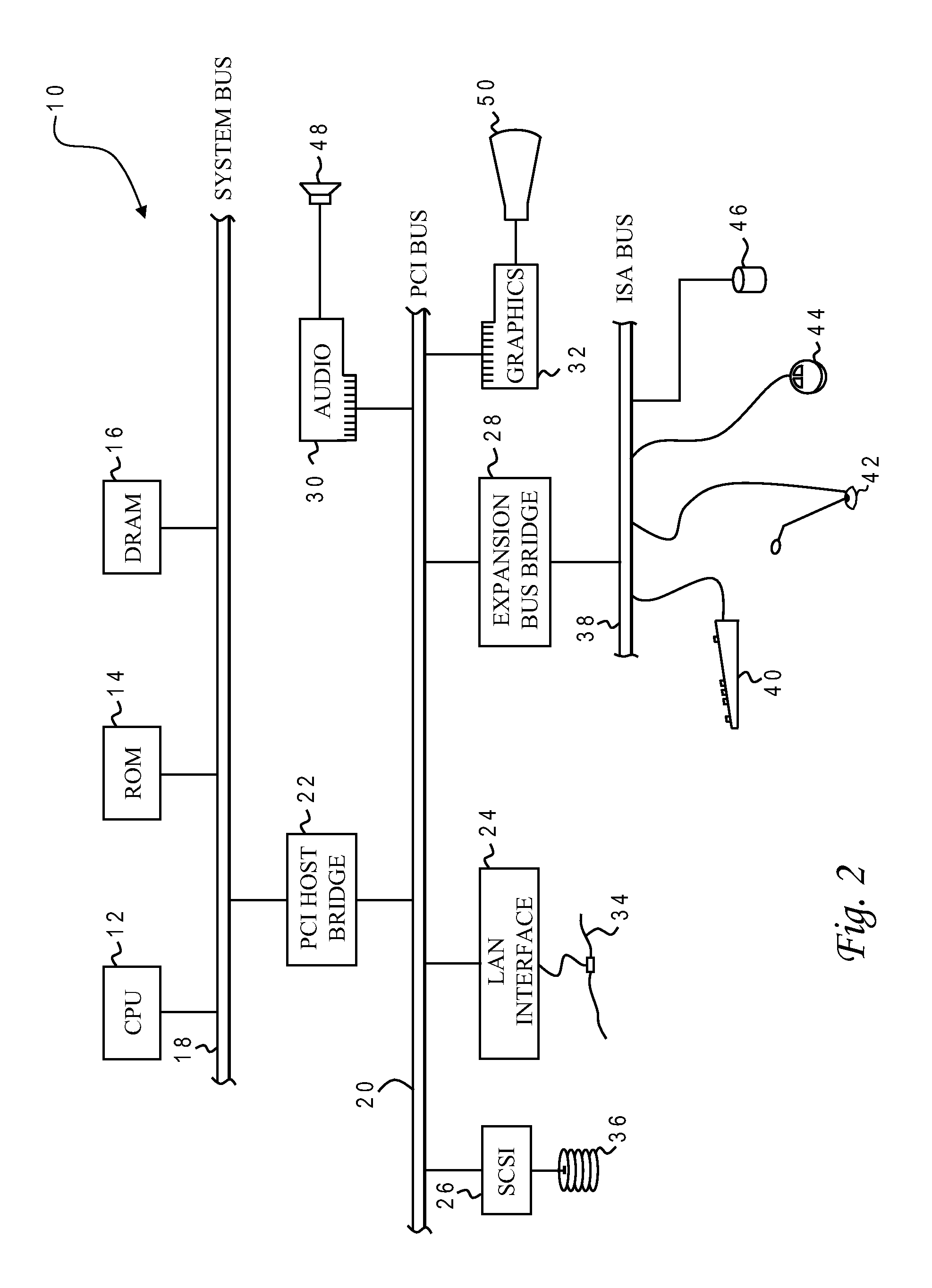

Method for radiation tolerance by automated placement

InactiveUS7774732B2Simple methodComputer aided designSpecial data processing applicationsCMOSCombined use

A method of designing a layout of an integrated circuit for increased radiation tolerance by ensuring that any critical components (those deemed particularly sensitive to radiation-induced soft errors) are at spacings greater than a predetermined threshold based on particle migration within the silicon substrate. The method starts with an initial placement, identifies the objects for which radiation tolerance is desired, determines whether any of those objects and, if so, moves the relevant objects to increase the spacing. An exemplary threshold for contemporary CMOS device technologies is 5 μm. The objects can be moved by vertically and / or horizontally shifting away from a reference point of the integrated circuit. The critical objects may include triplicated (redundant) structures, clock control latches, or a reset bit. The method can be used in conjunction with other placement optimizations such as area, power and timing.

