Preparation method of BiFeO3 nano particle compounded TiO2 nanotube array electrode material

A nanotube array and nanoparticle technology is applied in the field of environmental pollution control to achieve the effects of flexible method, improved photoactivity and easy operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

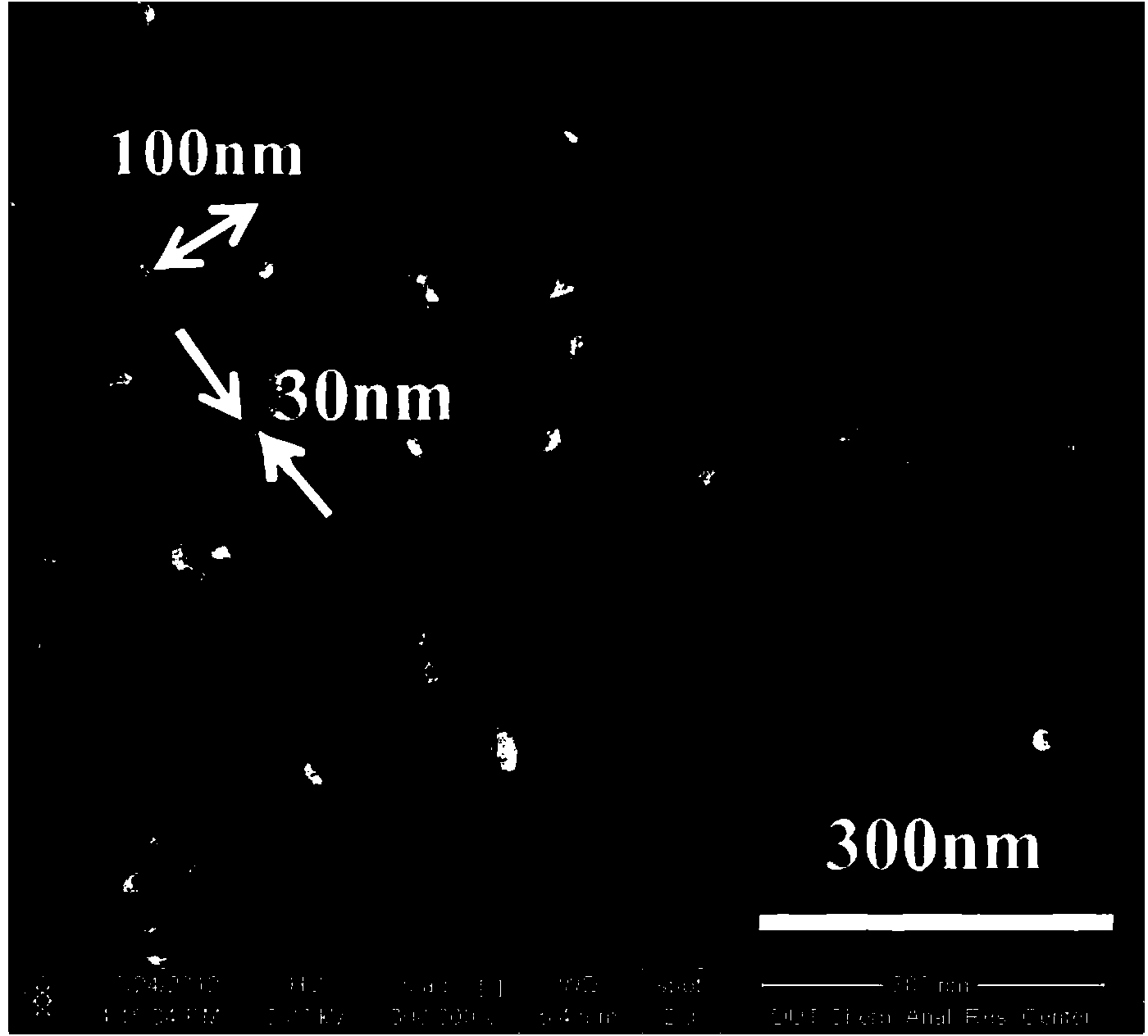

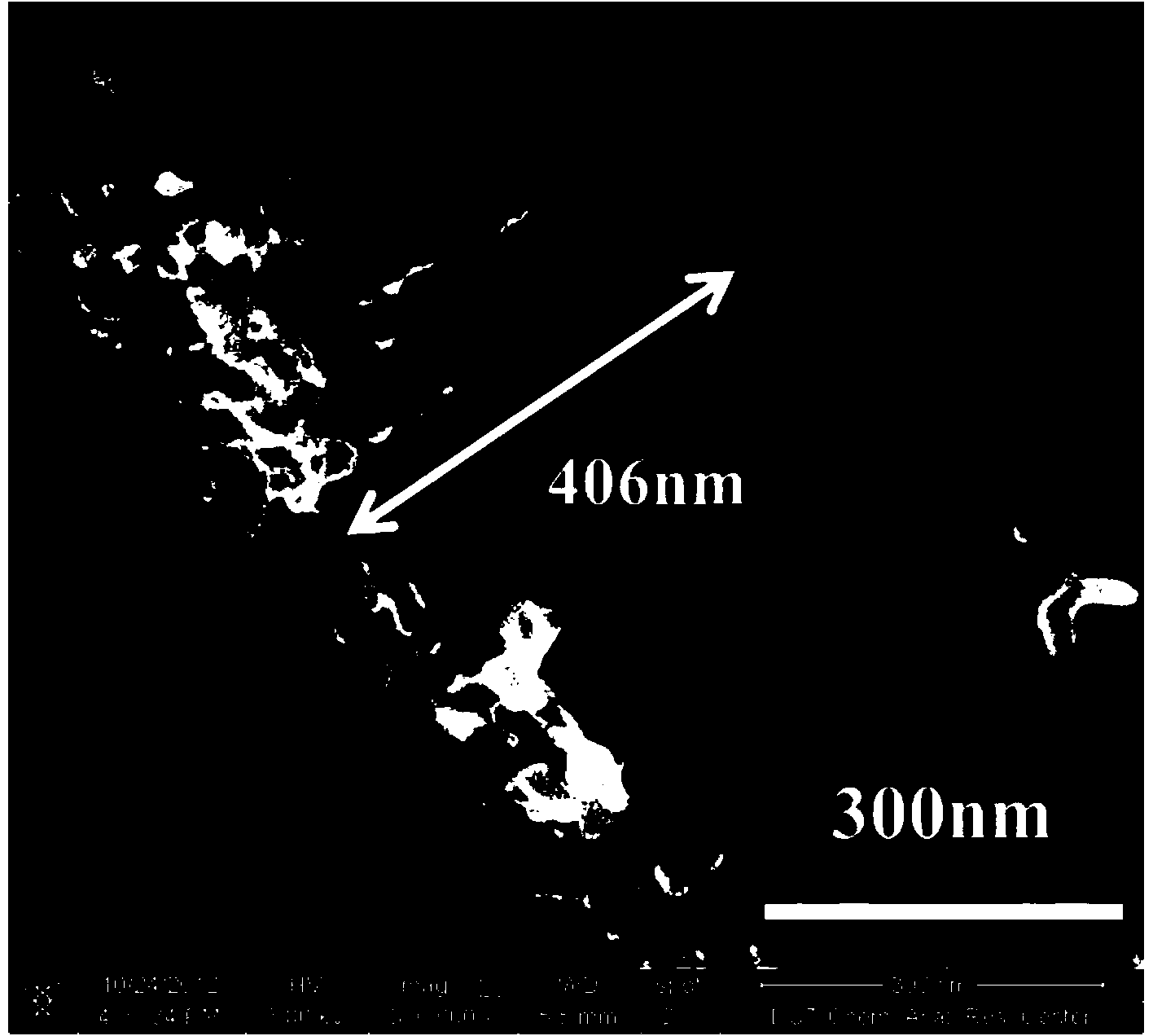

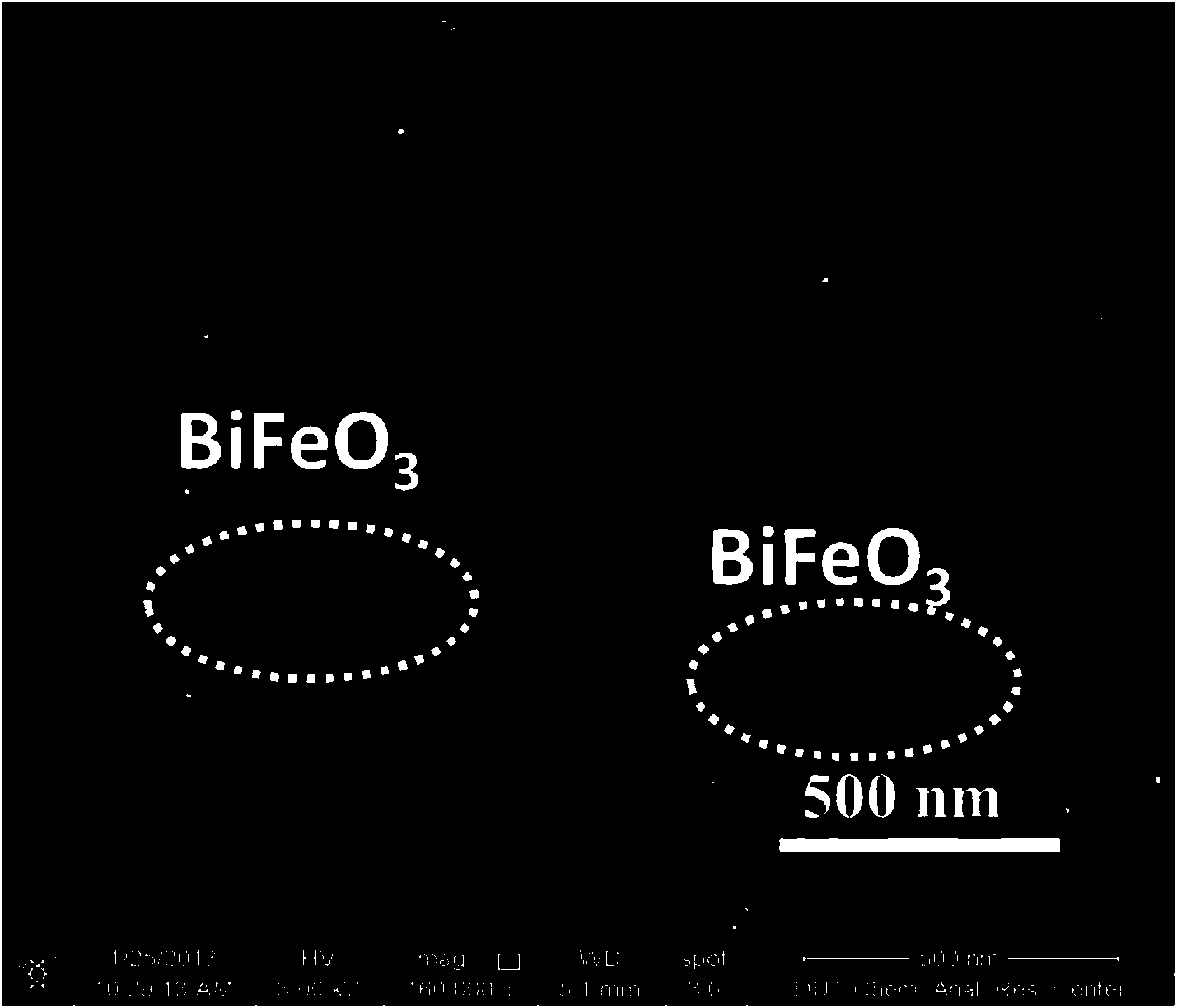

Embodiment 1

[0024] TiO was first prepared by anodic oxidation 2 Nanotube array electrode: After grinding the industrial pure titanium sheet with emery paper of different specifications, use HF / HNO 3 / H 2 The mixed acid solution with O volume ratio of 1:4:5 was etched for 30 s, and after ultrasonic