Chitosan-modified pH responsive medicine-loading controlled release material and preparation method thereof

A technology of controlled release material and chitosan, which is used in pharmaceutical formulations, medical preparations with inactive ingredients, etc., to achieve the effects of large loading capacity, large pore volume and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0047] The preparation method of the drug-loaded slow-controlled release material uses mesoporous silica nanoparticles as the carrier, and after loading the drug, the chitosan polyelectrolyte membrane is surface-modified. The specific steps are as follows:

[0048] A) Drug loading on mesoporous silica nanoparticles

[0049] The drug solution is loaded into the pore structure of mesoporous silica nanoparticles through diffusion by physical impregnation method;

[0050] B) Chitosan modification on the surface of drug-loaded mesoporous silica nanoparticles

[0051] Method i) dispersing drug-loaded mesoporous silica nanoparticles into chitosan sol solution, stirring and standing to obtain drug-loaded mesoporous silica coated with chitosan;

[0052] Method ii) Interacting mesoporous silica nanoparticles with a silane coupling agent to activate the surface of mesoporous silica, after physically impregnating the activated mesoporous silica to load drugs, using active groups and chit...

Embodiment 1

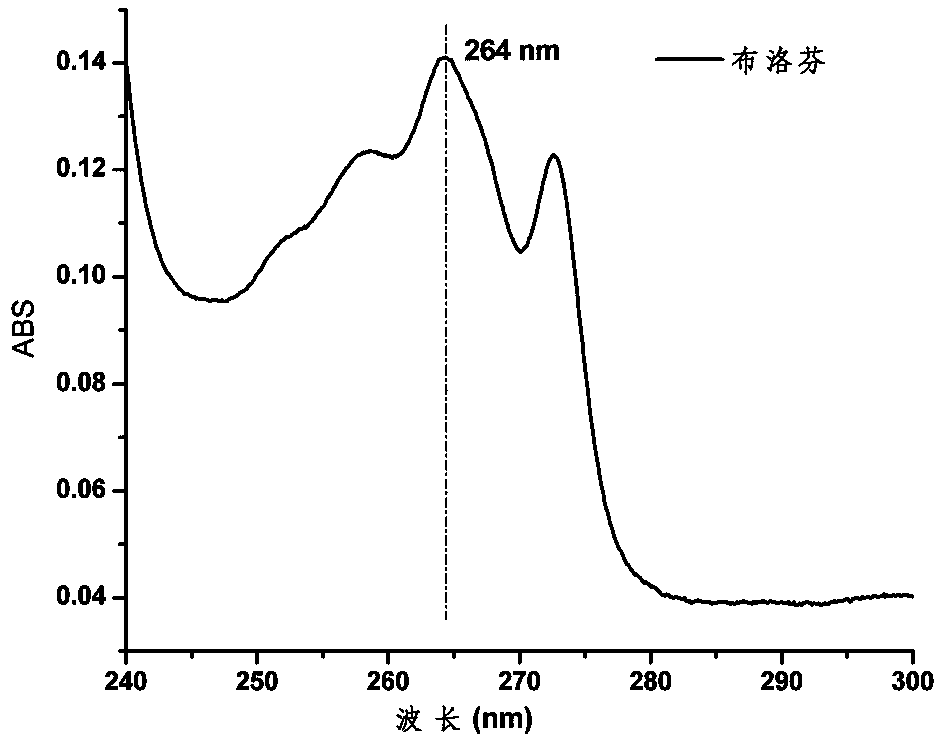

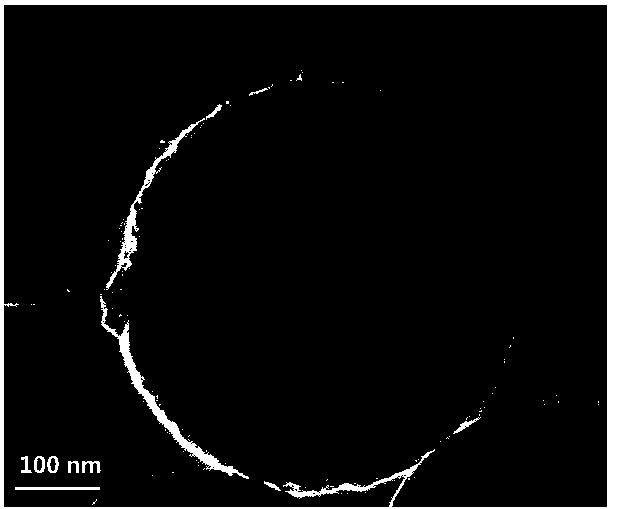

[0070] Preparation of mesoporous silica nanoparticles directly coated with chitosan (Cs) and loaded with ibuprofen (IBU) (IBUMSNs-Cs-1)

[0071] Step A) Preparation of Mesoporous Silica Nanoparticles (MSNs)

[0072] 0.28g sodium hydroxide (NaOH) and 1.0g cetyltrimethylammonium bromide (C 16 TAB) was dispersed into 480 mL of deionized water and stirred vigorously at 80 °C for 1 hour. Afterwards, 5.0 mL of tetraethyl orthosilicate (TEOS) was added to the above mixture, and stirring was continued at 80° C. for 2 hours. After the reaction, the obtained white precipitate was centrifuged, washed with a large amount of ethanol, and then vacuum freeze-dried. Finally, the surfactant C in the pores of the prepared mesoporous silica was removed by ion exchange. 16 TAB: The dried sample (0.5 g) obtained above was dispersed into a mixed solution containing 95% ethanol aqueous solution and 0.2 g ammonium nitrate, and the mixture was magnetically stirred at 60° C. for 5 hours, and the pro...

Embodiment 2

[0079] Preparation of mesoporous silica nanoparticles bound to chitosan (Cs) and loaded with ibuprofen (IBU) (IBUMSNs-Cs-2)

[0080] Step A) Preparation of Mesoporous Silica Nanoparticles (MSNs)

[0081] According to step A) of Example 1, HMSNs were prepared;

[0082] Step B) Loading Ibuprofen (IBU) into MSNs

[0083] A simple physical impregnation method was used to diffuse ibuprofen (IBU) molecules into the mesoporous channels of MSNs. Disperse the MSNs obtained in step A) into ibuprofen n-hexane solution (40 mg / mL), and stir at room temperature for 24 hours in a dark environment. Afterwards, centrifuge the obtained suspension, wash off the IBU molecules adsorbed on the surface with a small amount of water, and dry at room temperature in vacuum to obtain MSNs loaded with IBU, which are labeled as IBUSNs;

[0084] Step C) γ-MPS modification on the surface of drug-loaded mesoporous silica (IBUMSNs)

[0085] Taking advantage of the fact that the surface of MSNs is rich in s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Mesopore diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com