Owner:GLOBALFOUNDRIES INC

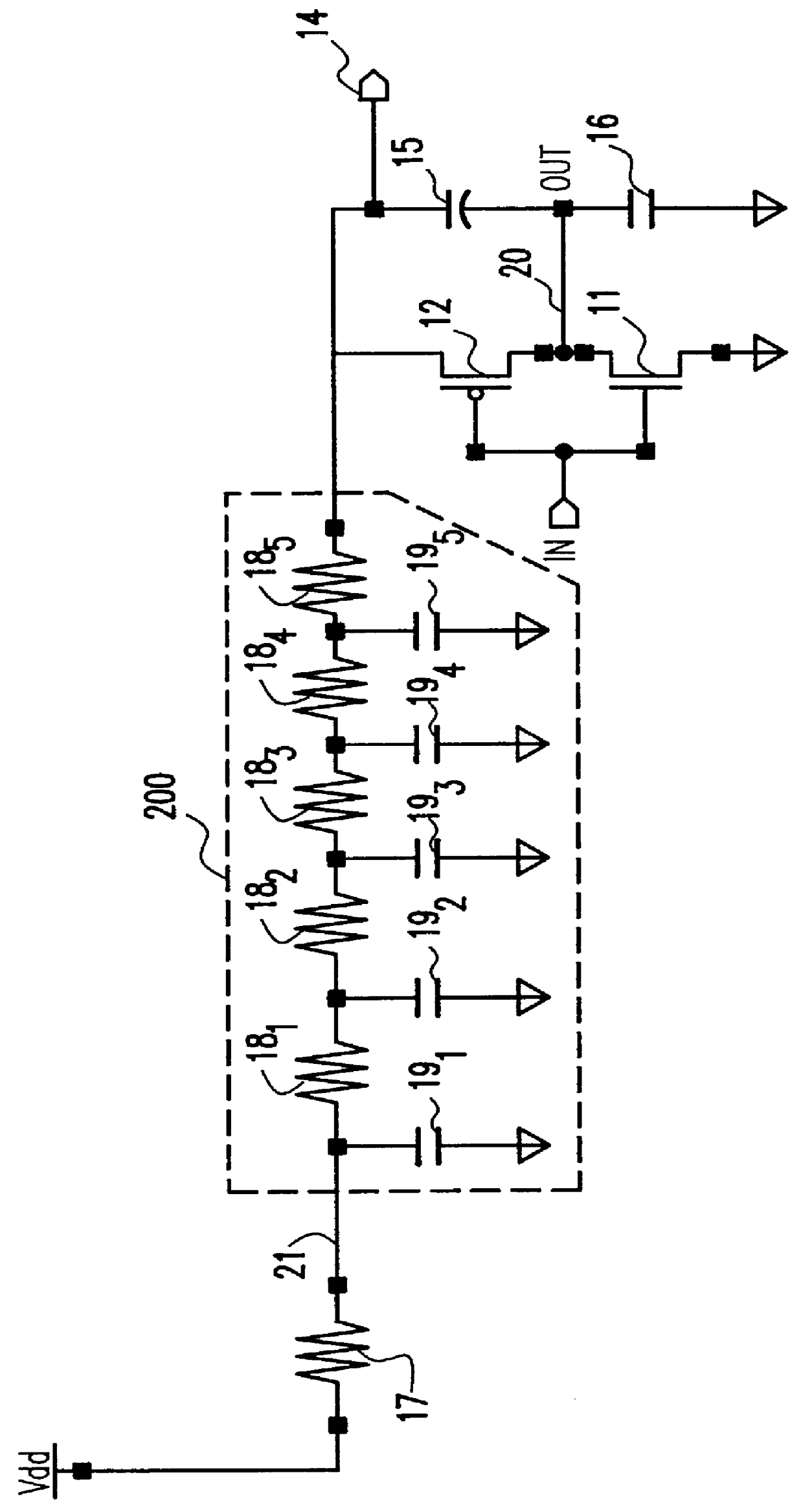

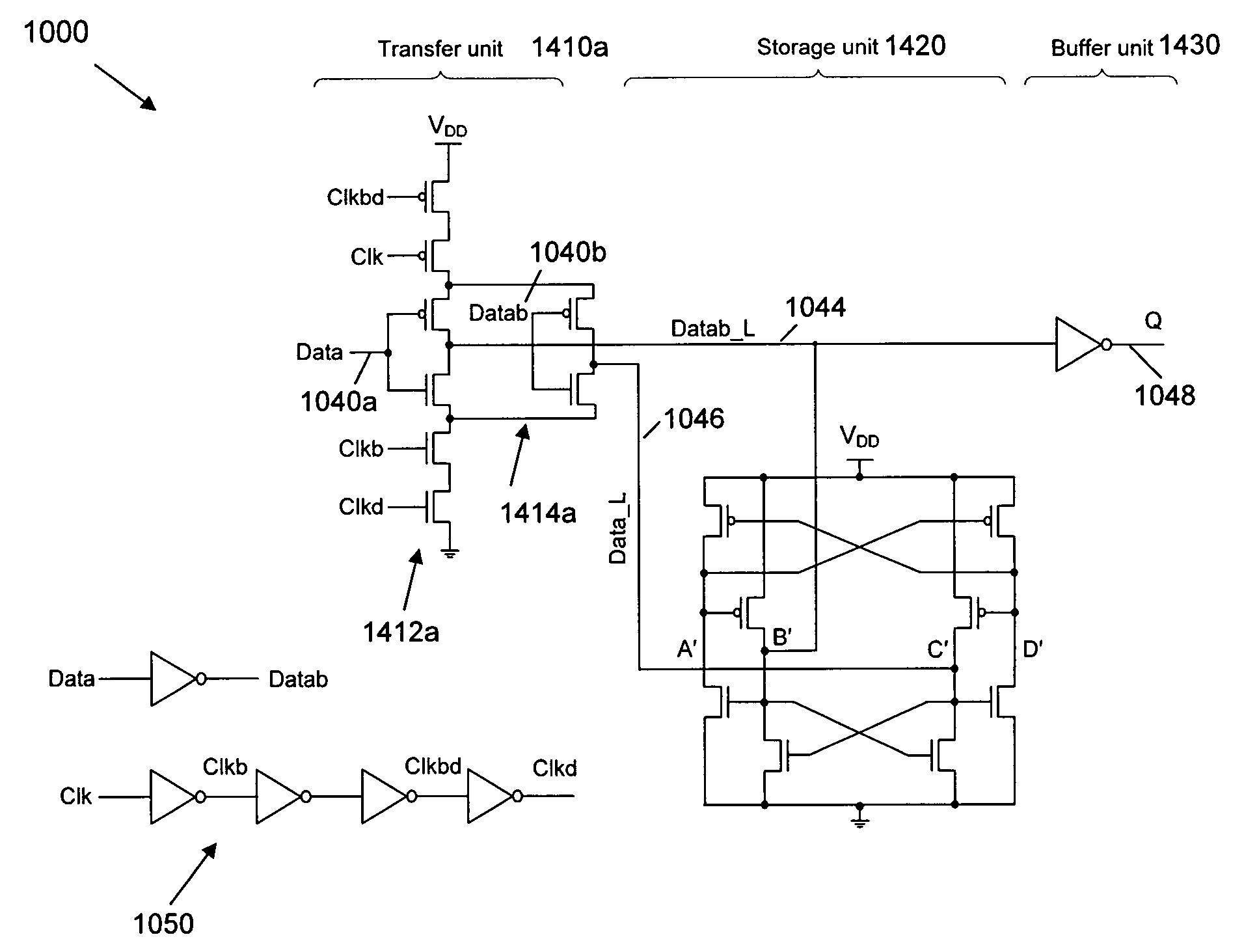

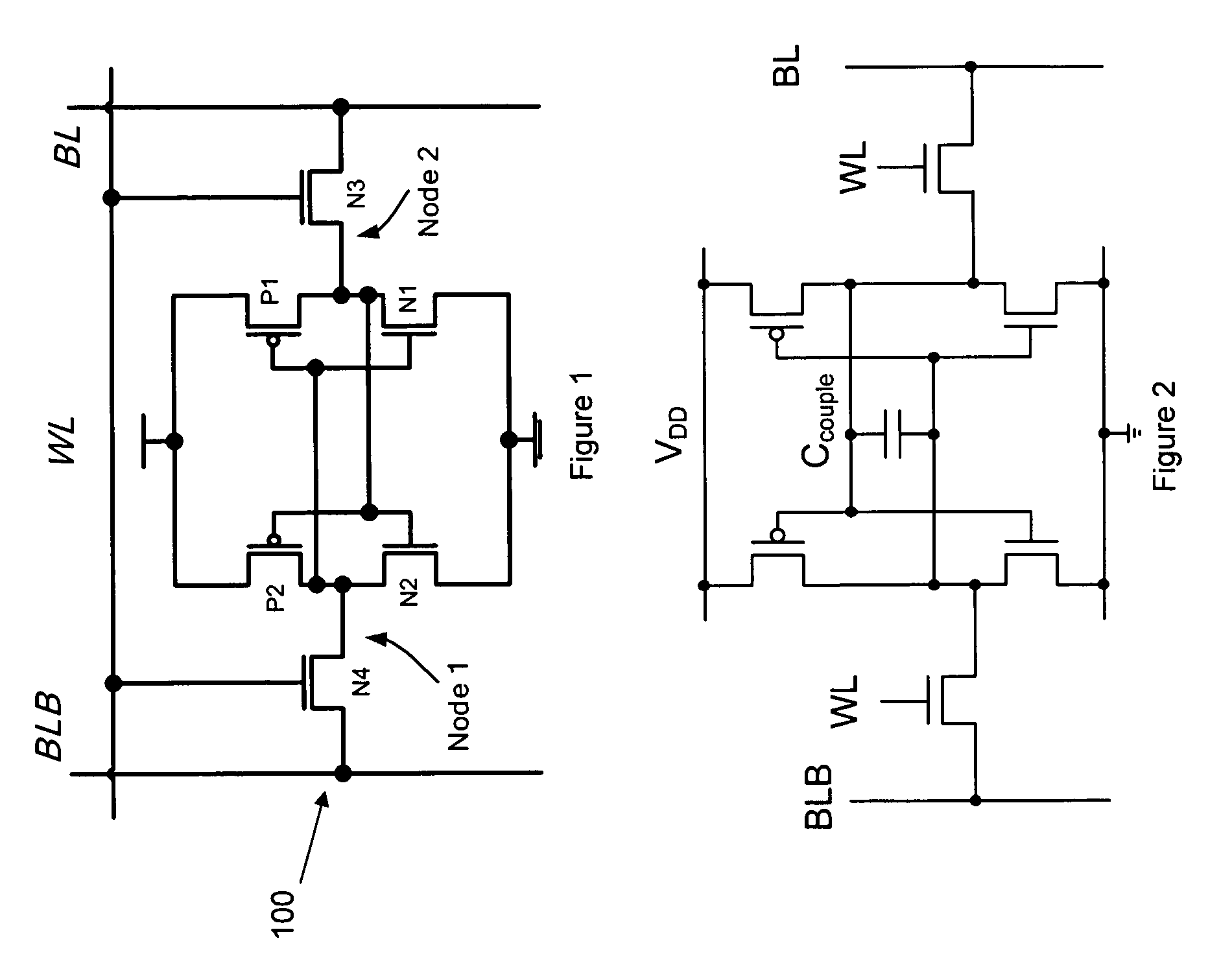

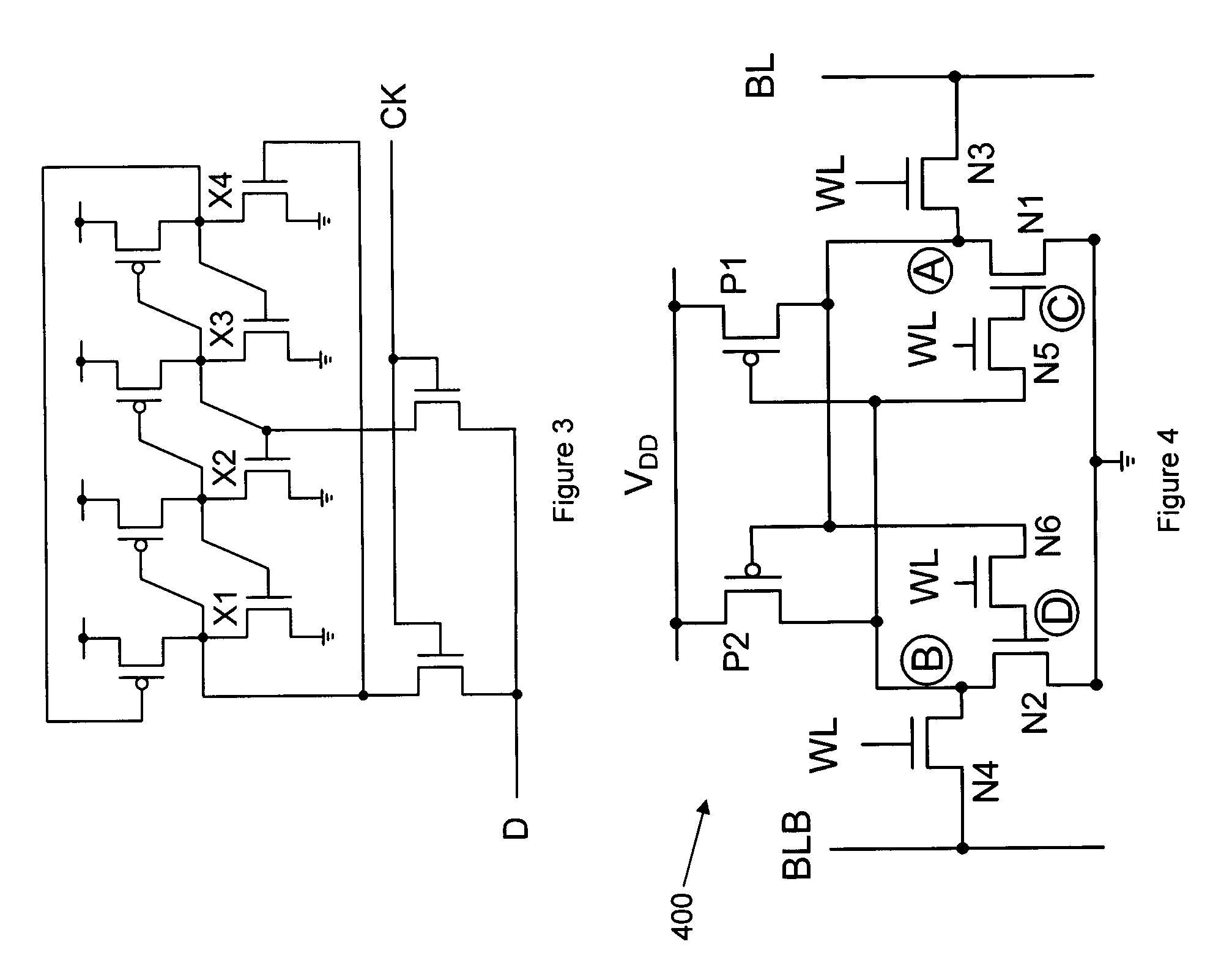

Soft Error Robust Flip-Flops

A flip-flop circuit is provided with an improved robustness to radiation induced soft errors. The flip-flop cell comprises the following elements. A transfer unit for receiving at least one data signal and at least one clock signal, a storage unit coupled to the transfer unit and a buffer unit coupled to the storage unit. The transfer unit includes a plurality of input nodes adapted to receive said at least one data signal and said at least one clock signal; a first output node for providing a sampled data signal in response to said at least one clock signal and said at least one data signal; and a second output node for providing a sampled inverse data signal, the sampled inverse data signal provided in response to said at least one clock signal and said at least one data signal. The storage unit comprises a first and a second storage nodes configured to receive and store the sampled data signal and the sampled inverse data signal. The storage unit comprises drive transistors configured to selectively couple one of the first and second storage nodes to ground; load transistors configured to selectively couple the other one of the first and second storage nodes to a power supply; and at least one stabilizer transistor configured to provide a corresponding redundant storage node and limit feedback between the first and second storage nodes, the redundant storage node being capable of restoring the first or second storage nodes in case of a soft error. The buffer unit provides an output sampled data signal as received from the storage unit.