cleaning, it was air-dried for later use. Connect the spare titanium and platinum electrodes to the positive and negative poles of the DC stabilized power supply respectively. The electrolyte is HF solution with a mass fraction of 0.2%, the applied voltage is 20V, and the reaction time is 1h. After the reaction, the electrode was cleaned, air-dried, and placed in a muffle furnace for annealing and calcination. The temperature was raised to 500°C at a heating rate of 2°C / min, calcined at a constant temperature for 1h, and naturally cooled to room temperature to obtain TiO 2 Nanotube array electrodes; BiFeO was then fabricated 3 Precursor, weigh 0.97gBi(NO 3 ) 3 ·5H 2 O and 0.80gFe(NO 3 ) ...

Embodiment 2

[0026] According to the method of the present invention in embodiment 1, anodic oxidation prepares TiO 2 The concentration of HF in the electrolyte was increased from 0.2% to 0.3% when the nanotube array electrode was used, and the amount of other raw materials and experimental procedures remained unchanged. BiFeO 3 / TiO 2 Nanotube array composite electrodes.

Embodiment 3

[0028] According to the method of the present invention in embodiment 1, anodic oxidation prepares TiO 2 The concentration of HF in the electrolyte was increased from 0.2% to 0.4% when the nanotube array electrode was used, and the amount of other raw materials and experimental procedures remained unchanged. BiFeO 3 / TiO 2 Nanotube array composite electrodes.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com