A kind of liquid fermented lotus seed core-germinated rice vinegar and its preparation process

A preparation process, lotus seed core technology, applied in liquid fermentation to prepare lotus seed core-germinated rice vinegar and its preparation field, can solve the problems of undiscovered, waste of resources, etc., achieve the effects of improving flavor, refreshing taste, and shortening saccharification time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

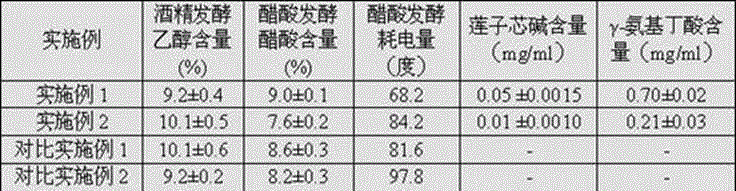

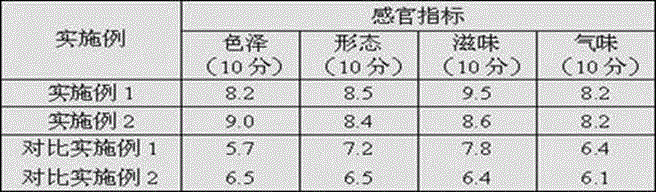

Embodiment 1

[0025] (1) Take 3kg of rice, soak it with 0.02mg / ml gibberellin at 25°C for 17h, spread it evenly in a dustpan with a diameter of 50cm, and germinate it at 25°C for 21h (measured germination rate > 95%), dry it at 45°C for 4 Hours later, crush it with a pulverizer; (2) Weigh 30kg of glutinous rice, wash it with 10L of water, wash it repeatedly 3 times, add 60L of water, soak it for 2 hours, and then steam it; (3) pour the steamed glutinous rice with cold water, When the temperature drops to 30°C, mix all the crushed germinated rice and 15kg of lotus seed heart powder, and put them in a 100L bucket (room temperature is controlled at 30°C, outdoor temperature is 20°C), and 30L of saccharified liquid is obtained after 12 hours; ( 4) Immediately mix in 1.3kg of active dry yeast, ferment at 38°C for 3 days, the alcohol content is 9.2% as determined by distillation, and prolonging the fermentation time will not increase the alcohol content; (5) Filter the fermented wine mash with pla...

Embodiment 2

[0029] (1) Take 1 kg of rice, soak it with 0.02 mg / ml gibberellin at 25°C for 17 hours, spread it evenly in a dustpan with a diameter of 50 cm, and germinate it at 25°C for 21 hours (measured germination rate >95%), dry it at 45°C for 4 hours After 1 hour, crush it with a pulverizer; (2) Weigh 10kg of glutinous rice, wash it with 10L of water, wash it repeatedly 3 times, add 60L of water, soak it for 2 hours, and then steam it; (3) pour the steamed glutinous rice with cold water, When the temperature drops to 30°C, mix all the crushed germinated rice and 5kg of lotus seed heart powder, and put them in a 100L bucket (room temperature is controlled at 30°C, outdoor temperature is 16°C), and 30L of saccharified liquid is obtained after 12 hours; ( 4) Immediately mix in 0.45kg of active dry yeast, ferment at 38°C for 3 days, the alcohol content is 10.1% by distillation method, and prolonging the fermentation time will not increase the alcohol content; (5) Filter the fermented wine ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bronsted acidity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com