Owner:CERTICHIP

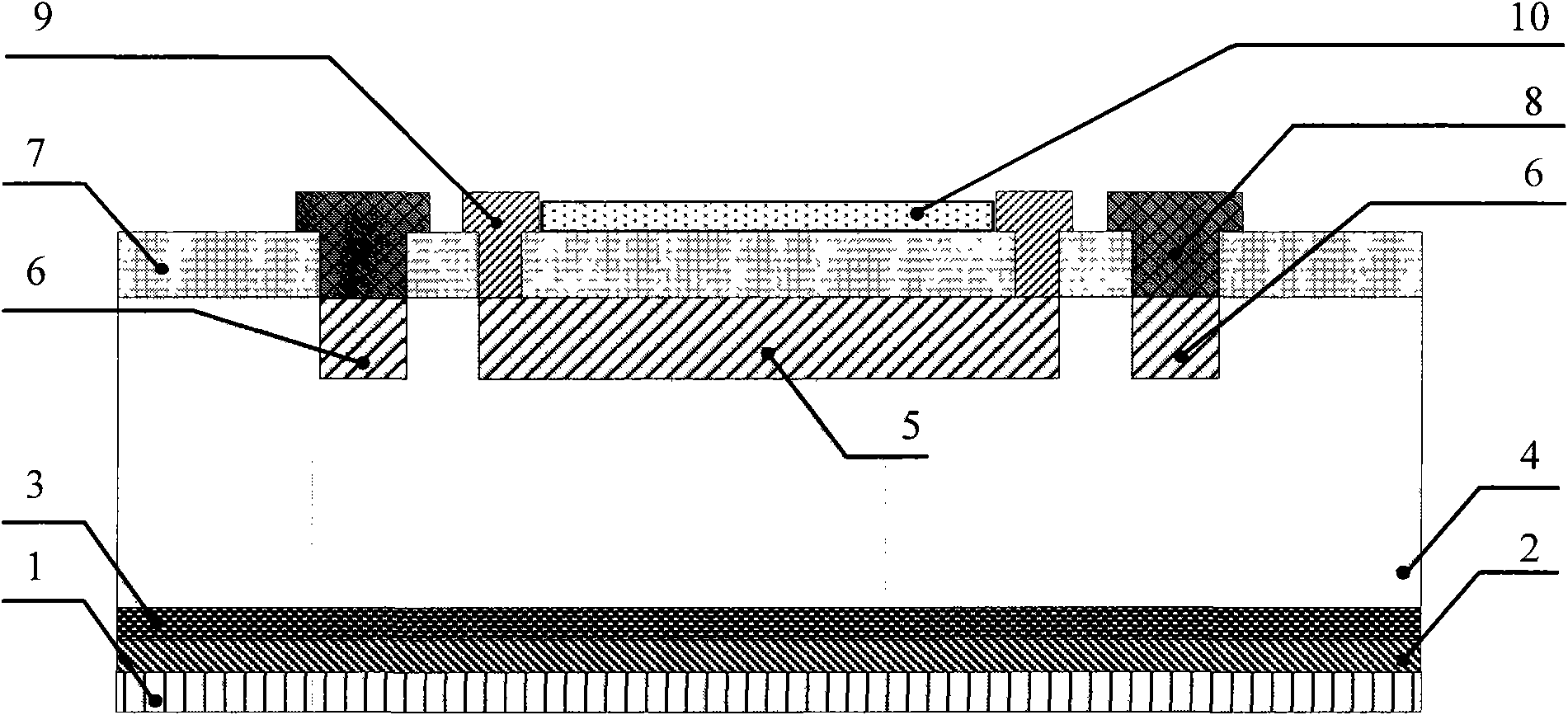

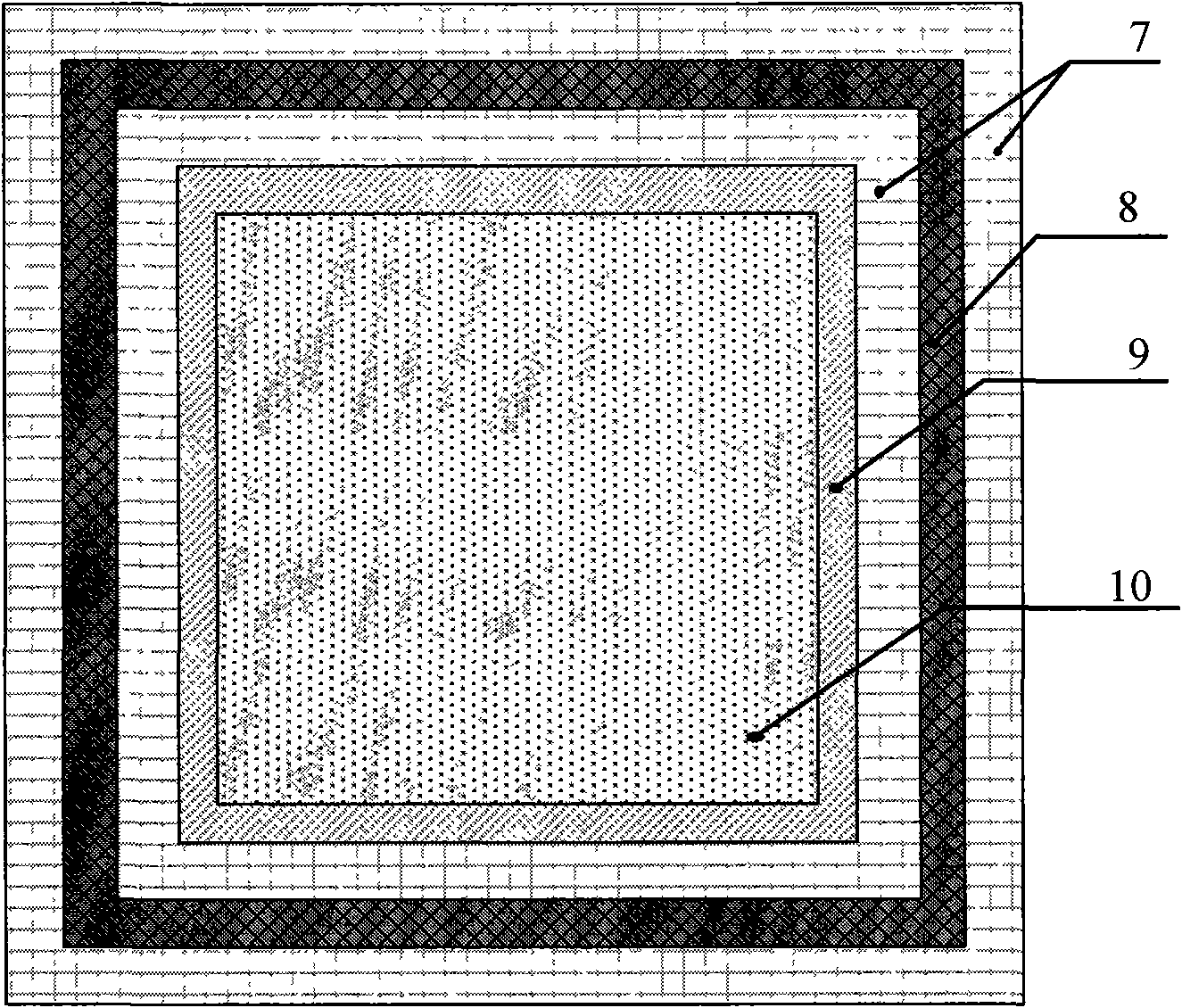

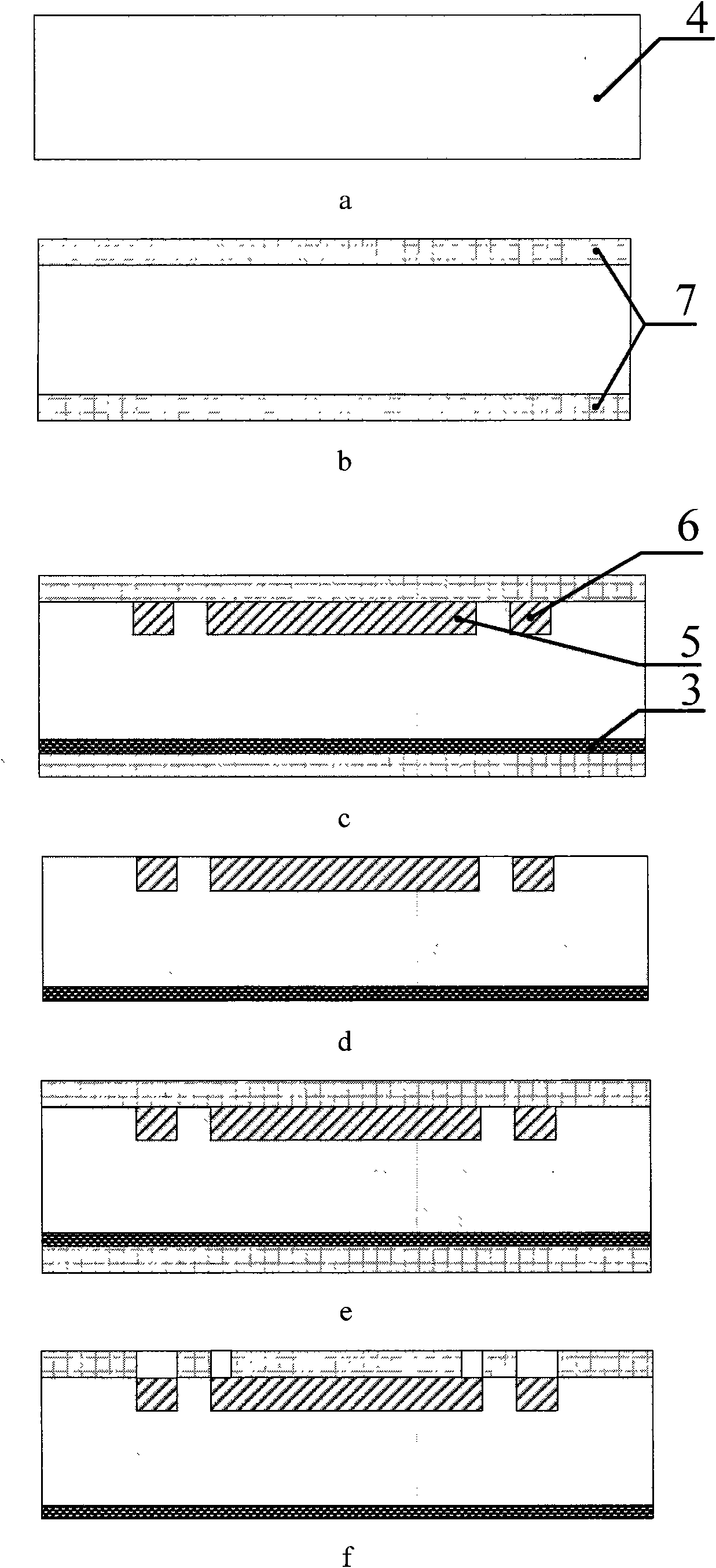

Micro nuclear battery with protection ring structure and manufacturing method thereof

InactiveCN101599308ASmall temperature changeImprove energy conversion efficiencyRadiation electrical energyElectrical batteryEngineering

The invention discloses a PN junction or PIN junction type micro nuclear battery and a manufacturing method thereof, belonging to the fields of semiconductor, nuclear physics and micro energy source. The battery is provided with a protection ring 6 in the periphery ring-shaped region of a p+ type semiconductor layer 5 on the basis of traditional PN junction or PIN junction type micro nuclear battery; meanwhile a protection ring contact electrode 8 is arranged above the protection ring 6 for leading an electrical signal out; in addition, the manufacturing method of the nuclear battery is also disclosed. In the micro nuclear battery disclosed by the invention, the added protection ring inhibits surface leakage and influence of interface state current on radiation induced current, indirectly increases open circuit voltage, and also improves sensibility of elements on low-energy radioactive source, thus improving energy conversion efficiency of elements.

