Hard and high-calcium oyster mushroom cultivation base stock and preparation method thereof

A cultivation base material, high-calcium technology, applied in fertilizer mixture, fertilization device, application, etc., can solve the problems of intolerance to transportation, poor commodity, no chewiness, etc., achieve storage and transportation resistance, improve internal quality, increase The effect of content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

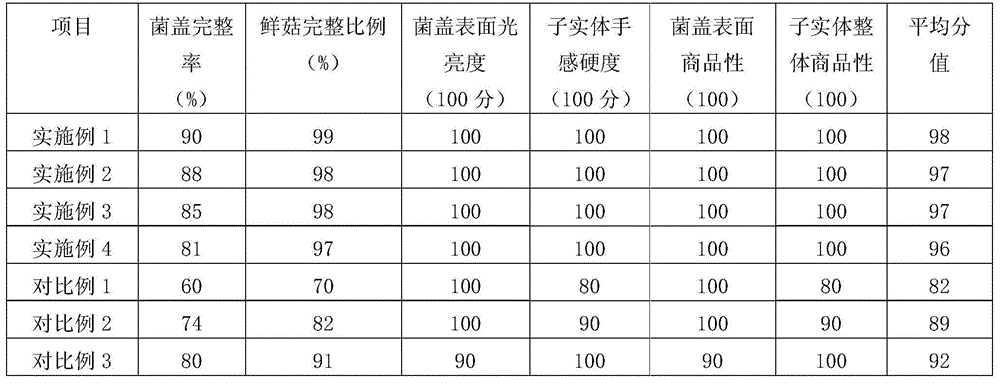

Examples

Embodiment 1

[0039] A kind of hard, high-calcium oyster mushroom cultivation base material, the components are as follows, all by weight kg:

[0040] Corn cob 30kg, bean dregs 50kg, clam shells 20kg, hydrochloric acid solution with a mass concentration of 0.1% 12kg, lime powder 5kg, light calcium carbonate 1kg, zinc sulfate 0.1kg.

[0041] The above components are all calculated by dry weight except dilute hydrochloric acid solution.

[0042] The preparation method of above-mentioned hard, high-calcium oyster mushroom cultivation base material comprises the following steps:

[0043] (1) After crushing the corn cobs, pass them through a sieve basket with a sieve diameter of 12 mm. The moisture content of the corn cobs is 15%. Add 2 kg of lime powder and ferment for 7 days at 8°C or below to obtain primary fermented corn. core;

[0044] (2) Dry the bean dregs in the air until the moisture content is ≤40%, then add the remaining lime powder, and ferment for 7 days at 8°C or below to obtain ...

Embodiment 2

[0050] A hard, high-calcium oyster mushroom cultivation base material, the components are as follows, all by weight kg:

[0051] Corncob 200kg, bean dregs 225kg, clam shells 75kg, hydrochloric acid solution with a mass concentration of 0.% 45kg, lime powder 20kg, light calcium carbonate 4.25kg, zinc sulfate 0.24kg.

[0052] The above components are all calculated by dry weight except dilute hydrochloric acid solution.

[0053] The preparation method of above-mentioned hard, high-calcium oyster mushroom cultivation base material comprises the steps:

[0054] (1) After crushing the corncob, pass it through a sieve basket with a sieve diameter of 12mm, the moisture content of the corncob is 14%, add 10kg of lime powder, and ferment for 6 days at 9-15°C to obtain the primary fermented corncob ;

[0055] (2) Dry the bean dregs in the air until the moisture content is ≤40%, then add the remaining lime powder, and ferment for 6 days at 9-15°C to obtain primary fermented bean dregs; ...

Embodiment 3

[0061] A kind of hard, high-calcium oyster mushroom cultivation base material, the components are as follows, all by weight kg:

[0062] Corncob 1500kg, bean dregs 1200kg, clam shells 300kg, hydrochloric acid solution with a mass concentration of 1% 180kg, lime powder 90kg, light calcium carbonate 27kg, zinc sulfate 1.44kg.

[0063] The above components are all calculated by dry weight except dilute hydrochloric acid solution.

[0064] The preparation method of above-mentioned hard, high-calcium oyster mushroom cultivation base material comprises the following steps:

[0065] (1) After crushing the corncob, pass it through a sieve basket with a sieve diameter of 12mm. The moisture content of the corncob is 13%, add 30kg of lime powder, and ferment for 5 days at 16-27°C to obtain the primary fermented corncob ;

[0066] (2) Air-dry the bean dregs until the moisture content is 15%, then add the remaining lime powder, and ferment for 5 days at 16-27°C to obtain primary fermente...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com