Owner:江苏福克斯电气集团有限公司 +1

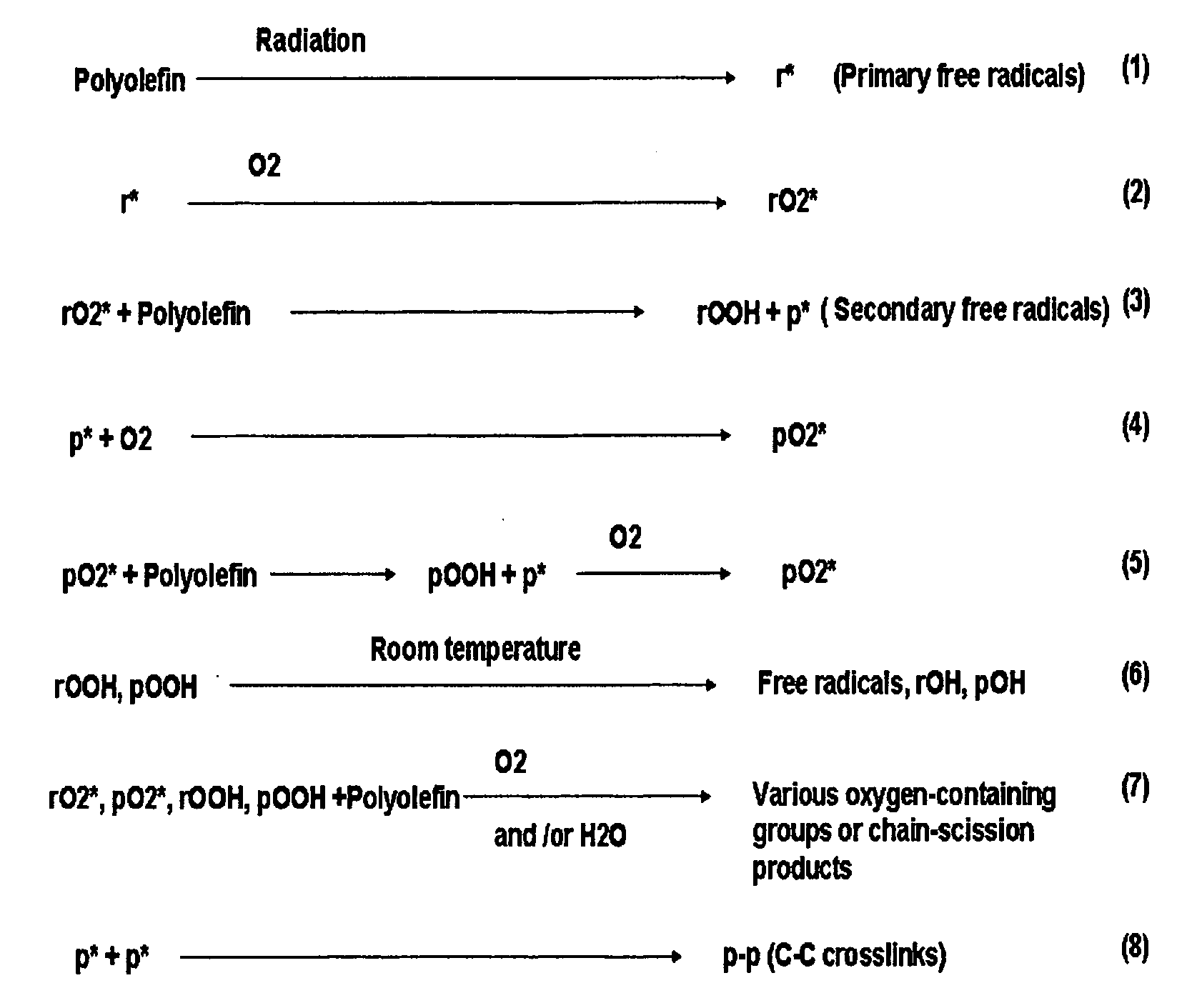

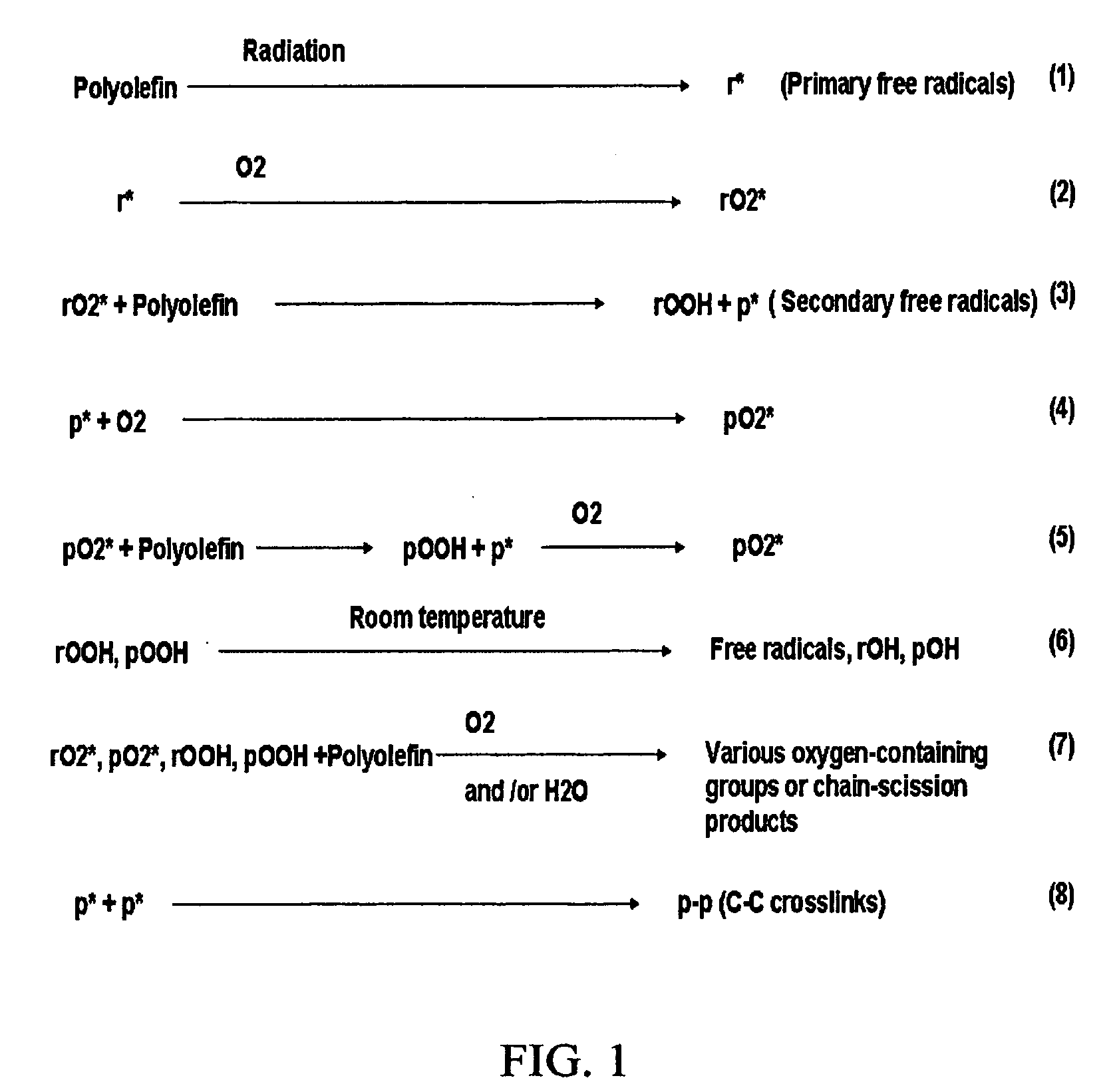

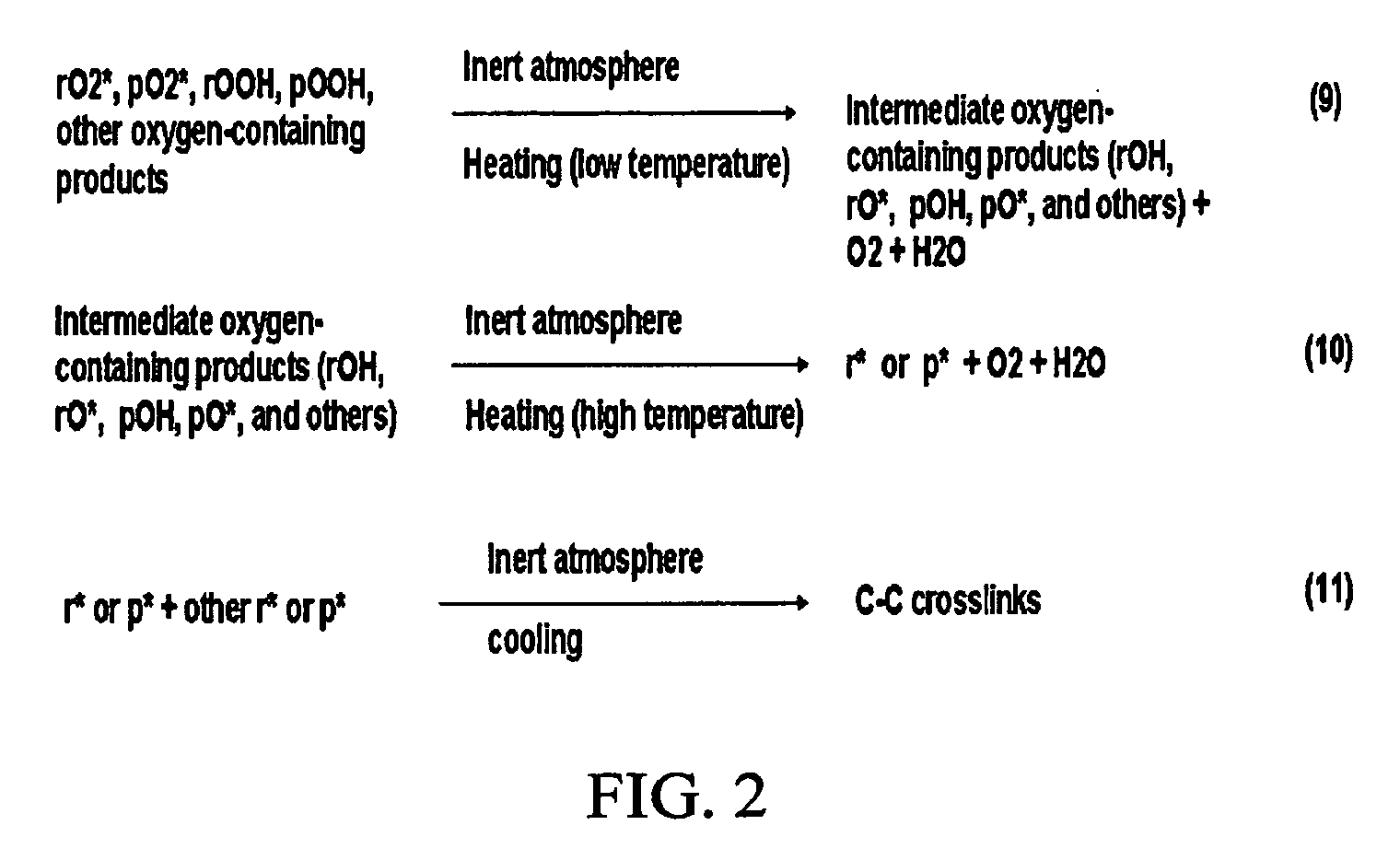

Method for thermal crosslinking of previously irradiated polymeric material and medical implant

InactiveUS20090243159A1Facilitate cross-linkingImprove antioxidant capacityDomestic articlesMicro structureThermal energy

A method for forming a crosslinked oxidation-resistant toughness-enhanced polymeric material includes the steps of placing a previously irradiated polymer material in a heating device under oxygen-reduced atmosphere at a temperature above the melting point of the polymeric material for a sufficient time to (a) eliminate oxidation in the polymeric material, (b) break existing crosslinks into free radicals, (c) migrate and re-distribute radiation-induced free radicals in an uniform manner, (d) create new free radicals by thermal energy and form uniform crosslinks within the polymer micro-structure, and followed by a cooling step to eliminate residual free radicals and form additional uniform crosslinks within the polymer micro-structure. A method of making a crosslinked oxidation-resistant toughness-enhanced wear-reduced UHMWPE medical implant from a previously irradiated solid form of UHMWPE is also disclosed.

Owner:TAIWAN SCI

Pyridyl-substituted porphyrin compounds and methods of use thereof

InactiveUS20060003982A1Extended half-lifeAntibacterial agentsOrganic active ingredientsSexual impotenceReperfusion injury

The present invention relates to Pyridyl-Substituted Porphyrin Compounds, compositions comprising an effective amount of a Pyridyl-Substituted Porphyrin Compound and methods for treating or preventing injury due to exposure to a reactive species, erectile dysfunction due to surgery, lung disease, hyperoxia, neurodegenerative disease, liver disease, myocardial damage during cardioplegia, an inflammatory condition, a reperfusion injury, an ischemic condition, a cardiovascular disease, diabetes, a diabetic complication, cancer, a side effect of cancer chemotherapy, or a radiation-induced injury, or to prolong the half-life of an oxidation-prone compound, comprising administering to a subject in need thereof an effective amount of a Pyridyl-Substituted Porphyrin Compound.

Owner:INOTECK PHARMA CORP

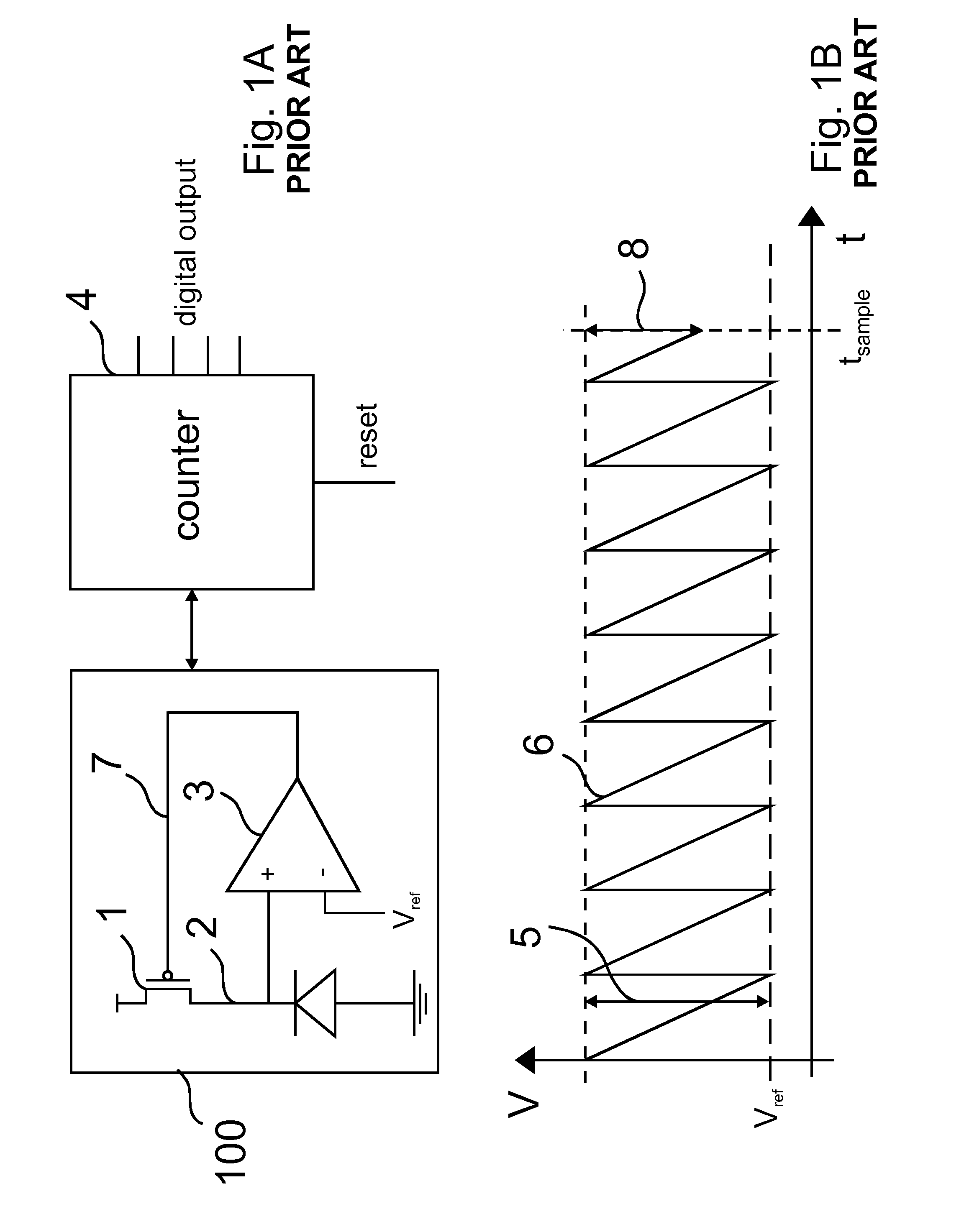

Method and pixel for performing correlated double sampling

ActiveUS20050270394A1Improve operating rateAnalogue/digital conversionTelevision system detailsRadiation inducedPhysics

The present invention provides an active pixel and an array of active pixels. The active pixel, and each active pixel in the array comprises: a sensor circuit for collecting radiation induced charges and for transducing them to a measurement signal corresponding to the amount of charge collected, two memory elements for storing the measurement signal at the beginning and the end of a first integration period respectively, and at least one further memory element for storing at least the measurement signal at the beginning of a next integration period. A corresponding method for performing correlated double sampling is described in which a reset level of the pixel at a beginning of the first integration period is stored in a first memory element, a measurement signal of the pixel at an end of the first integration period is stored in a second memory element, and, while performing the correlated double sampling with the stored reset level and the stored measurement signal, a reset level of the pixel at the beginning of the second integration period is stored in a third memory element.

Owner:SEMICON COMPONENTS IND LLC +1

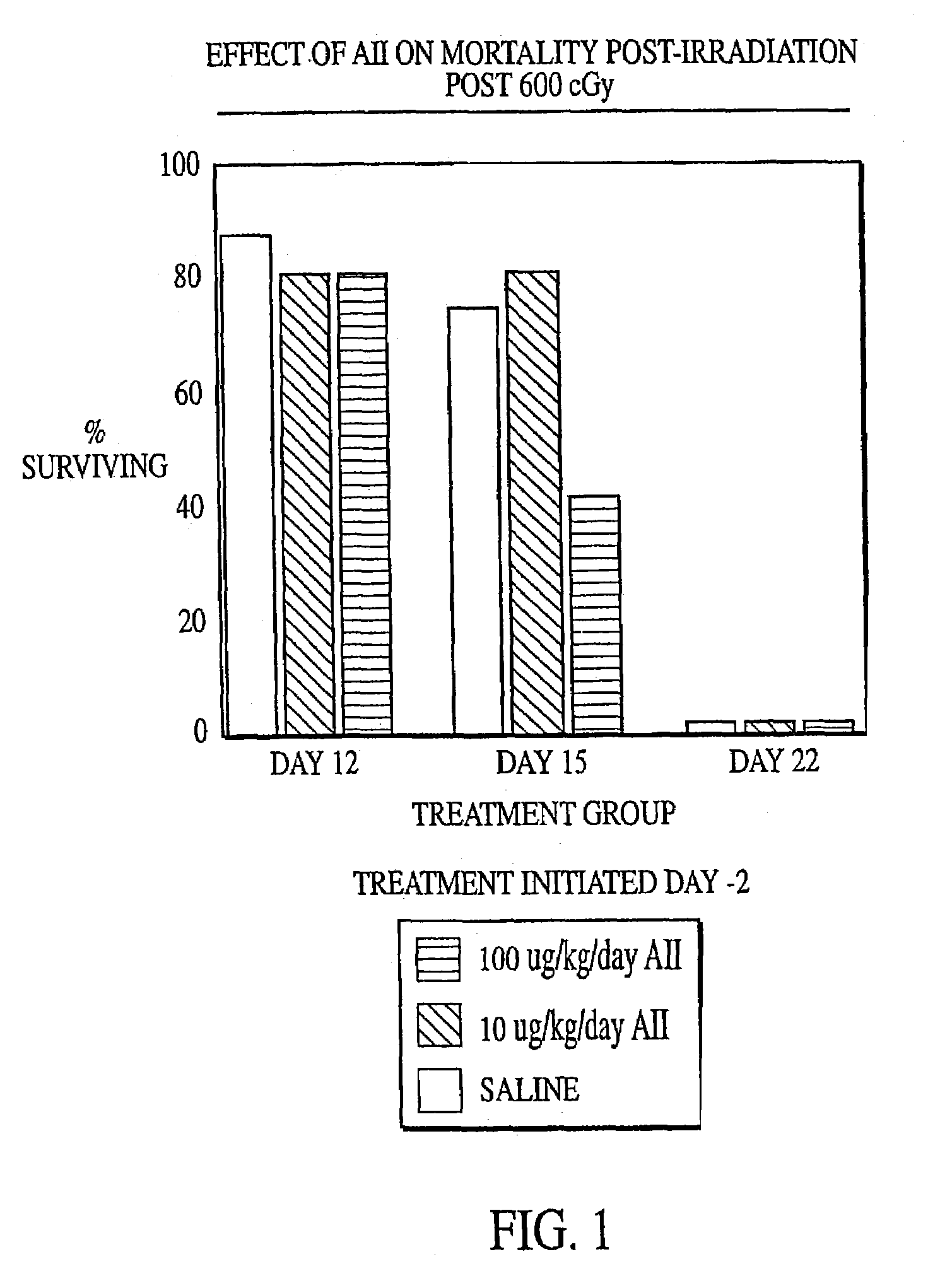

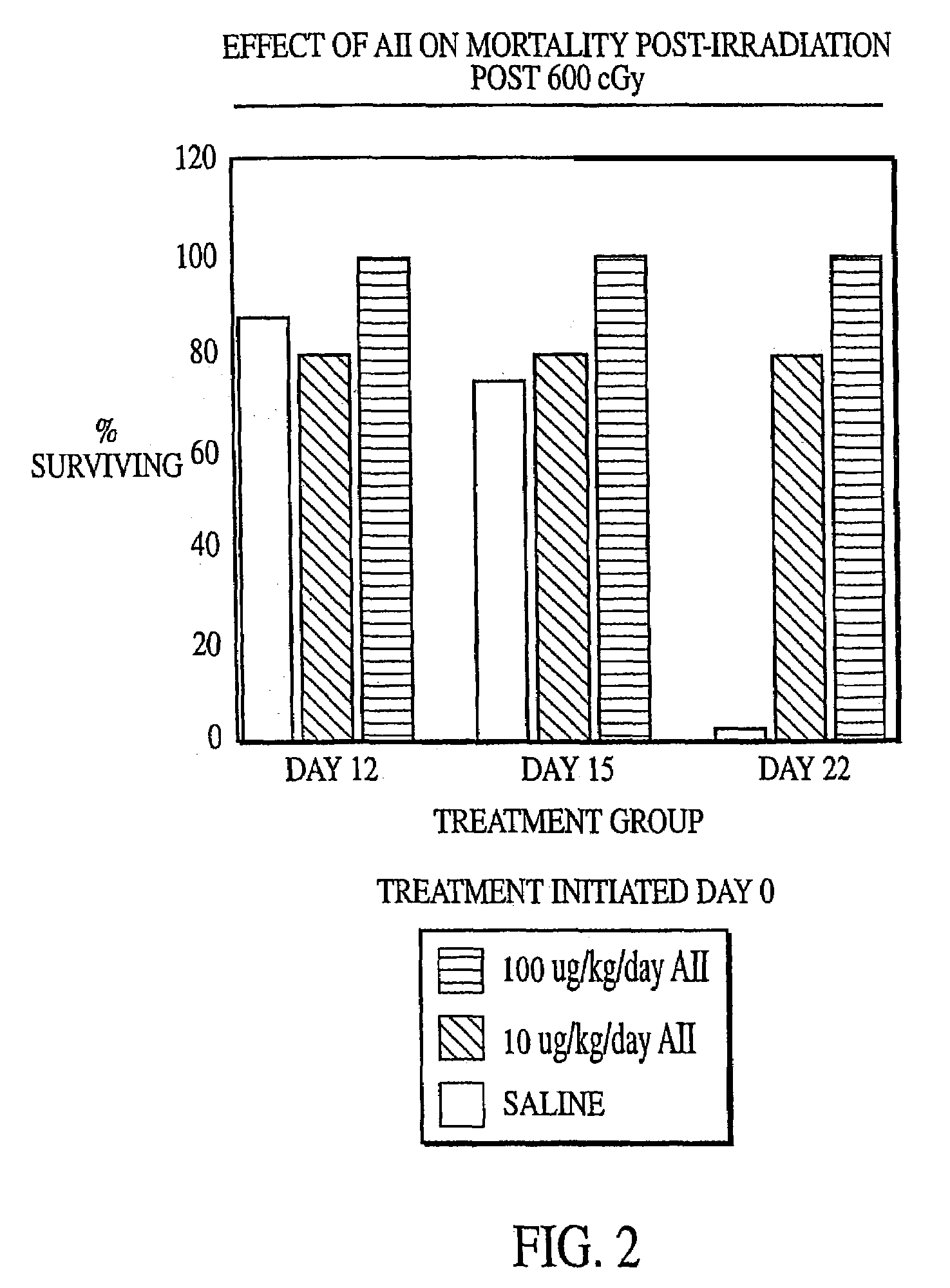

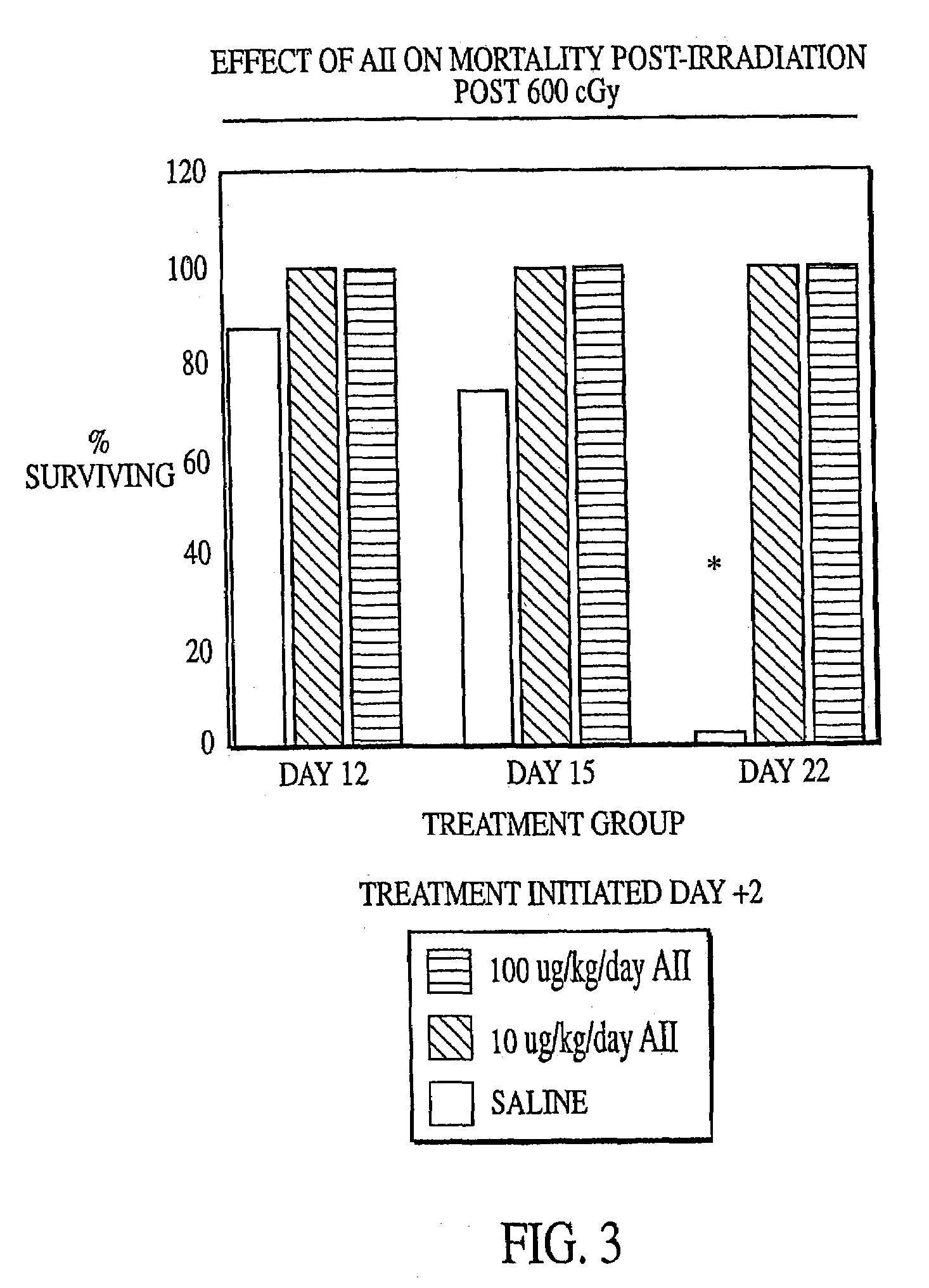

Radiation therapy methods

InactiveUS7173011B2Reduce tissue damageImprove efficiencyAngiotensinsPeptide/protein ingredientsMegakaryocyte productionAngiotensinogen mrna

The present invention provides methods and kits for mitigating radiation induced tissue damage, improving the effectiveness of radiation therapy, to support bone marrow transplantation, and promoting megakaryocyte production and mobilization and platelet production, each method comprising the administration of an effective amount of angiotensinogen, angiotensin I (AI), AI analogues, AI fragments and analogues thereof, angiotensin II (AII), AII analogues, AII fragments or analogues thereof or AII AT2 type 2 receptor agonists.

Owner:UNIV OF SOUTHERN CALIFORNIA

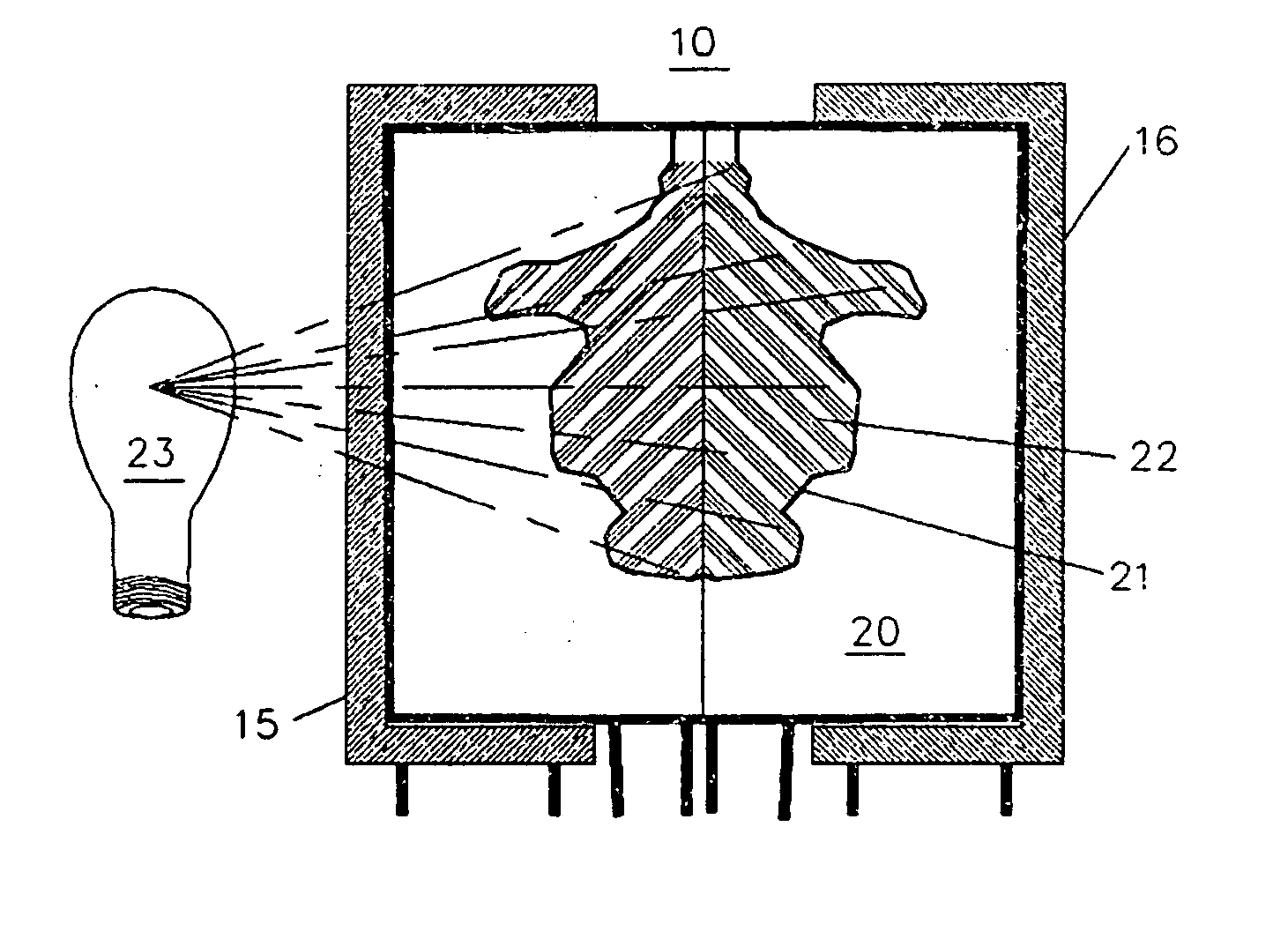

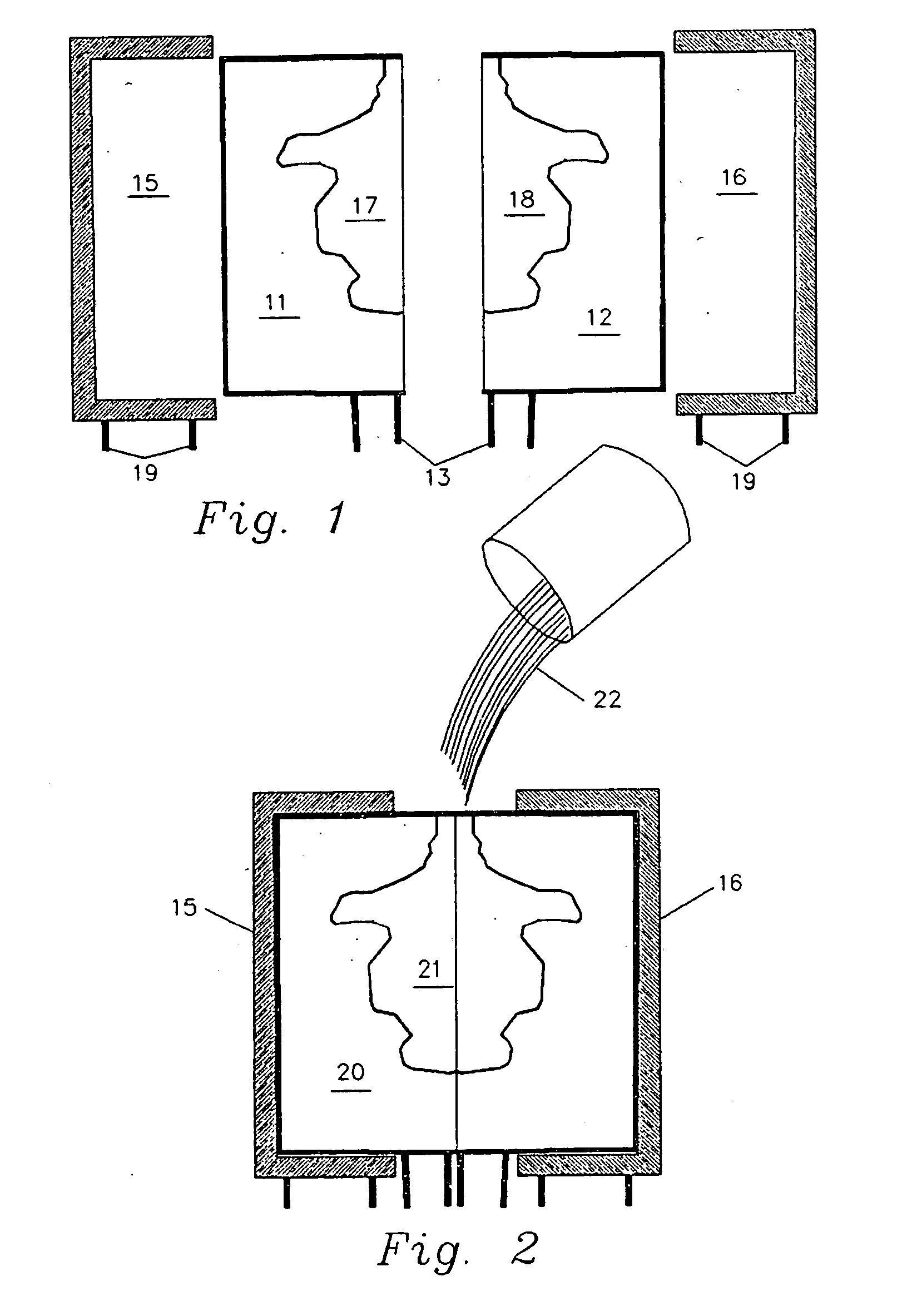

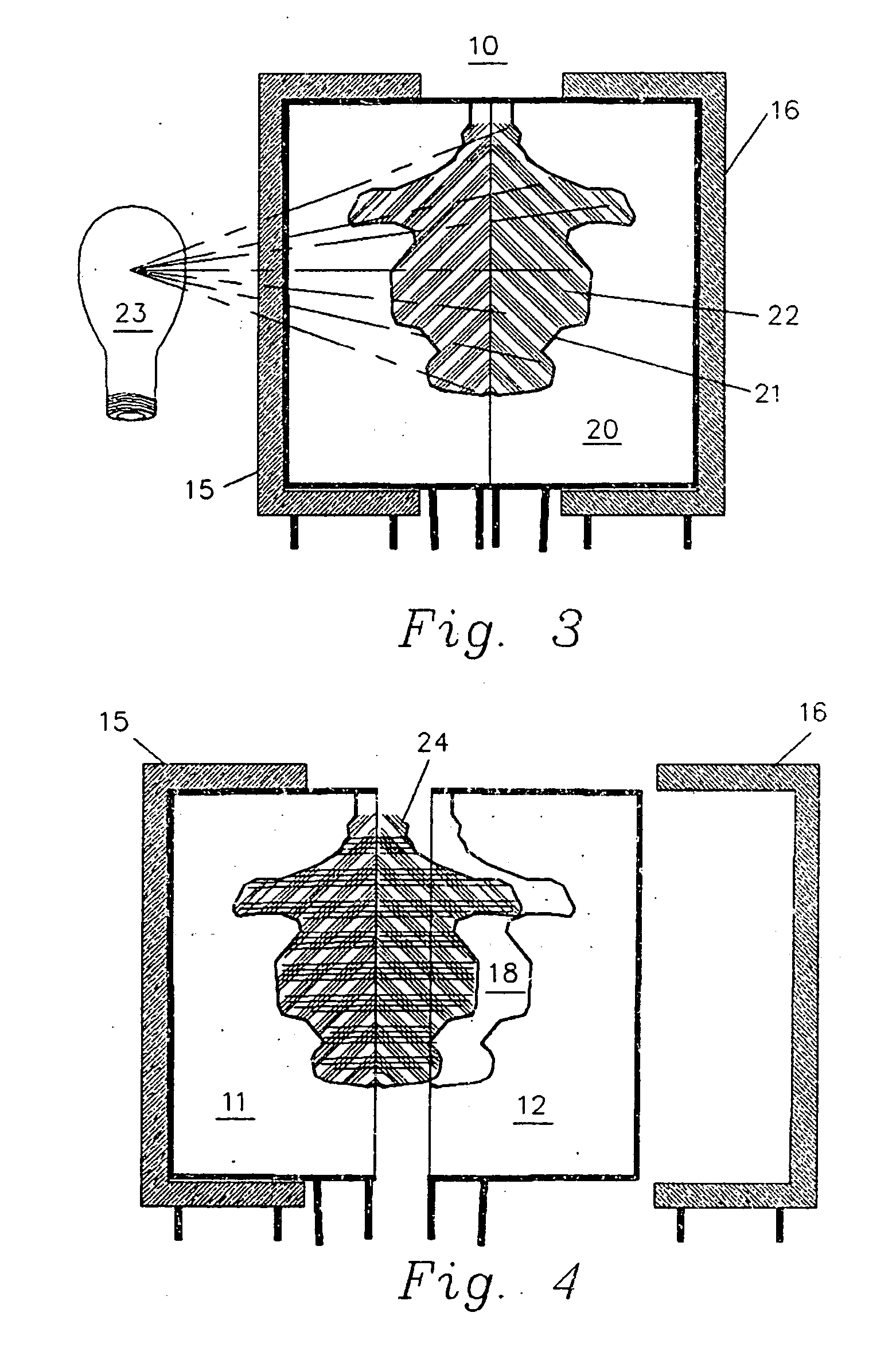

Method and apparatus for creating sacrificial patterns and cast parts

Owner:JOYNER VICTOR

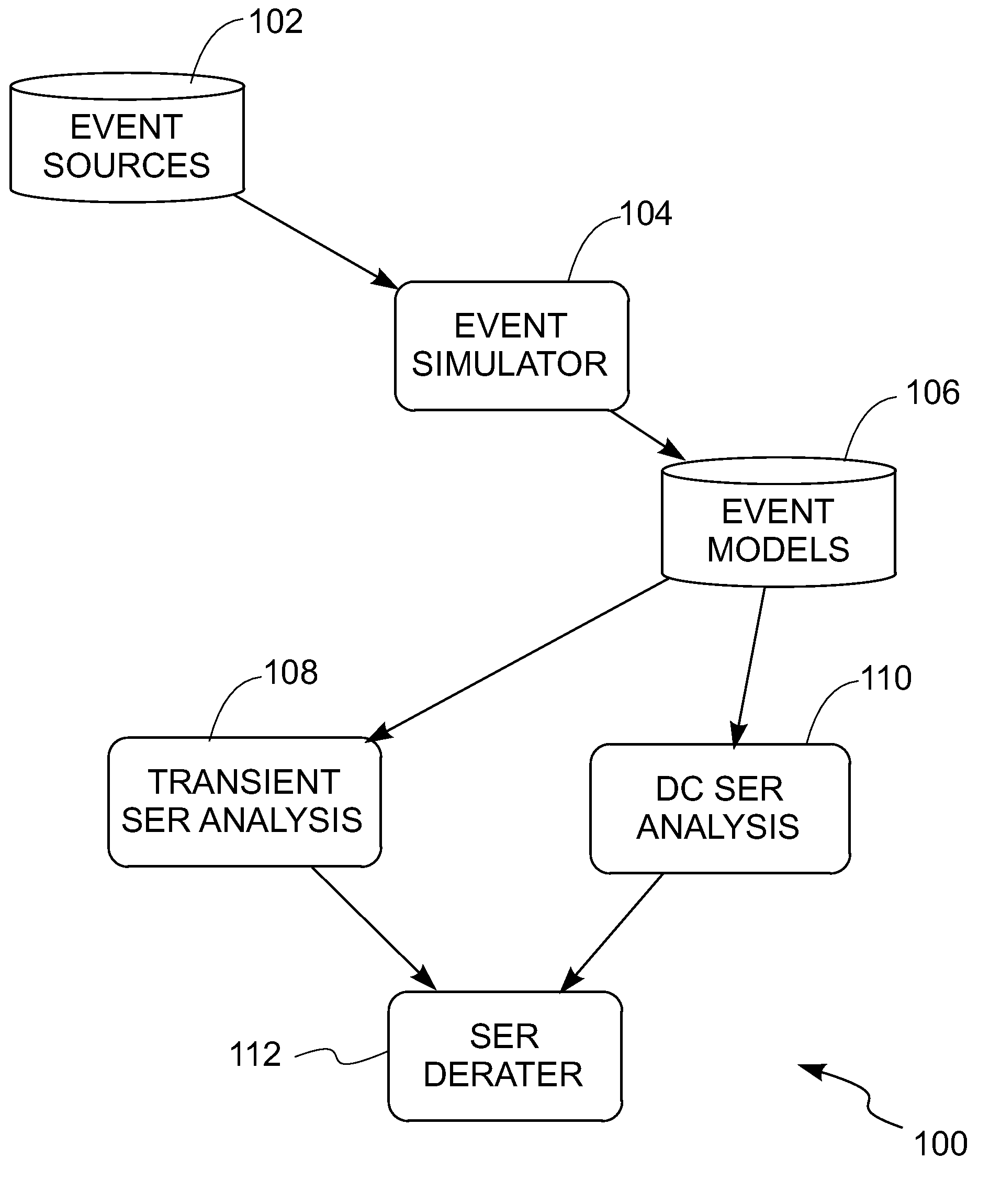

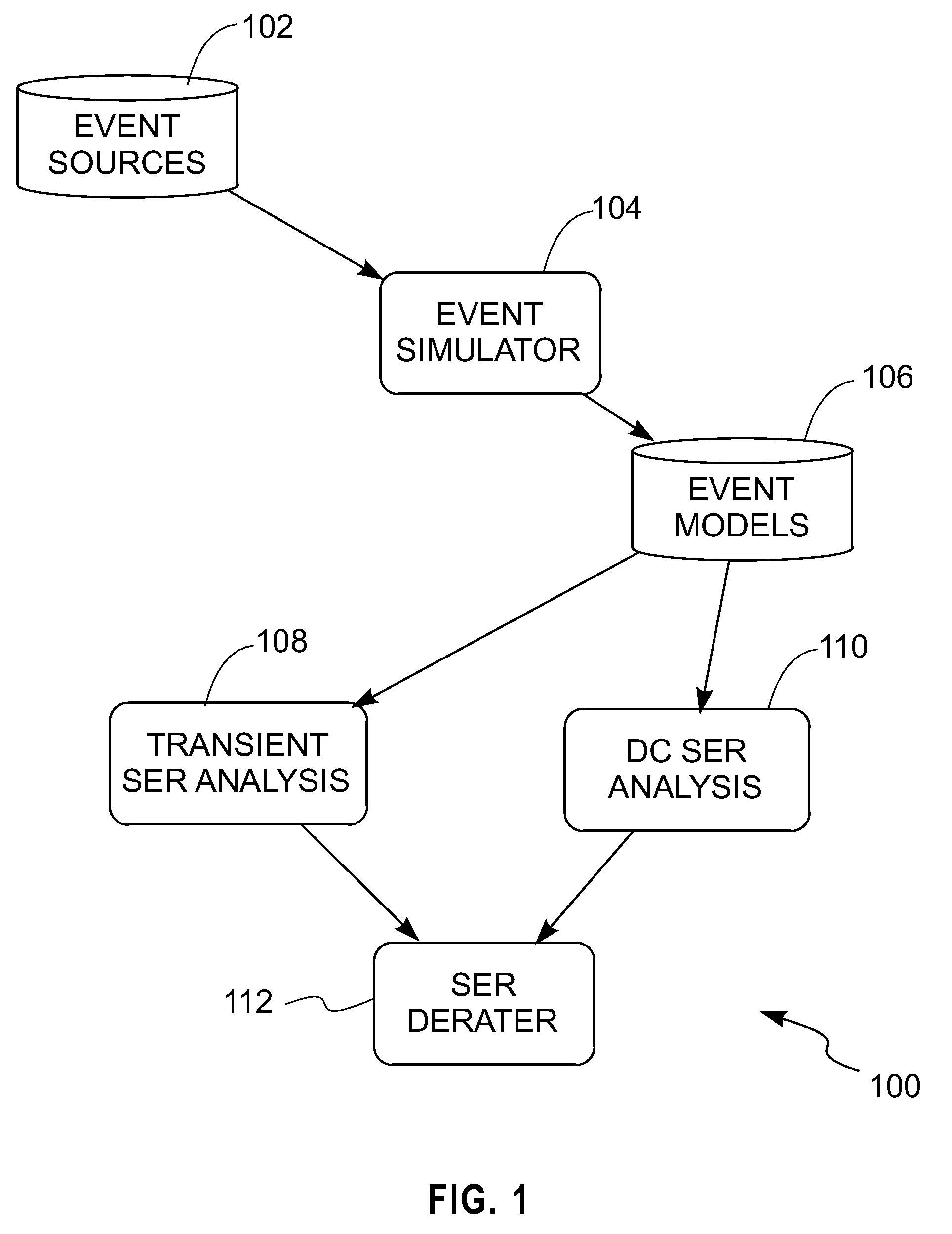

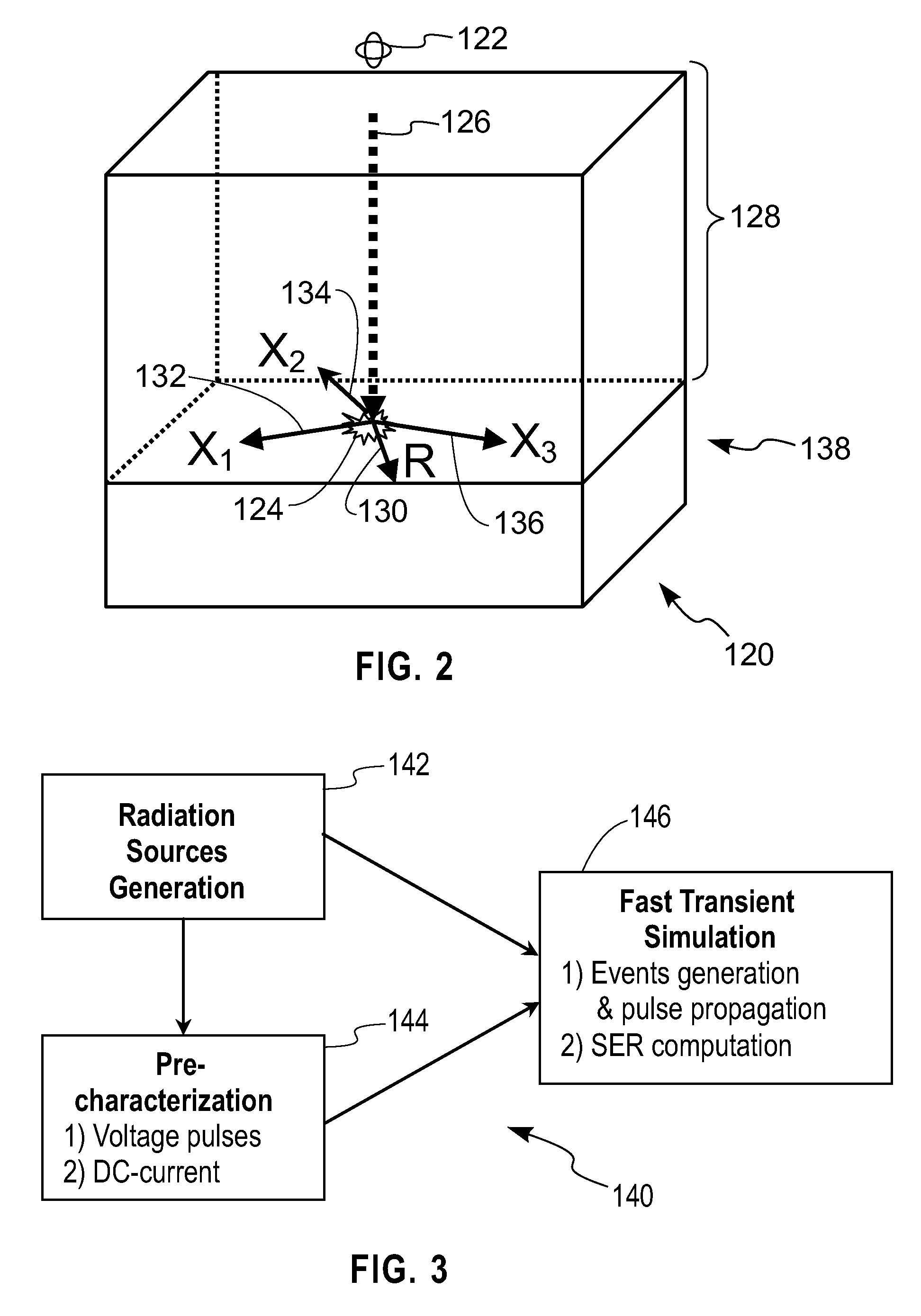

Integrated circuit (IC) design method and method of analyzing radiation-induced single-event upsets in CMOS logic designs

InactiveUS20080281572A1Reduce soft errorsReduced computing resourceDesign optimisation/simulationSpecial data processing applicationsCMOSEngineering

A logic design tool, a tool for analyzing soft error sensitivities in logic, and a program product for logic design. A particle generator simulates events likely to occur for a given operating environment. A pre-characterizer provides circuit block responses to simulated events. A circuit response simulator simulates events in a logic design and provides an indication of soft error sensitivity for the design. Based on the soft error sensitivity indication, the design may be modified to reduce the overall soft error sensitivity.

Owner:IBM CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com